Patents

Literature

46results about How to "Improve throwing power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

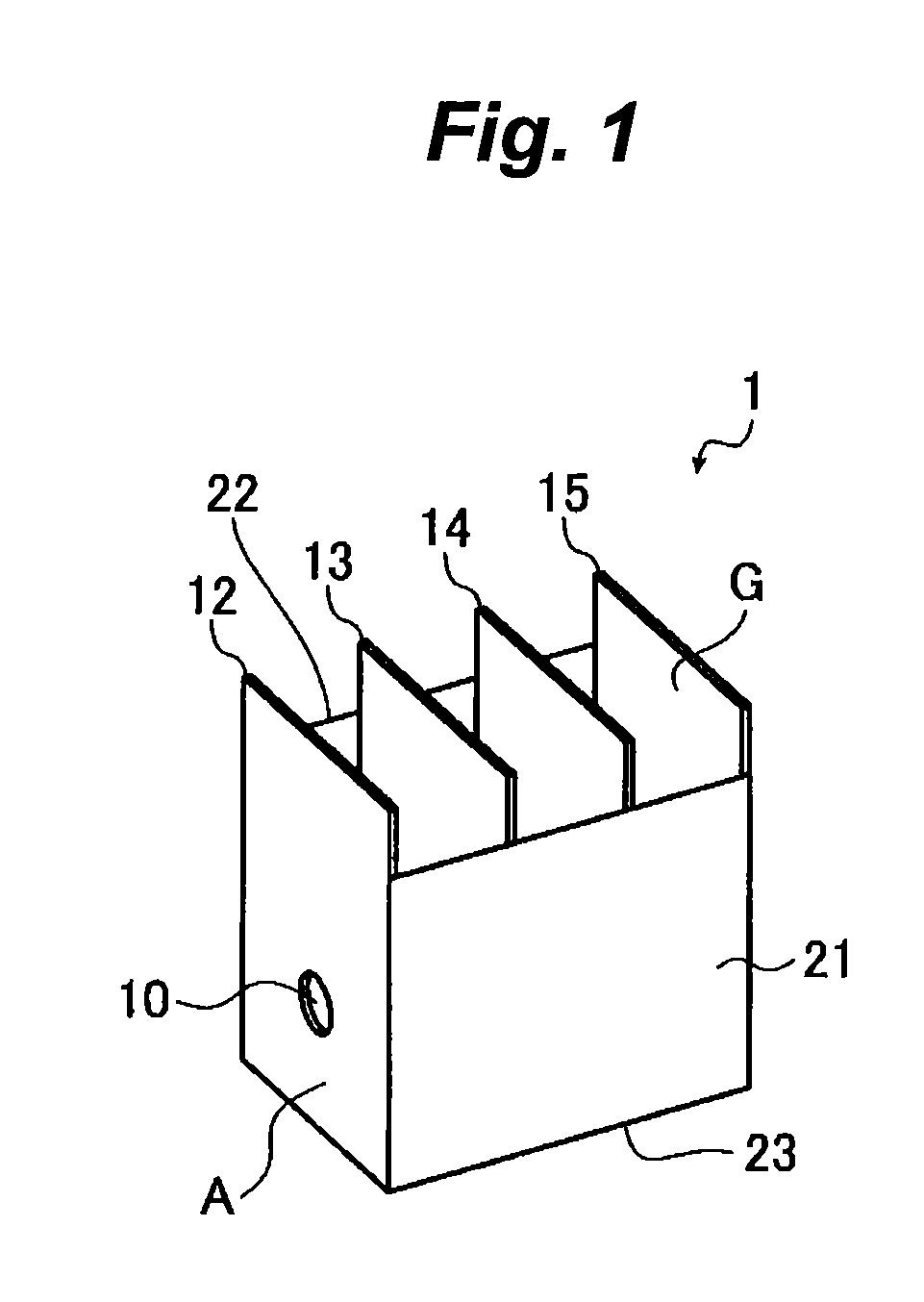

Metal surface treatment liquid for cation electrodeposition coating

ActiveUS20080230395A1Improve throwing powerPreventing copperElectrolysis componentsVolume/mass flow measurementAluminum IonIndium

A surface treatment with a zirconium ion that enables sufficient throwing power and superior anti-corrosion properties to be exhibited when thus surface treated metal base material is subjected to cation electrodeposition coating is provided. A metal surface treatment liquid thereof for cation electrodeposition coating includes zirconium ions, copper ions, and other metal ions, and having a pH of 1.5 to 6.5, in which: the other metal ions are at least one selected from the group consisting of tin ions, indium ions, aluminum ions, niobium ions, tantalum ions, yttrium ions and cerium ions; the concentration of zirconium ions is 10 to 10,000 ppm; the concentration ratio of the copper ions to the zirconium ions is 0.005 to 1 on a mass basis; and the concentration ratio of the other metal ions to the copper ions is 0.1 to 1,000 on a mass basis.

Owner:NIPPON PAINT SURF CHEM

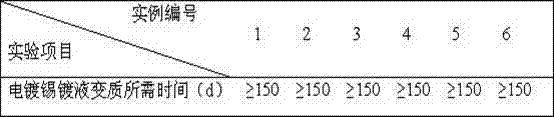

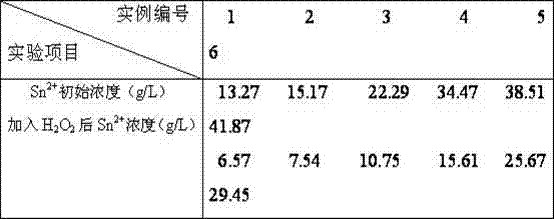

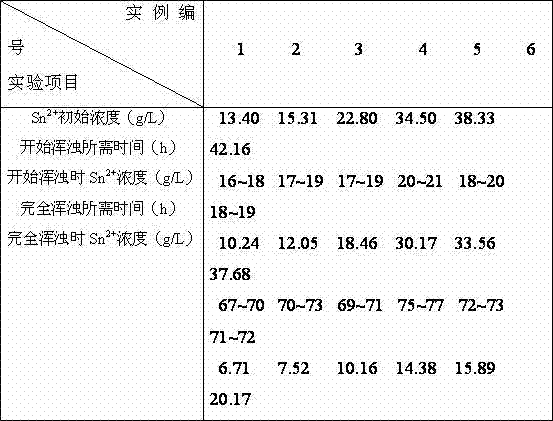

Methyl sulfonate tinning electrolyte and tinning method of steel strip or steel plate

The invention discloses methyl sulfonate tinning electrolyte using cerium salt as an additive. The electrolyte comprises the following components: 30 to 120 g / L of stannous methyl sulfonate, 60 to 180 g / L of methylsulfonic acid, 1 to 10 g / L of cerium sulfate, 0.1 to 2 g / L of antioxidant, 5 to 10 g / L of brightening agent and 5 to 10 g / L of surfactant. The invention also discloses a method for tinning a steel strip or a steel plate by adopting the electrolyte. During plating, the cerium salt in the electrolyte lightens the harm degree of 'hydrogen brittleness', and plays roles of the antioxidant and the brightening agent. On the basis of adaptability to the environment, the electrolyte meets the requirements that the process is simple, the solution is stable, the maintenance is easy and the quality of a coating is high.

Owner:张家港市凤凰科技开发有限公司

Cyanide-free sulfite gold plating solution and application thereof

The invention relates to the field of gold plating, and discloses a cyanide-free sulfite gold plating solution and application thereof. The cyanide-free sulfite gold plating solution is prepared from gold sulfite, alkali metal sulfite, 3-nitrobenzenesulfonate, organic polyamine, organic phosphonate, polyhydric alcohol compounds, a macromolecular polymer containing imine and thiourea compounds. The cyanide-free sulfite gold plating solution contains a current efficiency stabilizer with the excellent property, the current efficiency stabilizer participates in the cathode reduction process in the gold plating process to inhibit side reactions from occurring, therefore, the current efficiency is improved, and the cyanide-free sulfite gold plating solution is obviously beneficial for improving the uniform plating capacity of the plating solution; in addition, a series of the problems that the gold plating amount cannot be accurately estimated, the plating solution dispersing capacity is relatively poor, and the current density is low due to the unstable current efficiency caused by the low current are solved.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

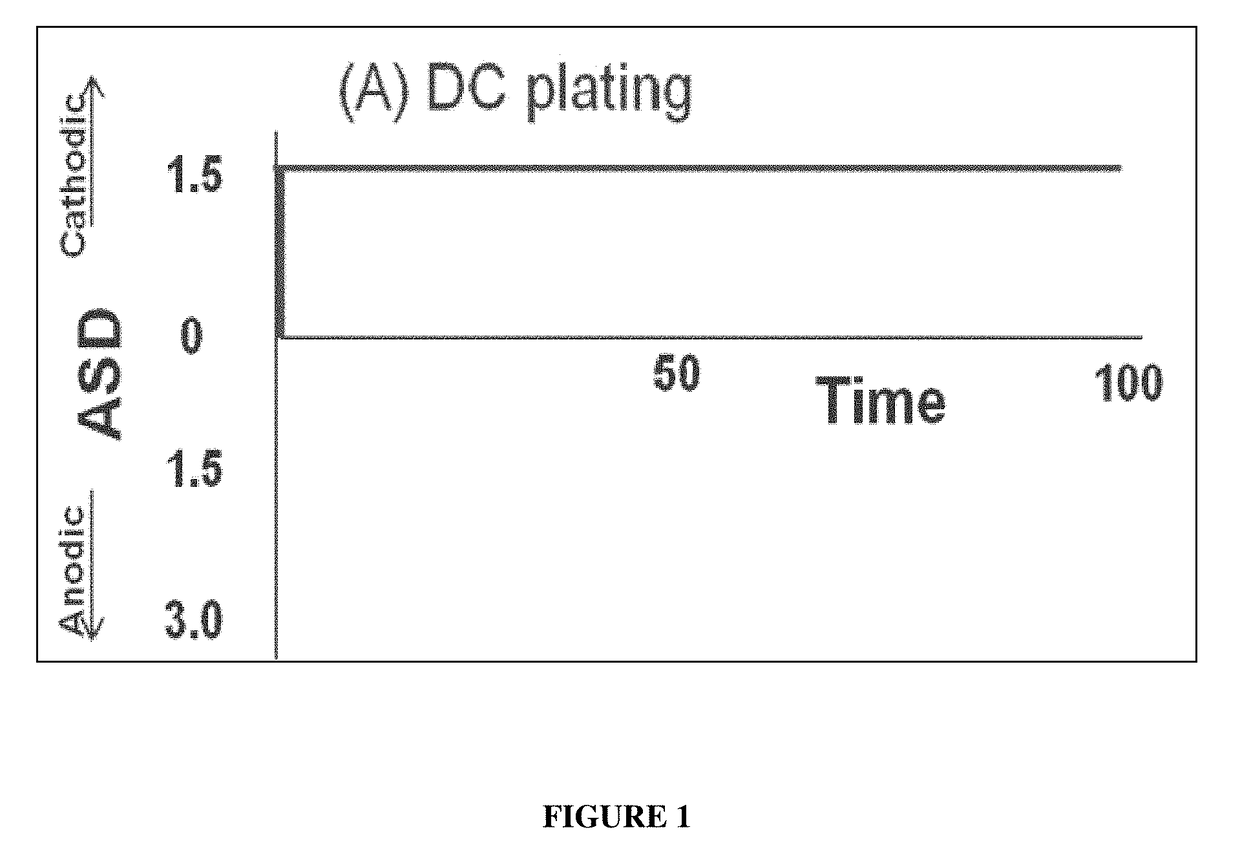

Reverse pulse plating composition and method

A composition and method for electroplating a metal on a substrate. The composition has a chloride to brightener concentration ratio of from 20:1 to 125:1. The method of electroplating, which employs the composition, employs pulse patterns that improve physical properties of metal surfaces.

