Patents

Literature

64results about How to "Fast plating speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed electroplating luminous tin-plating electroplating liquid as well as preparation method and application thereof

The invention discloses a high-speed electroplating luminous tin-plating electroplating liquid as well as a preparation method and application thereof. The high-speed electroplating luminous tin-plating electroplating liquid comprises the following raw materials calculated according to each liter of high-speed electroplating luminous tin-plating electroplating liquid: 120-200mL of tin methyl sulfonate, 100-175mL of 70 percent by weight methylsulfonic acid, 0.03-5g of brightening agent, 30-45g of conducting salt, 1-10g of grain refiner, 5-20g of antioxidant, 0.5-2g of wetting agent, 0.0005-0.001g of antifoaming agent and the balance water. The preparation method comprises the following steps of: dissolving the tin methyl sulfonate into the 70 percent by weight methylsulfonic acid; diluting the mixed solution with a proper amount of water; then adding the brightening agent, the conducting salt, the grain refiner, the antioxidant, the wetting agent and the antifoaming agent into the solution; and uniformly stirring and filtering to obtain filtrate, namely the high-speed electroplating luminous tin-plating electroplating liquid. The high-speed electroplating luminous tin-plating electroplating liquid disclosed by the invention has high coating speed, excellent dispersion capability and antifoaming capability and is suitable for a high-speed electroplating process.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

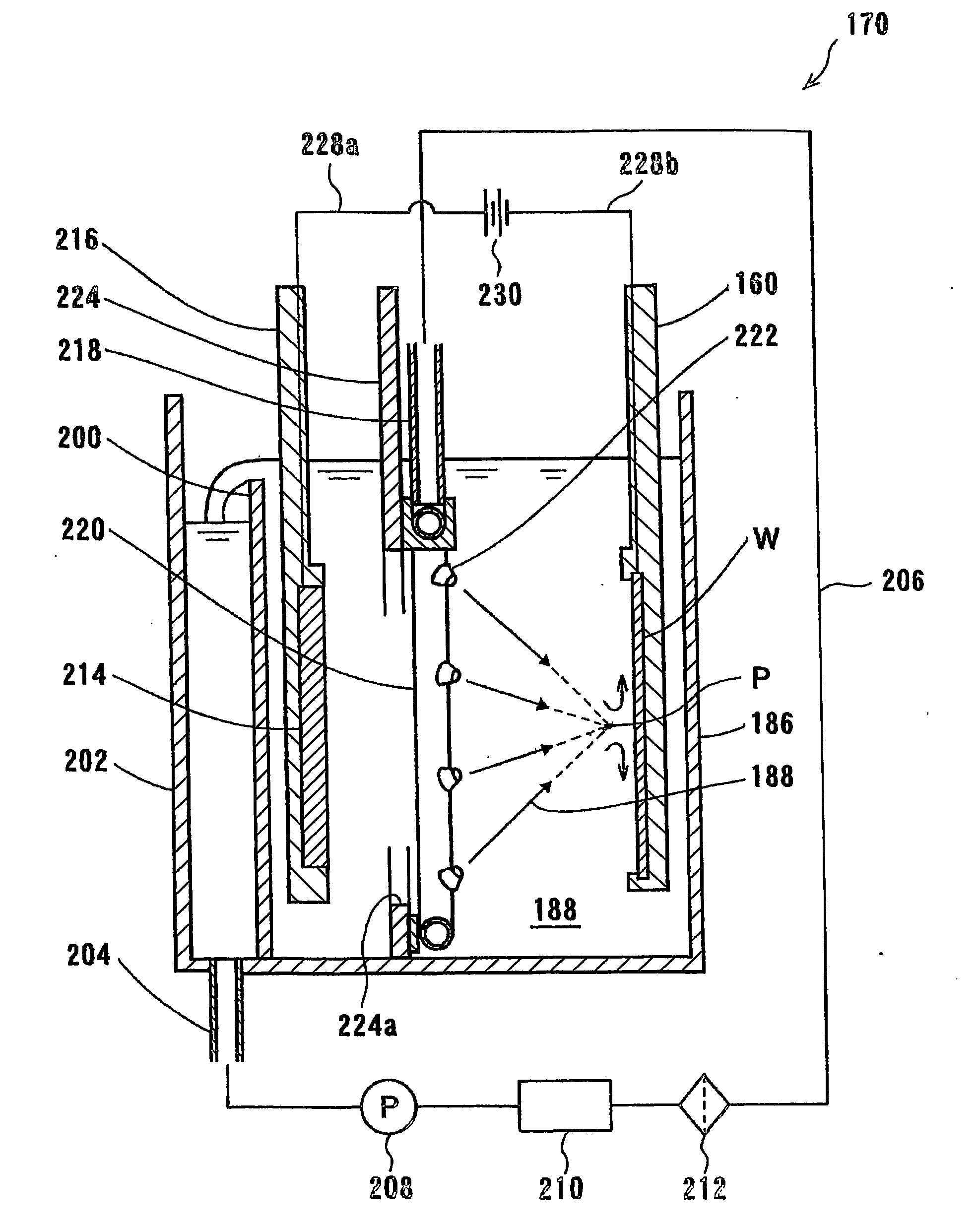

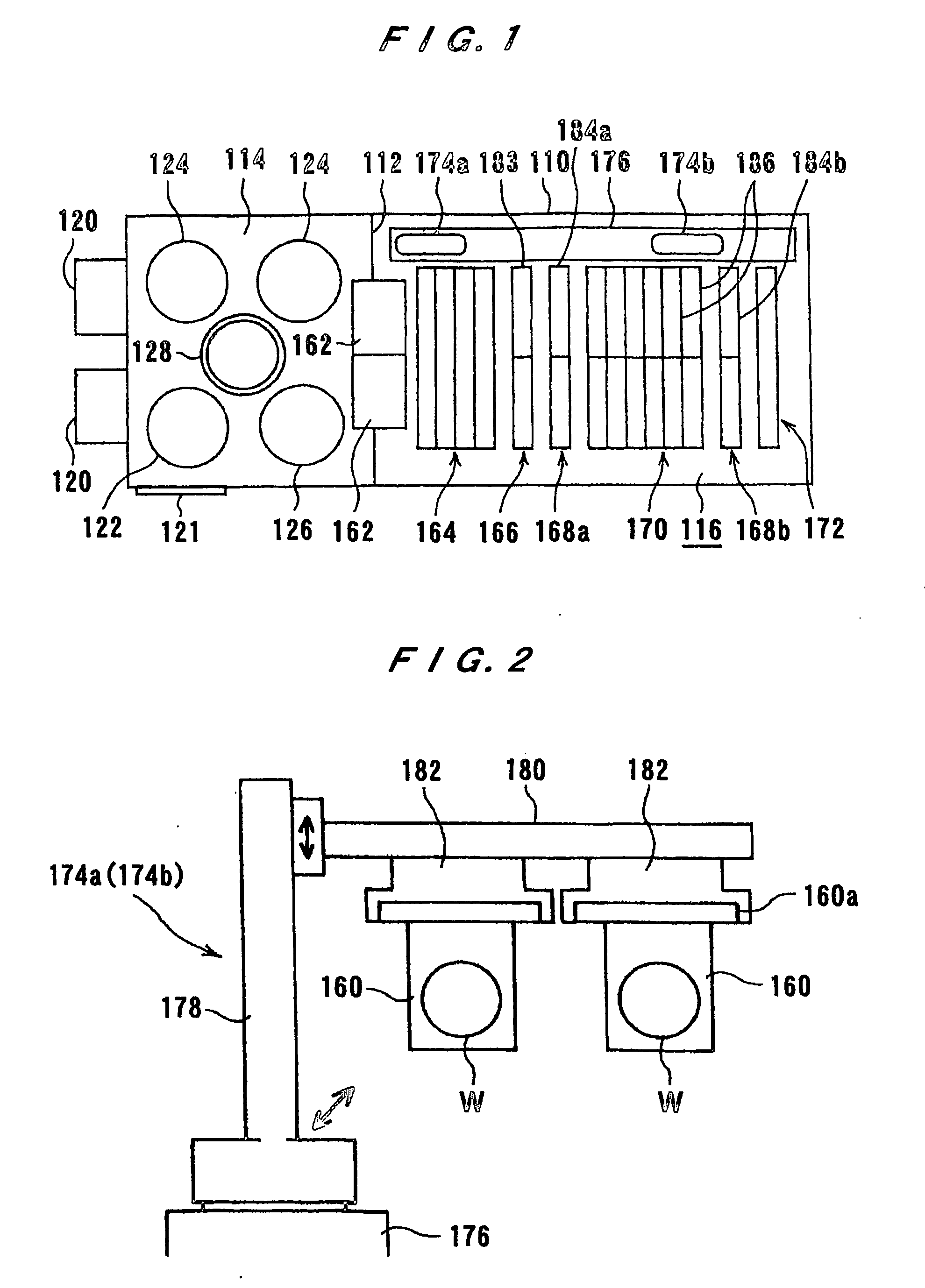

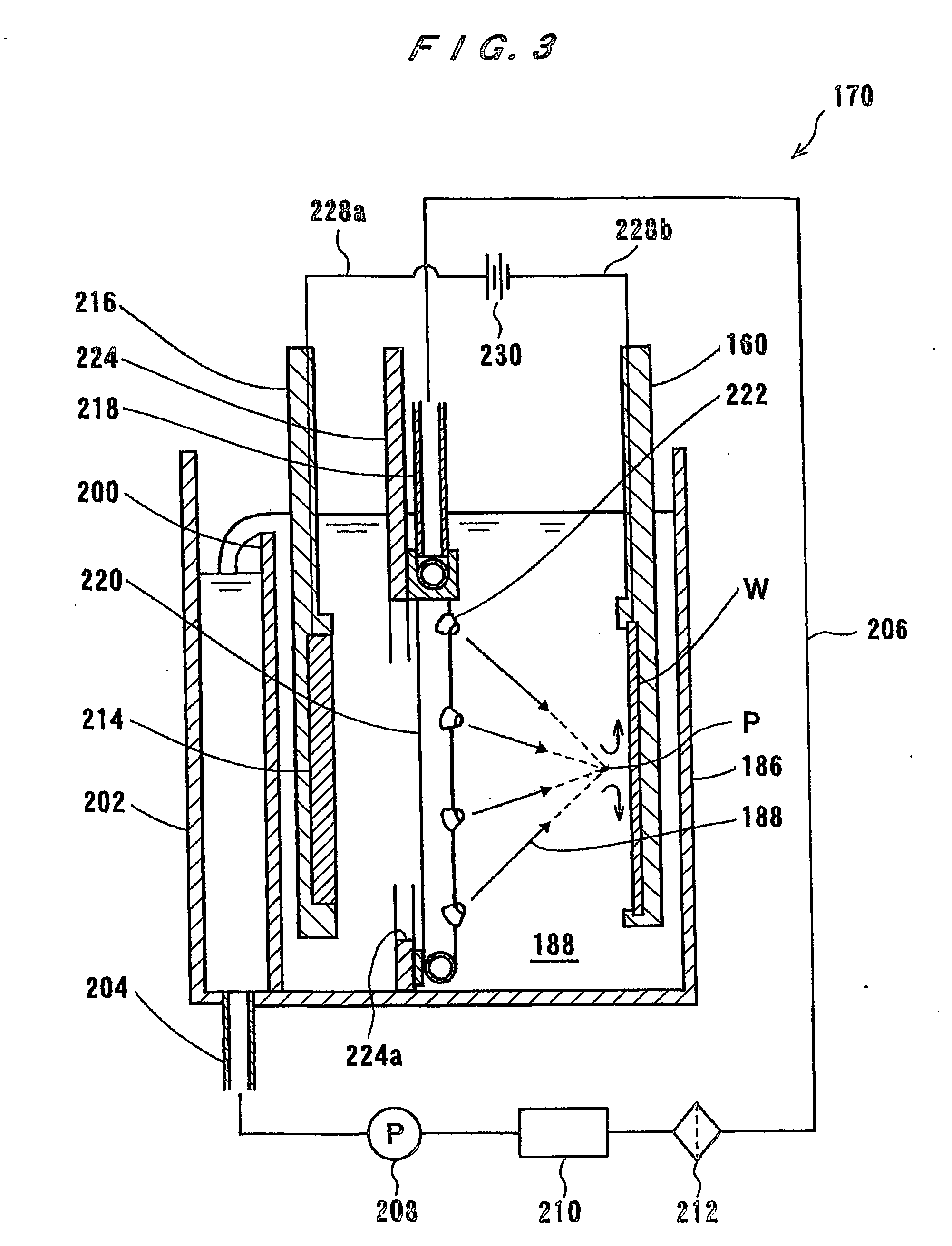

Plating apparatus

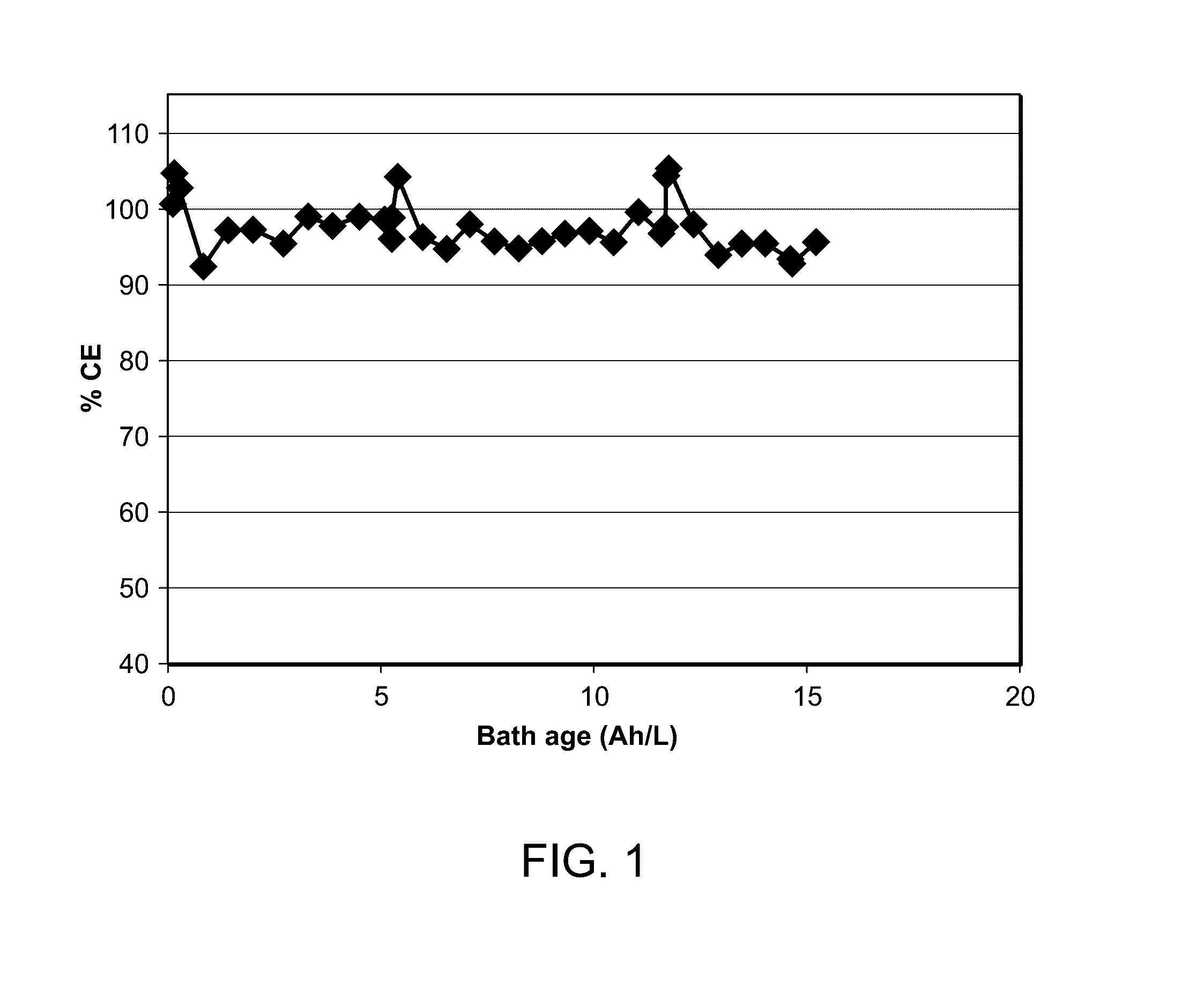

InactiveUS20060113185A1Fast plating speedHigh within-wafer uniformity of film thicknessCellsSolid-state devicesResistEngineering

The present invention is concerned with a plating apparatus for use in forming a plated film in trenches, via holes, or resist openings that are defined in a surface of a semiconductor wafer, and forming bumps to be electrically connected to electrodes of a package, on a surface of a semiconductor wafer. The plating apparatus (170) has a plating tank (186) for holding a plating solution (188), a holder (160) for holding a workpiece (W) and bringing a surface to be plated of the workpiece into contact with the plating solution (188) in the plating tank (186), and a ring-shaped nozzle pipe (220) disposed in the plating tank (186) and having a plurality of plating solution injection nozzles (222) for injecting the plating solution (188) to the surface to be plated of the workpiece held by the holder (160) to supply the plating solution (188) into the plating tank (186).

