Method for preparing copper-clad tungsten tungsten-copper composite powder

A composite powder, copper-clad tungsten technology, applied in liquid chemical plating, coating, metal material coating process and other directions, can solve the problems of low copper content, slow plating speed, thin coating, etc. The effect of rapid plating

Inactive Publication Date: 2012-03-21

UNIV OF SCI & TECH BEIJING

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the process of industrialized mass production, there are still problems such as slow plating speed, thin coating, low copper content and unstable plating solution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

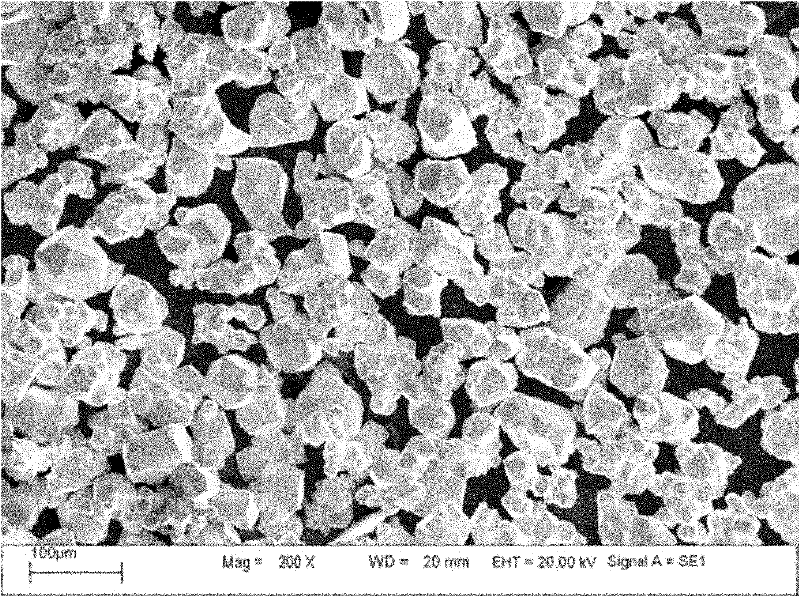

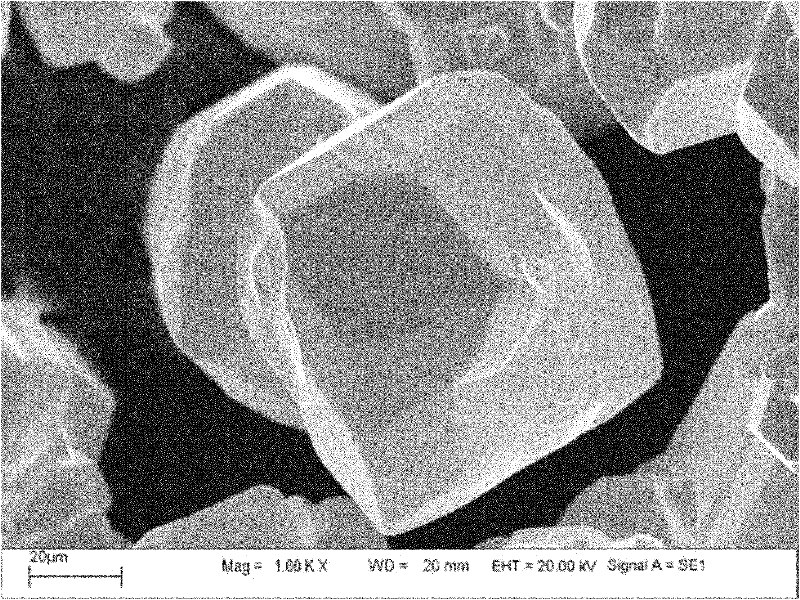

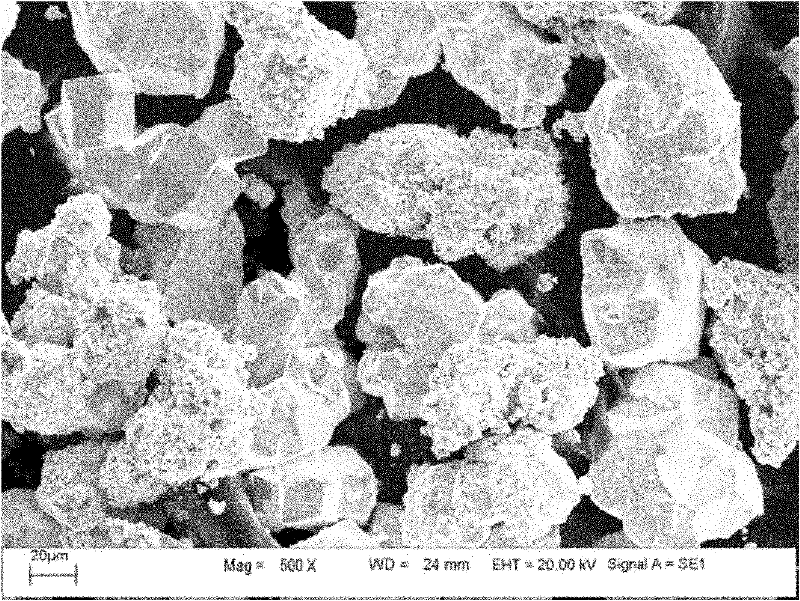

The invention provides a method for preparing copper-clad tungsten tungsten-copper composite powder. The method comprises the following steps of: preparing plating solution and heating a container accommodating the plating solution by using a constant temperature water bath; performing acid-washing and alkali-washing on tungsten powder; adding the tungsten powder into the plating solution; performing complex stirring of mechanical stirring and air stirring on the plating solution; and cleaning the plated composite powder, drying and annealing. The preparation method has the advantage that: the complex stirring of the mechanical stirring and the air stirring is adopted, so the plating speed can be increased, the plating coat can be thickened, the adjustment range of copper content can be widened and the plating solution can be kept stable during industrial mass production.

Description

technical field [0001] The invention belongs to the technical field of powder metallurgy, and in particular relates to a method for preparing copper-clad tungsten-tungsten-copper composite powder. Background technique W-Cu alloy is composed of highly conductive copper and refractory metal tungsten. Metal tungsten and copper neither dissolve each other nor form intermetallic compounds. Tungsten and copper can only be mixed uniformly as a monomer to form a pseudo-alloy alloy). Therefore, the W-Cu alloy presents the advantages of high temperature resistance, high hardness, and low expansion coefficient of tungsten, and the comprehensive excellent properties of copper such as high thermal conductivity and good plasticity. Therefore, tungsten-copper material has excellent resistance to arc ablation, welding resistance and good electrical and thermal conductivity, and has attracted much attention in the fields of medium and high voltage electrical appliances, communications, av...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F1/02C23C18/40

Inventor 林涛史萍萍邵慧萍王楠郭志猛

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com