Owner:SHIPLEY CO LLC

Chemical conversion solution for metal structure and surface treating method

InactiveUS20110094630A1Improve coating adhesionControl and reduceElectrophoretic coatingsSolid state diffusion coatingZinc compoundsSludge

The present invention provides a chemical conversion solution and the surface treating method for realizing high corrosion resistance and high coating adhesion of the metal surface, as well as high throwing power during electrodeposition, and generating no sludge.A chemical conversion solution comprising (A) at least one compound selected from water-soluble germanium compound, water-soluble tin compound, and water-soluble copper compound, (B) at least one compound selected from water-soluble titanium compound and water-soluble zirconium compound, (C) at least one water-soluble nitrate compound, (D) at least one compound selected from water-soluble aluminum compound and water-soluble magnesium compound, (E) at least one water-soluble zinc compound, and (F) at least one fluorine compound, and, the coating process for the metal structure.

Owner:HENKEL KGAA

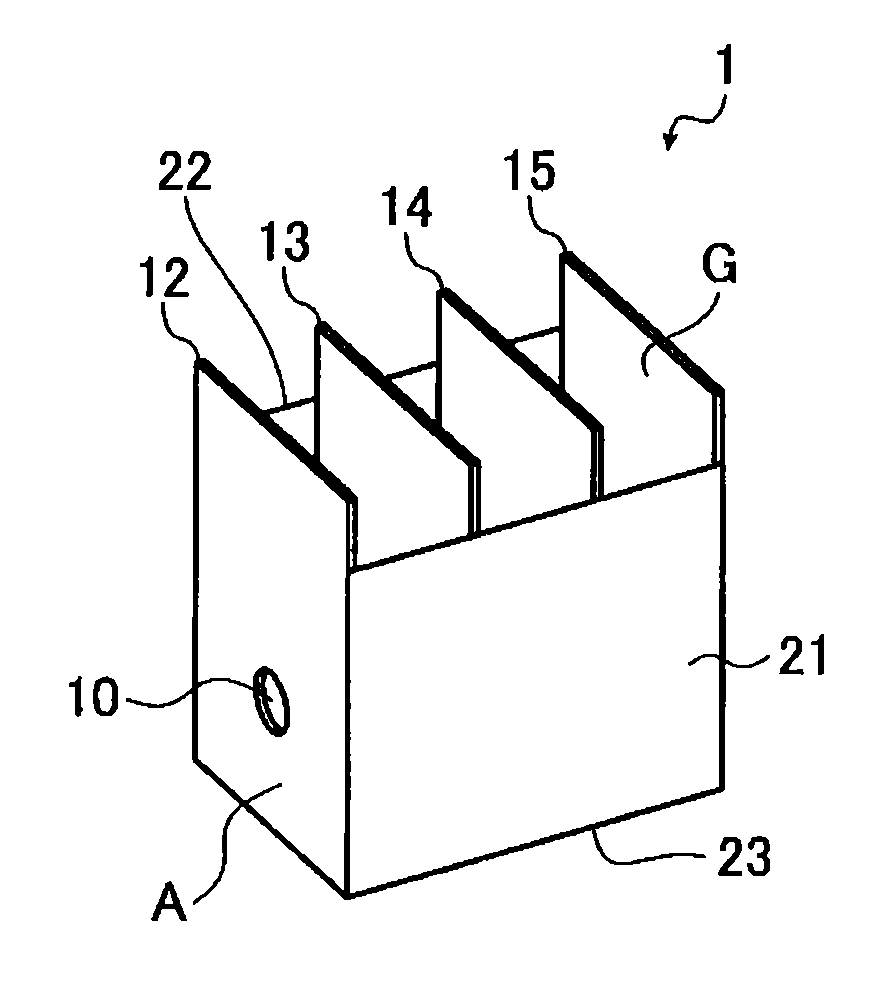

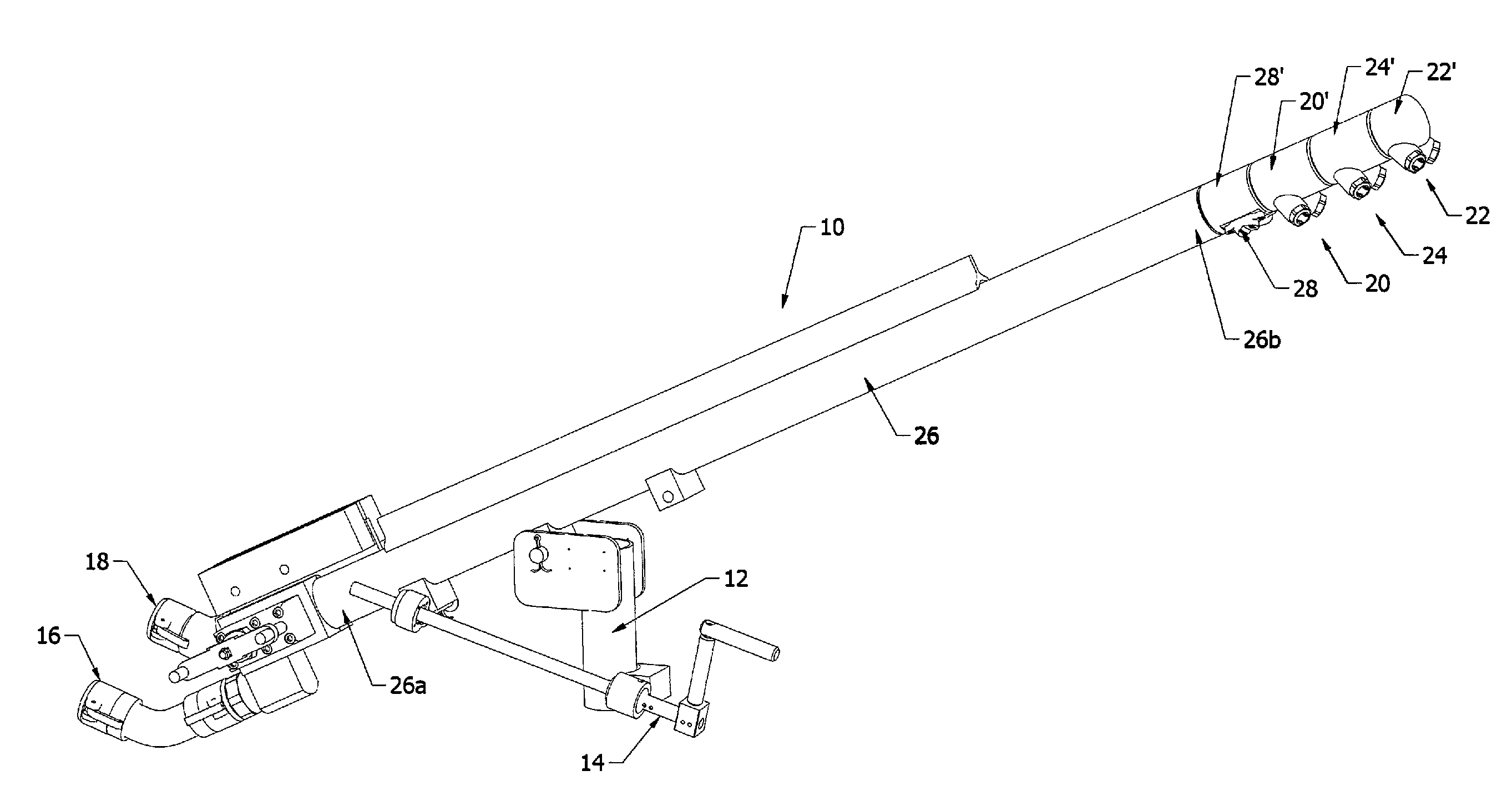

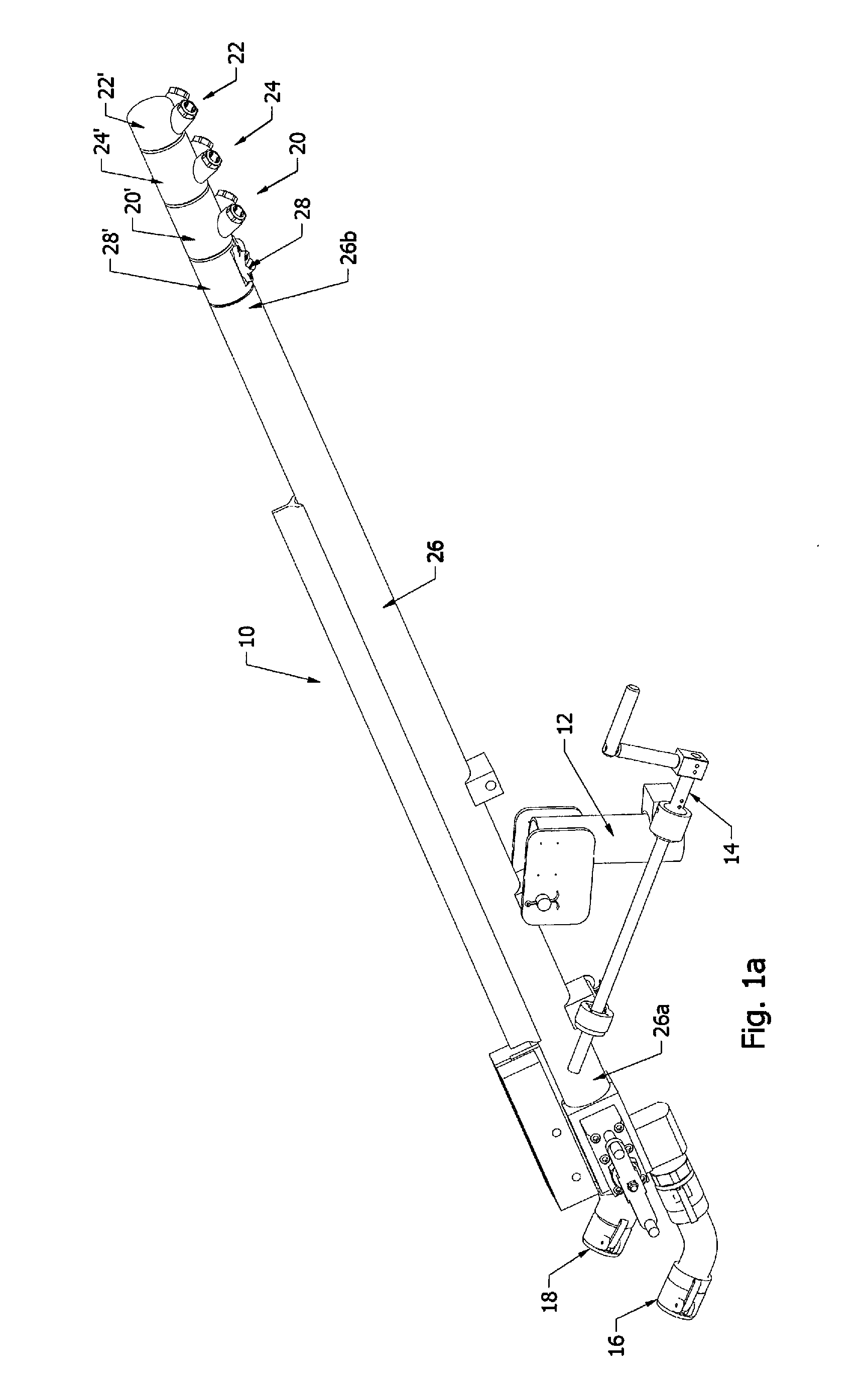

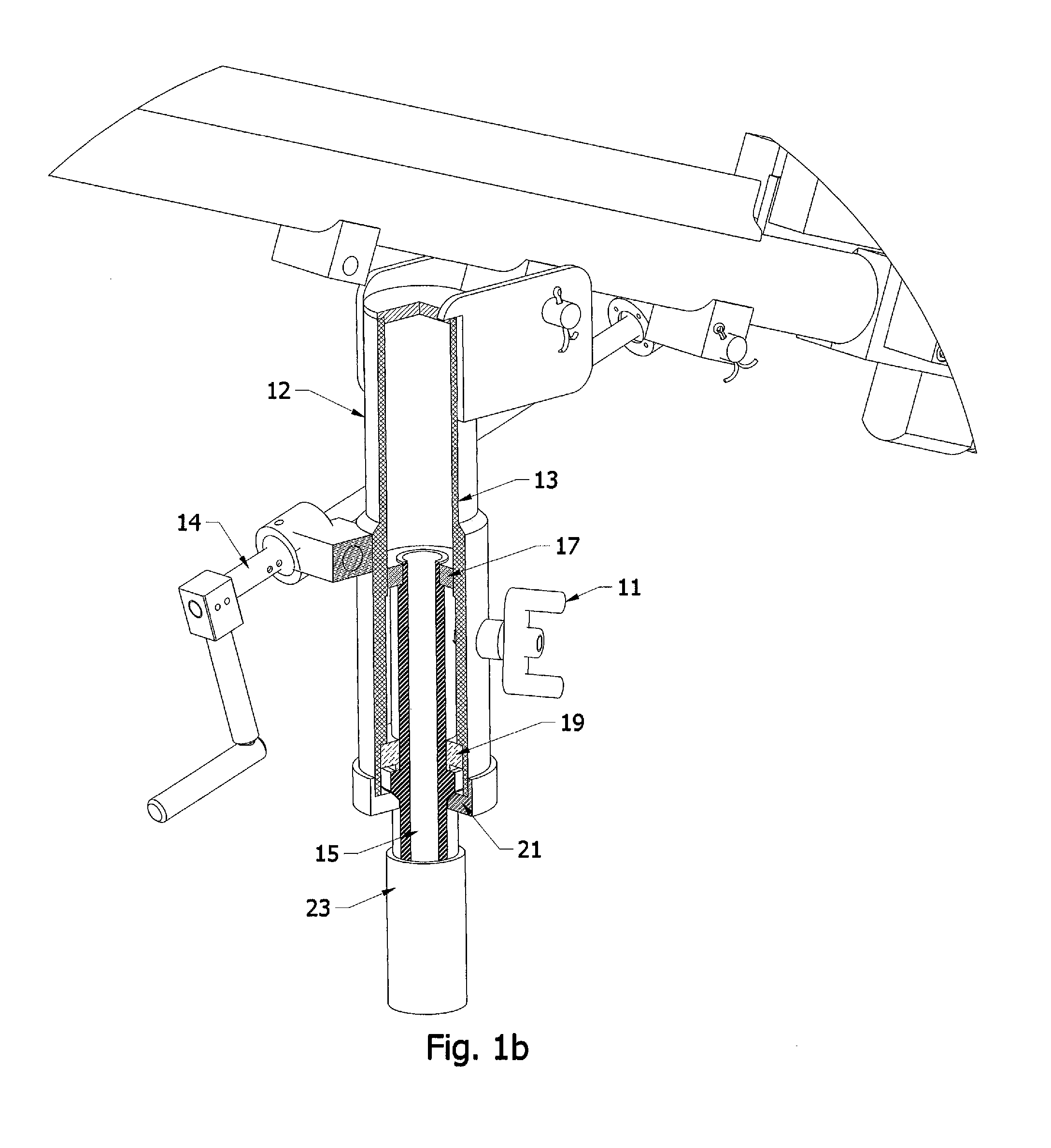

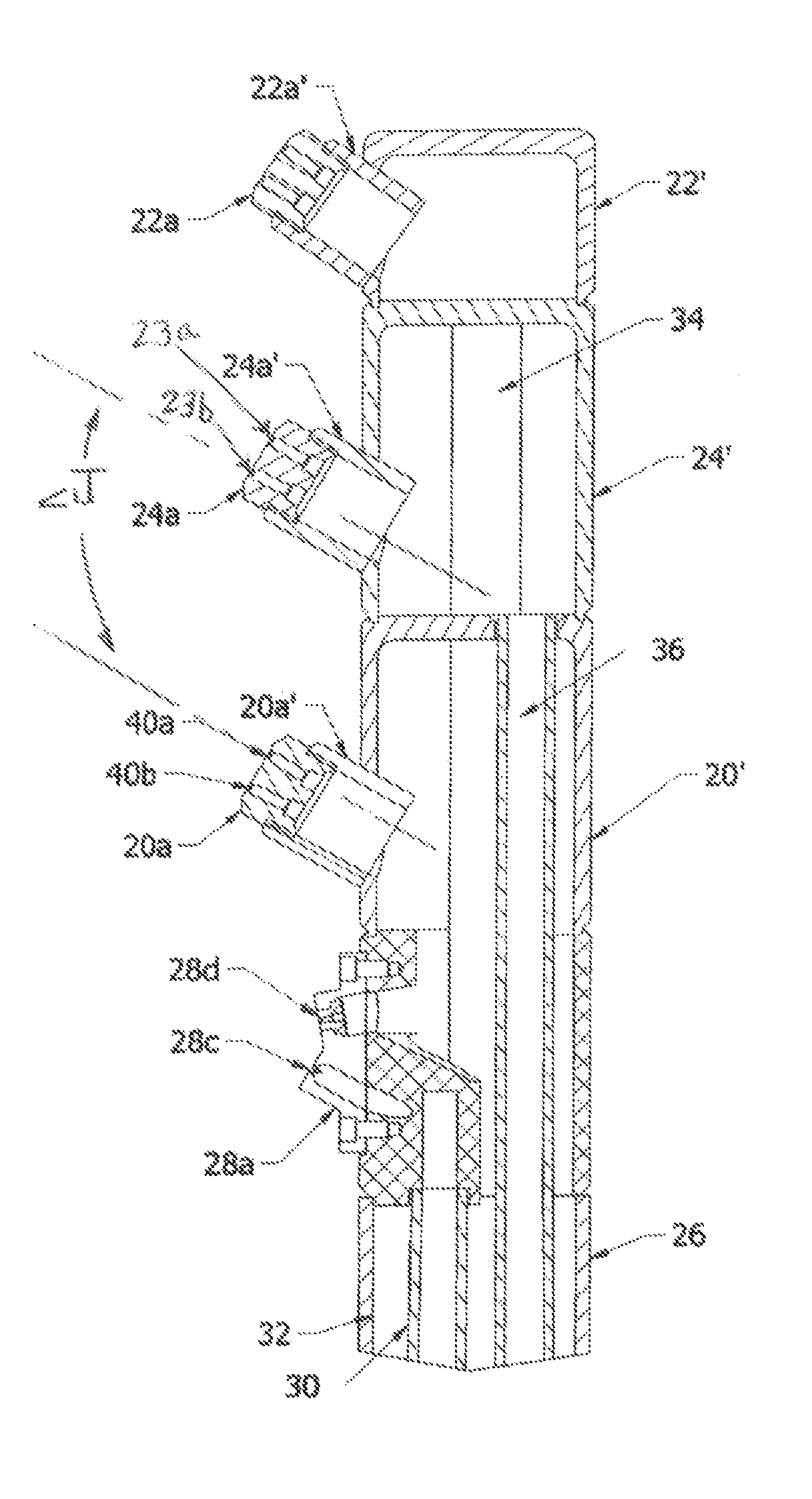