Owner:EBARA CORP

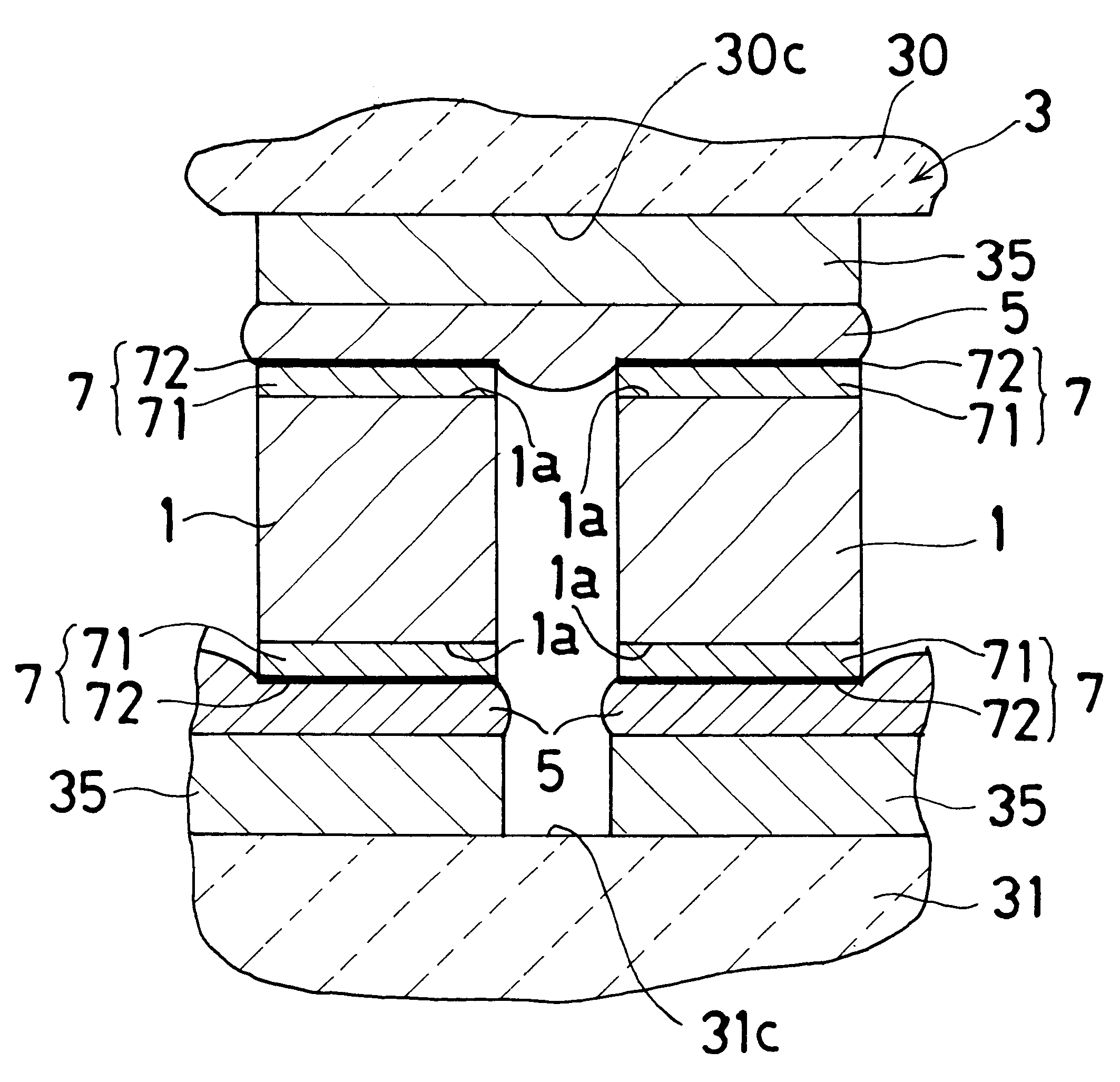

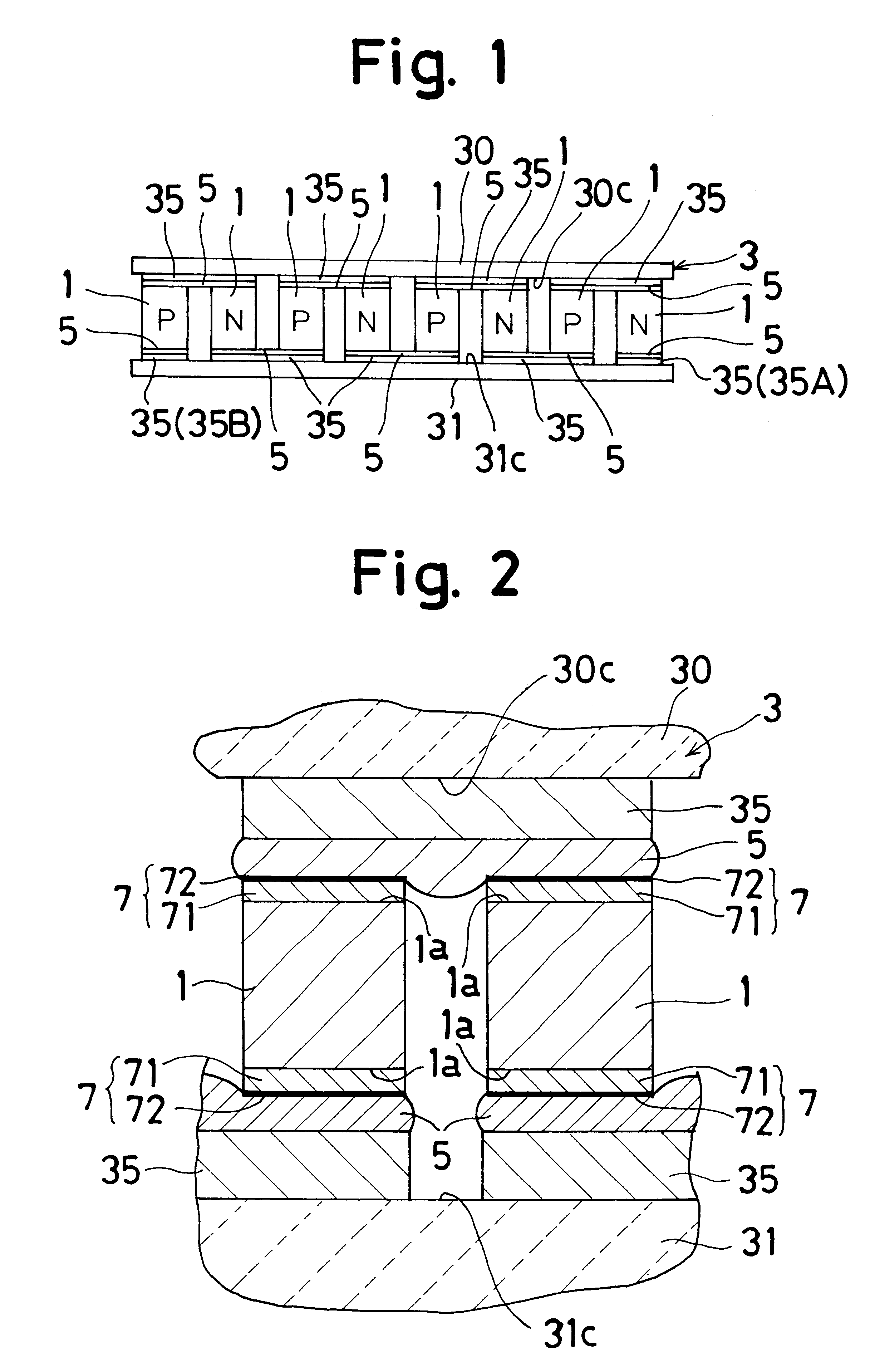

Thermoelectric device

InactiveUS6452085B2Improve wettabilityShorten speedThermoelectric device with peltier/seeback effectThermoelectric device detailsThermoelectric materialsMetallurgy

A thermoelectric device includes a thermoelectric element composed of principally thermoelectric material, a counter element adhered to the thermoelectric material. A solder layer lies between the thermoelectric element and the counter element and adheres the thermoelectric element to the counter element. A restraining layer prevents the solder ingredient of the solder layer from spreading into the thermoelectric element. The restraining layer is composed of a first layer to prevent the solder ingredient of the solder layer from spreading into the thermoelectric element and a second layer composed of material having a higher wetting property than the first layer with respect to the solder layer.

Owner:AISIN SEIKI KK

Production process for preparing high-performance diamond wire saw

InactiveCN101591796AUniform electrodepositionConcentration controllableElectrolytic coatingsChemical vapor deposition coatingHydrogenWater vapor

The invention discloses a production process for preparing a high-performance diamond wire saw, which comprises the following steps: firstly, reacting diamond with tungsten oxide, water vapor and hydrogen at a temperature of between 65 and 900 DEG C to form a W-W2C layer on the surface of the diamond so as to realize surface alloyed tungsten of the diamond; secondly, preparing electroplating bath by the diamond of the surface alloyed tungsten and watt type nickel plating solution, and carrying out electroplating by using a nickel plate as an anode and a steel wire as a cathode; making the diamond of the surface alloyed tungsten do electrophoresis motion under the action of an electric field and electrodeposited on the surface of the steel wire, and simultaneously electrodepositing the metal nickel on the surface of the steel wire. The diamond wire saw prepared by the production process has the advantages of even distribution of diamond grain, high mass percentage of a diamond plating layer and high electroplating speed; and the diamond and a nickel matrix are in metallurgical bonding, so the bonding capacity of the matrix for cutting diamond grains is remarkably improved, and the cutting capacity and the service life of the diamond wire saw are greatly improved. The production process is suitable for industrialized production, and can replace the prior production process for the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

