Chemical copper plating solution, preparation method of chemical copper plating solution and nonmetal chemical plating method

An electroless copper plating and electroless plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of environment and operator injury, formaldehyde is not environmentally friendly, etc., to reduce leakage and overplating, The effect of short initiation cycle and good electroless plating activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0016] According to a preferred embodiment of the present invention, the preparation method of described electroless copper plating solution comprises the following steps:

[0017] Dissolve complexing agent in water, then add hydroxide, stir until dissolved; then add copper salt, stir until dissolved; then add accelerator and stir until dissolved; then add stabilizer and buffer, finally add reducing agent and high Stir the iodate ions until dissolved.

[0018] Preferably, when the pH value is controlled at 10-13, the electroless plating effect is the best.

[0019] The present invention also provides a method for electroless plating on a non-metallic surface, comprising activating the pretreated non-metallic substrate with an ionic palladium activation solution, then placing it in an ionic palladium reducing solution for reduction treatment, and finally immersing it in Perform electroless plating in an electroless copper plating solution; wherein, the electroless copper plati...

Embodiment 1~5

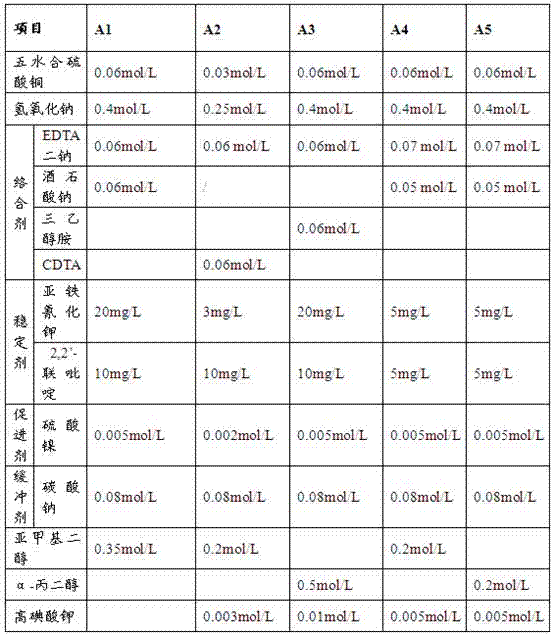

[0026] 1. Prepare electroless copper plating solution: dissolve complexing agent in water, add hydroxide, stir until completely dissolved, then add copper salt, stir until completely dissolved, then add nickel salt and stir until completely dissolved, then add Stabilizer and buffering agent, finally add reducing agent and periodate ion and stir until dissolved. Electroless copper plating solutions A1-A5 were obtained according to the composition ratio in Table 1. The specific dosage of each component is shown in Table 1.

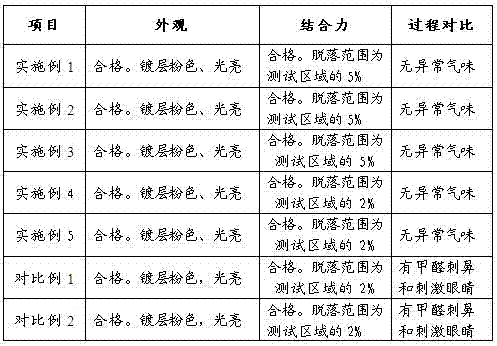

[0027] 2. Put the 2×2cm ABS sample into the ionic activation solution at 25°C for 3 minutes after ultrasonic degreasing and chromic anhydride roughening. Activation solution of AD-457; after the activation is completed, immerse the plastic parts in the reducing solution for 1 min. The reducing solution is 1% hydrazine hydrate solution, and the reduction treatment temperature is 25°C; Electroless plating is performed in electroless copper plating solutions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com