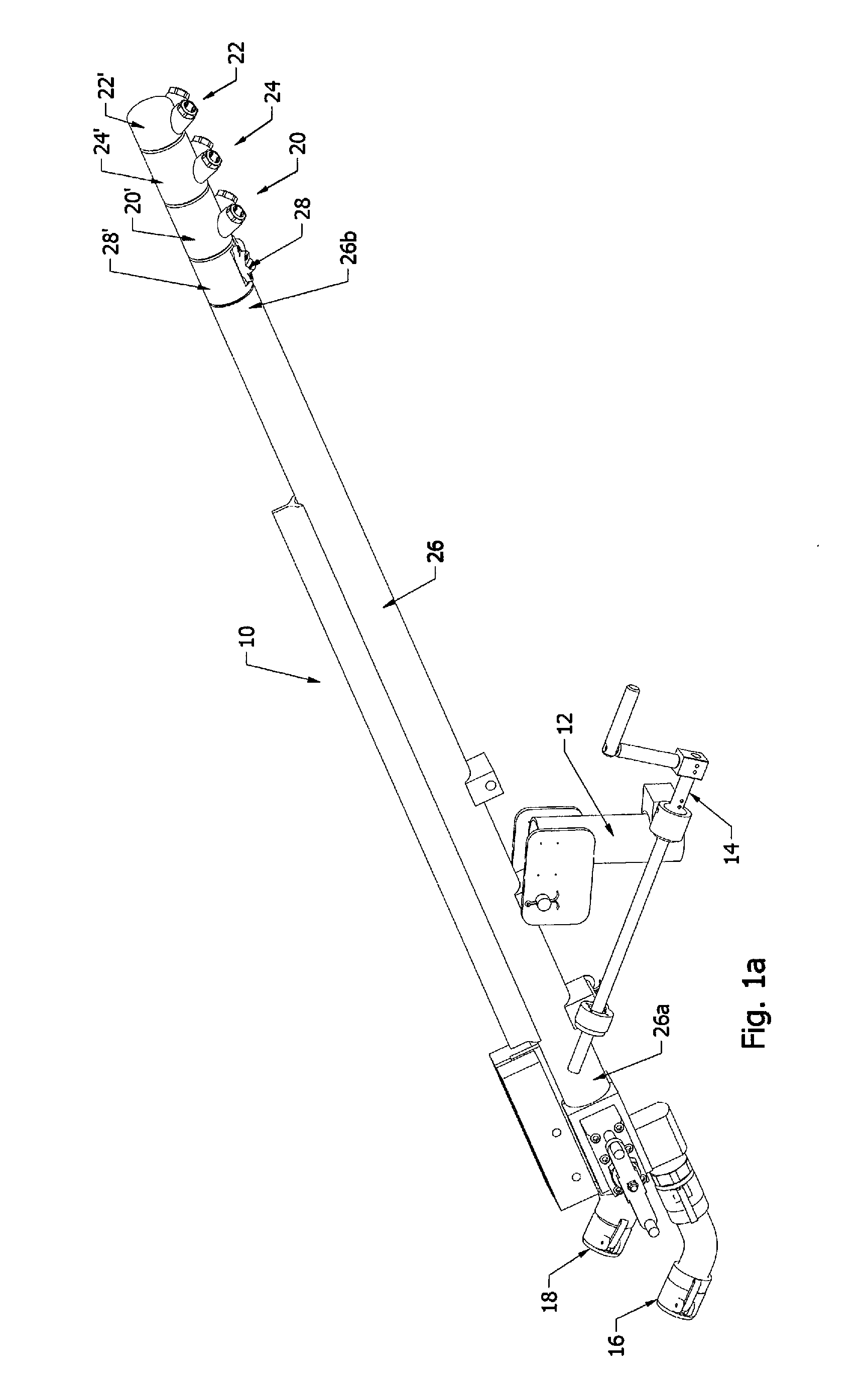

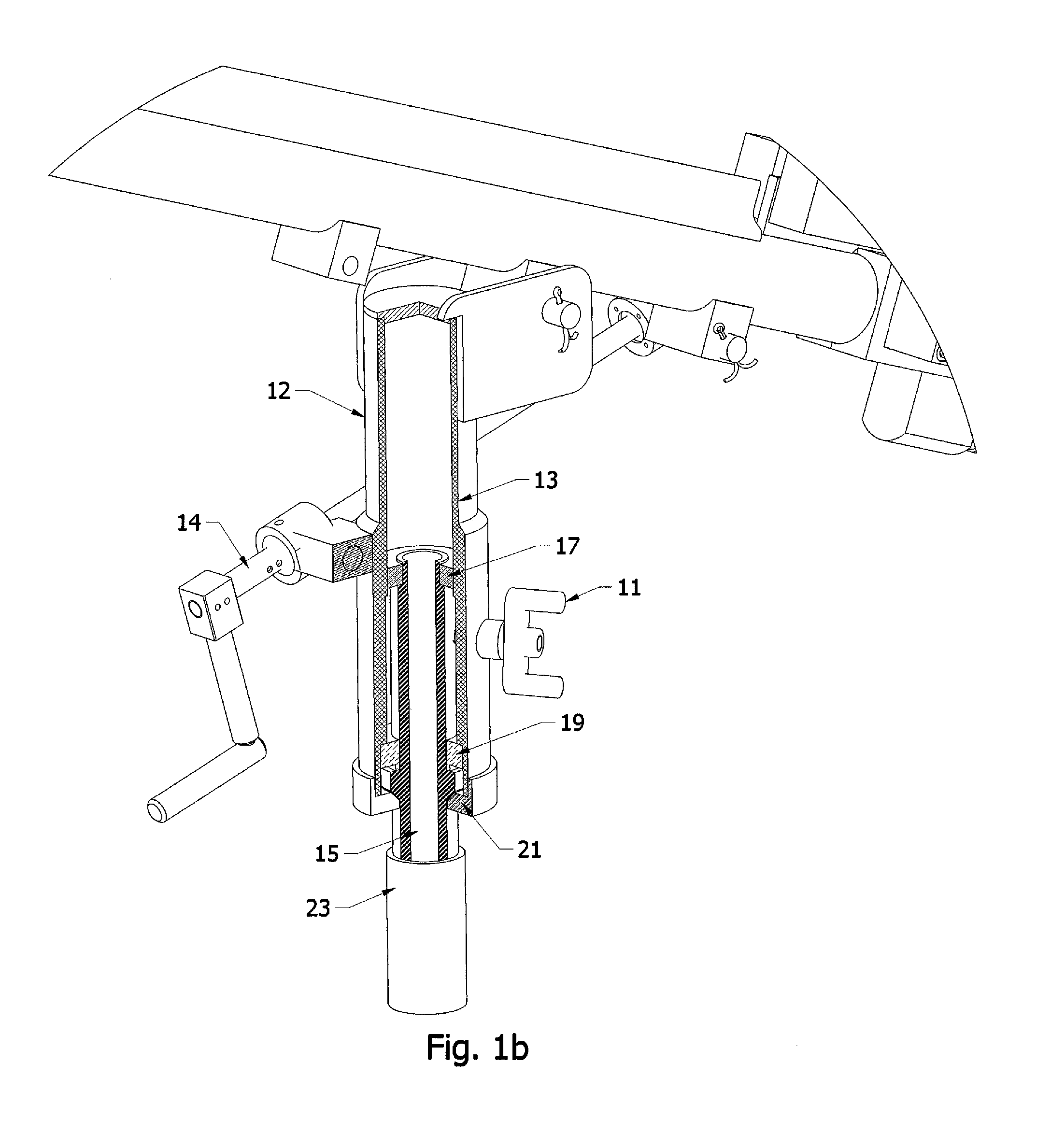

Snow Making Apparatus and Method

ActiveUS20110174895A1Low profileEasily and quickly attach and/or removeRecreational ice productionLighting and heating apparatusPhysicsSnow

A low energy snow making gun having at least one but preferably three operational stages each having at least one pair of small aperture water outlets which are oriented at a divergent angle to generate a respective pair of narrow angled water droplet streams which do not interfere with each other until they have reached a distance from the gun. A second pair of water outlets may be provided on each stage with each pair on each stage oriented at a divergent angle to maintain singularity of the streams over a distance thereby increasing the throwing power of the gun.

Owner:RATNIK IND

Tin plating electrolyte

The invention discloses tin plating electrolyte. The tin plating electrolyte comprises the following components 60 to 90g / L of tin methane sulfonate, 10 to 30g / L of tin sulfate, 110 to 140mg / L of p-cresolsulphonic acid, 60 to 120mg / L of sulfosalicylic acid, 30 to 50g / L of phosphinic acid, 45 to 70mg / L of 2,2-PySSPy, 15 to 25mg / L of 8-hydroxyquinoline, 20 to 30mg / L of catechins, 10 to 15g / L of 2,2-dihydroxy diethyl sulfide, 5 to 10mg / L of hexadecylpyridinium bromide, 8 to 12 g / L of dodecyl-phenol polyoxyethylene ether, 5 to 10g / L of ethylene glycol, 4 to 8g / L of benzalacetophenone, 5 to 10g / L of sodium hexametaphosphate, 4 to 8g / L of sodium dodecyl sulfate, and the balance of deionized water. According to the tin plating electrolyte, Sn2<+> can be effectively restrained to convert into Sn4 <+> in an electrolytic process by improving an electrolyte formula, and the stability of plating solution is improved; and meanwhile, the throwing power of the electrolyte is increased, and the luminance, the corrosion resistance and the welding performance of tin coatings are improved.

Owner:郎溪县金科金属有限公司

Multilayer coating film

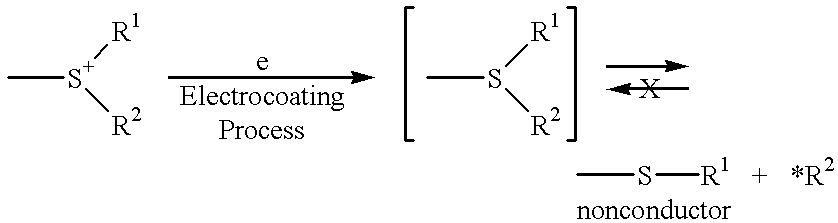

InactiveUS6168864B1Reduce reactivityImprove thermal response performanceSynthetic resin layered productsPaints for electrolytic applicationsEpoxySulfonium

A multilayer coating film which comprises:a cationic electrodeposition coat formed from an epoxy-based cationic electrocoating composition containing 5 to 300 millimoles of sulfonium group and 50 to 2,000 millimoles of carbon-carbon unsaturated bond per 100 g of the resin solid content, with carbon-carbon triple bond accounting for at least 15% of said carbon-carbon unsaturated bond; anda top coat formed thereon.

