Plastic film brush copper plating process

A technology of plastic film and brush plating, which is applied in the coating process of metal materials, sputtering plating, and plating of superimposed layers, etc., which can solve the problem that the square resistance of the film surface cannot be reduced, the film is easy to break when pulled, and the edge of the film is easy to burn Coke and other problems, to reduce the risk of perforation, increase the thickness of the copper plating layer, the effect of excellent film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

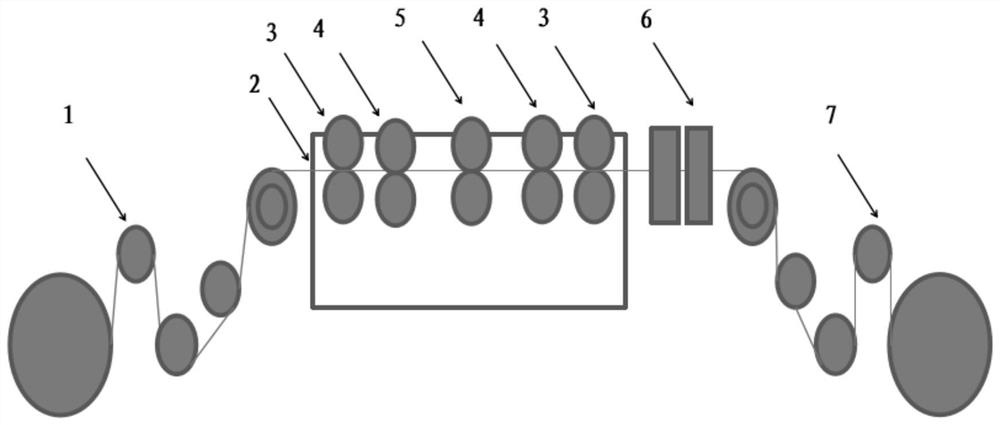

Image

Examples

Embodiment 1

[0089] This embodiment provides a PP thin film copper plating process, the steps are as follows:

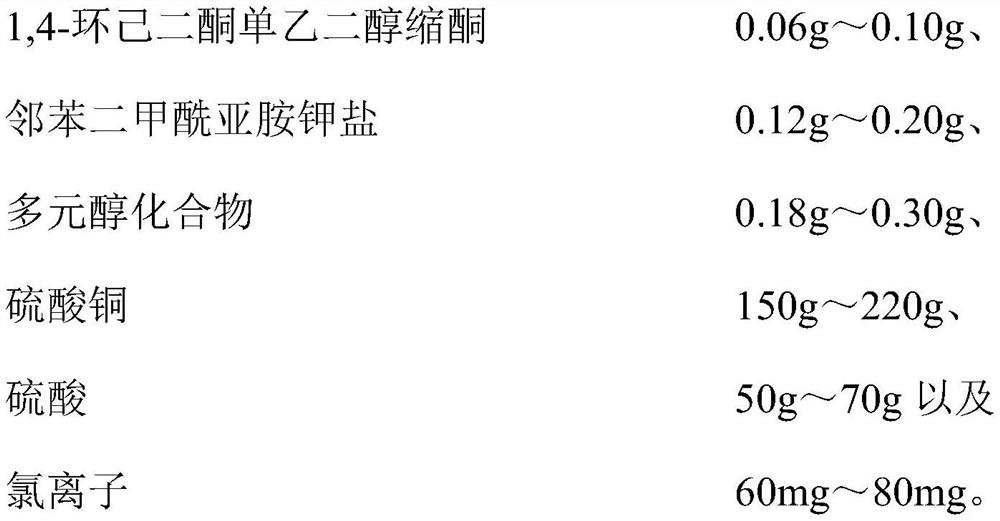

[0090] (1) prepare copper plating liquid, in the present embodiment, described copper plating liquid of every liter is made up of water and following components:

[0091]

[0092] The specific configuration process is as follows:

[0093] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 10 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0094] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 20 g for preparation, and set aside;

[0095] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 30g of 3-amino-1,2-propanediol in 500ml of deionized water, stir and dissolve until clear, set aside;

[0096] 4) Preparation of copper plating additive: use step 2) to weigh phthalimide potassium salt and slowly add it to the 1,4-cyclohexanedione mo...

Embodiment 2

[0102] This embodiment provides a PP thin film copper plating process, the steps are as follows:

[0103] (1) prepare copper plating liquid, in the present embodiment, described copper plating liquid of every liter is made up of water and following components:

[0104]

[0105] The specific configuration process is as follows:

[0106] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 10 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0107] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 20 g for preparation, and set aside;

[0108] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 30g of 3-amino-1,2-propanediol in 500ml of deionized water, stir and dissolve until clear, set aside;

[0109] 4) Preparation of copper plating additive: use step 2) to weigh phthalimide potassium salt and slowly add it to the 1,4-cyclohexanedione mo...

Embodiment 3

[0115] This embodiment provides a PP thin film copper plating process, the steps are as follows:

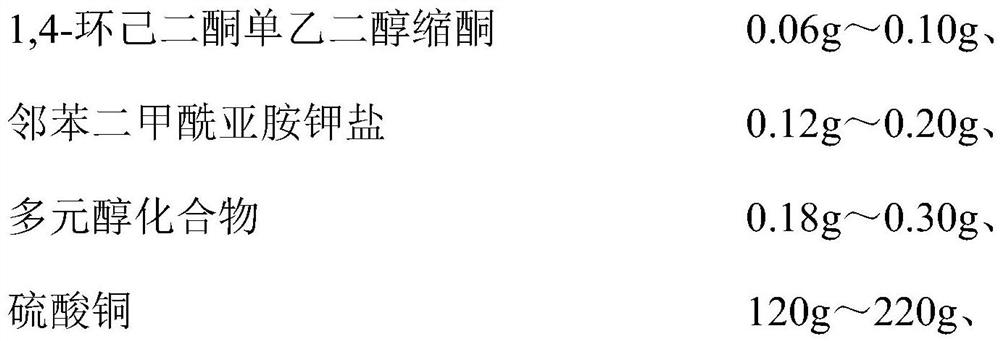

[0116] (1) prepare copper plating liquid, in the present embodiment, described copper plating liquid of every liter is made up of water and following components:

[0117]

[0118] The specific configuration process is as follows:

[0119] 1) Prepare 1,4-cyclohexanedione monoethylene glycol ketal solution: dissolve 10 g of 1,4-cyclohexanedione monoethylene glycol ketal in 200 ml of deionized water, stir and dissolve until clear, and set aside;

[0120] 2) Preparation of phthalimide potassium salt: use an analytical balance to weigh 20 g for preparation, and set aside;

[0121] 3) Prepare 3-amino-1,2-propanediol solution: dissolve 30g of 3-amino-1,2-propanediol in 500ml of deionized water, stir and dissolve until clear, set aside;

[0122] 4) Preparation of copper plating additive: use step 2) to weigh phthalimide potassium salt and slowly add it to the 1,4-cyclohexanedione mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com