Carrying tool for printed circuit board (PCB)

A technology for printed circuit boards and carriers, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of low rigidity of printed circuit boards, poor electroplating effect of printed circuit boards, easy bending and deformation, etc., to achieve rapid electroplating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

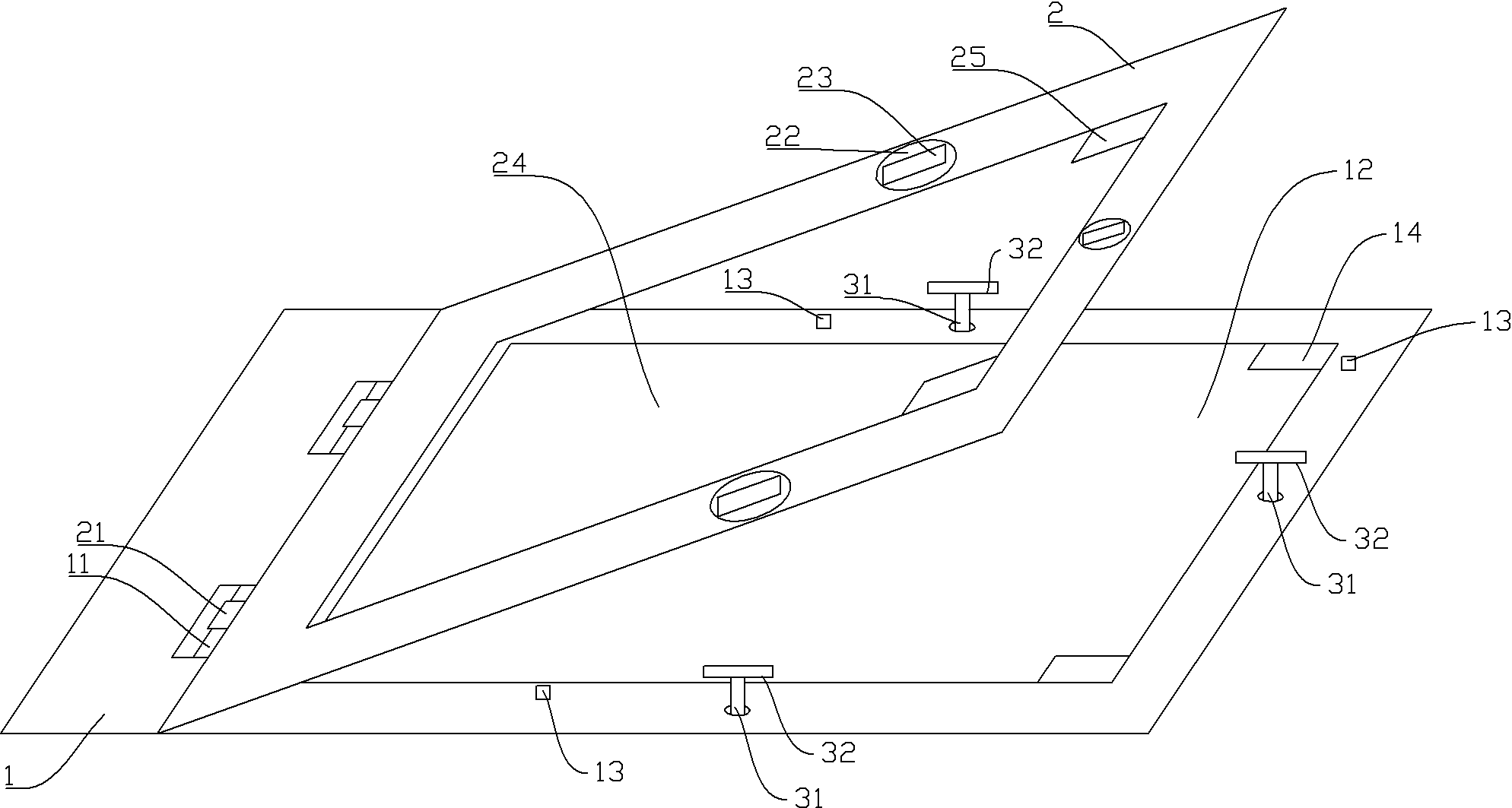

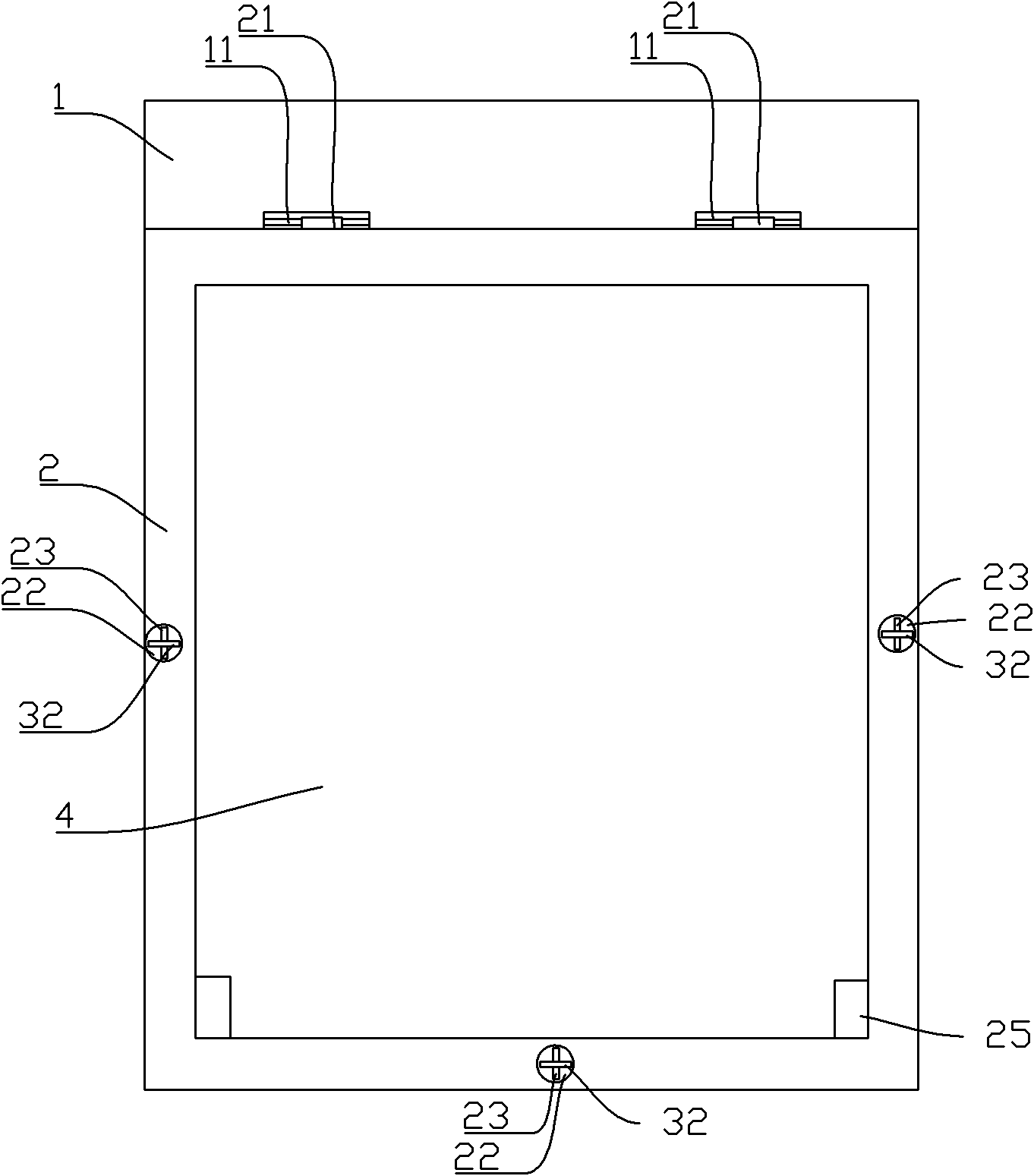