Owner:NIPPON PAINT CO LTD

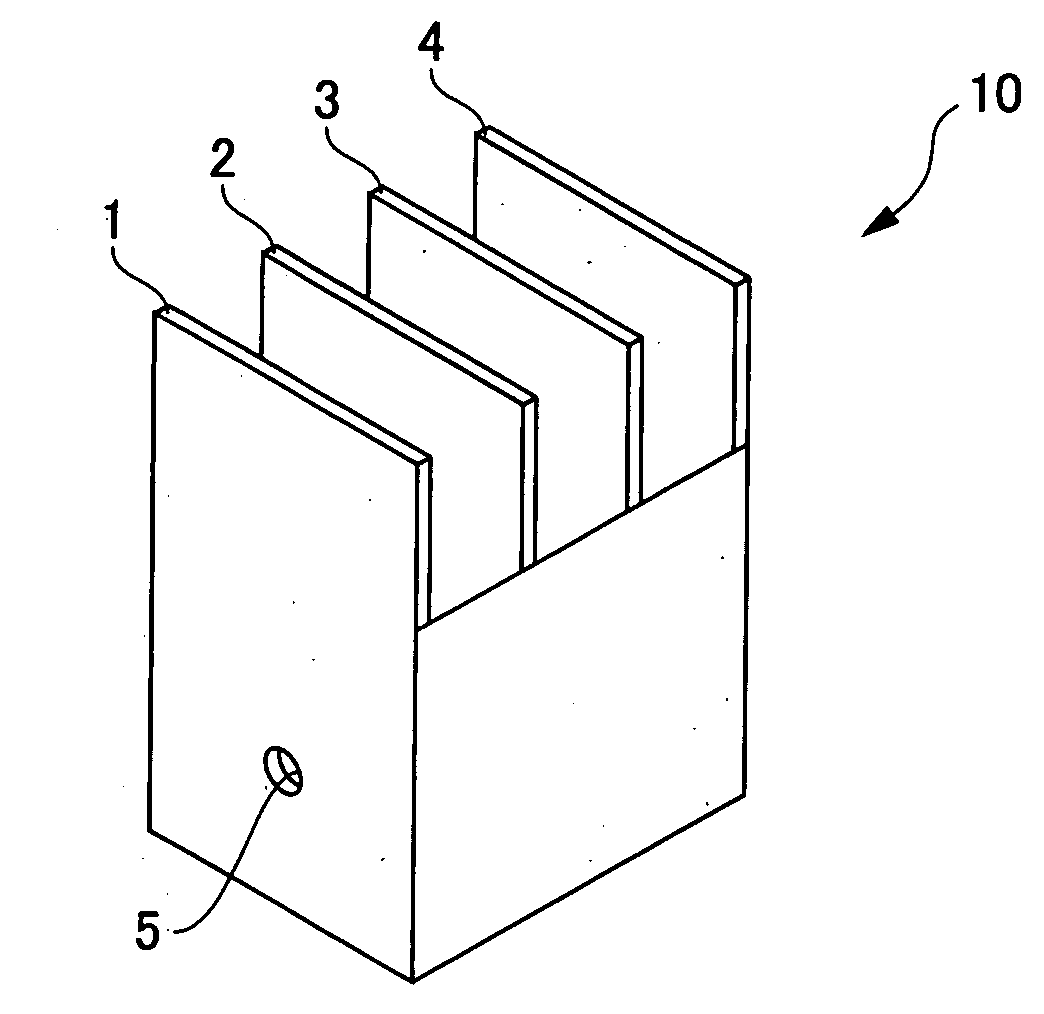

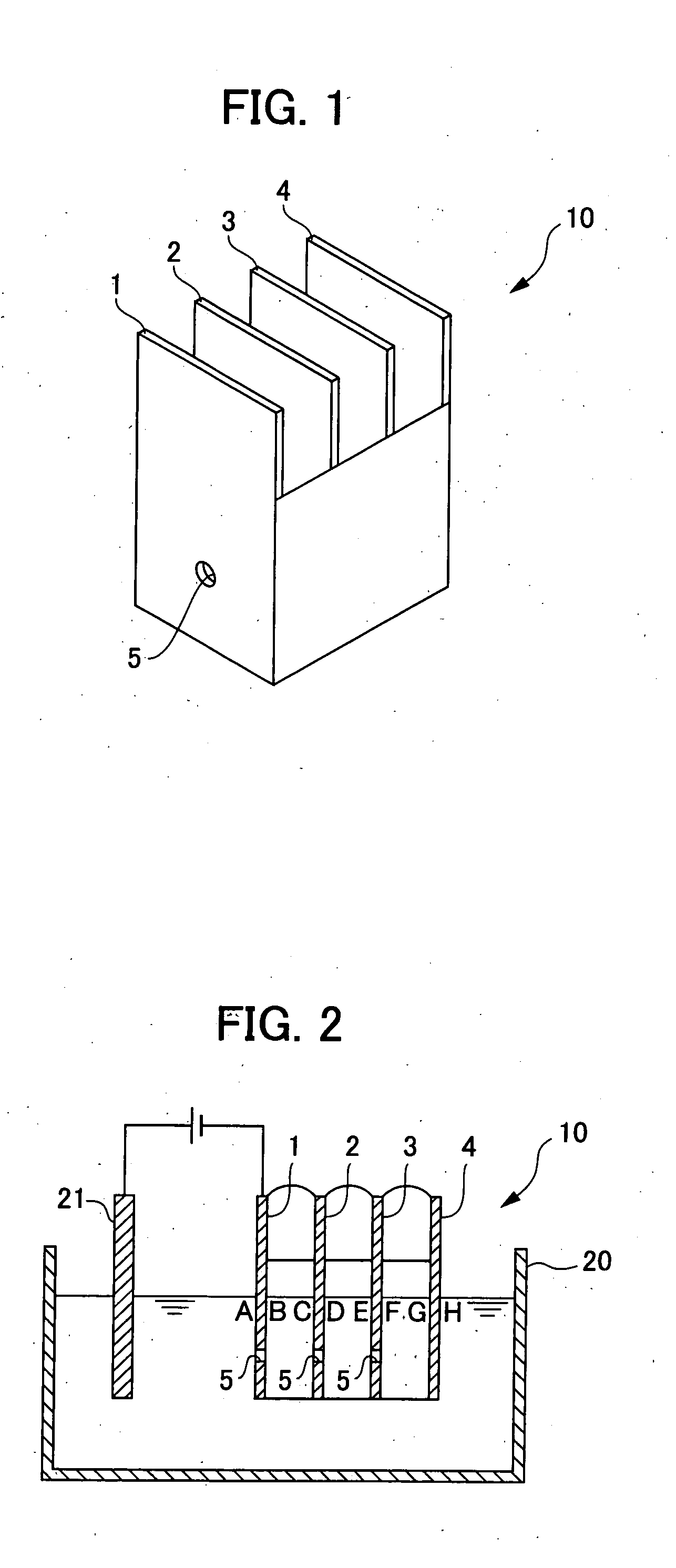

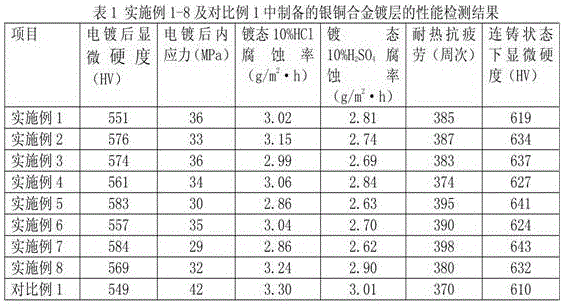

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Reverse pulse plating composition and method

Owner:SHIPLEY CO LLC

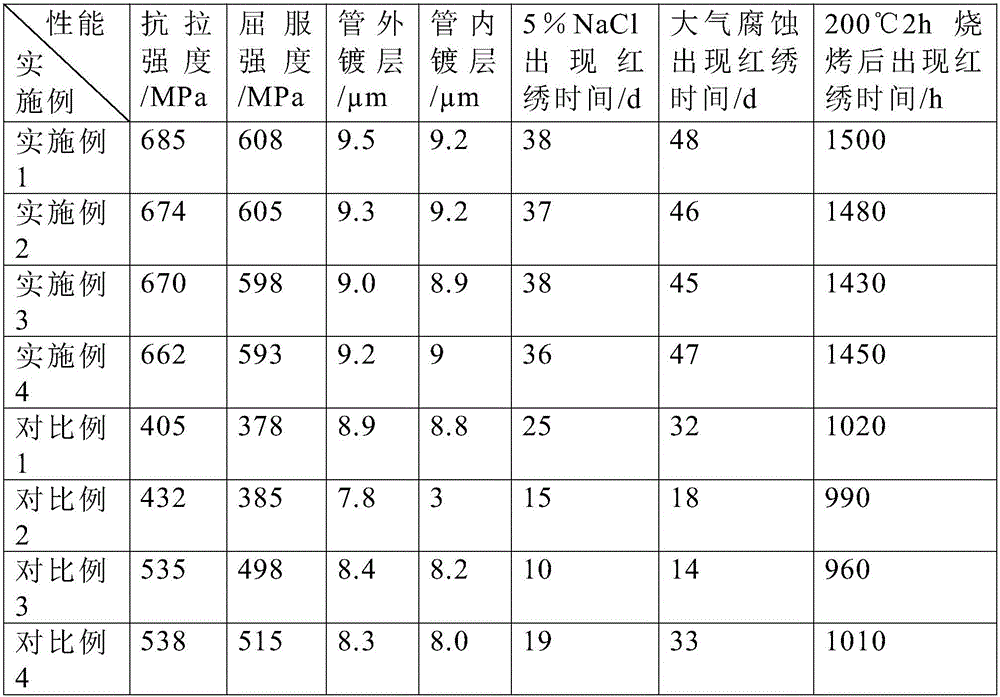

Processing technique of oil delivery pipe

ActiveCN106282822AFast deposition rateStable eutectoid ratioSuperimposed coating processComponents of crude oilMechanical property

The invention relates to a processing technique of an oil delivery pipe, belonging to the technical field of alloy processing. The technique comprises the following steps: machining alloy steel to obtain an oil delivery pipe blank; carrying out electroplating treatment on the oil delivery pipe blank in a 20-30-DEG C nickel-electroplating solution by an auxiliary anode electroplating technique, wherein the electroplating solution is composed of 5-7 g / L zinc oxide, 110-130 g / L sodium hydroxide, 0.6-1 g / L nickel and 150-300ml of additive; sequentially carrying out polishing treatment, passivating treatment and rust prevention treatment on the electroplated oil delivery pipe blank to obtain an oil delivery pipe semifinished product; and carrying out seal treatment on the oil delivery pipe semifinished product to obtain the oil delivery pipe finished product. The oil delivery pipe has reasonable component combination; and under the synergistic actions of the component elements, the zinc-nickel alloy is electroplated on the surface by the auxiliary anode electroplating technique, the passivating treatment and rust prevention treatment are then carried out, and finally, the seal treatment for silanization treatment is carried out to further enhance the corrosion resistance and mechanical properties of the oil delivery pipe.