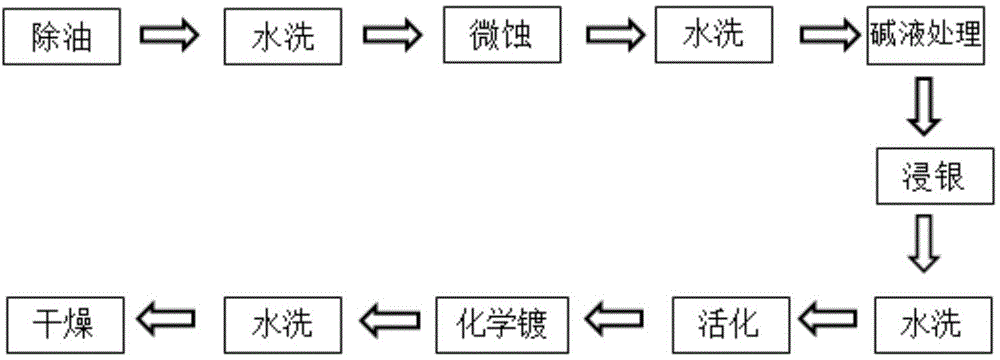

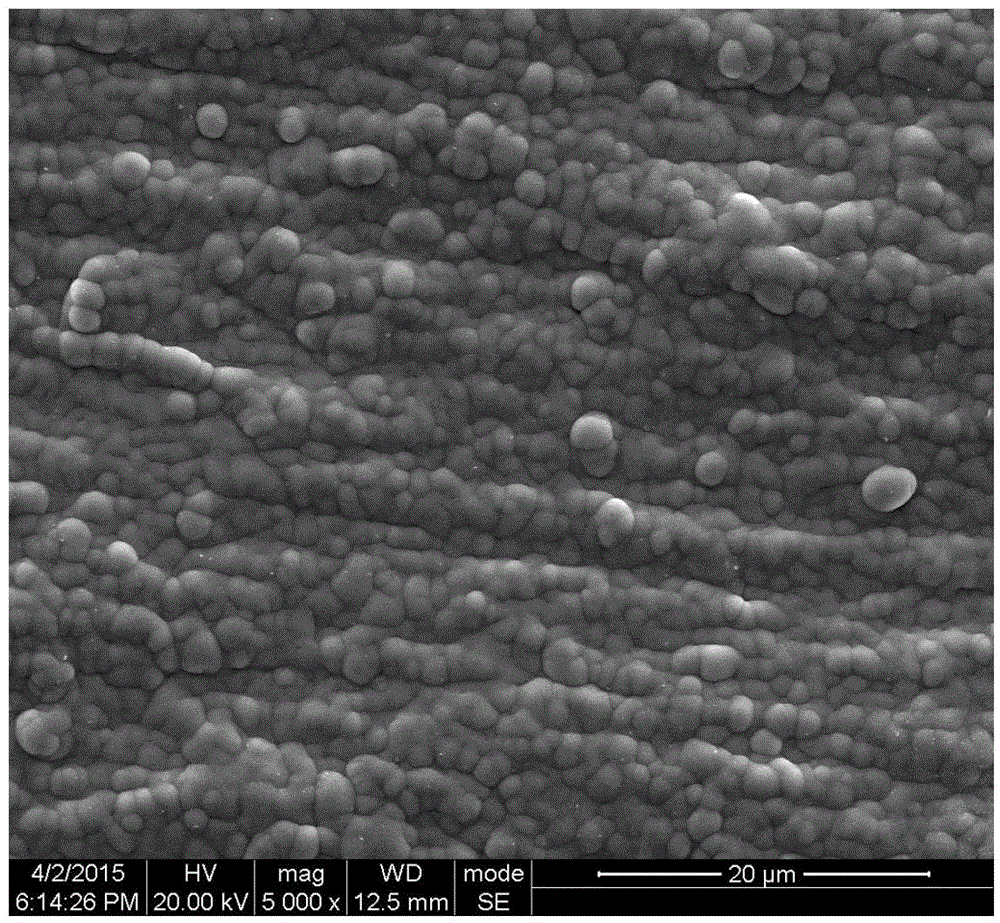

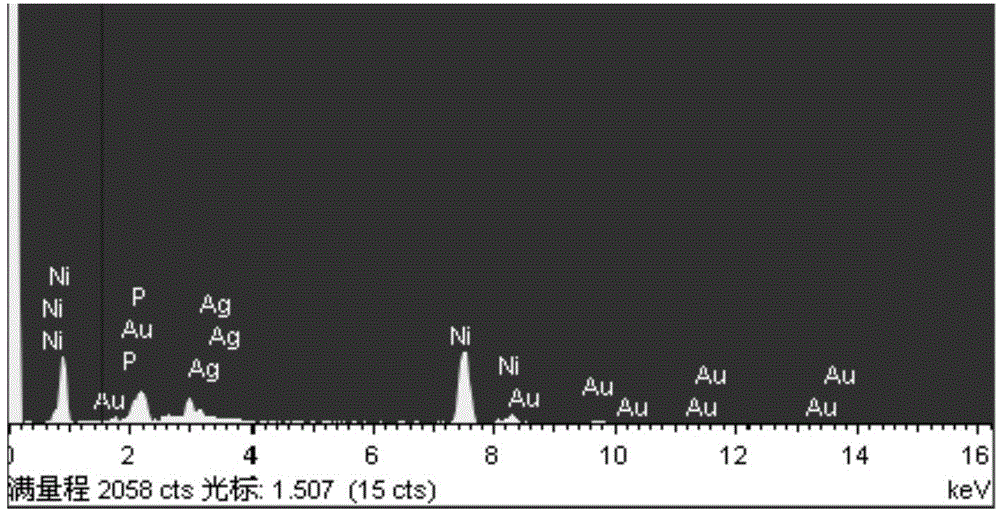

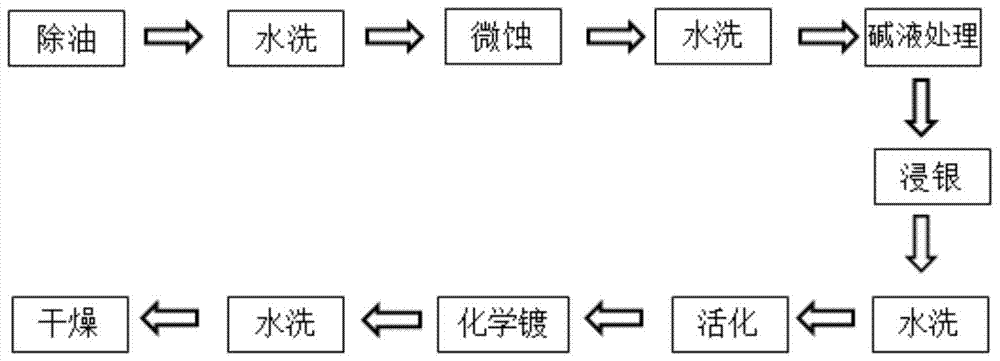

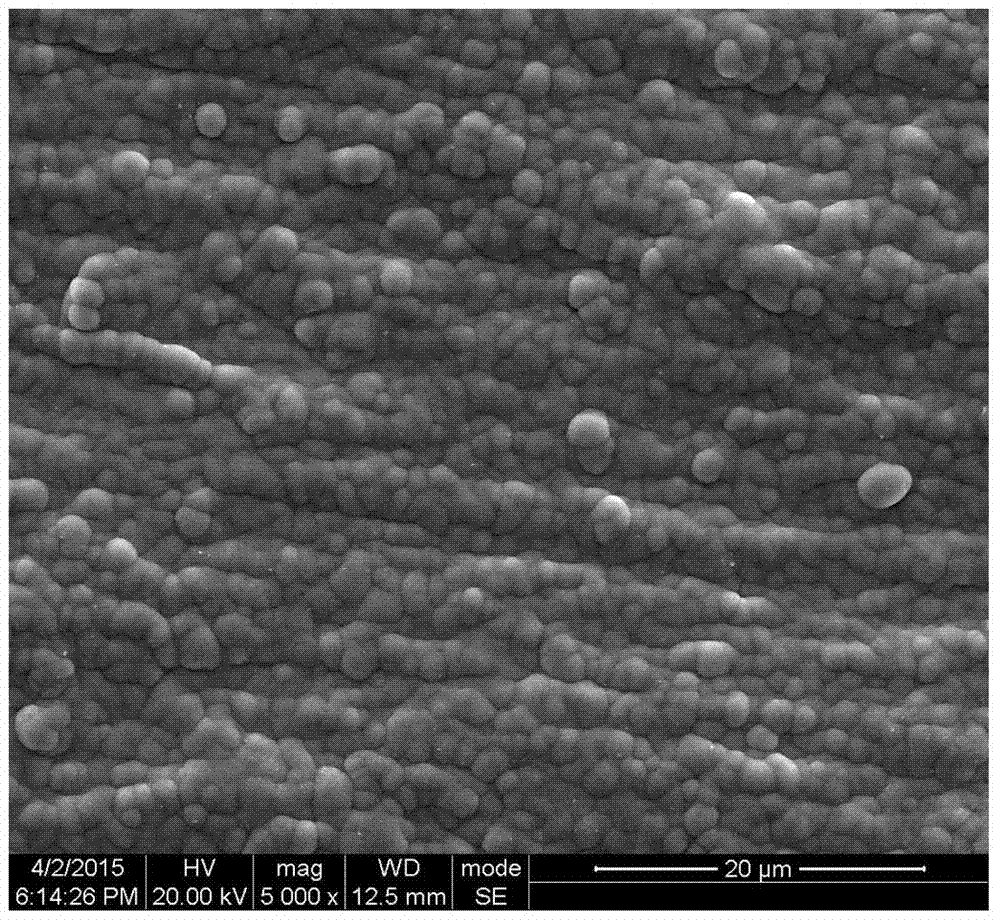

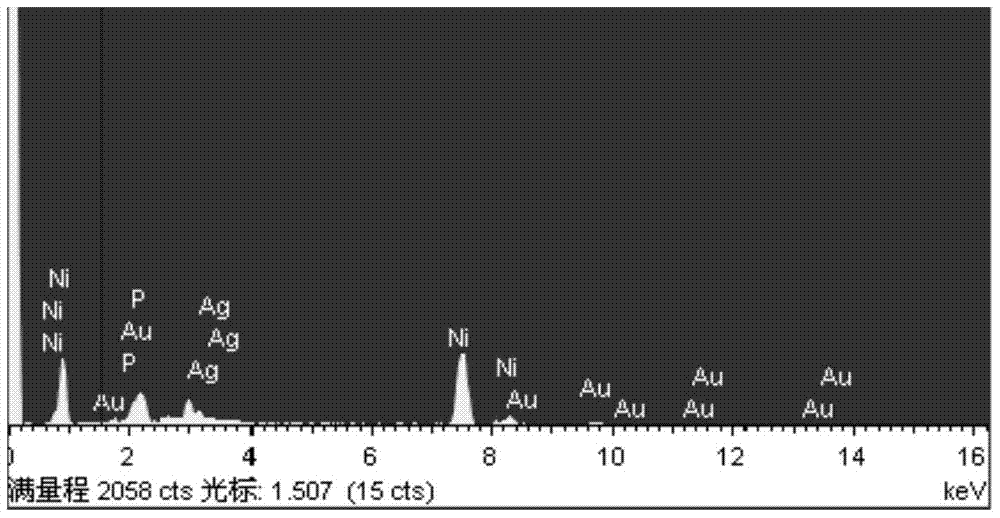

Method for achieving chemical nickel plating by activating surface of PCB

InactiveCN104862677AStrong reductionQuick restoreLiquid/solution decomposition chemical coatingSodium acetateVitamin C

The invention discloses a method for achieving chemical nickel plating by activating the surface of a PCB and belongs to the field of printed circuit board manufacturing. The method comprises the following steps that 1, 0.01-10 g / L soluble silver salt is prepared to serve as a silver soaking solution; 2, activating liquor is prepared from 1-100 g / L pH stabilizer and 10-50 g / L reducing agent, wherein the pH stabilizer is one or more of sodium hydroxide, potassium hydroxide, ammonia water, sodium acetate and the like, and the reducing agent is one or more of formaldehyde, acetaldehyde, glyoxylic acid, methyl alcohol, vitamin C, citric acid and the like; 3, pretreatment of the PCB is conducted; 4, the PCB is soaked in the silver soaking solution for 10-120 seconds after pretreatment, washed and then soaked in the activating liquor for 10-80 seconds; and 5, the PCB obtained in the step 4 is placed in chemical nickel-plating liquor for chemical nickel-plating. According to the method for achieving chemical nickel plating by activating the surface of the PCB, no precious metal palladium is used during activating; the stability of the activating liquor is high; diffusion coating is avoided; and the production cost of the PCB is effectively reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Chemical nickeling phosphorus alloy plating liquid and coating process thereof

InactiveCN1614088AFast plating speedFast platingLiquid/solution decomposition chemical coatingSodium acetateAcetic acid

The invention relates to a chemical Ni-P alloy-plating liquid and its process. The liquid is stable, works fast, has long service life, and does not contain chromium. So, it was widely used in industry. The Ni-P alloy coating is of fine corrosion-proof, containing 10-30g nickel sulfate, 20-40g sodium hypophosphite, 5-20g sodium acetate, 12-60g complexing agent and 0.002-0.01g complex stabilizer, with pH value of 4.5-5.0.

Owner:NANJING UNIV OF TECH

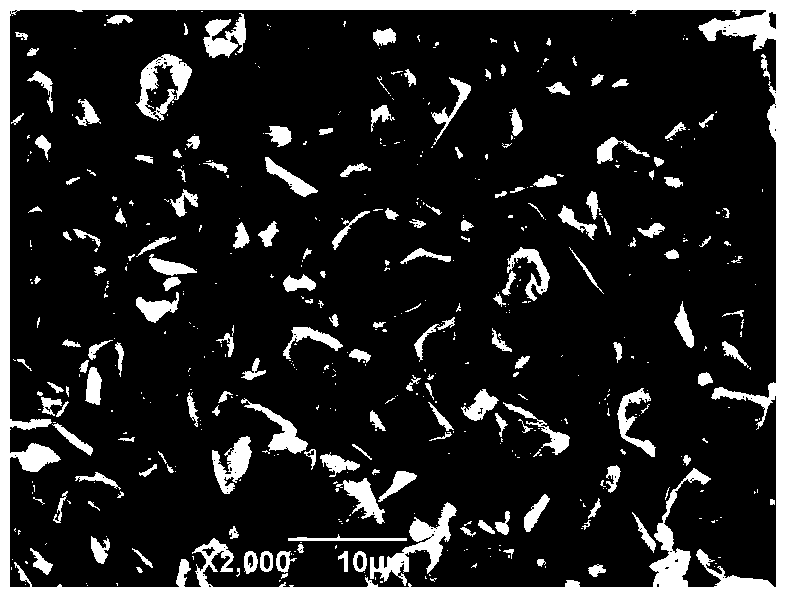

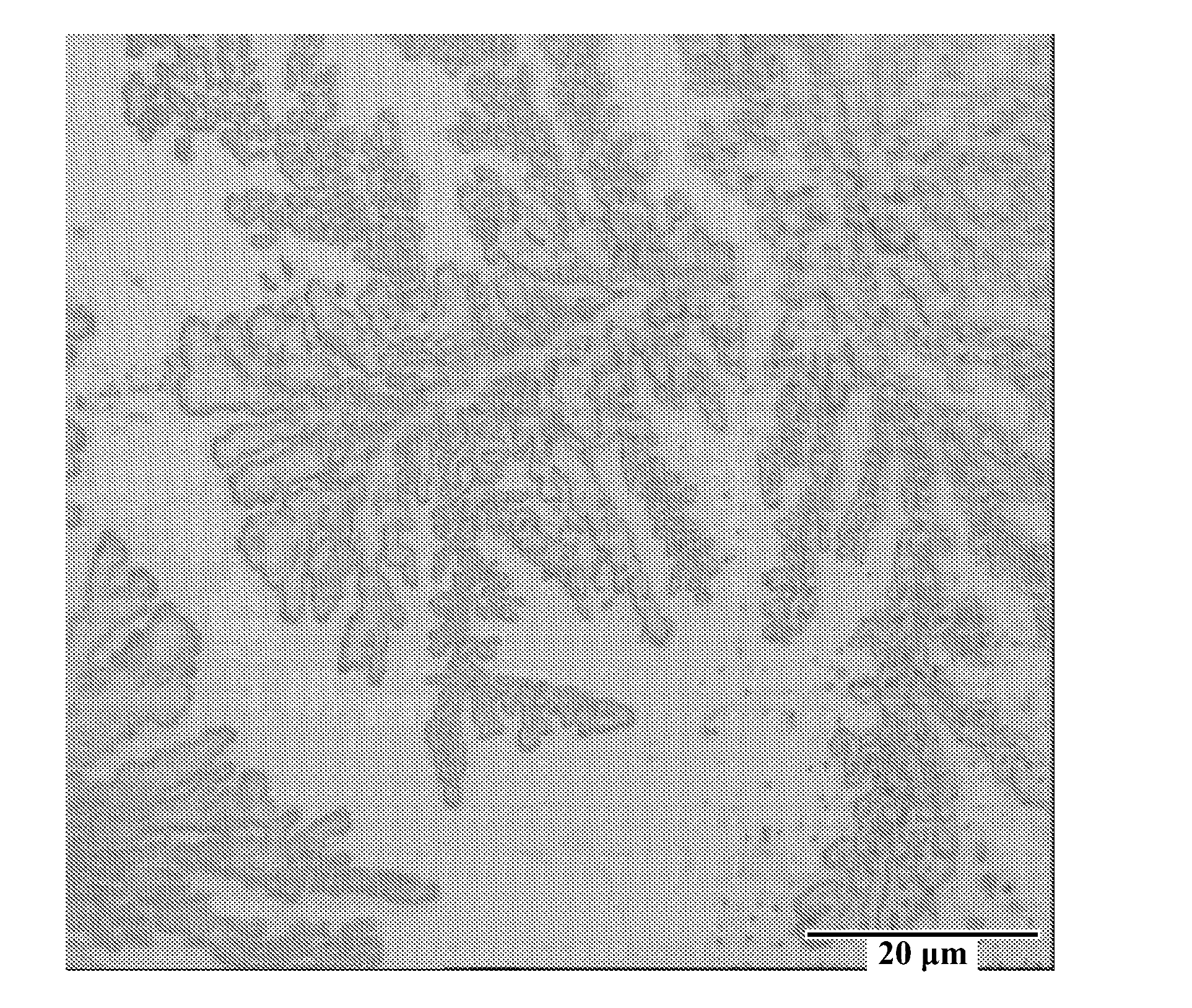

Preparation method of Ni-SiC compound coating on surface of aluminum alloy and electroplating solution thereof

ActiveCN105506526AImprove bindingHigh hardnessHot-dipping/immersion processesElectrolytic coatingsHardnessAmmonium bromide

The invention discloses a preparation method of a Ni-SiC compound coating on the surface of an aluminum alloy. The preparation method adopts an anode type surfactant which is hexadecyl trimethyl ammonium bromide for replacing a cathode type surfactant which is lauryl sodium sulfate adopted by the invention at present. The preparation method is characterized by increasing the concentration of an anode activator NiCl2 while reducing current density and the concentration of silicon carbide in a plating solution, obtaining a fine and dense compound coating at an electroplating rate of 1-2 micron per minute, stirring by using air with volume flow being 4-7L / min and fully dispersing the silicon carbide, simultaneously adding CTAB to improve the wettability of the silicon carbide and obtain a fine and dense compound coating with high content of uniformly-dispersed silicon carbide. Through the preparation method of the Ni-SiC compound coating on the surface of the aluminum alloy, the technical problem of low tensile performance and low abrasion resistance of the aluminum alloy can be solved; the Ni-SiC compound coating with high adhesion strength, high content of uniformly-distributed hard silicon carbide particles, high hardness and high abrasion resistance can be prepared on the surface of the aluminum alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

