Environmental friendly chemical plating nickel plating brightener and use thereof

A technology of electroless nickel plating and electroless nickel plating solution, which is applied in the field of surface treatment of metal materials, can solve the problems of environmental hazards, inability to form a coating, and affect the quality of the coating, so as to achieve accelerated plating speed, dense coating without pores, and good hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

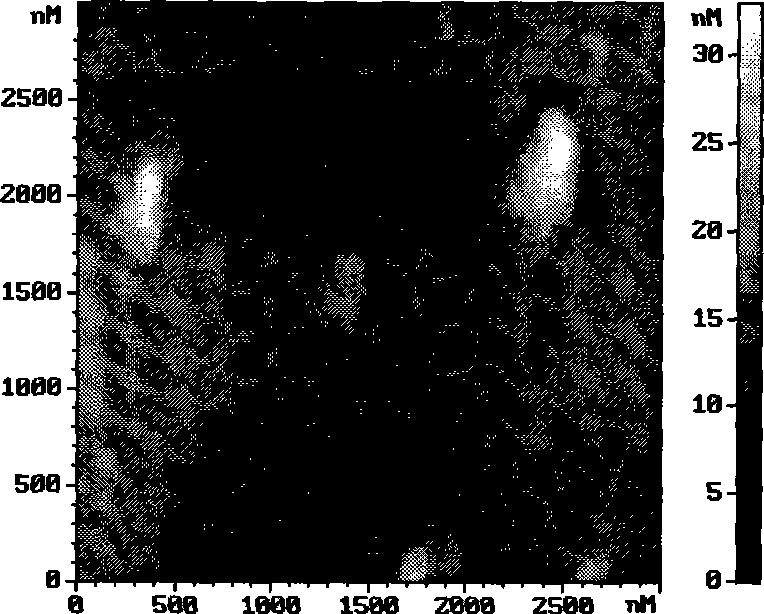

Image

Examples

Embodiment Construction

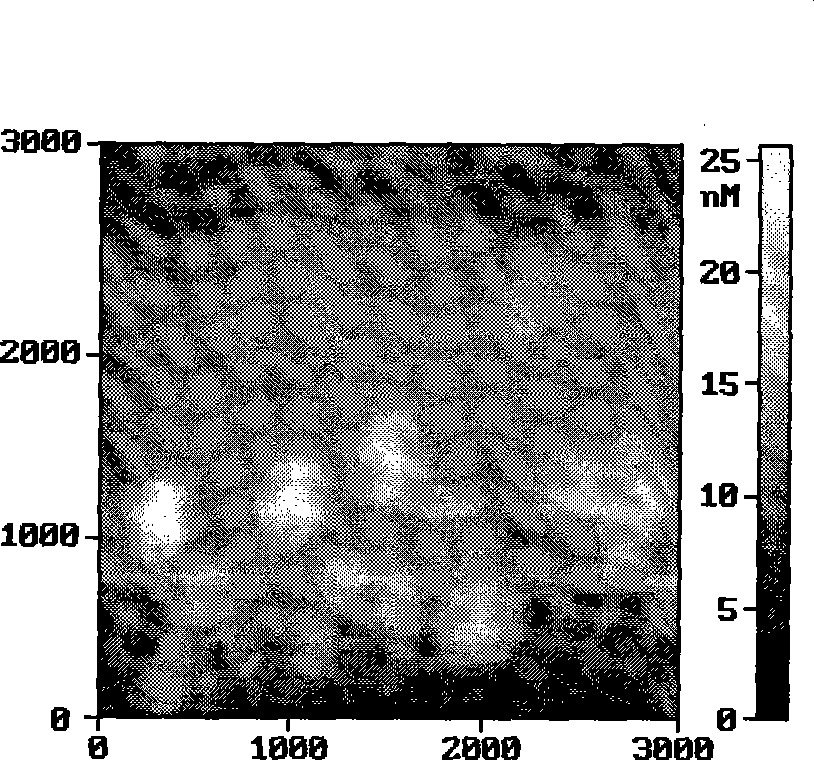

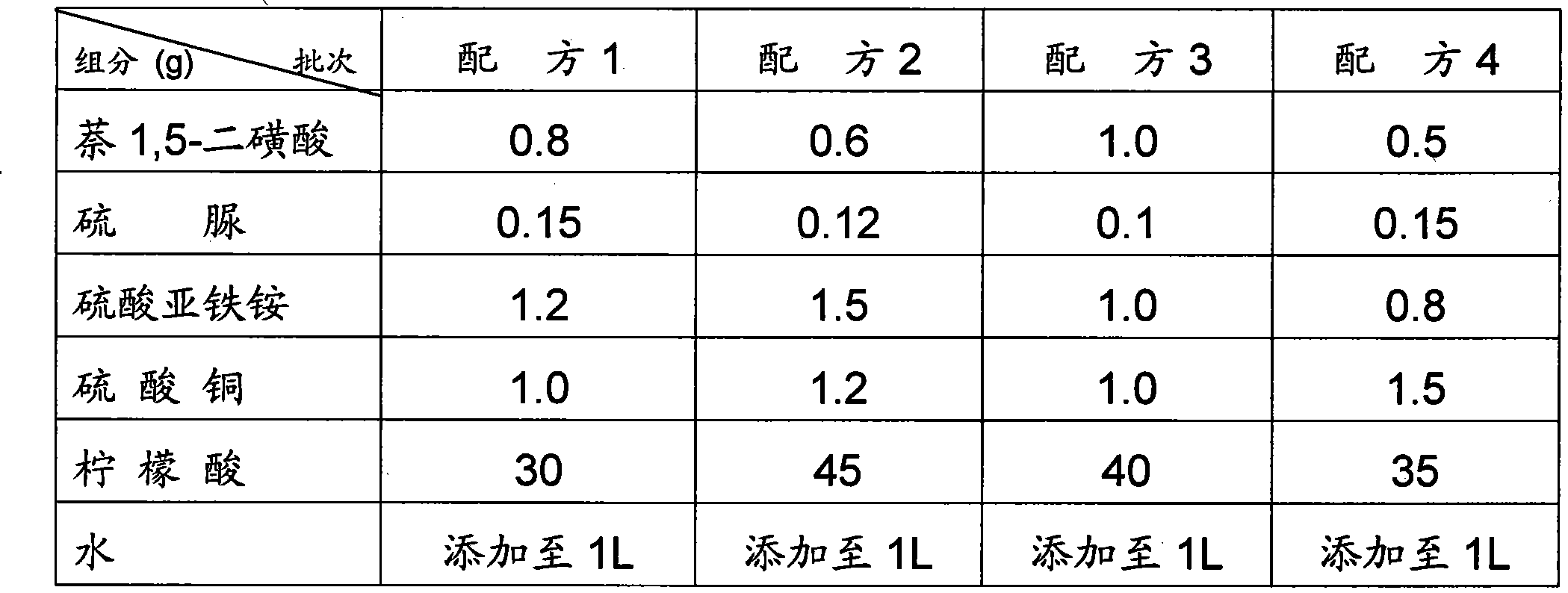

[0017] 1. Group ratio

[0018] 1.1 Brightener

[0019]

[0020] 1.2 Supplement A

[0021]

[0022] 1.3 Supplement B

[0023]

[0024] 2. Preparation

[0025] 2.1 Preparation of brightener

[0026] Weigh naphthalene 1,5-disulfonic acid and thiourea respectively according to the above formula, place them in a container with a volume of 1L, and add deionized water; after they are completely dissolved, dissolve ferrous ammonium sulfate and copper sulfate in the above solution After completely dissolved, add citric acid, shake well, add deionized water to 1L.

[0027] 2.2 Preparation of Supplement A

[0028] Weigh ferrous ammonium sulfate and copper sulfate respectively according to the above formula, place them in a container with a volume of 1L, and add deionized water; after they are completely dissolved, add citric acid, shake well, and add deionized water to 1L.

[0029] 2.3 Preparation of supplement B

[0030] Weigh naphthalene 1,5-disulfonic acid and thiourea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com