Owner:NINGBO YADA METAL SURFACE TREATMENT

Plating method

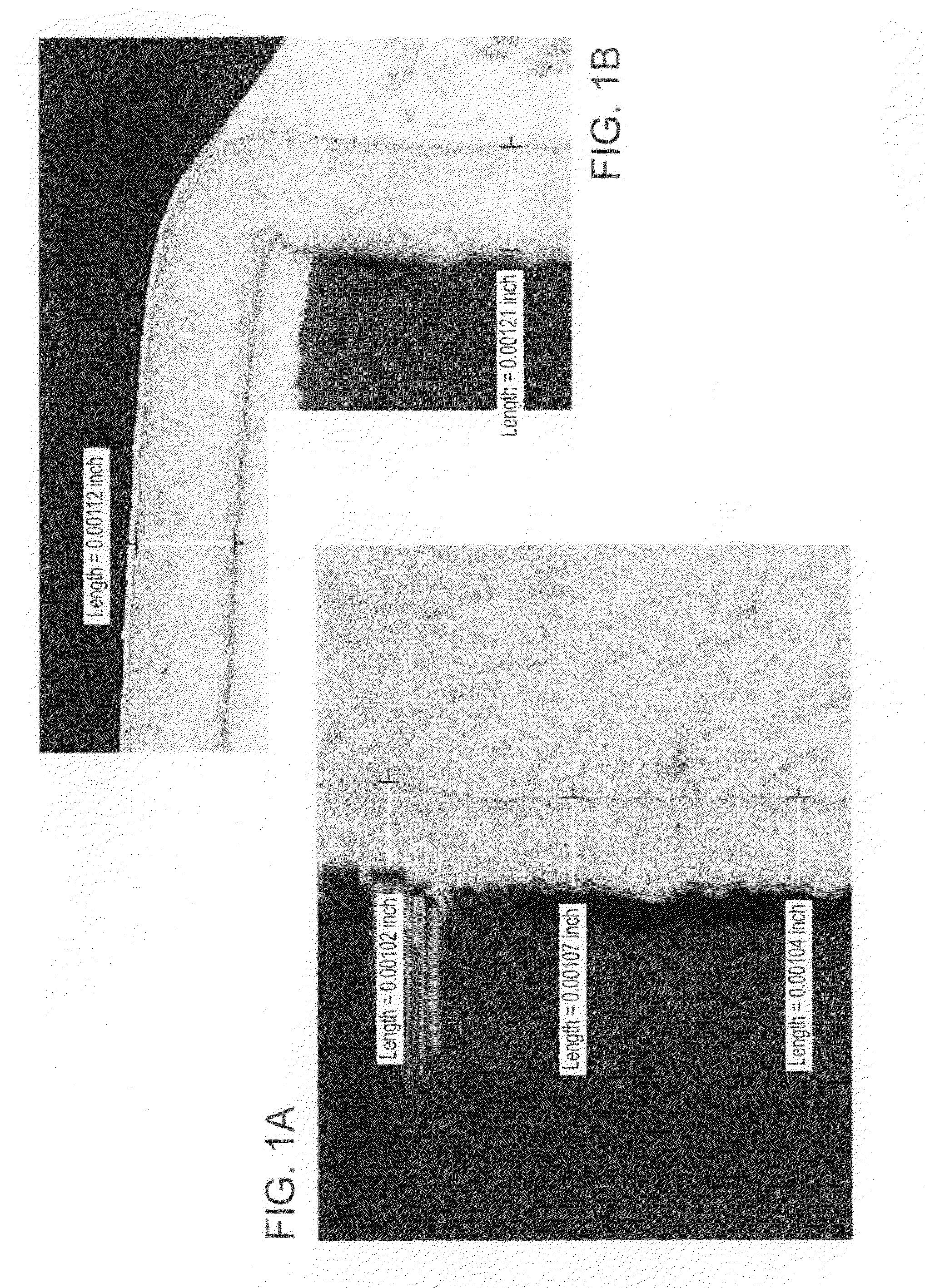

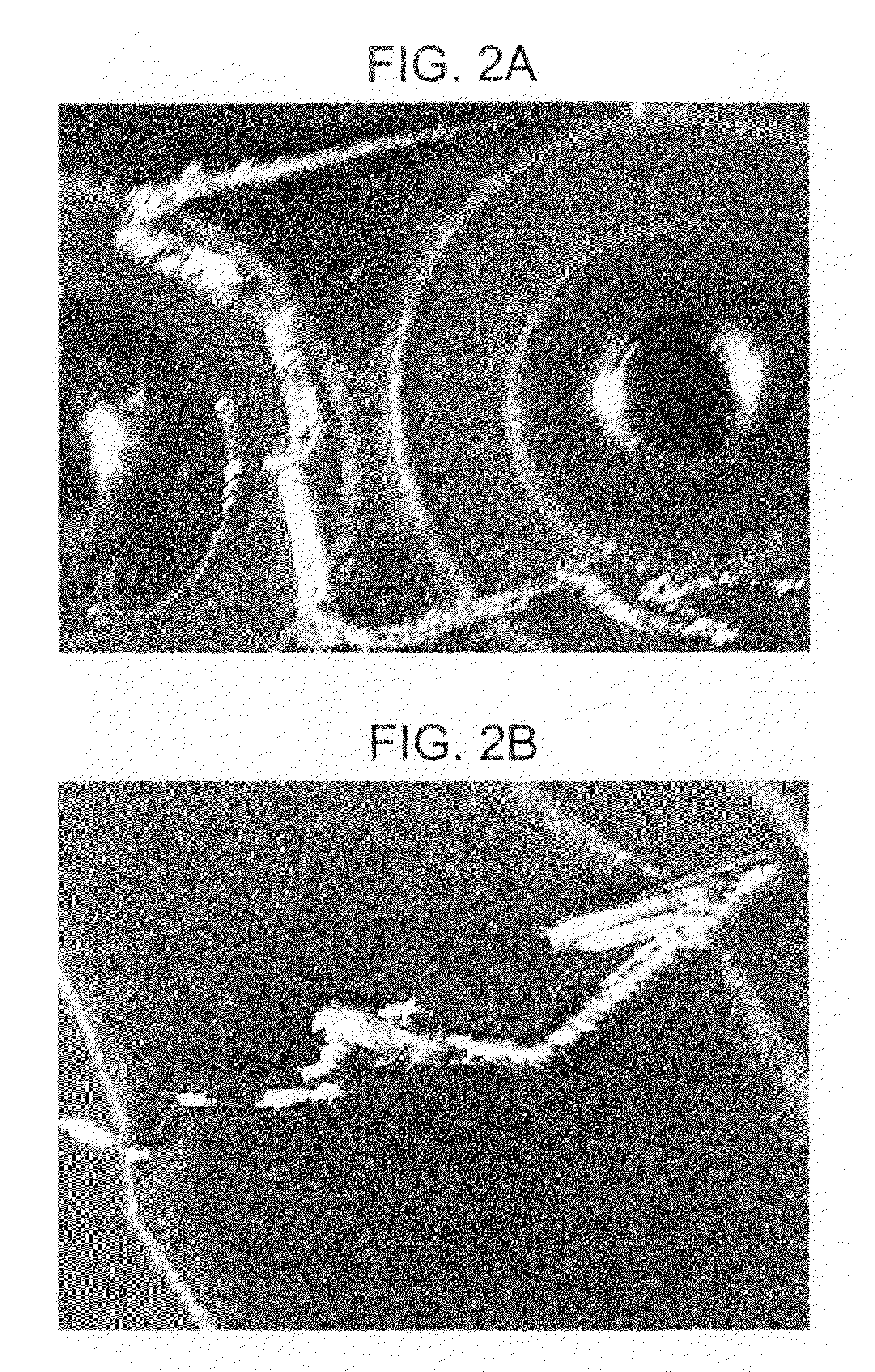

InactiveUS20090188804A1Reduced noduleImprove throwing powerCellsSolid-state devicesElectrolysisMetal alloy

Methods for depositing a metal or metal alloy on a substrate and articles made with the methods are described. The metal or metal alloy is deposited on the substrate electrolytically. The current is periodically interrupted during deposition to improve throwing power and reduce nodule formation on the metal or metal alloy deposit.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Preparation method of high-tinning-amount tinned plate and product

The invention belongs to the technical field of steelmaking, and particularly relates to a preparation method of a high-tinning-amount tinned plate and a product. The method comprises the following steps that cold-rolled strip steel is sequentially subjected to electrolytic alkali washing, electrolytic acid washing, electrotinning, soft melting, passivating and oiling, and the high-tinning-amounttinned plate is obtained; in the electrolytic pickling process, a sulfuric acid aqueous solution with the concentration of 40-50 g / L is adopted as an electrolytic pickling solution; and the temperature of the electrolytic pickling solution is 40-60 DEG C. According to the method, in the process of preparing the high-tinning-amount tinned plate, a series of optimization is carried out on the basisof novel environment-friendly electroplating solution MSA and induction soft melting process technology and aiming at the technical scheme influencing the corrosion resistance index, so that the production difficulty of an existing production process is reduced, and the corrosion resistance of the obtained high-tinning-amount tinned plate is superior to industrial requirements.

Owner:SHOUGANG CORPORATION

Metal surface treatment liquid for cation electrodeposition coating

ActiveUS8221559B2Improve throwing powerExcessive depositionElectrolysis componentsVolume/mass flow measurementAluminum IonIndium

A surface treatment with a zirconium ion that enables sufficient throwing power and superior anti-corrosion properties to be exhibited when thus surface treated metal base material is subjected to cation electrodeposition coating is provided. A metal surface treatment liquid thereof for cation electrodeposition coating includes zirconium ions, copper ions, and other metal ions, and having a pH of 1.5 to 6.5, in which: the other metal ions are at least one selected from the group consisting of tin ions, indium ions, aluminum ions, niobium ions, tantalum ions, yttrium ions and cerium ions; the concentration of zirconium ions is 10 to 10,000 ppm; the concentration ratio of the copper ions to the zirconium ions is 0.005 to 1 on a mass basis; and the concentration ratio of the other metal ions to the copper ions is 0.1 to 1,000 on a mass basis.

Owner:NIPPON PAINT SURF CHEM

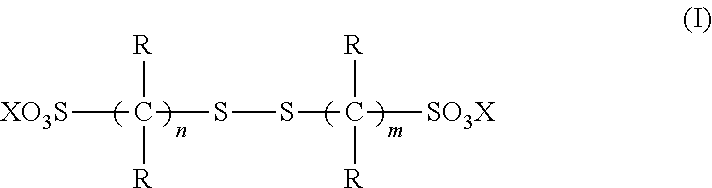

Method of filling through-holes

InactiveUS20140262801A1Reduce and inhibit dimple formationReduce and inhibit and voidLiquid/solution decomposition chemical coatingPrinted circuit manufactureCopperElectroplating

The methods inhibit or reduce dimpling and voids during copper electroplating of through-holes with flash copper layers in substrates such as printed circuit boards. An acid solution containing disulfide compounds is applied to the through-holes of the substrate followed by filling the through-holes with copper using an acid copper electroplating bath which includes additives such as brighteners and levelers.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Method of filling through-holes to reduce voids and other defects

