A kind of surface electroplating solution and electroplating process for alloy

An electroplating solution and alloy technology, applied in the field of electroplating, can solve problems such as tediousness, affecting the function of the film layer, and the coating is not environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

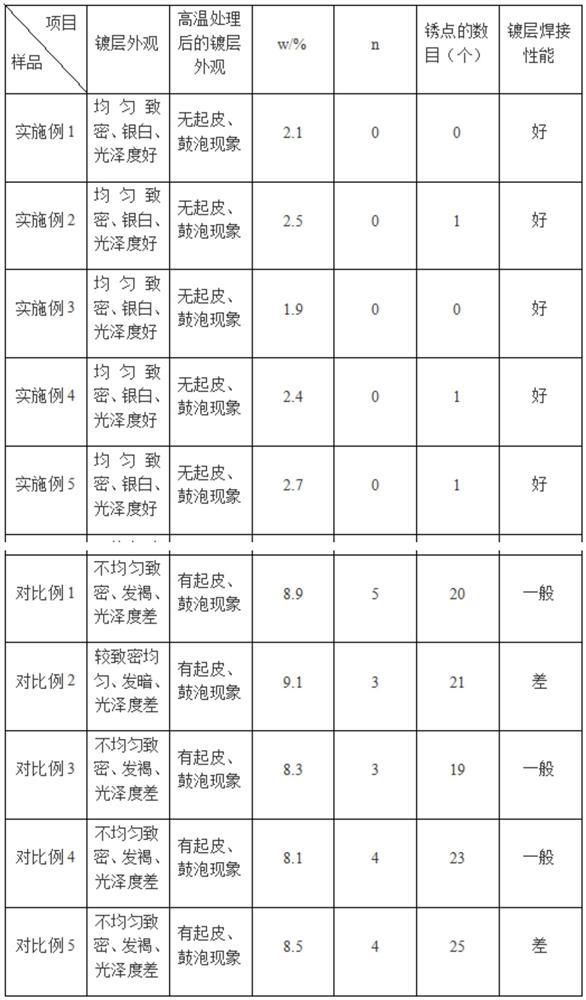

Examples

Embodiment 1

[0037] The manufacturers, CAS numbers or models of the materials used in this example are as follows: palladium chloride is produced by Suzhou Jinwo Chemical Co., Ltd., and the CAS number is 7647-10-1; potassium chloroplatinate is produced by Suzhou Jinwo Chemical Co., Ltd. Production, CAS No. 16921-30-5; Dimethylthiourea is produced by Shanghai Tebo Chemical Technology Co., Ltd., CAS No. 6972-05-0; Aluminum Potassium Sulfate is produced by Zibo Dazhong Edible Chemical Co., Ltd., CAS No. It is 7784-24-9; citrate is produced by Hefei Sifeng Biotechnology Co., Ltd.; antimony potassium tartrate is produced by Anhui Aibo Biotechnology Co., Ltd., CAS number is 11071-15-1; fatty amine is produced by Zibo Yingzhao Chemical Produced by Science and Technology Co., Ltd.; Polyethylene Glycol is produced by Shanghai Macklin Biochemical Technology Co., Ltd., CAS No. 25322-68-3; Sodium Lauryl Sulfate is produced by Suzhou Dongbai Chemical Co., Ltd., CAS No. 151-21- 3.

[0038] A surface el...

Embodiment 2

[0048] The manufacturers, CAS numbers or models of the substances used in this example are as follows: palladium sulfate is produced by Wuhan Fengzhulin Chemical Technology Co., Ltd., and the CAS number is 13566-03-5; sodium chloroplatinate is produced by Shaanxi Ruike New Materials Co., Ltd. Co., Ltd., CAS No. 19583-77-8; dithioethylene glycol is produced by Shanghai Xinyu Biotechnology Co., Ltd.; magnesium chloride is produced by Shandong Shouguang Jinxing Chemical Co., Ltd., CAS No. 7786-30-3; ammonia Butanetriol is produced by Shanghai Wodian Chemical Co., Ltd., with a CAS number of 77-86-1; trioctyl phosphite is produced by Guangzhou Wengjiang Chemical Reagent Co., Ltd., with a CAS number of 3028-88-4.

[0049] A surface electroplating solution for alloys, the electroplating solution is composed of the following components: palladium sulfate 8g / L, sodium chloroplatinate 5g / L, dithioethylene glycol 12g / L, magnesium chloride 35g / L, ambutene Triol 15g / L, brightener 2g / L, tri...

Embodiment 3

[0059] The manufacturers, CAS numbers or models of the substances used in this example are as follows: palladium acetylacetonate is produced by Shaanxi Ruike New Materials Co., Ltd., and the CAS number is 14024-61-4; chloroplatinic acid is produced by Shanghai Tuosi Chemical Co., Ltd. Produced by the company, CAS number is 16941-12-1; Guanidinoacetic acid is produced by Jinan Nengwei Biotechnology Co., Ltd., CAS number is 352-97-6; Magnesium sulfate is produced by Zibo Hongkun Chemical Co., Ltd., CAS number is 7487- 88-9; 2-amino-2-methyl-1-propanol was produced by Shanghai Merrill Chemical Technology Co., Ltd., CAS No. 124-68-5; trioctyl phosphite was produced by Shanghai Yuanye Biotechnology Co., Ltd. , CAS No. 3028-88-4.

[0060] A surface electroplating solution for alloys, the electroplating solution is composed of the following components: palladium acetylacetonate 10g / L, chloroplatinic acid 7g / L, guanidinoacetic acid 14g / L, magnesium sulfate 40g / L, 2-amino- 2-methyl-1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com