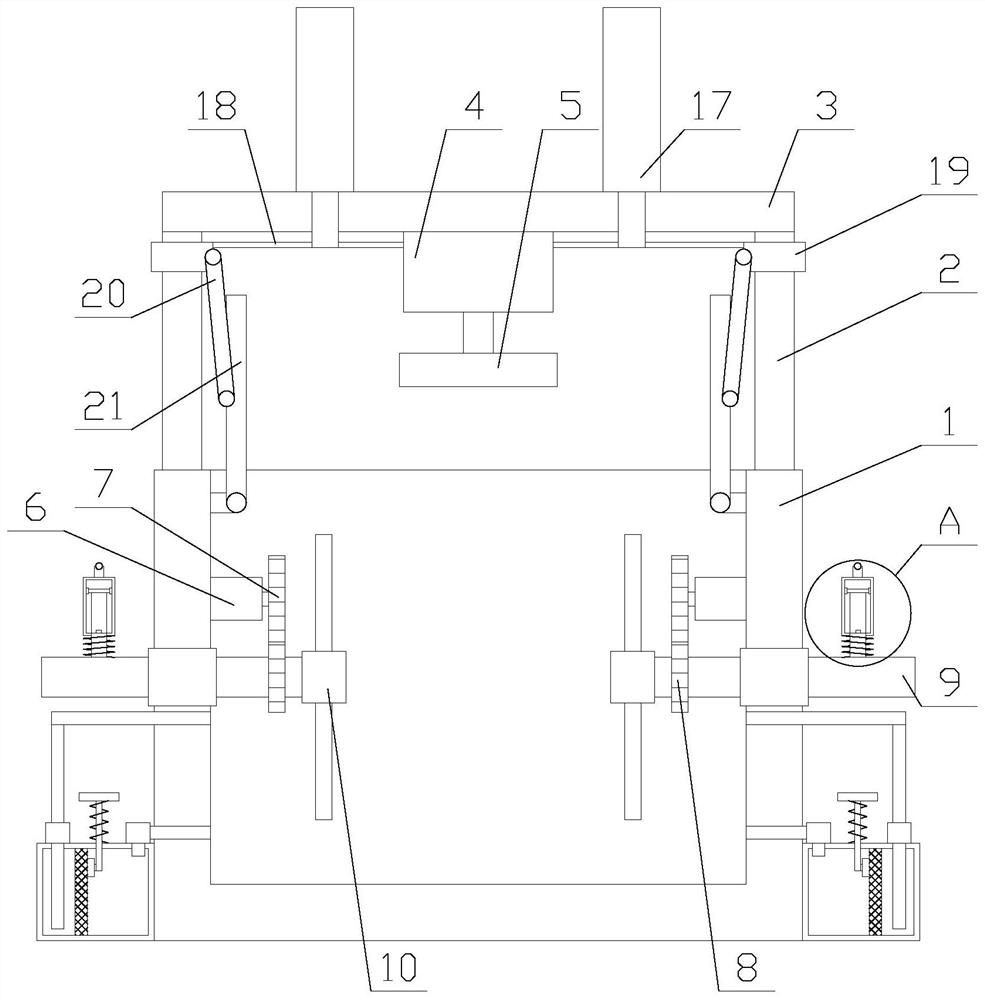

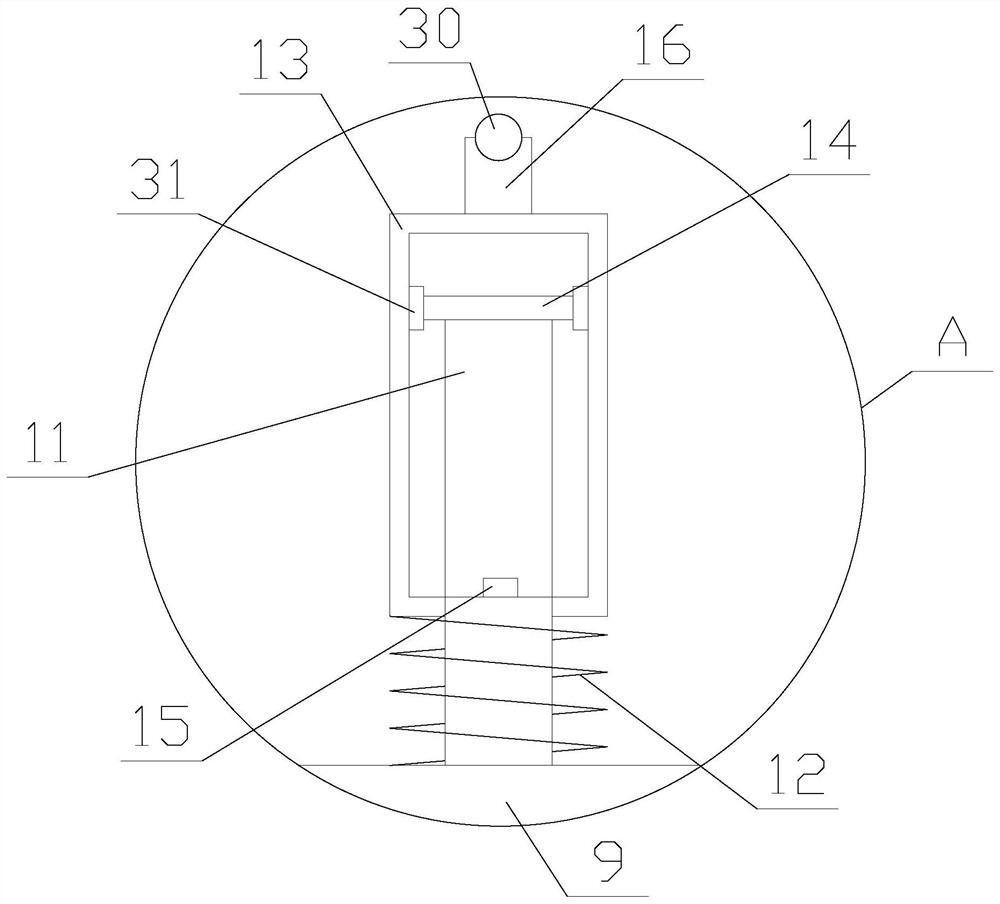

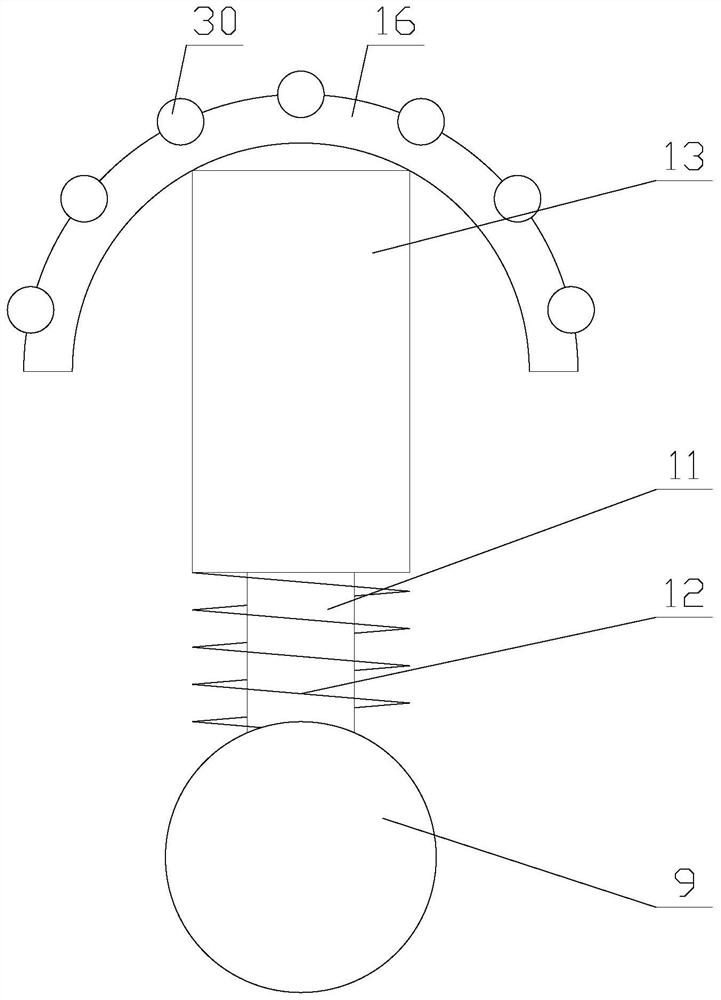

Method for ultrasonic electroplating of diamond drilling bit

The invention discloses a plating method of diamond driller through ultrasound, which is characterized by the following: exerting ultrasound in the plating course; adopting putting vibrating exchanger with bottom vibration pattern, lateral vibrating pattern and top vibrating pattern; setting the frequency scale of ultrasound at 20-50KHz and unit power factor scale at 0.5-2W / cm2; adopting the following plating liquid with 220-300g / l nickel sulfate, 15-25g / l cobalt sulfate, 30-40g / l boracic acid and 15-20g / l sodium chloride, wherein the temperature of plating liquid is 30-45 Deg C with pH value at 3.8-4.8 and current density at 4-10A / dm2.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Tin plating electrolyte

The invention discloses tin plating electrolyte. The tin plating electrolyte comprises the following components 60 to 90g / L of tin methane sulfonate, 10 to 30g / L of tin sulfate, 110 to 140mg / L of p-cresolsulphonic acid, 60 to 120mg / L of sulfosalicylic acid, 30 to 50g / L of phosphinic acid, 45 to 70mg / L of 2,2-PySSPy, 15 to 25mg / L of 8-hydroxyquinoline, 20 to 30mg / L of catechins, 10 to 15g / L of 2,2-dihydroxy diethyl sulfide, 5 to 10mg / L of hexadecylpyridinium bromide, 8 to 12 g / L of dodecyl-phenol polyoxyethylene ether, 5 to 10g / L of ethylene glycol, 4 to 8g / L of benzalacetophenone, 5 to 10g / L of sodium hexametaphosphate, 4 to 8g / L of sodium dodecyl sulfate, and the balance of deionized water. According to the tin plating electrolyte, Sn2<+> can be effectively restrained to convert into Sn4 <+> in an electrolytic process by improving an electrolyte formula, and the stability of plating solution is improved; and meanwhile, the throwing power of the electrolyte is increased, and the luminance, the corrosion resistance and the welding performance of tin coatings are improved.

