Environmentally-friendly chemical gilding liquid

An environmentally friendly, chemical gold plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of easy erosion of printed circuit board solder mask substrate, subsequent component welding failure, and poor coating quality. Good and other problems, to achieve the effect of inhibiting the black disk phenomenon, improving the bonding force of nickel and gold, and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Composition of electroless gold plating solution:

[0028] Gold sodium sulfite 2g / L, sodium sulfite 5g / L, sodium thiosulfate 15g / L, ethylenediamine 6g / L, disodium edetate 5g / L, triethanolamine 2g / L, borax 15g / L.

[0029] Plating conditions: pH value is 6.0, temperature is 80°C.

[0030] (2) Test sample preparation:

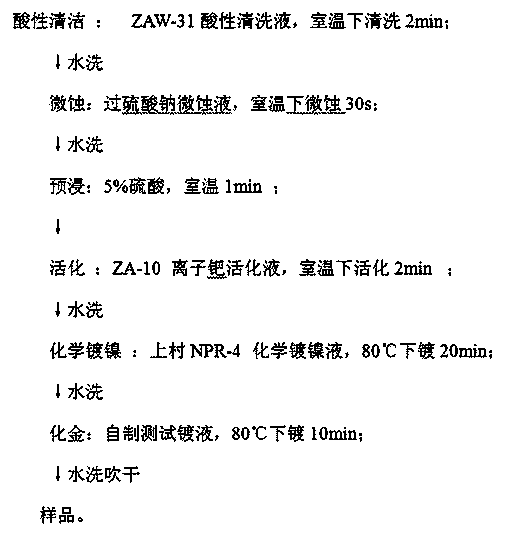

[0031] The experimental substrate is glass fiber copper clad laminate, such as figure 1 The process flow shown prepares the test sample;