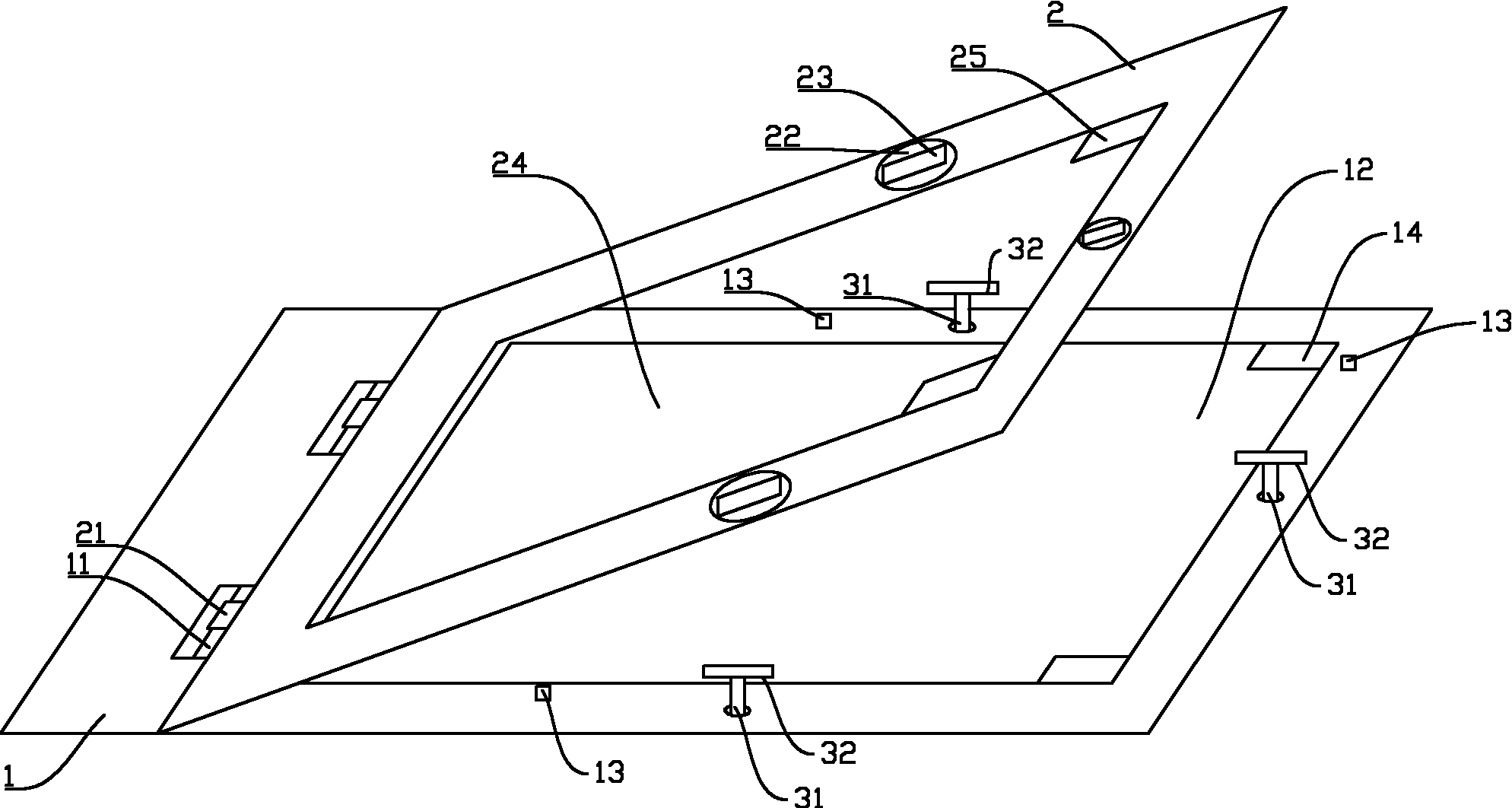

[0019] Such as figure 1 , figure 2 As shown, the printed circuit board carrier includes a first clamping frame 1 and a second clamping frame 2 . The first clamping frame 1 is provided with a first through hole 12 . The second clamping frame 2 is provided with a second through hole 24 .

[0020] Two shafts 11 are arranged on the first clamping frame 1 . Two sleeves 21 are arranged on the second clamping frame 2 , and the sleeves 21 are sleeved on the shaft 11 . The first clamping frame 1 is rotatably connected to the second clamping frame 2 , and when the first clamping frame 1 is fixed, the second clamping frame 2 can rotate around an axis 11 .

[0021] Three connecting rods 31 are rotatably installed on the first clamping frame 1 . Each connecting rod 31 passes through the first clamping frame 1 , one end of the connecting rod 31 is provided with an end cap (not shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com