Owner:郎溪县金科金属有限公司

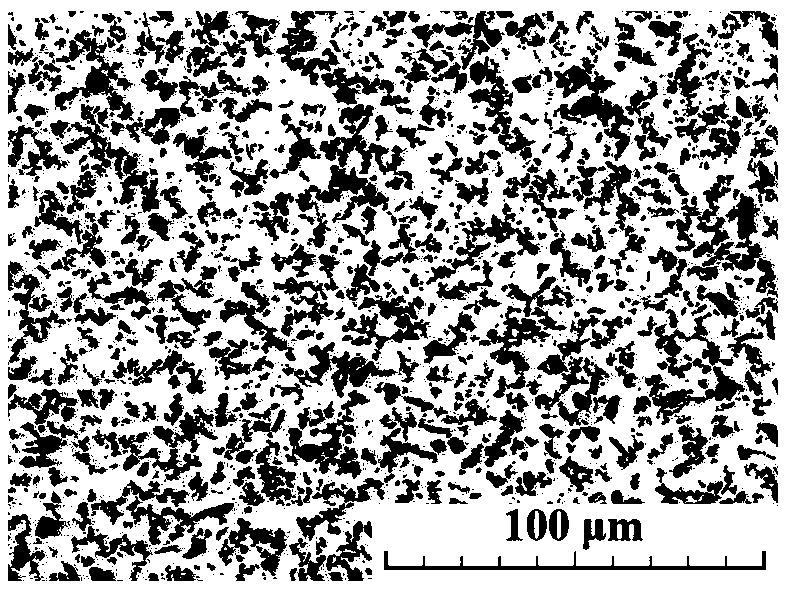

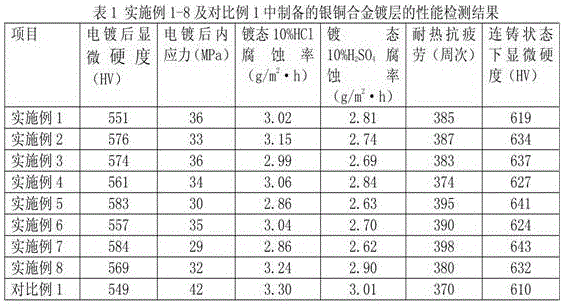

Repairing method of scrapped continuous casting crystallizer copper plate

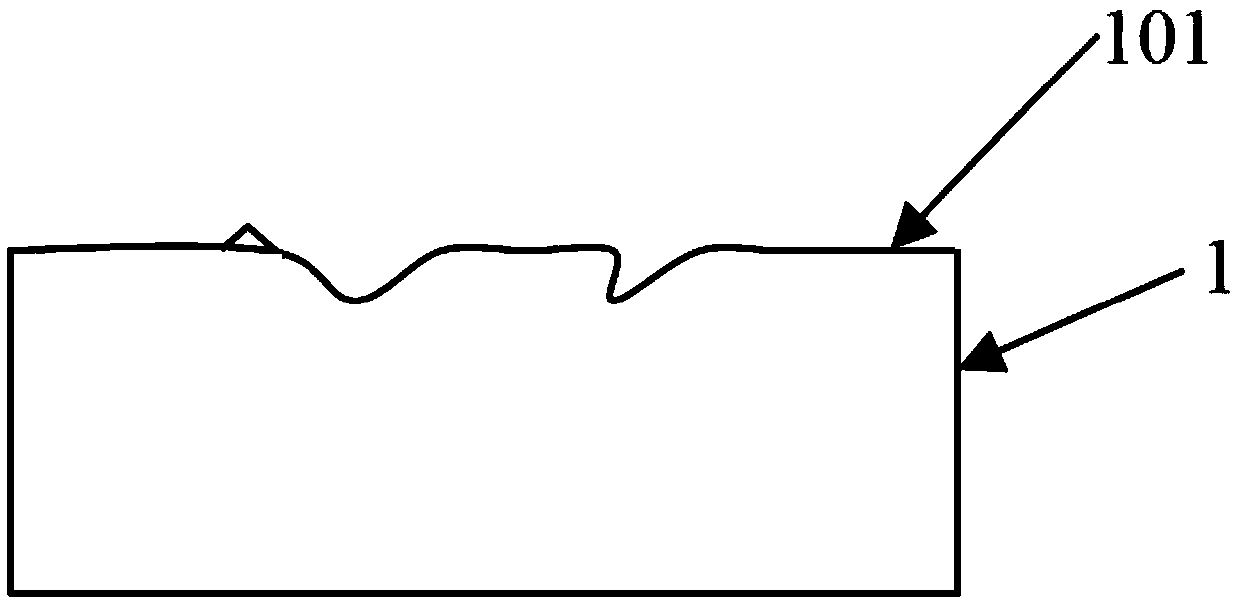

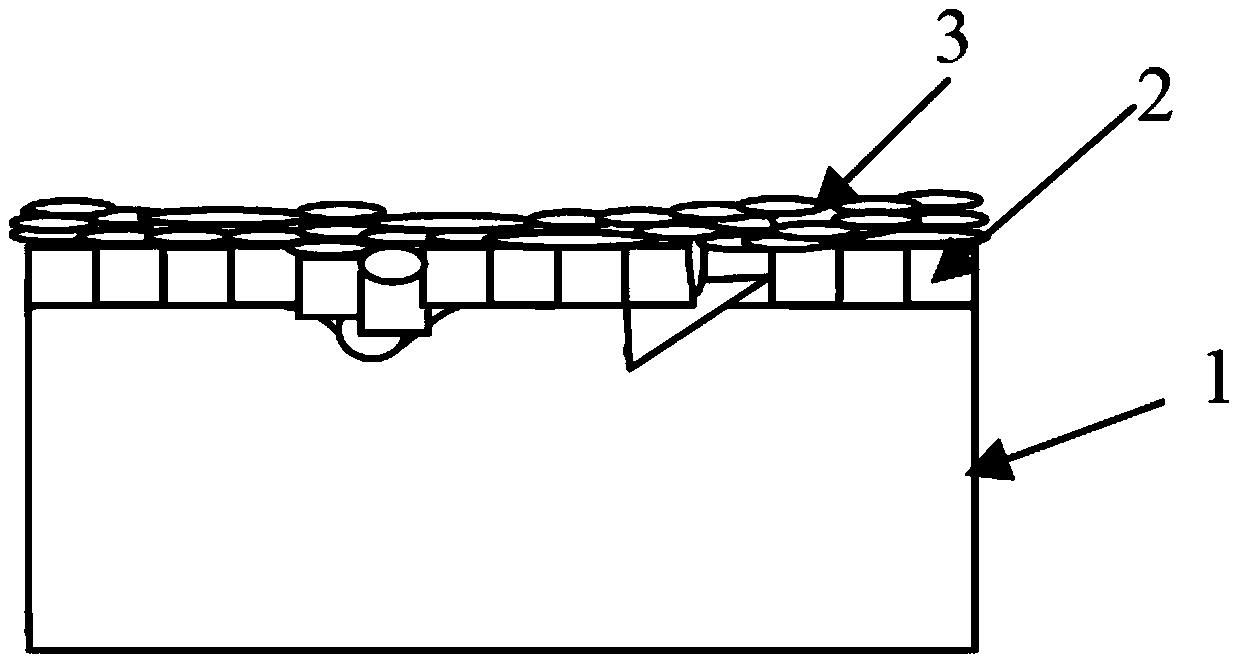

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Gold plating solution

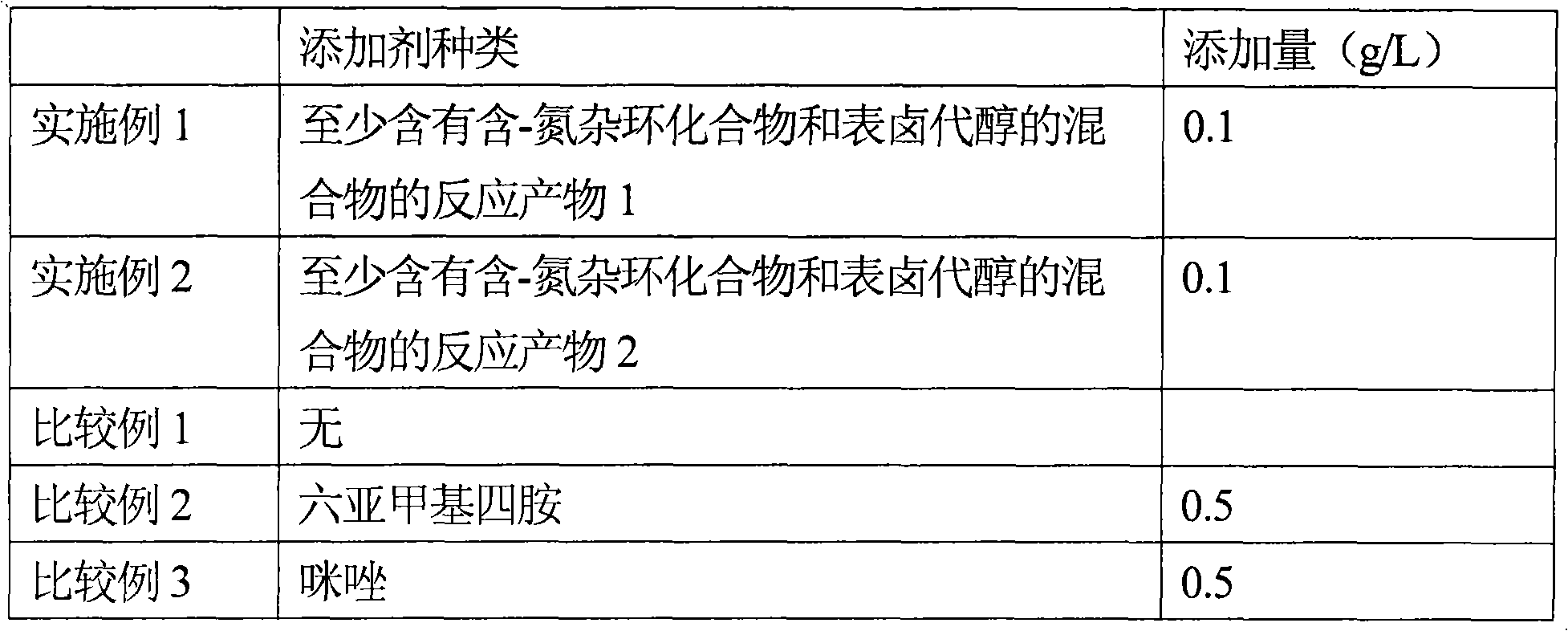

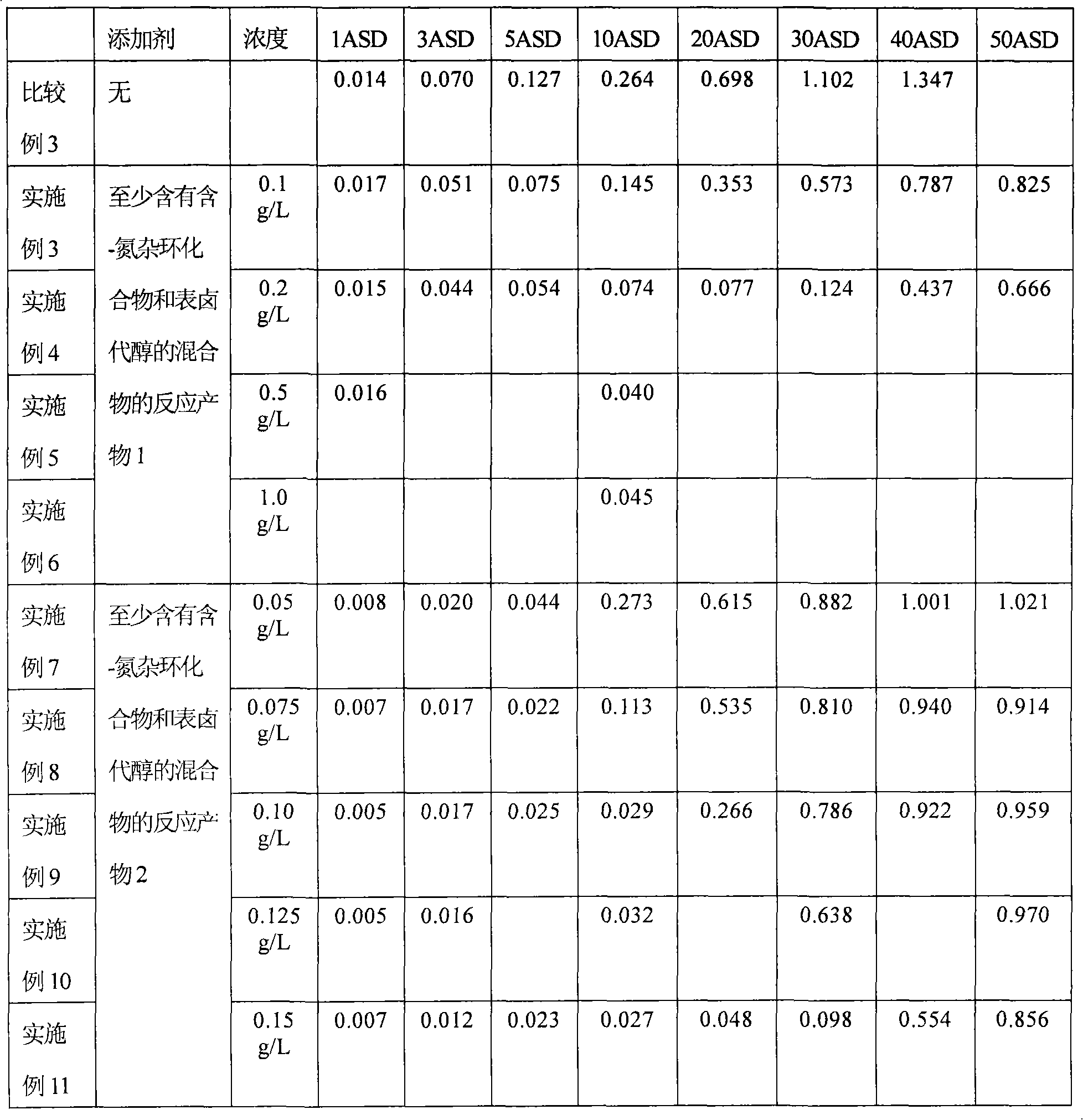

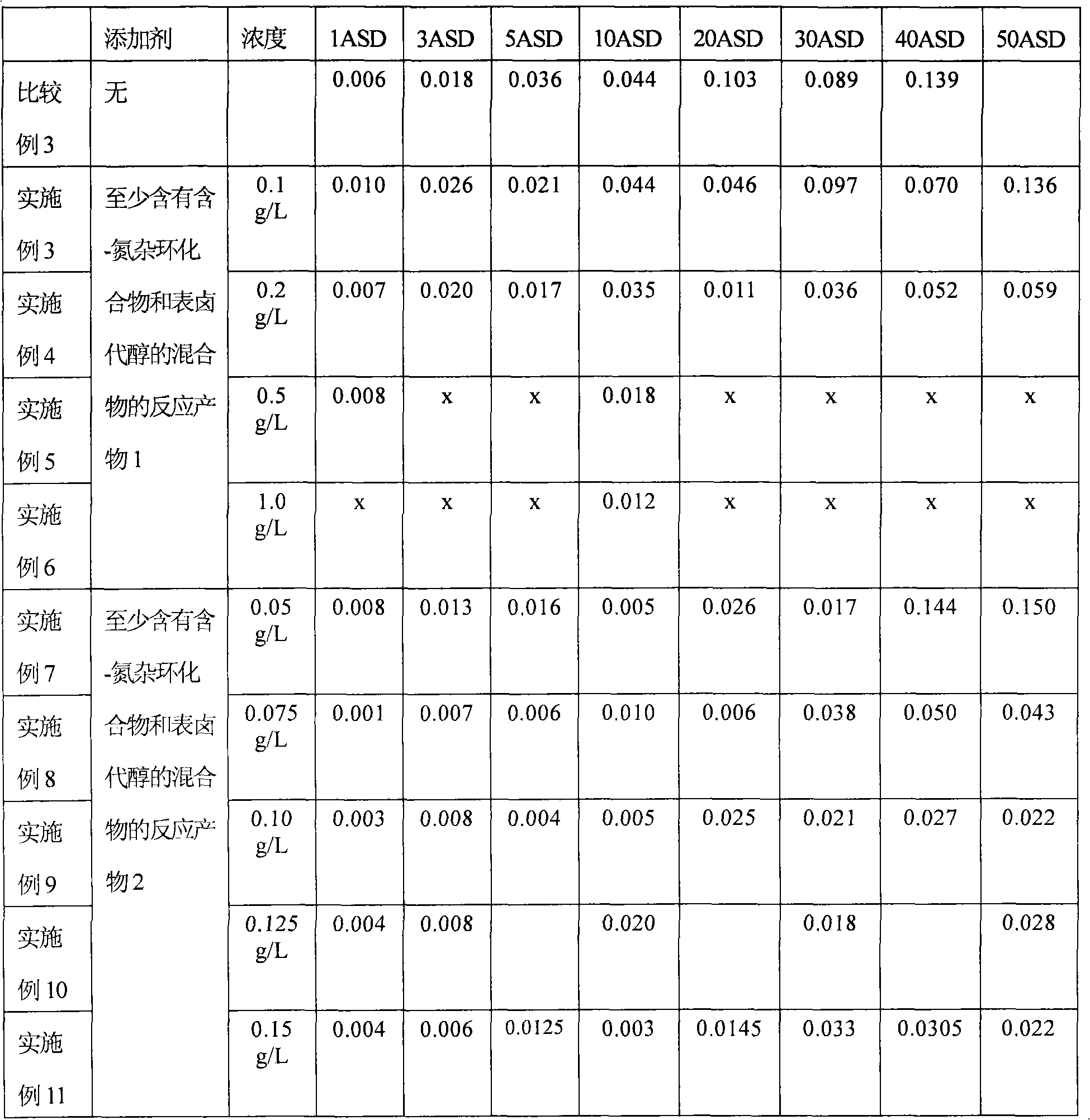

A gold plating bath and a plating method is disclosed where gold cyanide or salts thereof provide the source of gold, a cobalt compound, and a reaction product of compound containing at least a nitrogen-containing heterocyclic compound and an epihalohydrin. The gold plating bath has high deposition selectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Method for plating double-layer zinc on surface of neodymium-iron-boron permanent magnet material

InactiveCN110791787AHigh porosityStrong dispersion abilityJewelleryCorrosion resistantNeodymium iron boron

The invention discloses a method for plating double-layer zinc on the surface of a neodymium-iron-boron permanent magnet material, and belongs to the field of surface treatment of sintered neodymium-iron-boron permanent magnet materials. The method is characterized in that the method comprises the following steps: (1) deoiling the neodymium-iron-boron permanent magnet material; (2) cleaning the deoiled neodymium-iron-boron permanent magnet material, and then pickling the neodymium-iron-boron permanent magnet material; (3) activating the acid-washed neodymium-iron-boron permanent magnet material; (4) performing sulfate zinc electroplating on the neodymium-iron-boron permanent magnet material to form a bottom zinc layer; (5) performing potassium salt zinc plating on the neodymium-iron-boronpermanent magnet material to form a surface zinc layer; and (6) passivating the surface of the galvanized neodymium-iron-boron permanent magnet material. The neodymium, iron and boron treated by the method for plating the double-layer zinc on the surface of the neodymium-iron-boron permanent magnet material are excellent in corrosion resistance, the salt spray resistance experiment after passivation can reach more than 120 hours, the bonding strength of a galvanized layer and the neodymium-iron-boron permanent magnet material is improved, and the corrosion resistance of the galvanized layer isalso improved.

Owner:ARCFL TECHNOLOGY LIMITED

Production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products

InactiveCN102534741AImprove surface qualityFast Galvanizing EfficiencyCellsLiquid surface applicatorsElectrogalvanizationPower flow

The invention relates to a production process for rapidly achieving galvanization and polyvinyl fluoride (PVF) paint coating of tubular products, which belongs to the technical field of metal plating coating processes. The production process for rapidly achieving the galvanization and the PVF paint coating of the tubular products enables a plurality of tubes to move parallelly, achieves process integration of galvanization PVF paint coating, achieves high-speed electrogalvanization and PVF coating surface processing, and simultaneously meets organic combination of trivalent chromium galvanization passivation and trivalent chromium PVF paint with the speed as high as 20m / min. Surface quality of produced tubular products is excellent, galvanization efficiency is high, yield is improved, and production cost is reduced. Key technical problems that an existing electroplating device has poor environment protection, tightness and product operation stability, large current can generate heat during electroplating, and the like are solved. When the process is utilized, tubes do not generate electric sparks during continuous galvanization operation, the plating is free of burns and rough black phenomena. Besides, due to large current density, high galvanization efficiency and fast electroplating speed in galvanization, the production purposes of high efficiency and low cost are achieved.

