Steel wire electrochemical copper plating process

A technology of steel wire and copper plating, applied in the direction of metal material coating process, etc., can solve the problems of toxicity and environmental hazards for workers, and achieve the effects of increasing electrical conductivity, alleviating excessive thickness of plating layer, and high plating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

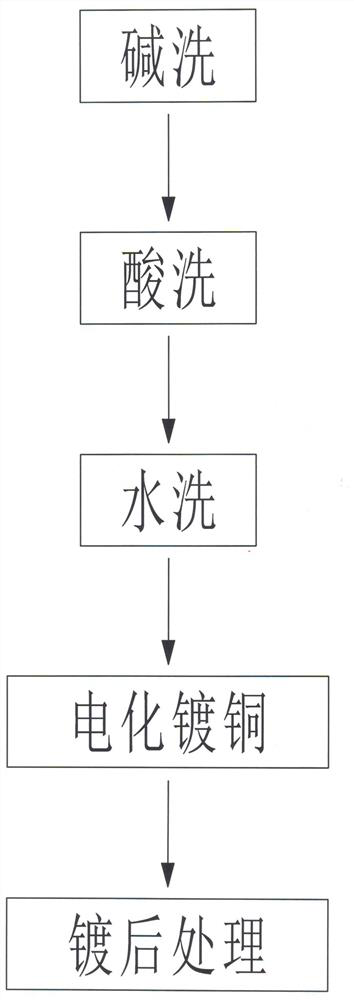

Method used

Image

Examples

Embodiment 1

[0022] A kind of steel wire electrochemical copper plating process of embodiment 1 is realized through the following steps:

[0023] A. Alkali cleaning: Make a steel wire with a diameter of 30mm pass through an alkali solution at 80°C at a speed of 60m / min, and combine it with 6A / dm 2 The current density electrolytically cleans the oil stains on the steel wire in the process of packaging, transportation, etc., and then removes the impurities on the surface of the steel wire; the alkaline solution is made by mixing the following components: Na 2 CO 3 40g / L, NaOH 80g / L, NaOH 2 SiO 3 8g / L, conductive agent 16g / L;

[0024] B. Pickling: The steel wire after alkali washing passes through the acid solution at 95°C at a speed of 60m / min, and is combined with 9.5A / dm 2 The current density is high, and the straight-forward non-contact cathode and anode alternate electrolytic pickling is used to neutralize the residual lye on the surface of the steel wire, further remove the corrosio...

Embodiment 2

[0033] A kind of steel wire electrochemical copper plating process of embodiment two is realized through the following steps:

[0034] A. Alkali cleaning: Make a steel wire with a diameter of 45mm pass through an alkaline solution at 95°C at a speed of 50m / min, and mix with 7.5A / dm 2 The current density electrolytically cleans the oil stains on the steel wire in the process of packaging, transportation, etc., and then removes the impurities on the surface of the steel wire; the alkaline solution is made by mixing the following components: Na 2 CO 3 30g / L, NaOH100g / L, NaOH 2 SiO 3 9g / L, conductive agent 20g / L;

[0035] B. Pickling: The steel wire after alkali washing passes through the acid solution at 80°C at a speed of 50m / min, and is combined with 7.5A / dm 2 The current density is high, and the straight-forward non-contact cathode and anode alternate electrolytic pickling is used to neutralize the residual lye on the surface of the steel wire, further remove the corrosion...

Embodiment 3

[0044] A kind of steel wire electrochemical copper plating process of embodiment three is realized through the following steps:

[0045] A. Alkali cleaning: Make the steel wire with a diameter of 60mm pass through the alkali solution at 85°C at a speed of 30m / min, and electrolytically clean the oil stains on the steel wire during packaging and transportation with a current density of 9.5A / dm2, and then remove the surface of the steel wire impurities; the alkaline solution is made by mixing the following components: Na 2 CO 3 35g / L, NaOH 90g / L, NaOH 2 SiO 3 10g / L, conductive agent 24g / L;

[0046] B. Pickling: The steel wire after alkali washing passes through the acid solution at 85°C at a speed of 30m / min, and is combined with 6A / dm 2 The current density is high, and the straight-forward non-contact cathode and anode alternate electrolytic pickling is used to neutralize the residual lye on the surface of the steel wire, further remove the corrosion spots on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com