Nickel-silicon carbide composite plating solution for electroplating

A composite electroplating, silicon carbide technology, applied in electrolytic coatings, coatings, mechanical equipment, etc., can solve problems such as low hardness and slow plating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

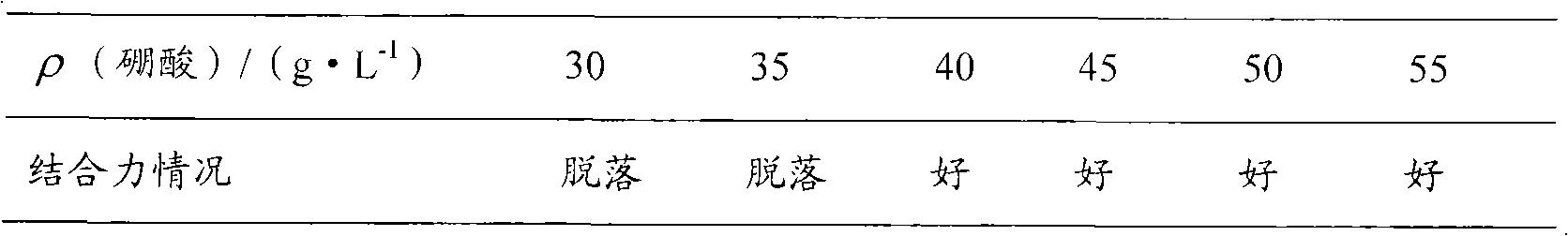

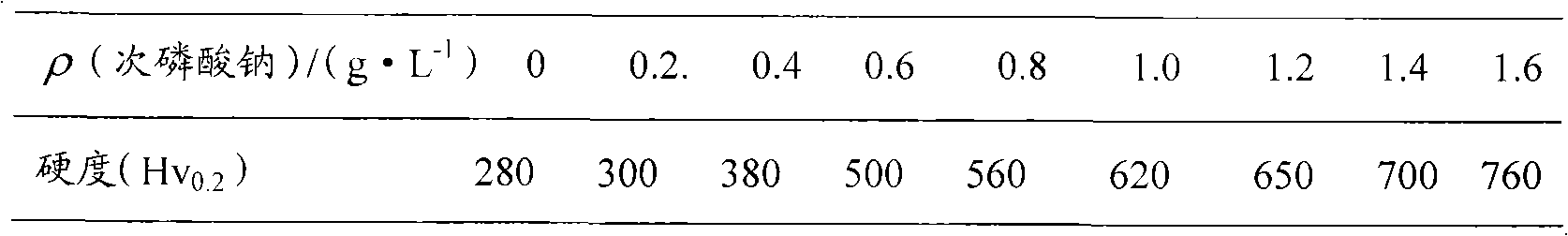

[0032] A composite electroplating solution for electroplating nickel-silicon carbide: it includes nickel sulfamate 350g / L, boric acid 50g / L, sodium hypophosphite 0.85g / L, silicon carbide 25g / L, pH 4.4T (℃) 52 wherein . It is carried out by stirring method.

[0033] The following is the process of electroplating cast aluminum alloy cylinders with this electroplating solution:

[0034] Aluminum cylinder - degreasing - alkali corrosion - Idemitsu - first galvanizing - zinc stripping - second galvanizing - composite electroplating

[0035] This process is known as post-galvanizing plating. It must be thoroughly washed with water between each step to avoid the residual liquid from the previous process being brought into the next process.

[0036] 1. Degreasing: Before the surface treatment of any part, it must be degreased. The purpose of degreasing is to remove the dirt on the surface of the part, anti-rust oil and substances left on the surface in the previous process;

[003...

Embodiment 2

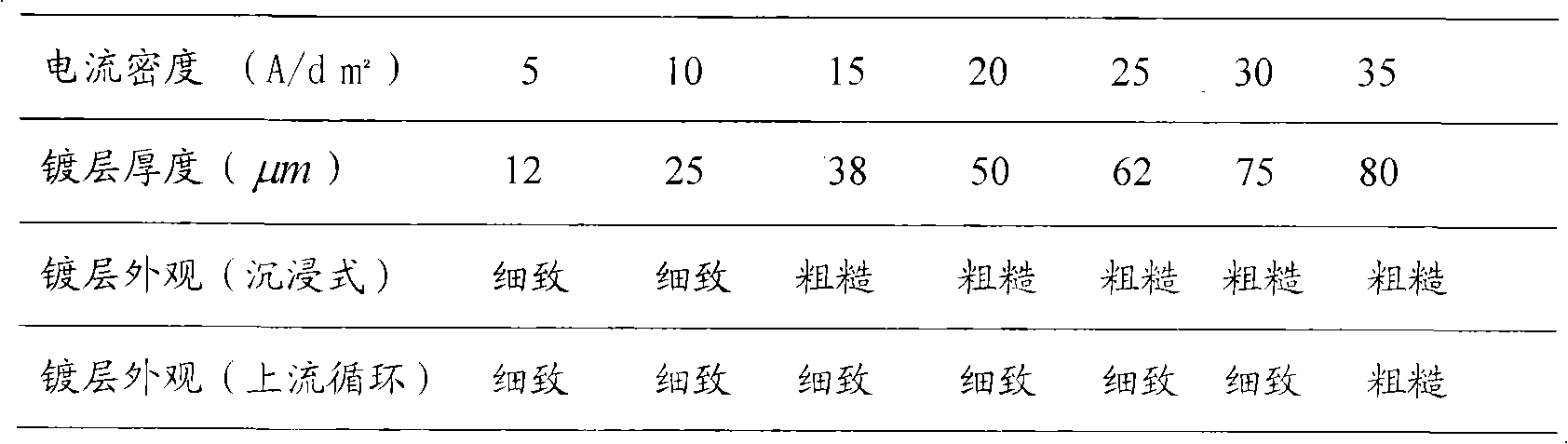

[0045] The process of this embodiment is the same as that of Embodiment 1, except that the composite plating solution and stirring method are changed to some extent. It includes nickel sulfamate 398g / L, boric acid 59g / L, sodium hypophosphite 0.9g / L, silicon carbide 29g / L, pH 4.5, T(°C) 54. The stirring method used in the composite plating solution is the D of the upflow circulation method. K =25A / dm 2 .

[0046] The part not described in this implementation is the same as that of Embodiment 1

Embodiment 3

[0048] The process of this embodiment is the same as that of Embodiment 2, except that the composite plating solution and stirring method are changed to some extent. It includes nickel sulfamate 320g / L, boric acid 45g / L, sodium hypophosphite 0.75g / L, silicon carbide 21g / L, pH 4.3, T(°C) 50. The stirring method used in the composite plating solution is the D of the upflow circulation method. K =20A / dm 2 .

[0049] The parts not described in this embodiment are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com