Owner:COOPER STANDARD JINGDA JINGZHOU AUTOMOBILE FITTINGS

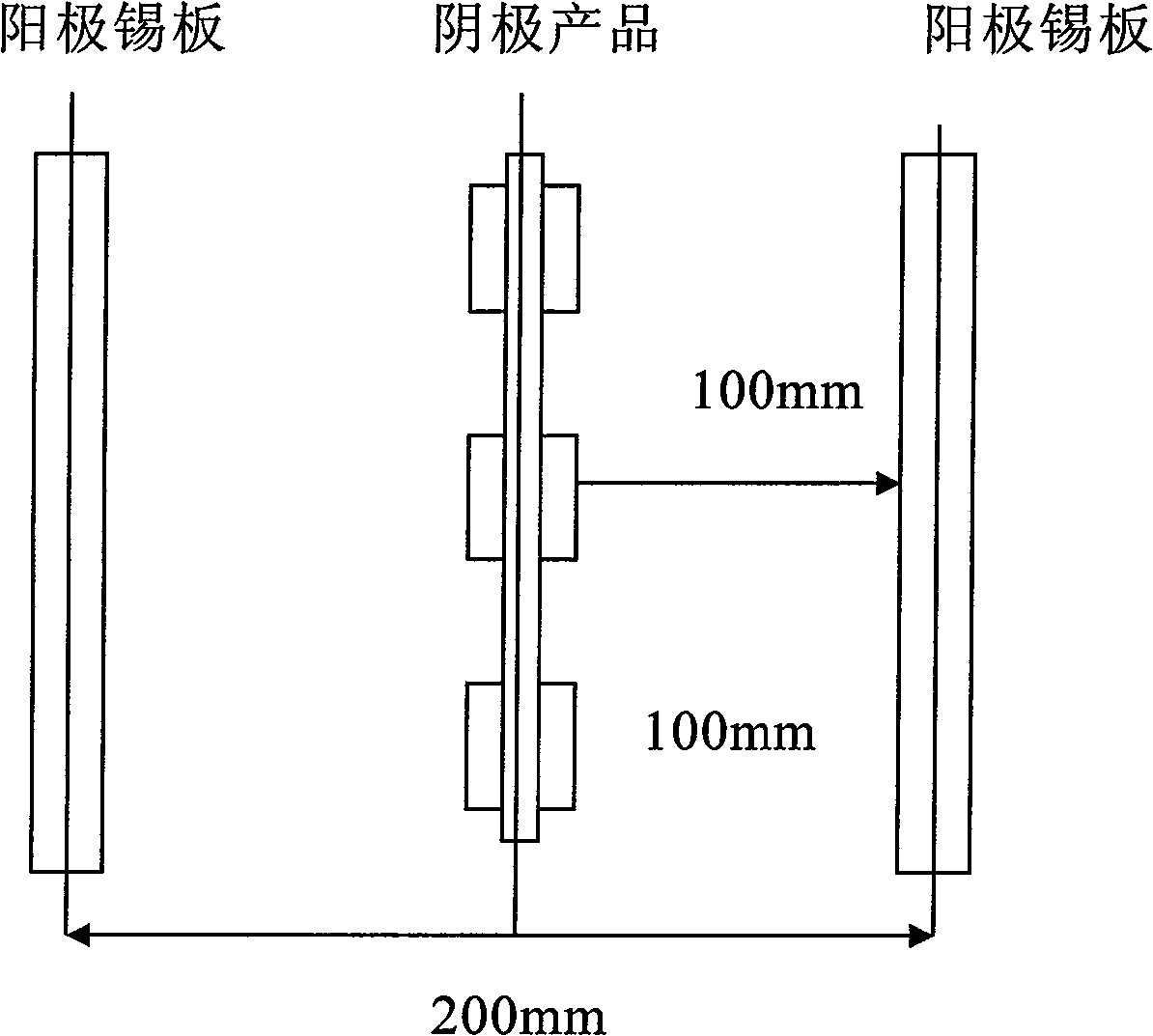

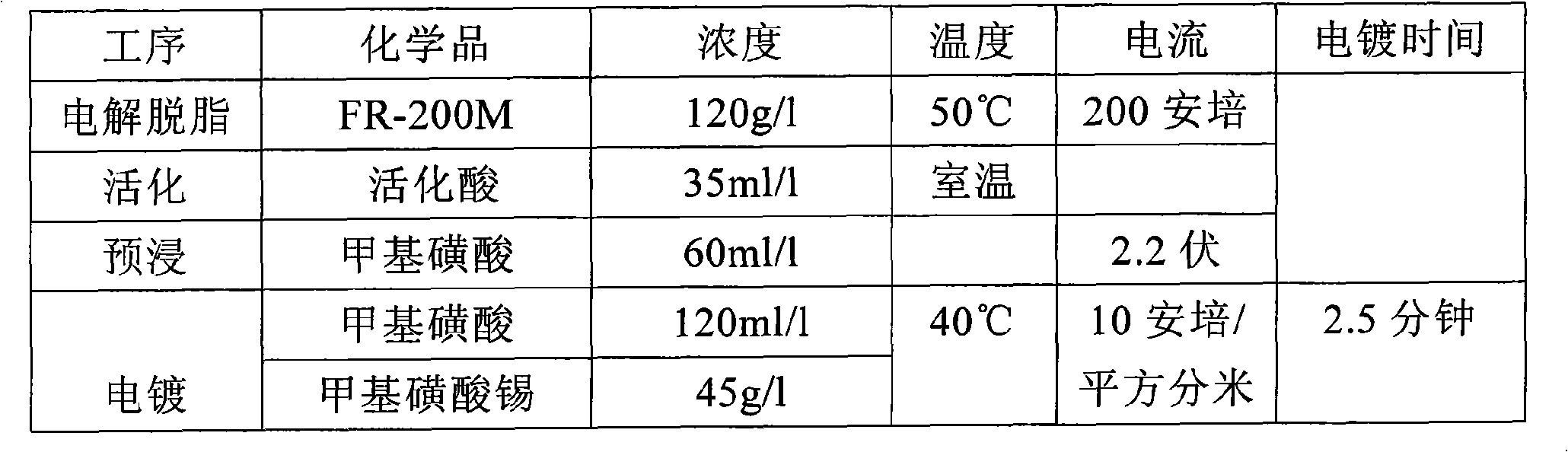

Method for electroplating metals of tin and bismuth

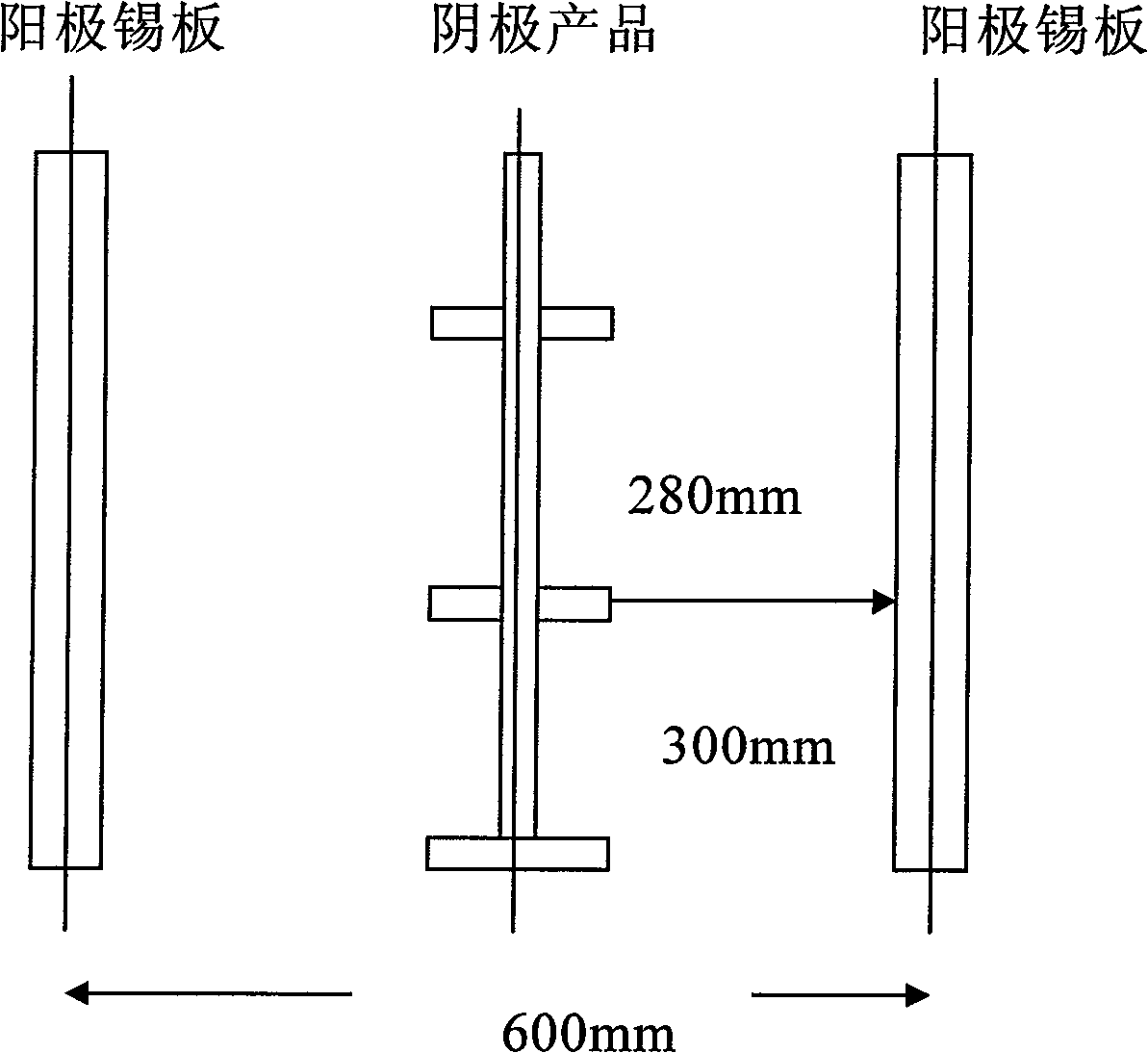

InactiveCN101538726AUniform thicknessEvenly distributed ingredientsSquare decimeterMethane sulfonate

The invention relates to a method for electroplating metals of tin and bismuth, which is characterized by comprising 40-80g / l of tin methane-sulfonate and 1-3g / l of bismuth methane-sulfonate in terms of volume mass ratio, and also comprising 100-280ml / l of methylsulfonic acid, 30-100ml / l of additive SNB31 produced by Dr. Ing Max Schlotter GmbH & Co. KG, 5-15ml / l of additive SNB14 produced by Dr. Ing Max Schlotter GmbH & Co. KG, and the balanced water in terms of volume ratio; and the electroplate liquid is used for electroplating for 1.5-2.5min with a current density of 10-20 ampere / square decimeter and at a temperature of 35-65 DEG C. The cathode plate of the plating tank containing the electroplate liquid is a conveying steel belt, and the distances between an electroplating part and two anode plates are the same. The tin and bismuth metal layers electroplated by the invention have uniform thickness and even distribution of bismuth, and tin and bismuth metal layers have good weldability.

Owner:WUXI WELNEW MICRO ELECTRONICS

Cyanide-free high-speed silver plating electroplating solution

The invention relates to the technical field of electrochemical silver plating, in particular to a cyanide-free high-speed silver plating electroplating solution, which solves the problem that the existing silver plating electroplating solution has high toxicity or low productivity and provides a cyanide-free high-speed silver plating electroplating solution. The electroplating solution comprises the following components in mass concentration: 40-60g / L of silver nitrate, 100-300g / L of sodium thiosulfate, 45-85g / L of sodium metabisulfite, 8-22g / L of sodium sulfate, 15-38g / L of boric acid and 0-2.5mg / L of brightener. The invention has low toxicity and high plating speed.

Owner:NINGBO SHUNJIA COMM TECH CO LTD

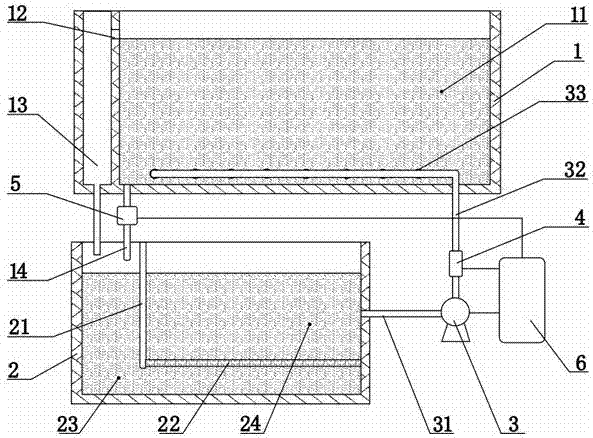

Electroplating solution circulating filtration device used in electroplating technology

The invention discloses an electroplating solution circulation filtering device used in electroplating process, which comprises an electroplating tank, an electroplating solution filtering tank and a circulation system. tube; the electroplating solution filter tank is located below the electroplating solution discharge pipe, and a vertical partition and a horizontal filter plate are arranged on the electroplating solution filter tank; the circulation system includes a liquid inlet pipe, a suction pump and Liquid outlet pipe, the inlet of the liquid inlet pipe is located on the side wall of the post-filtration area in the electroplating solution filter tank, and the liquid outlet pipe extends into the electroplating tank. In the electroplating solution circulating filter device of the present invention, since the electroplating solution in the electroplating tank and the electroplating solution filter tank is filtered through the filter plate and then returns to the electroplating tank through the circulation system, a cyclic agitation is formed around the workpiece to be plated in the electroplating tank, thereby reducing the loss of the electroplating solution. Concentration polarization increases the upper limit of allowable cathode current density, effectively preventing solid particles from adhering to the workpiece to be plated and forming pinhole-like plating defects.

Owner:CHONGQING CITY YONGCHUAN DISTRICT CONTACTS MACHINE MFG CO LTD

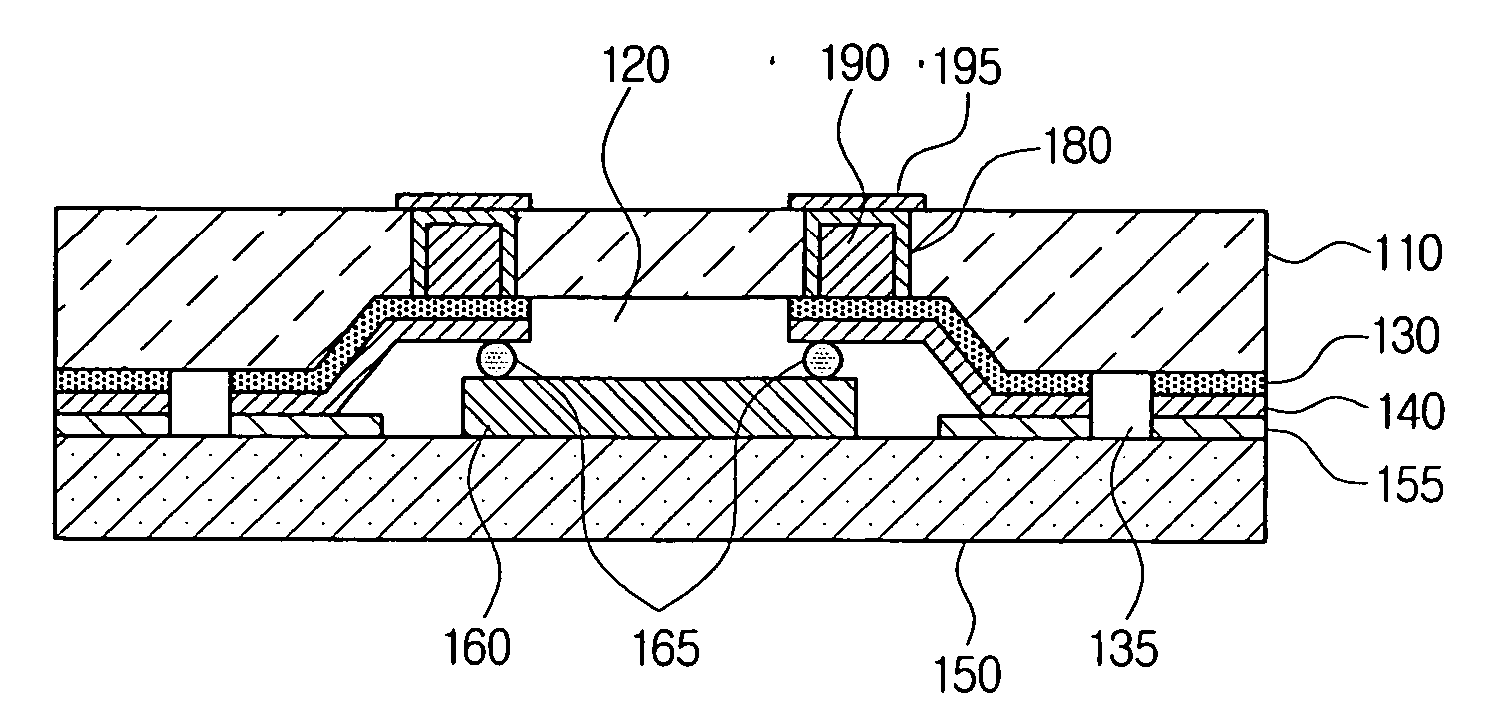

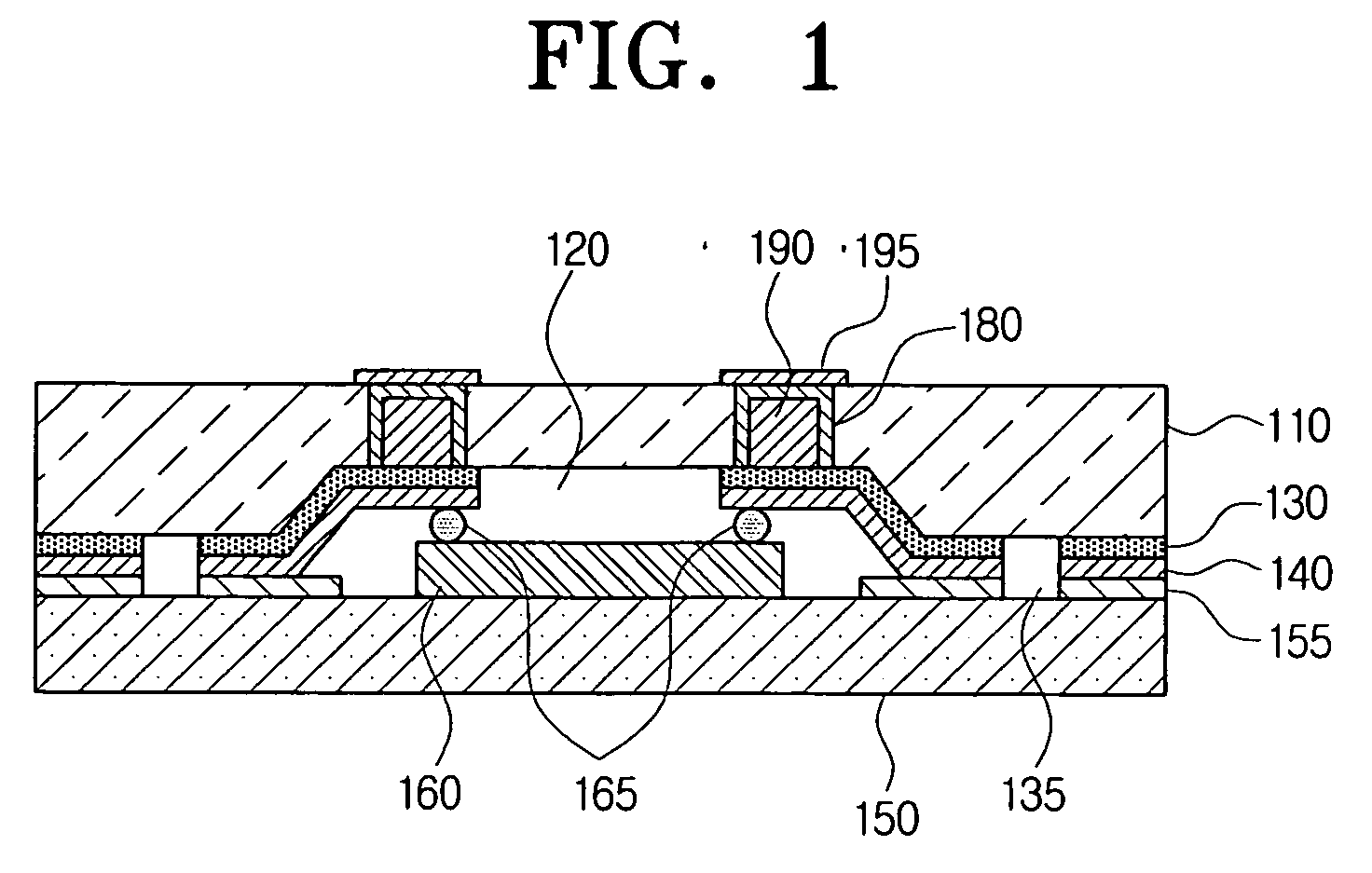

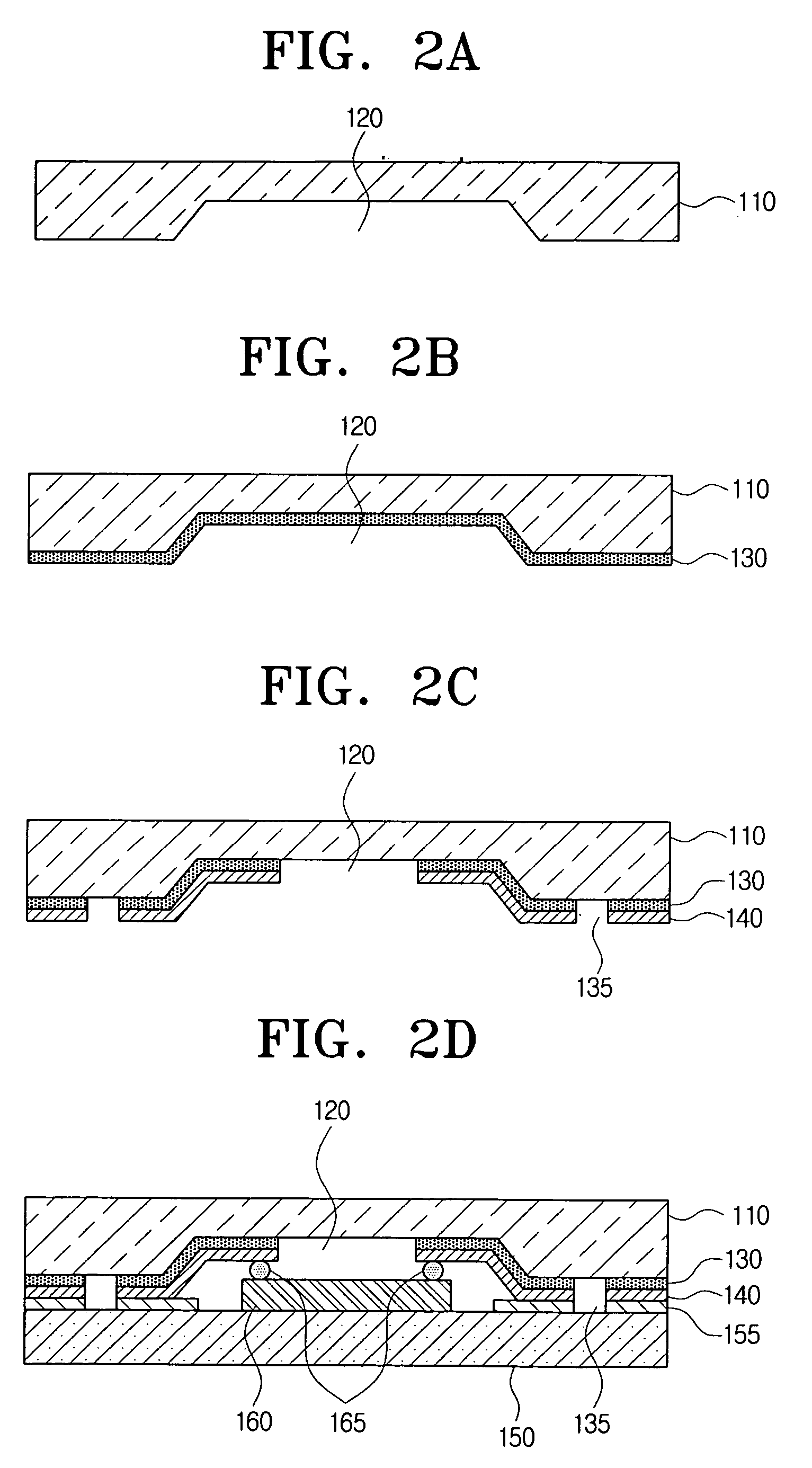

Packaging chip and packaging method thereof

InactiveUS20060273444A1Fast plating speedShorten packing timeSemiconductor/solid-state device detailsSolid-state devicesEngineeringAdemetionine

A packaging chip in which a circuit module is packaged and a method of packaging a circuit module are provided. The packaging chip includes a base wafer; a circuit module on the base wafer; a packaging wafer having a cavity and combined with the base wafer so that the circuit module fits inside the cavity; a connecting electrode connecting upper and lower surfaces of the cavity; and a seed layer between the connecting electrode and the packaging wafer. The method includes etching a lower surface of the packaging wafer to form a cavity, stacking a metal layer in an area of the lower surface, combining the base wafer with the packaging wafer, polishing the packaging wafer, forming a viahole through the packaging wafer, stacking a seed layer on the packaging wafer, plating the inside of the viahole, removing the seed layer and forming an electrode.

