Adjustable fixed plate and hanging fixture

A fixed plate, adjustable technology, applied in the direction of electrical components, electrolysis process, printed circuit manufacturing, etc., can solve the problem of poor conduction at the movable jaw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

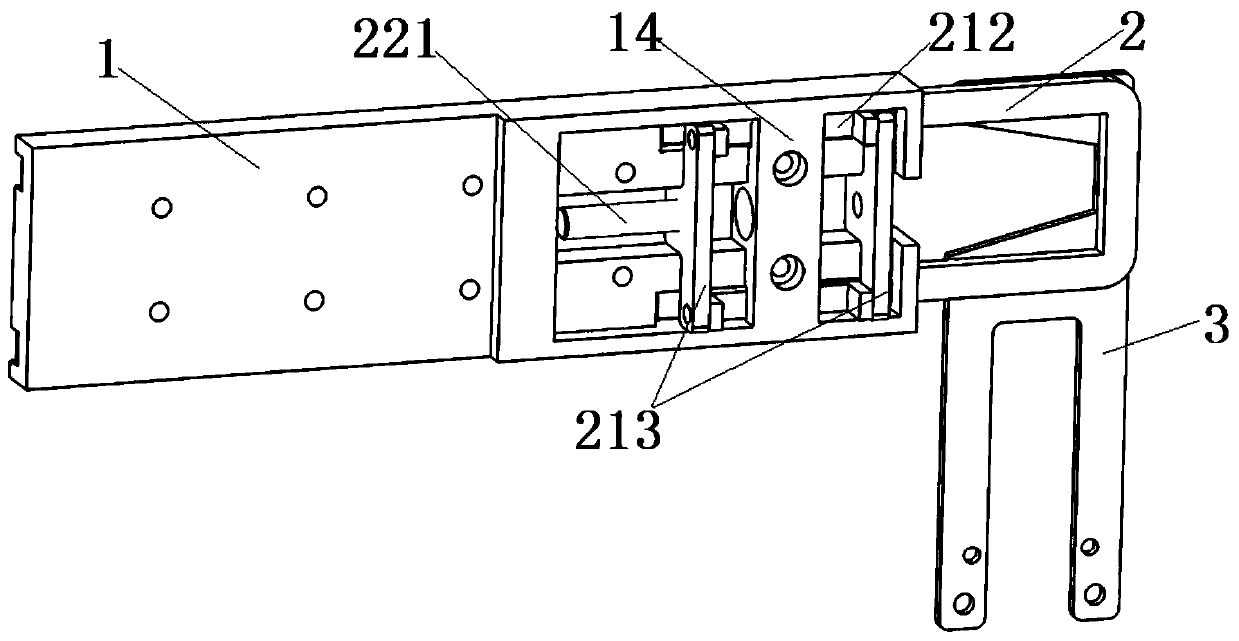

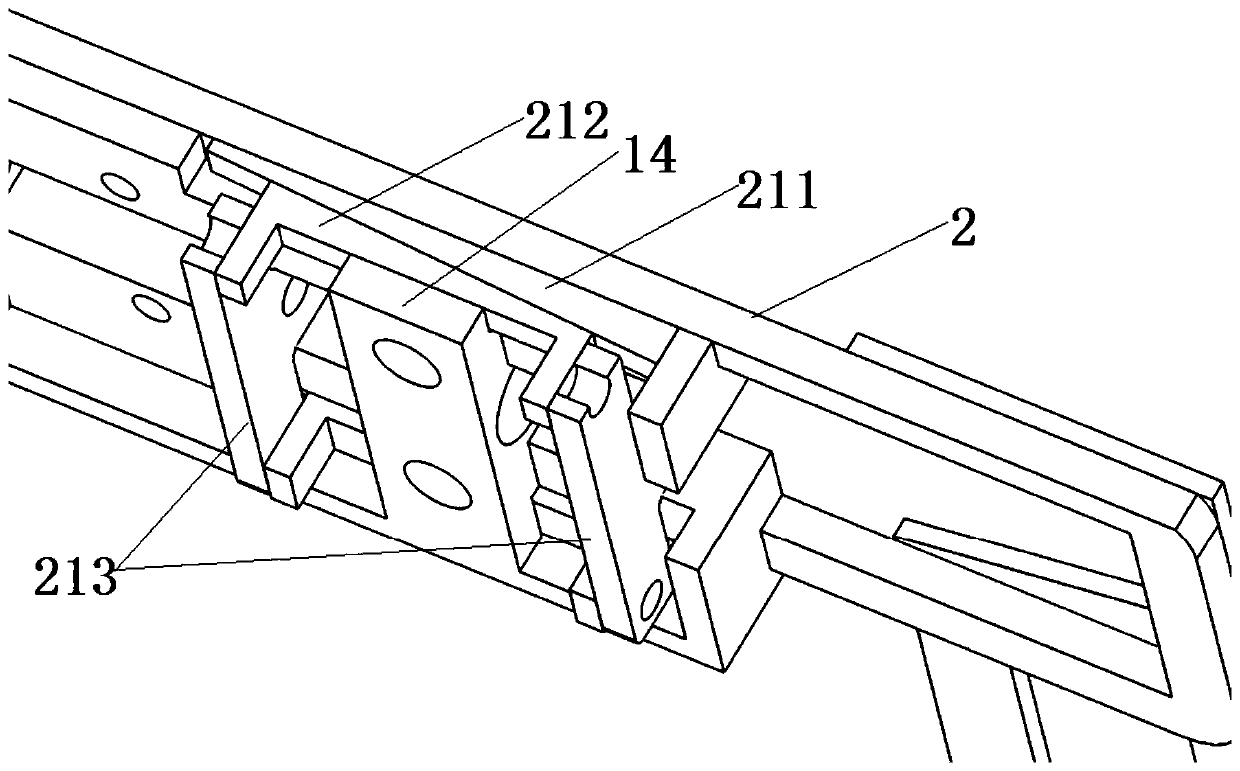

[0052] This embodiment provides an adjustable fixed plate, such as Figure 1 to Figure 6 As shown, it is suitable to be fixed on the bottom of the conductive plate 4, and a fixed jaw 5 is connected to the bottom of the conductive plate 4. The adjustable fixed plate includes a body 1, a conductive slide bar 2 and a locking mechanism.

[0053] Wherein, the body 1 is arranged on the conductive plate 4; the conductive slider 2 is slidably arranged between the body 1 and the conductive plate 4, and one side of the conductive slider 2 is connected with a sliding jaw 6, and the sliding jaw 6 is connected to the conductive plate 4. The conductive sliding bar 2 is conductively connected; the locking mechanism has a pressing structure arranged between the body and the conductive sliding bar to press the conductive sliding bar 2 on the conductive plate 4 .