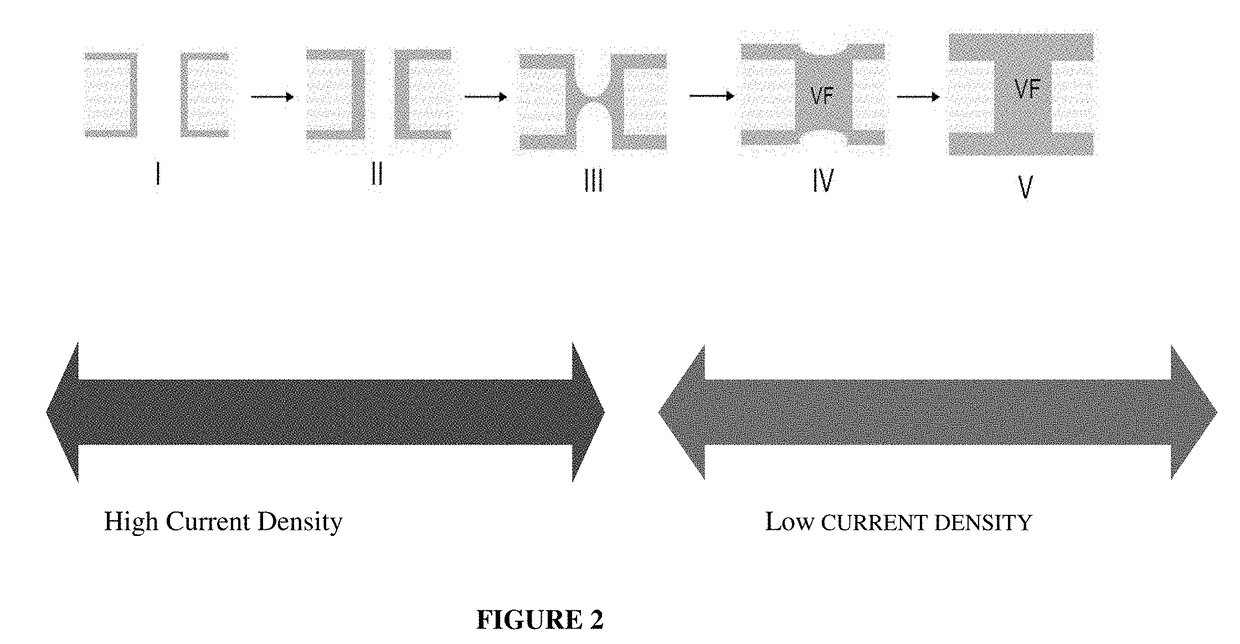

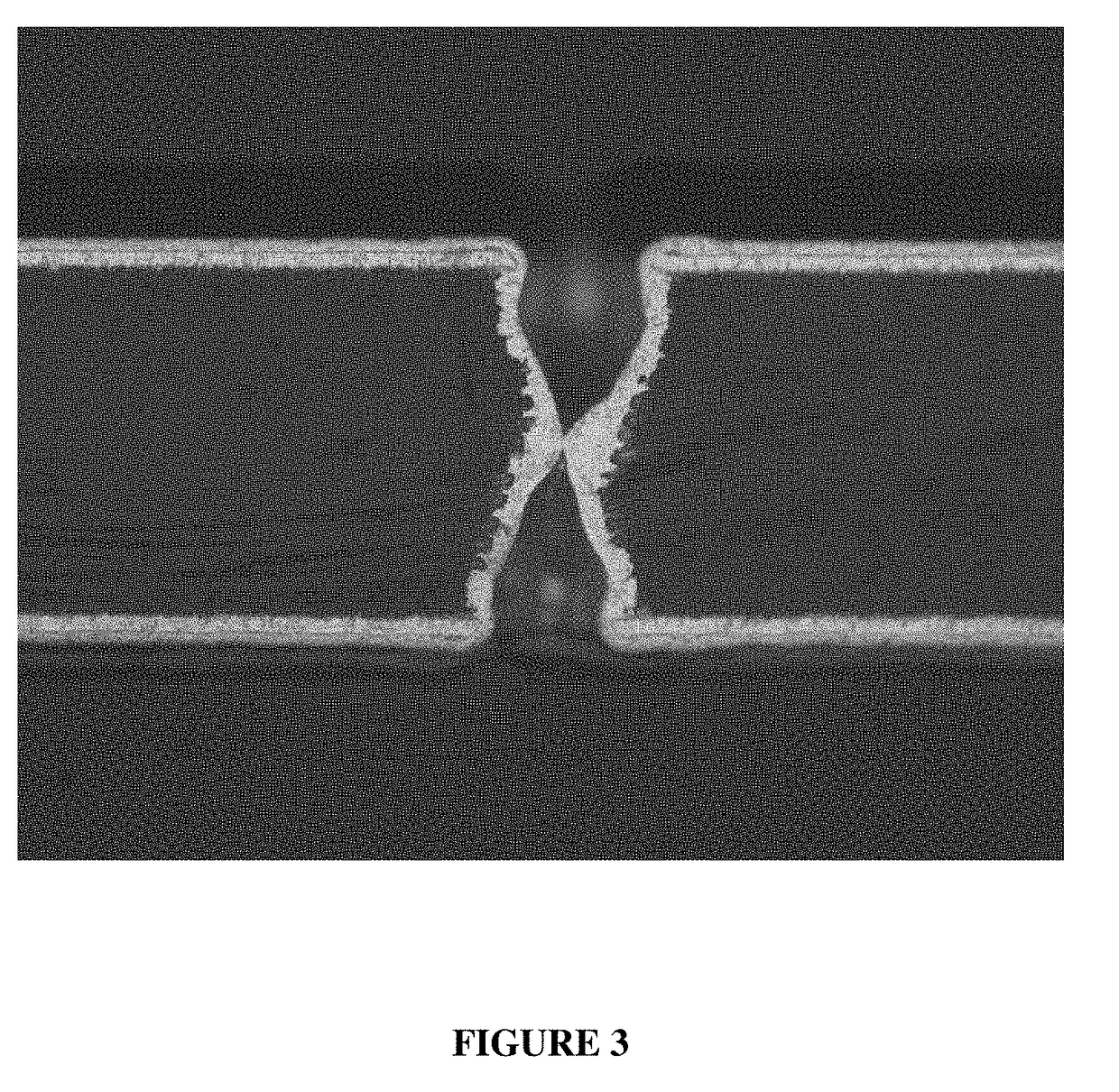

ActiveUS20170238427A1Reduce and inhibit dimple formationReduce and inhibit and voidPrinted circuit aspectsLiquid/solution decomposition chemical coatingHigh current densityPower flow

Direct current plating methods inhibit void formation, reduce dimples and eliminate nodules. The method involves electroplating copper at a high current density followed by electroplating at a lower current density to fill through-holes.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Method for electroplating stannum-cerium-bismuth alloy on microwave high-frequency circuit board

ActiveCN101899691AReduce the amount of side corrosionHigh precisionElectrolysis componentsSoldering apparatusMicrowaveCerium

The invention discloses a method for electroplating stannum-cerium-bismuth alloy on a microwave high-frequency circuit board, which comprises the following steps of: firstly, opening a cylinder for medicinal liquid for a electroplating stannum-cerium-bismuth alloy process; and secondly, electroplating the stannum-cerium-bismuth alloy according to a graph to complete the manufacturing of the process for electroplating the stannum-cerium-bismuth alloy on the microwave high-frequency circuit board. The high-frequency circuit board prepared by the method has high weldability and corrosion resistance, high chemical stability and anti-interference, low medium consumption and high signal transmission.

Owner:TAIZHOU BOTAI ELECTRONICS

Extra-hardness chrome plating additive and application thereof

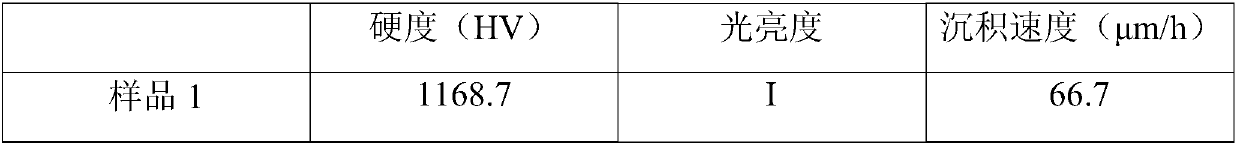

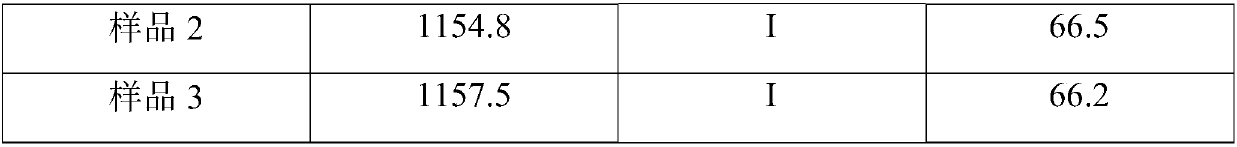

The invention relates to an extra-hardness chrome plating additive. The extra-hardness chrome plating additive comprises organic compounds containing single carbon atom, rare-earth cerium salts and VIB family oxysalts, wherein the mass ratio of the organic compounds containing the single carbon atom to the rare-earth cerium salts to the VI B family oxysalts is 1-5:0.002-0.1:0.02-0.04. Adding theadditive into the standard chrome plating solution for use, an obtained coating has a high hardness of 1150-1250HV, and meanwhile, the coating is good in brightness and has characteristics of omittingsubsequent mechanical polishing. No halogen family elements such as F are contained in the additive, the covering power and the current efficiency of the plating solution containing the additive arehigh, the plating solution has little corrosion to an anode, the operation process is simple, and the cost is low.

Owner:CHONGQING LIDAO SURFACE TECH

Acid cyanide-free cadmium plating additive, plating solution preparation and electroplating process

The invention discloses an acid non-cyanide cadmium-plating additive, preparation of a plating solution and an electro-plating process. The plating solution comprises the following components: 35-40 g / L of cadmium chloride, 140-180 g / L of potassium chloride, 120-160 g / L of a complexing agent, 1.5-2.5 mL / L of a brightener, and 25-35 mL / L of an auxiliary agent. Electro-plating operation conditions comprise that the plating bath temperature is 15-35 DEG C, the negative electrode current density is 0.5-1.5 A / dm<2>, the area ratio of a negative electrode to a positive electrode is 2 to 1, and the positive electrode comprises two materials of a cadmium plate and an electro-plating high-density graphite plate. The advantages mainly comprise that a brightener and an auxiliary agent are prepared by adopting a high-performance electro-plating additive intermediate, the combined complexing agent and cadmium ions are used for generating polybasic complex ions, and the performance of the plating solution and the performance of a plating layer are improved; the plating solution of the process is stable and is easy to maintain, the current efficiency is relatively high, the deep plating ability is strong, the brittleness of the plating layer is small, the corrosion resistance is good, various properties meet requirements of the Ministry of Astronautics Industry standards QJ 453-1988 ''cadmium plating layer technology conditions'', and electroplating wastewater treatment results meet requirements of GB 21900-2008 ''electroplating pollutant discharge standards'' table 3.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Plating compositions for electrolytic copper deposition, its use and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate

The present invention relates to a plating composition for electrolytic copper deposition, comprising copper ions, halide ions and at least one acid, at least one benzothiazole compound, at least onephenanzine dye and at least one ethanediamine derivative. The present invention further concerns the use of above plating composition and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate.

Owner:ATOTECH DEUT GMBH

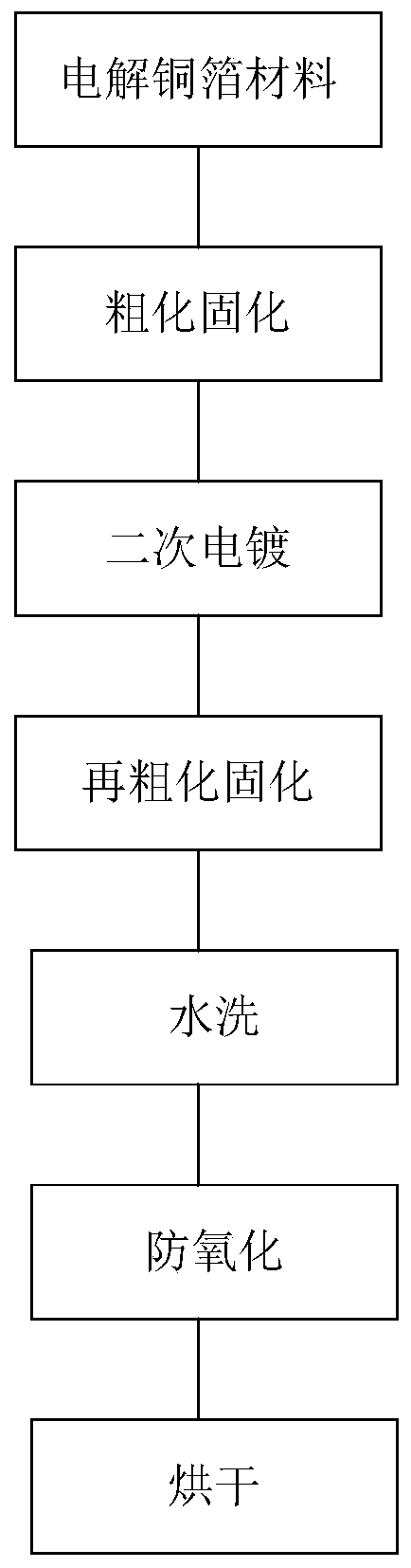

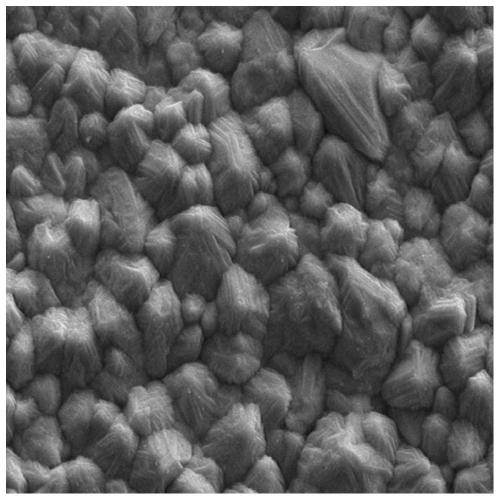

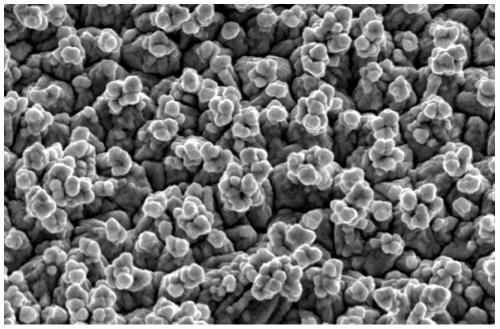

Preparation method of reverse copper foil

PendingCN111304700AImprove throwing powerIncrease brightnessElectroforming processesCopper foilIridium

The invention discloses a preparation method of reverse copper foil. The preparation method of the reverse copper foil comprises the following steps of electrolytic bath arrangement, addition agent addition, stirring operation, primary electroplating operation, primary roughening operation, primary curing operation, secondary electroplating operation, secondary roughening operation, secondary curing operation, cleaning operation, anti-oxidation treatment and drying operation. A titanium iridium anode plate and a titanium roller are adopted, an electrolytic solution is used in an electrolytic bath, specifically, the copper content of the electrolytic solution ranges from 130g / L to 220g / L, and the sulfuric acid content of the electrolytic solution ranges from 70g / L to 100g / L. When addition agents are added, the electrolytic solution is heated to enable the temperature to range from 45 DEG C to 50 DEG C, and 5-10 parts of WH-001 addition agents, 3-5 parts of WH-002 addition agents and 2-3parts of WH-003 addition agents by mass are added to 1000 parts of electrolytic solutions by volume every hour. When the secondary electroplating operation is conducted, 5-10 parts of WH-004 additionagents by mass are added. When the secondary roughening operation is conducted, 5-15 parts of WH-005 addition agents by mass are added, and the secondary roughening operation is accomplished. By theadoption of the technology, the potential barrier of metal nucleation is reduced, the nucleation speed is increased, high-density copper particle crystals can be formed on the surface of the copper foil, the non-uniformity degree of the surface is reduced, the mechanical property of the copper foil is improved, and therefore the tensile strength and the peeling resistance strength of the copper foil are improved.