Owner:SAMSUNG ELECTRONICS CO LTD +1

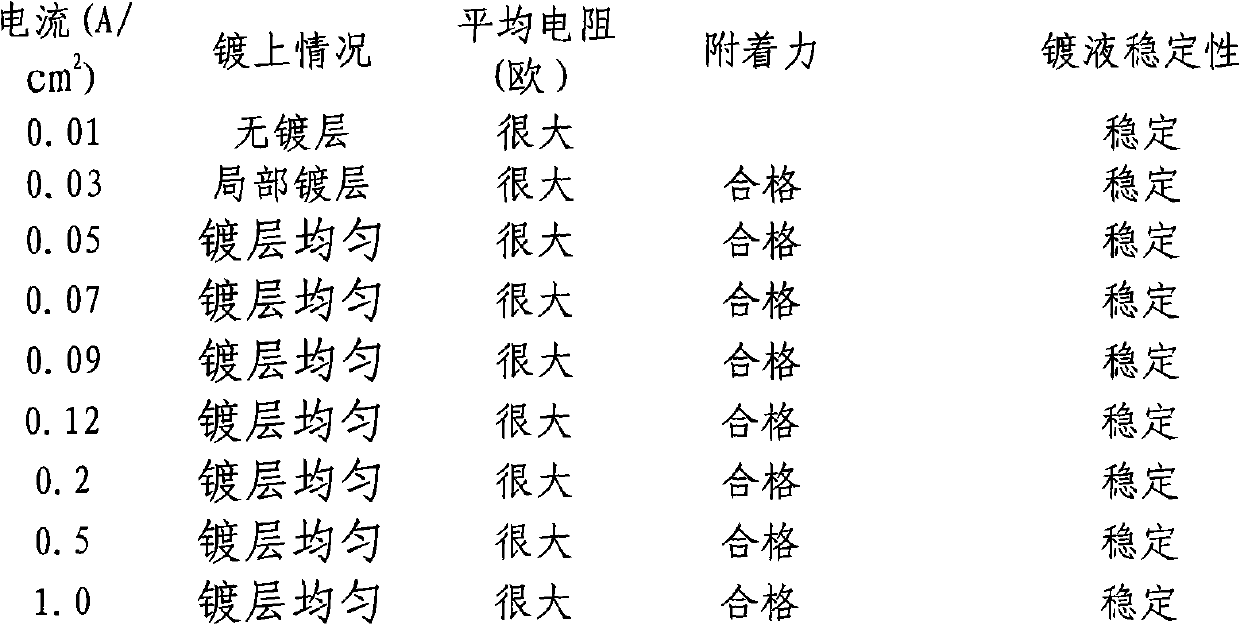

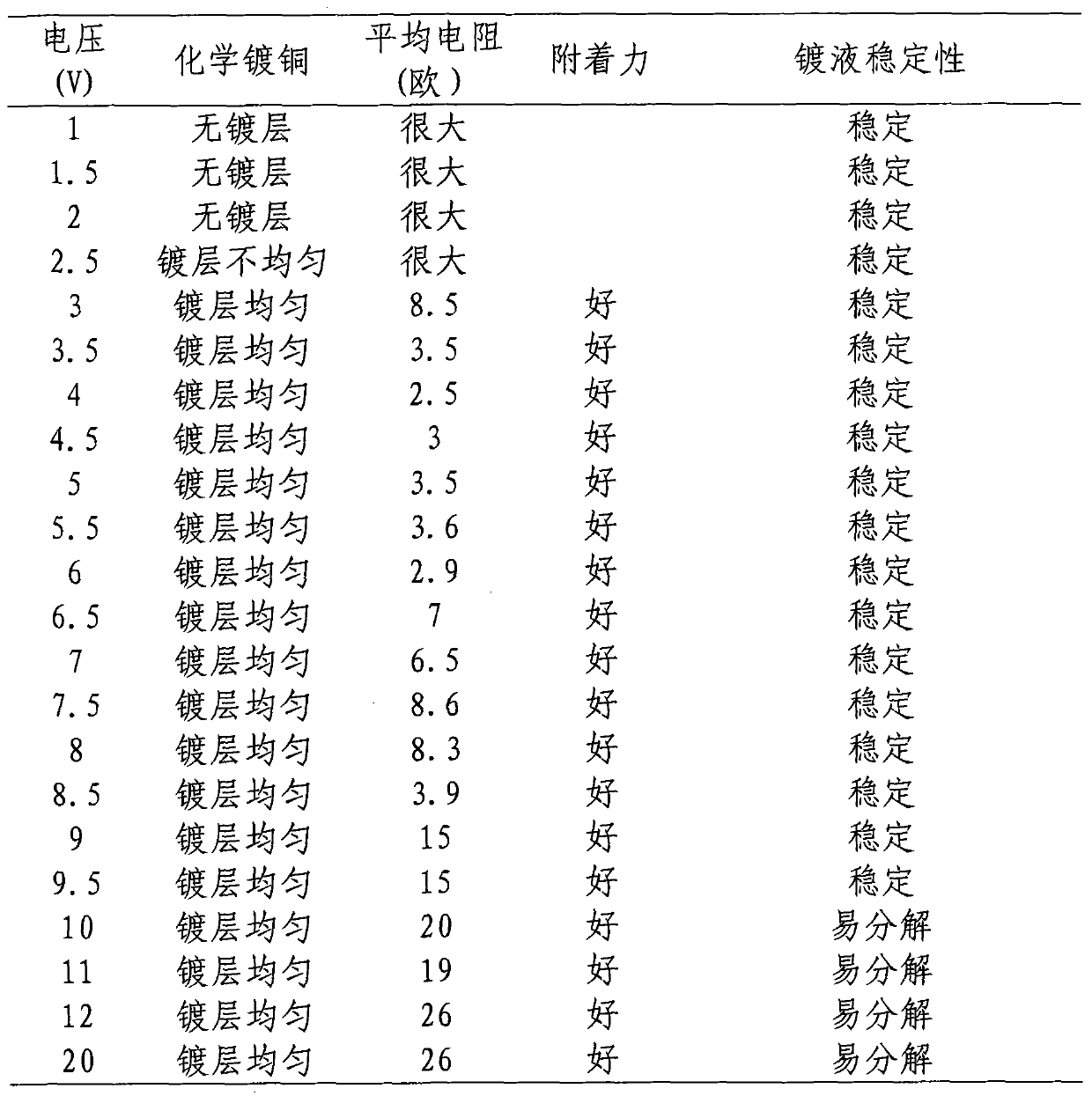

Method for manufacturing printed circuit board by power triggering electroless plating addition process

ActiveCN101922001ANo activation requiredReduce stepsLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectricityPrinted circuit board

The invention discloses a method for manufacturing a printed circuit board by a power triggering electroless plating addition process. The method comprises the following the steps: forming circuit patterns made of conducting materials on a non-conducting substrate in various printing modes; soaking the prepared circuit patterns in an electroless plating solution; placing two electrodes in the electroless plating solution, connecting the inertia positive electrode with the positive electrode of a DC constant-voltage or constant-current power source, and connecting the negative electrode with the negative electrode of the DC constant-voltage or constant-current power source; powering on after setting the voltage or current, utilizing the circuit patterns printed by contact of the negative electrode to trigger the electroless plating process, and depositing metal on the circuit patterns; and after carrying out electroless plating for 30 minutes, taking out the circuit patterns and cleaning, thus obtaining the metalized circuit patterns. The method of the invention has no need of carrying out activating treatment on the printed circuit patterns, less operating steps, less control process parameters, easy operation, high plating speed and even plating.

Owner:GUANGDONG UNIV OF TECH +1

Electroplating equipment with impurity removal function

The invention relates to electroplating equipment with an impurity removal function. The electroplating equipment comprises a main body, a supporting plate, a lifting device, a lifting plate and two supporting columns, and further comprises a stirring mechanism and two impurity removal mechanisms; the stirring mechanism comprises a protection assembly and two stirring assemblies, and each stirringassembly comprises a first bearing, a rotating shaft, a paddle, a driving unit and a control unit; the protection assembly comprises a connecting ring, two protection units and two air cylinders; each impurity removal mechanism comprises an impurity removal box, a filter screen, a water pumping assembly, a circulating assembly and an impurity removal assembly; and each impurity removal assembly comprises an abutting plate, a second spring, a connecting rod and a scraper blade. According to the electroplating equipment with the impurity removal function, the stirring mechanism can be used forstirring liquid zinc inside the main body, and flow of the liquid zinc is accelerated, so that the galvanizing quality is guaranteed, meanwhile, the electroplating speed can be increased, the electroplating time is shortened, and the working efficiency is improved; and through the impurity removal mechanisms, the function of removing impurities from the liquid zinc is achieved, and reduction of the galvanizing quality due to the excessive impurity content in the liquid zinc is avoided.

Owner:广州市欧伊若科技有限公司

Cyanide-free electroplating baths for white bronze based on copper (i) ions

Copper alloy electroplating baths include one or more sources of copper (I) ions and one or more sources of tin ions to electroplate copper / tin alloys of mirror bright white bronze. The copper alloys may also include one or more sources of silver ions to electroplate ternary alloys of bright white bronze containing copper / tin / silver. The copper alloy electroplating baths are cyanide-free.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Preparation process of acid-base compound Magni coating

InactiveCN105506688AReduce production line operating costsUniform coatingChloride potassiumPre treatment

The invention discloses a preparation process of an acid-base compound Magni coating and relates to a metal surface antiseptic treatment process. The preparation process comprises the procedure of pretreatment conducted before coating, preparation of the coating and treatment conducted after coating, wherein the procedure of preparation of the coating comprises the steps of firstly, conducting potassium chloride galvanization on the surface of a workpiece, and then conducting zincate galvanization, wherein the steps of 21, potassium chloride galvanization, 22, washing III, 23, zincate galvanization, 24, washing IV, 25, film removal and 26, washing V are included; the procedure of treatment conducted after coating comprises the steps of 31, ultralow chromium passivation, 32, washing VI and 33, drying. According to the preparation process of the acid-base compound Magni coating, the potassium chloride galvanization process and the zincate galvanization process are combined together, product quality can be well stabilized, production efficiency is greatly improved, production line operation cost is lowered, the coating on the surface of a product prepared through the preparation process is uniform, surface quality is good, the preparation process has the advantages that the coating speed is high, drying can be conducted easily, product defects are few, the service life of the product is prolonged, the ultralow chromium passivation process is adopted, sewage treatment cost is lowered, and the preparation process is easy to use and popularize.

Owner:GUANGXI LIUZHOU LONGFA METAL SURFACE TREATMENT TECH

A kind of surface electroplating solution and electroplating process for alloy

The invention discloses a surface electroplating solution and an electroplating process for alloys. The electroplating solution consists of the following components: soluble palladium salt, soluble platinum salt, complexing agent, conductive salt, buffer, brightener, stabilizer and Anti-pinhole agent, the balance is solvent, and the solvent is deionized water. The electroplating process is: preparation of electroplating solution; pre-plating treatment includes degreasing, grinding, polishing, activation; electroplating; the electroplating solution has good stability and environmental protection; The platinum-palladium plating layer obtained by electroplating with the electroplating solution of the present invention is uniform and compact, has high hardness, good corrosion resistance, good adhesion with alloy parts substrate, bright plating layer, no peeling and bubbling phenomenon of the plating layer; the electroplating process is simple to operate, The conditions are controllable. By controlling the process parameters in the electroplating process and evenly distributing the electroplating anodes around the cathodes, the composition of the coating layer is controllable, the electroplating efficiency is high, the environment is friendly, and it is suitable for promotion.

Owner:杭州云会五金电镀有限公司

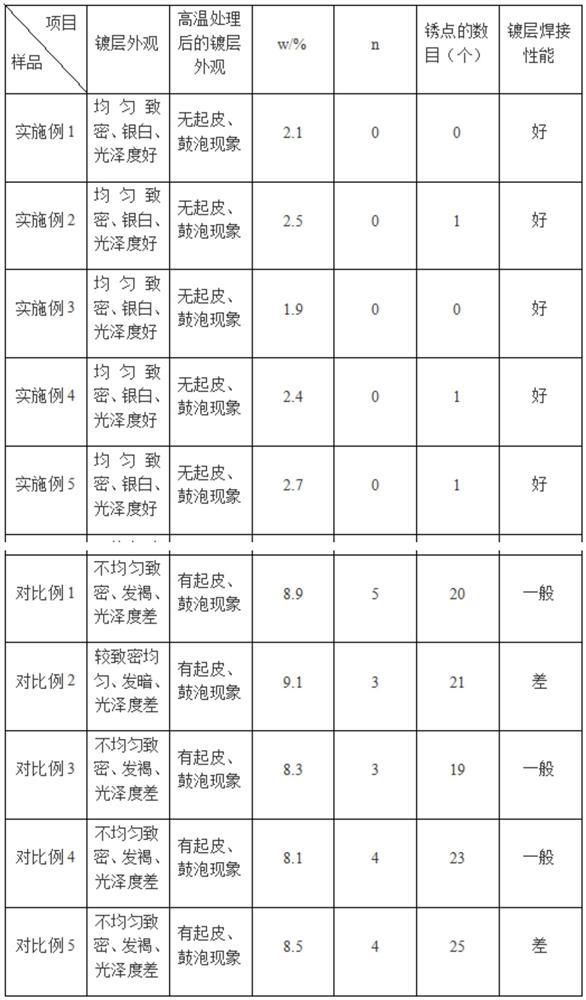

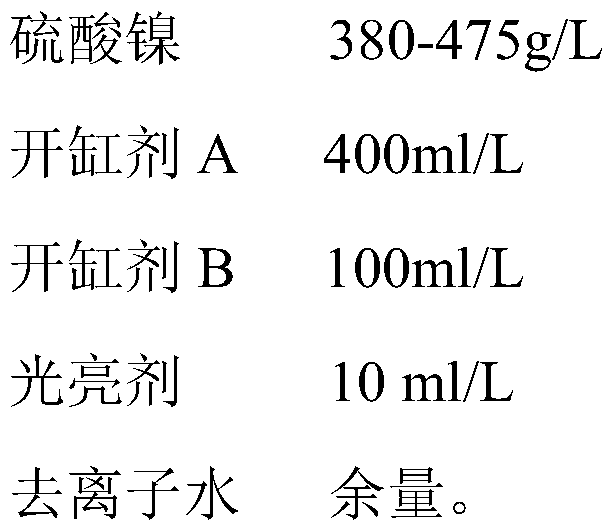

Nickel phosphorus ally electroplating liquid and electroplating process thereof

The invention relates to the field of electroplating, in particular to nickel phosphorus ally electroplating liquid. The nickel phosphorus ally electroplating liquid comprises the following raw materials: 380-475 g / L of nickel sulfate, 400 ml / L of cylinder opening agent A, 100 ml / L of cylinder opening agent B, 10 ml / L of brightening agent, and the balance of de-ionized water. A nickel phosphorus ally electroplating process comprises the steps of bath building, deoiling, acid activation, liquid plating, dehydration and drying; the overall process is stable in operation and high in plated layerstability; the nickel phosphorus ally electroplating liquid contains no chlorine to improve the pH value stability; the hardness of formed plated layers is 550-600 HV 0.05; the wear resisting index is2 mg / 1000 t; the wear resistance is excellent; the brightening agents are used for improving the deep plating capacity and the brightening capacity of the plating liquid; and when shorted, holes anddumb plated layers are generated in low levels, so that the service life is further prolonged.