[0054] With the adjustable fixed plate of this structure, the conductive slide bar 2 can slide outward between the main body 1 and ...

Embodiment 2

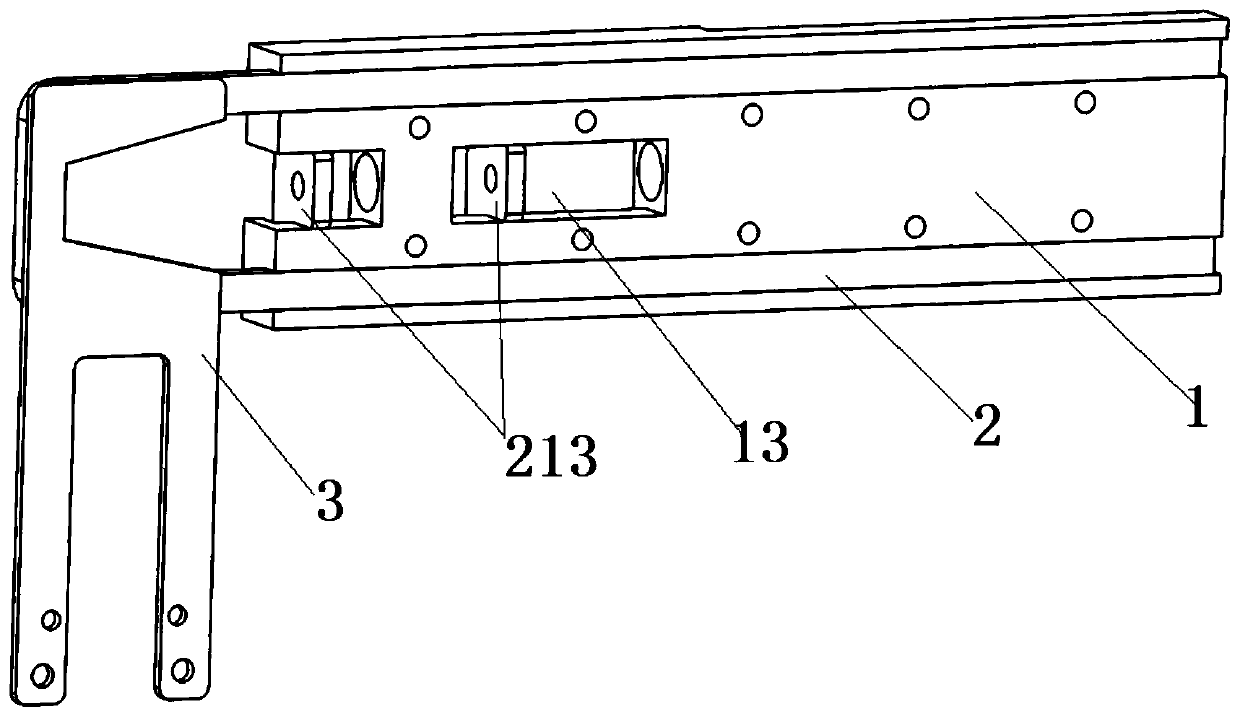

[0082] This embodiment provides a hanger, such as Figure 7 As shown, it includes two sets of adjustable fixed plates and conductive plates 4 in Embodiment 1.

[0083] The adjustable fixed plate is arranged on the lower part of the conductive plate 4 , and the fixed jaw 5 is arranged on the fixed plate below the adjustable plate, and the first side of the body 1 is attached to the conductive plate 4 . Two sets of adjustable fixing plates are located on opposite sides of the conductive plate 4 in the thickness direction; the two sliding jaws 6 are symmetrical about the central axis of the fixed guide plate 213 in the initial state, and slide the two conductive slide bars 2 outward or inward to Adjusting the distance between the two sliding jaws 6 can adapt to the clamping of circuit boards of different widths.

[0084] Alternatively, an adjustable fixing plate can be provided on only one side of the conductive plate 4, and the distance between the sliding jaw 6 and the fixed j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com