[0032] (3) Test items and requirements

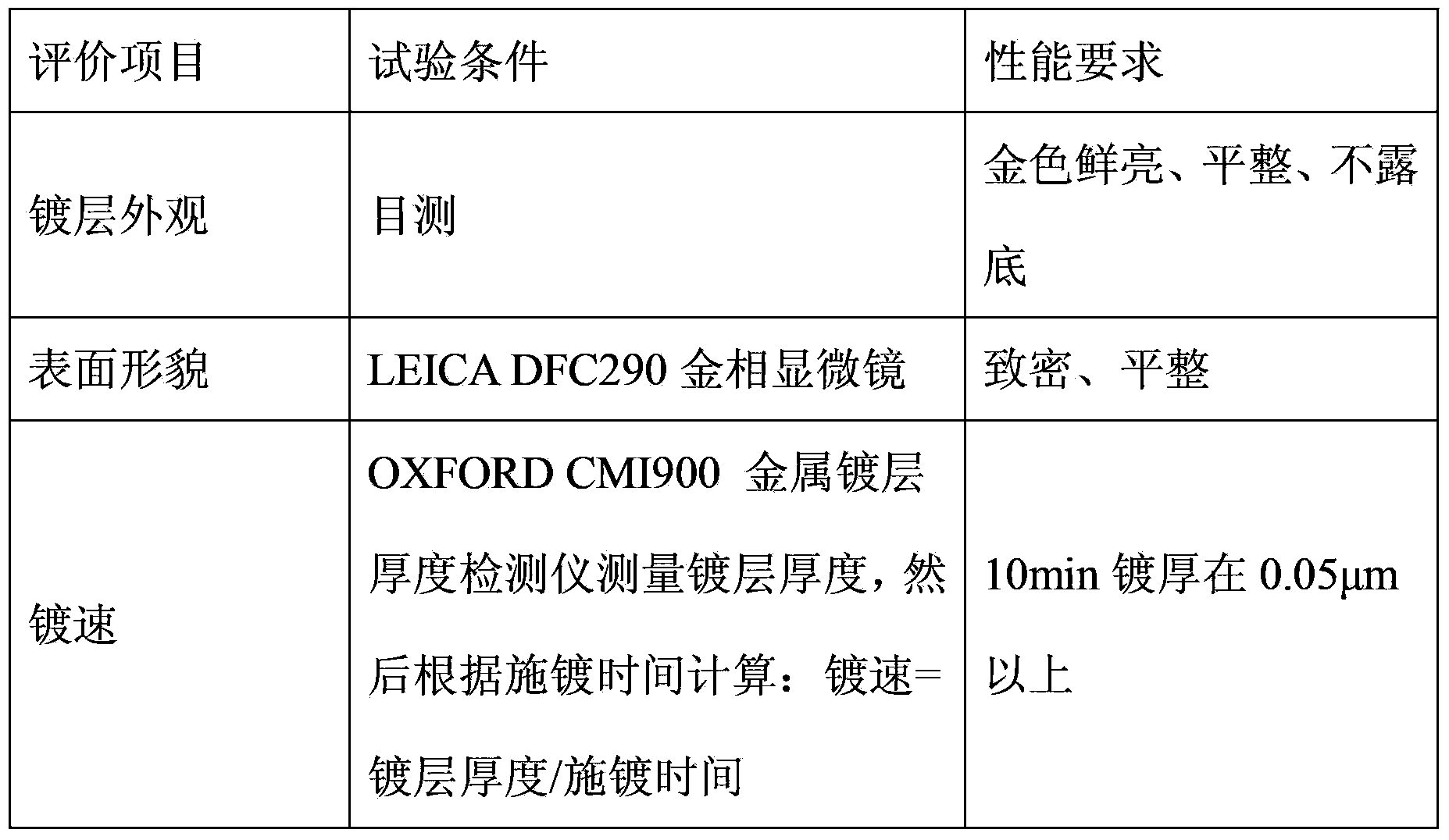

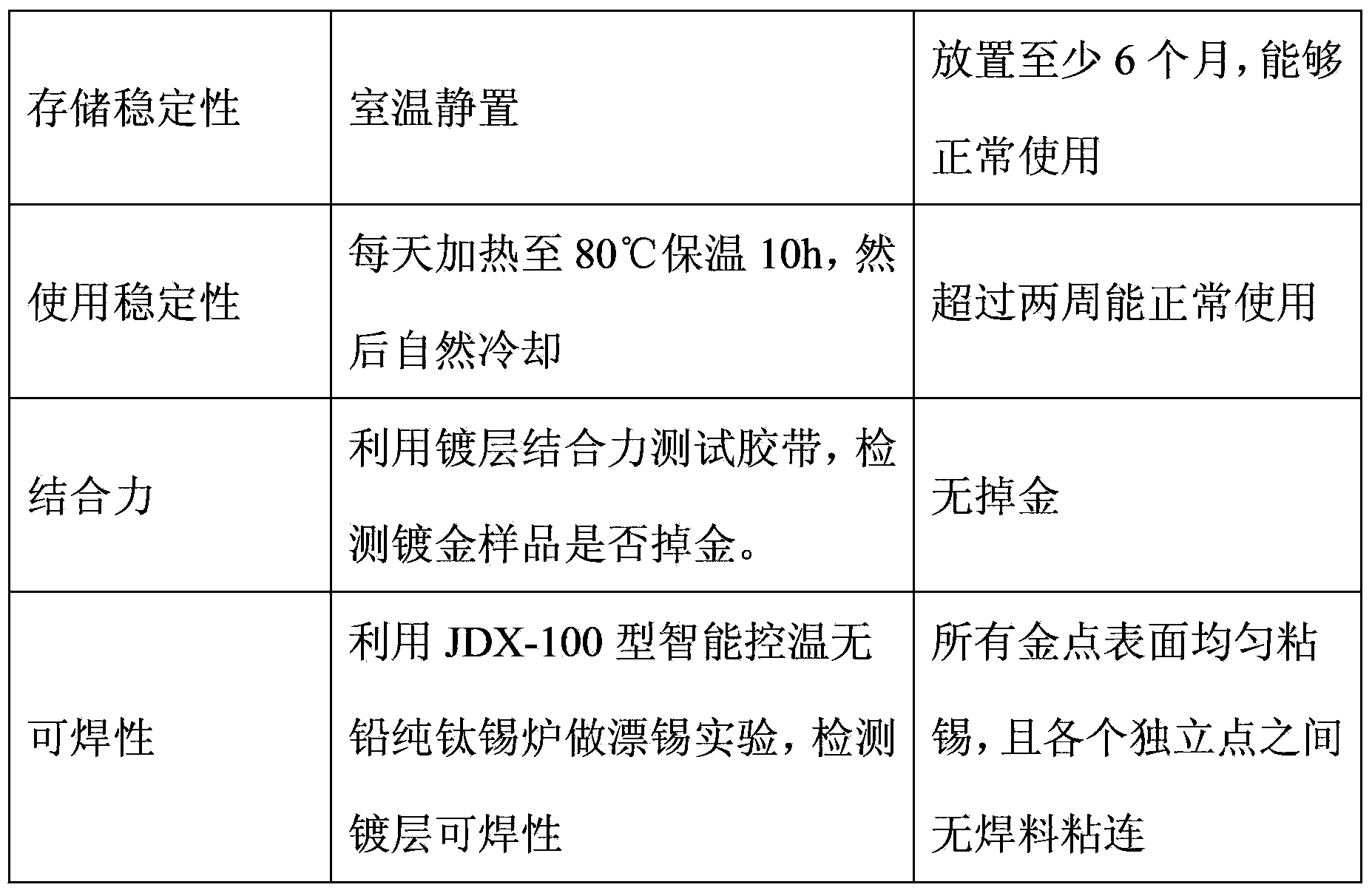

[0033] Table 1 shows the test items, test conditions and performance requirements for the samples prepared in Example 1.

[0034] Table 1 Performance Evaluation Items, Test Conditions and Requirements of Electroless Gold Plating Layer

[0035]

[0036]

[0037] Embodiment one test result:

[0038] The appearance of the gold-plated sample is bright and golden, and there is no phenomenon of overflow plating or missing plating. Visually and under a microscope, the su...

Embodiment 2

[0040] Composition of chemical gold plating solution:

[0041] Gold sodium sulfite 2g / L, sodium sulfite 5g / L, sodium thiosulfate 10g / L, organic phosphonic acid (HEDP) 10g / L, malic acid 5g / L, 2-mercaptobenzothiazole 1g / L, dihydrogen phosphate Sodium 15g / L. Plating conditions: pH value is 7.0, temperature is 80°C.

[0042] The preparation process of the test sample is the same as in Example 1, and the test appearance and stability are all qualified. The plating thickness is 0.09μm in 10 minutes, and the plating speed is fast. Coating strength and solderability test of tin-floating test are qualified.

Embodiment 3

[0044] Chemical gold plating solution composition and process conditions:

[0045] Gold sodium sulfite 2g / L, sodium sulfite 20g / L, sodium thiosulfate 5g / L, sodium citrate 5g / L, disodium edetate 10g / L, triethanolamine 1g / L, sodium dihydrogen phosphate 15g / L. Wherein, the pH value is 6.5, and the temperature is 80°C.

[0046] The preparation process of the test sample is the same as that in Example 1. The properties of the sample and the plating solution are all qualified, and the plating thickness is 0.07 μm in 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com