Owner:东莞市合航精密科技有限公司

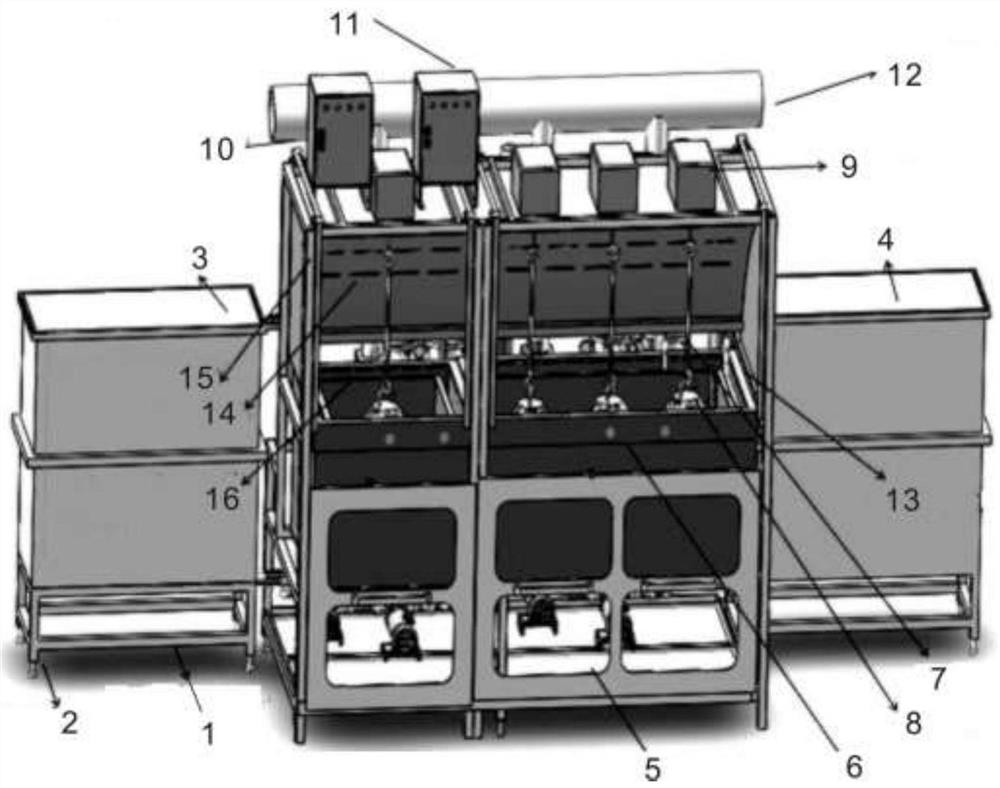

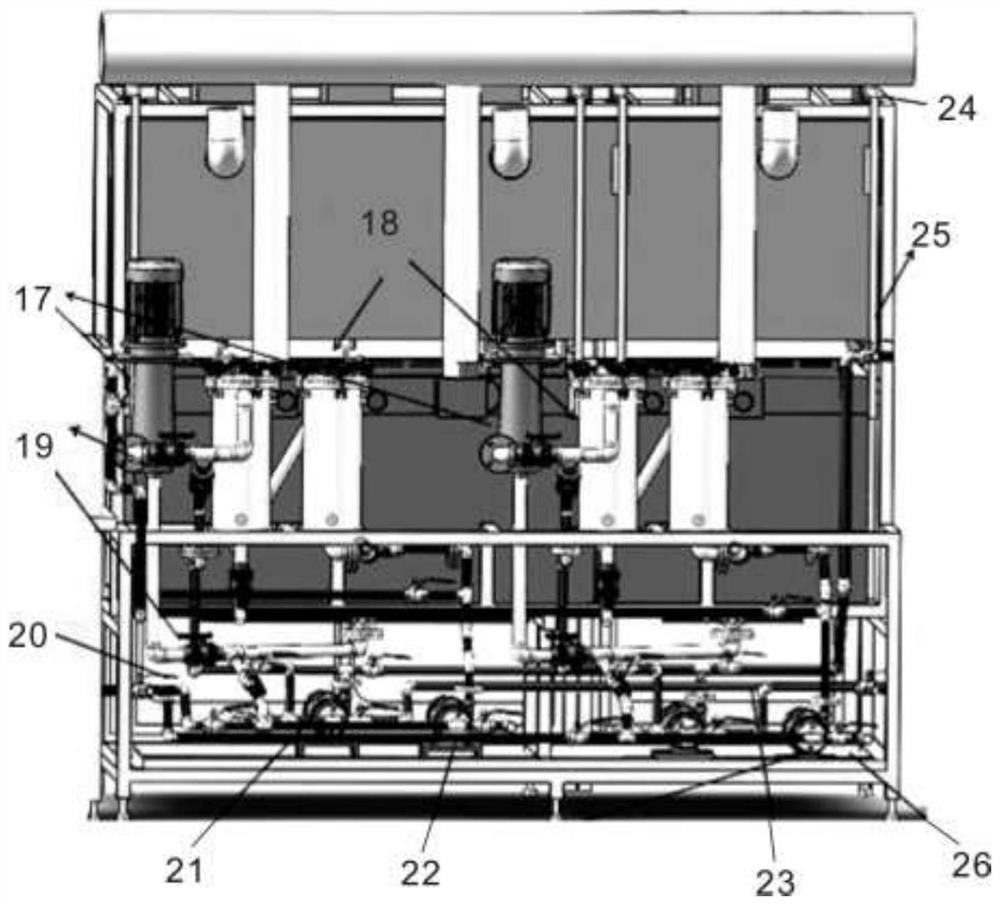

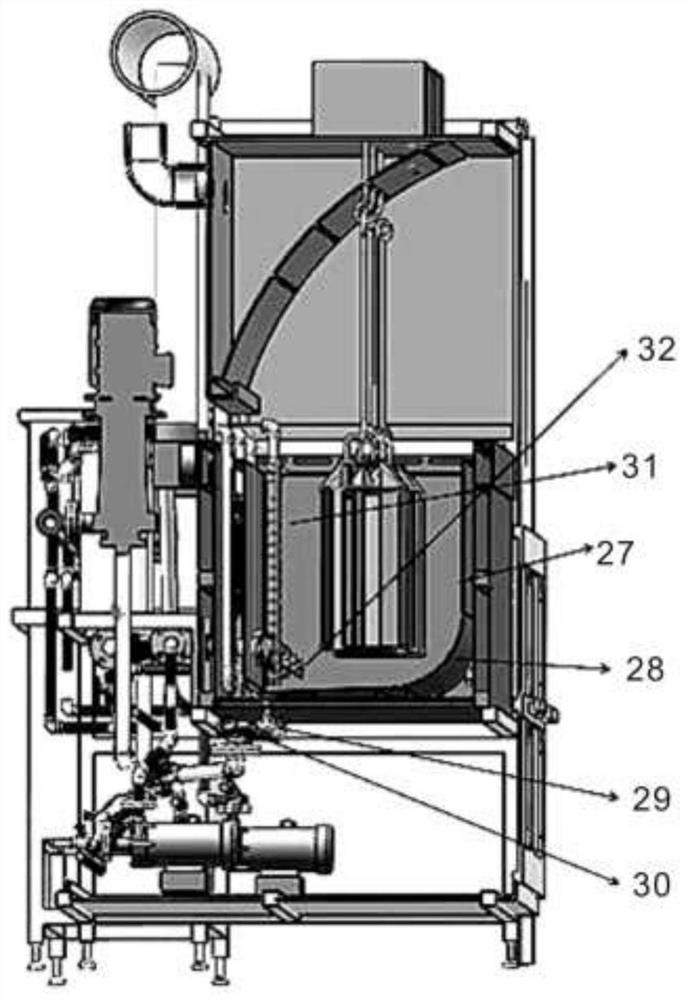

Novel chemical nickel plating equipment

PendingCN114045472AHeating evenlyEasy maintenance and operationLiquid/solution decomposition chemical coatingPolypropyleneChemical plating

The invention provides novel chemical nickel plating equipment. The novel chemical nickel plating equipment comprises an acid and alkali corrosion resistant rack, an acid and alkali corrosion resistant polypropylene waste gas collecting cover, four hanger rotation control systems, an anode protection system and an acid and alkali corrosion resistant stainless steel arc bottom water bath type plating tank. The bottom of the plating tank is provided with a plurality of water outlets which are integrated on a pipe. An acid and alkali corrosion resistant polypropylene chemical nickel solution storage tank, an acid and alkali resistant nitric acid solution storage tank, an acid and alkali resistant high-temperature resistant stainless steel circulating pump, two acid and alkali resistant high-temperature resistant stainless steel filter cartridges, an acid and alkali resistant chemical nickel liquid medicine pumping pump, a nitric acid solution pumping pump, an acid and alkali resistant and high temperature-resistant stainless steel pipeline system and an artificial intelligence temperature control and variable frequency speed regulation electrical control system are arranged. According to the device, chemical plating operation can be carried out only by hanging a product on the rotary hook, so that the labor intensity of operators is reduced.

Owner:中江立江电子有限公司

Chemical nickeling phosphorus alloy plating liquid and coating process thereof

InactiveCN1304636CFast plating speedFast platingLiquid/solution decomposition chemical coatingSodium acetateAcetic acid

The invention relates to a chemical Ni-P alloy-plating liquid and its process. The liquid is stable, works fast, has long service life, and does not contain chromium. So, it was widely used in industry. The Ni-P alloy coating is of fine corrosion-proof, containing 10-30g nickel sulfate, 20-40g sodium hypophosphite, 5-20g sodium acetate, 12-60g complexing agent and 0.002-0.01g complex stabilizer, with pH value of 4.5-5.0.

Owner:NANJING TECH UNIV

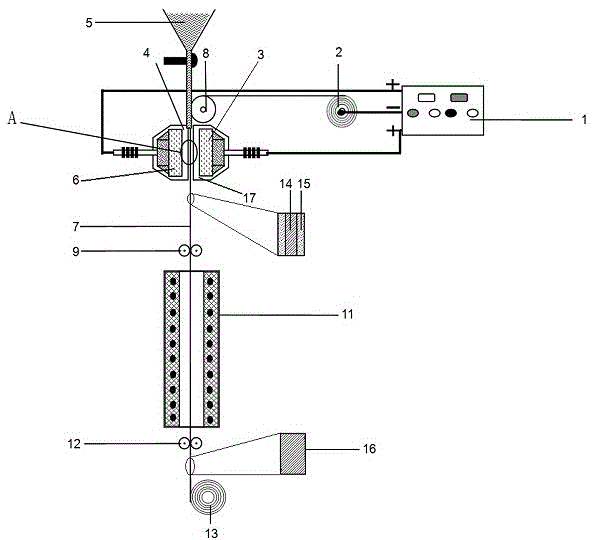

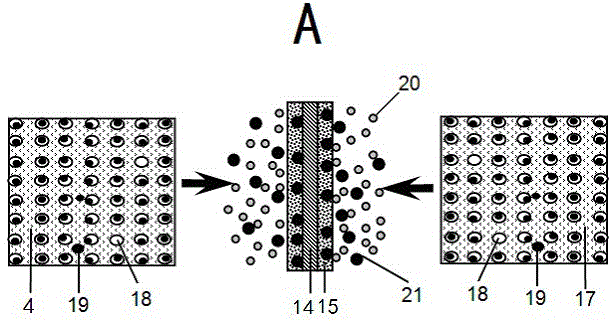

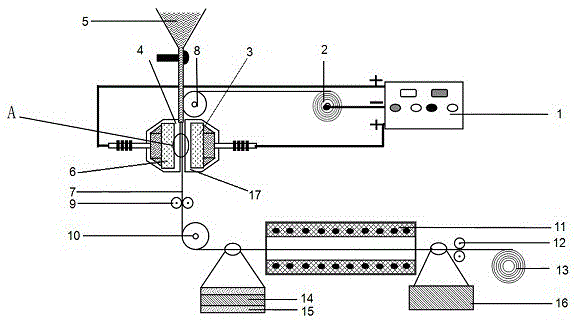

Method for preparing high-silicon silicon steel thin strip by electric brush composite plating method and continuous preparation device for silicon steel strip

ActiveCN103320842BReduce adverse effectsSolve the problem of fragmentationElectrolytic coatingsFerrosiliconBrush

The invention discloses a method for preparing a high-silicon silicon steel strip by an electric brush composite plating method. A pure iron strip, a low-carbon steel strip or a low-silicon silicon steel strip is used as a cathode plated strip, and an anode plate is plated by an electric brush. As the anode, a layer of iron-iron-silicon particle composite coating is covered on the cathodic plating thin strip through the brush composite silicon plating process to form a composite coated steel strip with the core as the steel strip matrix, and then perform uniform diffusion heat treatment to make the iron - The silicon-containing particles in the composite coating of ferrosilicon particles are uniformly diffused into the steel strip matrix at the core, thereby continuously preparing high-silicon steel thin strips. The invention also discloses a silicon steel strip continuous preparation device, which includes an unwinding guiding device, a conveying device, an electroplating device, a diffusion heat treatment device and a winding device. In the invention, the high-silicon silicon steel strip with excellent magnetic properties is obtained by electroplating the high-silicon coating on the cathode-plated thin strip, and then undergoing a heat treatment process. The method is simple to operate, has the characteristics of high efficiency and continuous preparation, and can greatly reduce the preparation cost.

Owner:SHANGHAI UNIV

Gold plating solution

ActiveUS9212429B2Stable during storageSatisfactory propertyOther chemical processesCoupling contact membersCyanideNitrogenous heterocyclic compound

A gold plating bath and a plating method is disclosed where gold cyanide or salts thereof provide the source of gold, a cobalt compound, and a reaction product of compound containing at least a nitrogen-containing heterocyclic compound and an epihalohydrin. The gold plating bath has high deposition selectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Circuit board and method of producing the same

InactiveUS6764747B2Improve accuracyAvoid it happening againDecorative surface effectsGlass/slag layered productsElectrical conductorMetal powder

A circuit board comprising a resin molded article which includes a metal powder coated by an insulation film and a metal conductor which is formed by metal deposition over a circuit pattern drawn by laser beam irradiation on the surface of the resin molded article through electroless plating, and the method of producing the same.

Owner:MTEX MATSUMURA CORP

A method for activating the surface of pcb circuit to realize electroless nickel plating

InactiveCN104862677BStrong reductionQuick restoreLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention discloses a method for activating the surface of a PCB circuit to realize electroless nickel plating, which belongs to the field of printed circuit board manufacturing. The method comprises the following steps: 1) preparing 0.01-10 g / L soluble silver salt as a silver immersion solution; 2) preparing an activation solution according to the ratio of 1-100 g / L pH stabilizer and 10-50 g / L reducing agent, and the pH stabilizer is hydrogen One or more of sodium oxide, potassium hydroxide, ammonia water, sodium acetate, etc., and the reducing agent is one or more of formaldehyde, acetaldehyde, glyoxylic acid, methanol, vitamin C, citric acid, etc.; 3) Pretreatment of PCB board; 4) After pretreatment, the PCB board is immersed in the immersion silver solution for 10-120s, cleaned, and then immersed in the activation solution for 10-80s; 5) The PCB board obtained in the previous step is chemically nickel plated. The invention avoids the use of precious metal palladium in the activation process, the activation solution has high stability and no seepage phenomenon, and effectively reduces the PCB production cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

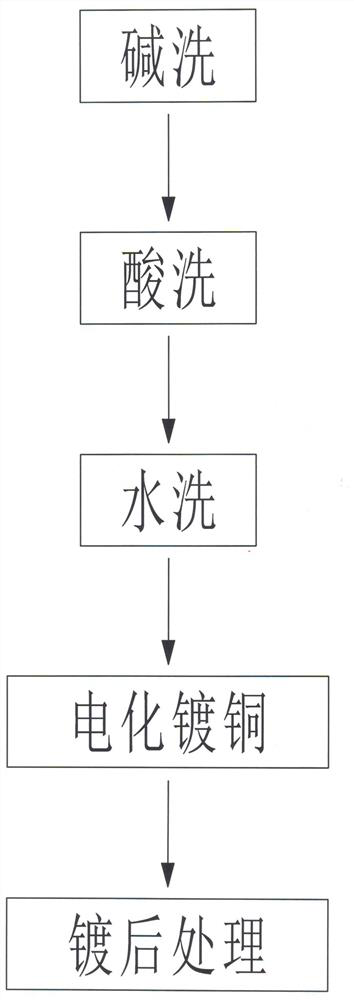

Steel wire electrochemical copper plating process

PendingCN112410832AAvoid it happening againImprove bindingMetallic material coating processesCopper platingElectroplating

The invention discloses a steel wire electrochemical copper plating process, and relates to the technical field of steel wire processing. The process is realized through the following steps: alkali washing, acid washing, water washing, electrochemical copper plating and post-plating treatment. By means of the process, a uniform, compact, flat, smooth and clean copper plating layer can be smoothlygenerated on the surface of a steel wire, and the process has the advantages of being high in electroplating efficiency, low in cost, simple in process and safe and non-toxic in plating solution.

Owner:中钢集团郑州金属制品研究院股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com