Owner:深圳市惟华电子科技有限公司

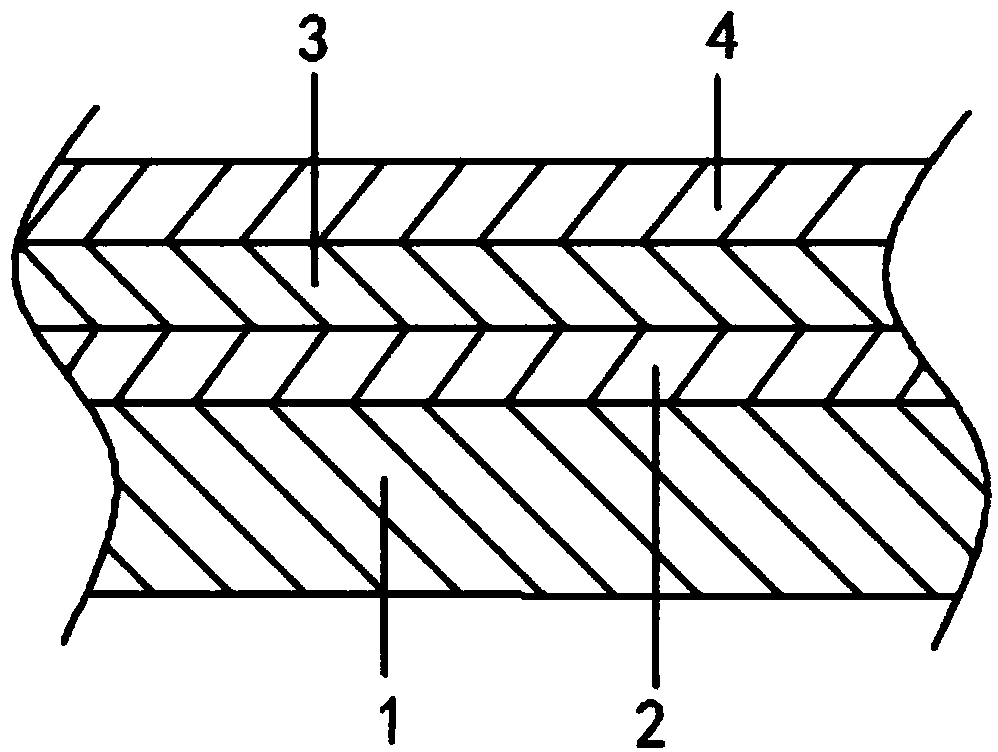

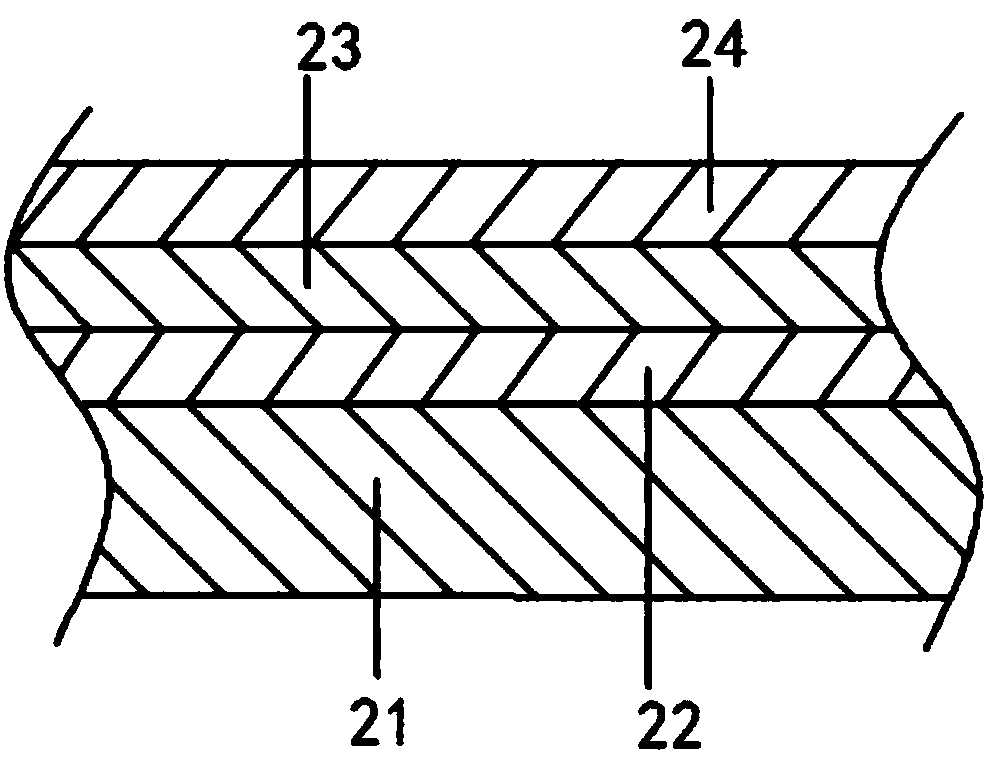

Preparation method of metal surface plating layer structure applicable to ocean severe corrosion environment

ActiveCN108385138AReduce the amount of inclusionsReduce difficultyMetallic material coating processesCyanideRare earth

The invention belongs to the field of electroplating, and particularly relates to a preparation method of a metal surface plating layer structure applicable to an ocean severe corrosion environment. The preparation method of the metal surface plating layer structure applicable to the ocean severe corrosion environment comprises the following steps of S1, pretreating a metal matrix; S2, preparing anon-cyanide cadmium plating layer; S3, preparing a rare-earth modified chromate low-chromium passivation layer; and S4, preparing a hydroxyl graphene modified confining bed. The plating layer prepared through the method provided by the invention is good in corrosion resistance, capable of remarkably prolonging the service life of the metal matrix, and suitable for the ocean severe corrosion environment.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Composite chrome plating additive

The invention discloses a composite chrome plating additive comprising an organic matter and an inorganic matter. The organic matter is alkyl-chain sulfonic acid and / or alkyl-chain disulfonic acid with a dose of 1-20g / L of standard chrome plating liquid. Or the organic matter is 0.01-0.1g / L of a nitrogen-containing organic compound. The inorganic matter is light rare earth fluoride with a dose of 0.001-0.01g / L of standard chrome plating liquid, and / or one of VA element oxides, hydroxides, and sulfates, wherein the dose of the VA element oxide or hydroxide or sulfate is 0.01-0.1g / L of standard chrome plating liquid. According to the invention, the organic matter and the inorganic matter are added into the standard chrome plating solution, such that advantages such as high current efficiency, good plating brightness, wide process brightness range, and good deep plating performance are provided. The plating has the advantages of high hardness, high current efficiency, no anode corrosion, wide process brightness range, good deep plating performance, simple operation process, and low cost.

Owner:太原特益达科技有限公司

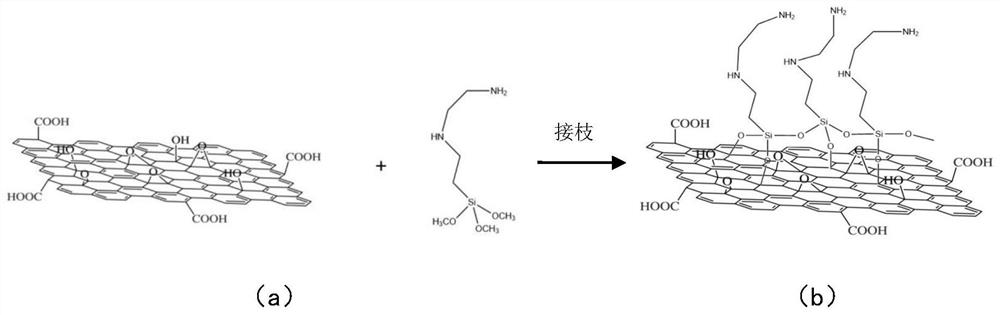

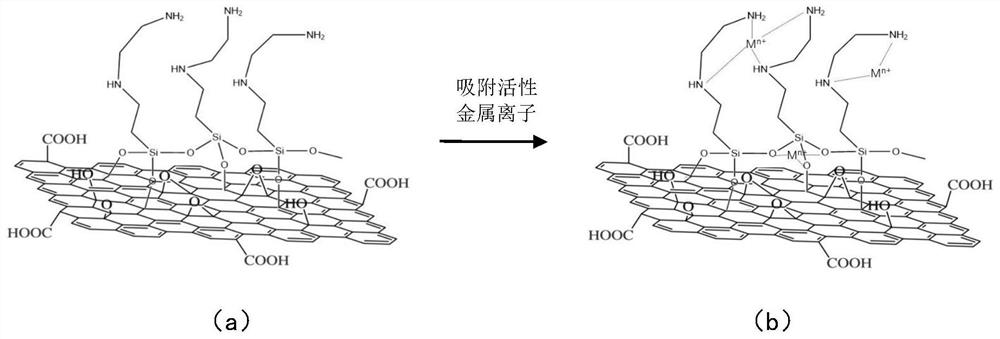

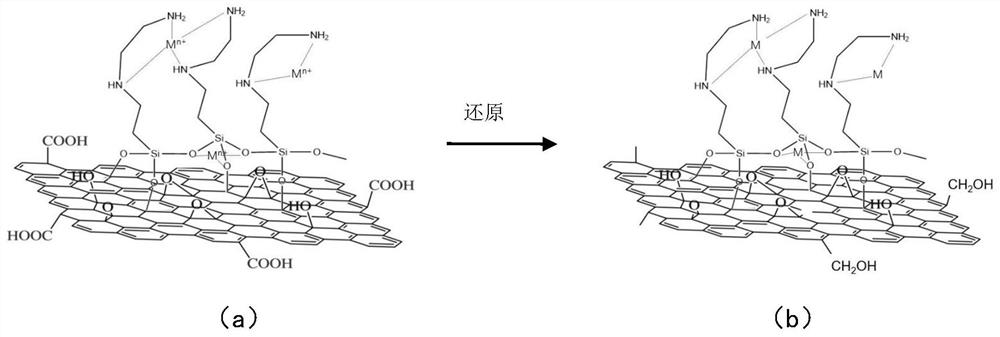

A kind of through-hole electroplating method of printed circuit board

The invention relates to a through-hole electroplating method of a printed circuit board, comprising the following steps: grafting graphene oxide with γ-aminoethylaminopropyltrimethoxysilane to obtain a product A; making the product A adsorb active metal ions, The product B is obtained; the product B is physically adsorbed to the surface of the insulating substrate of the through-hole wall of the printed circuit board to form an adsorption layer; the adsorption layer is converted into a conductive layer through a chemical reduction process; the through-hole wall with a conductive layer is electroplated A metal layer is formed. In the present invention, graphene oxide is selected and grafted with γ-aminoethylaminopropyltrimethoxysilane. Due to the formation of high-density oxygen bond functional sites at the grafting interface, the adsorption capacity for active metal ions is effectively improved, and the conductive layer The ethylenediamine groups on the surface can effectively improve the ability to capture copper ions in the solution during the electroplating process, accelerate the mass transfer of copper ions, and facilitate the accelerated deposition of copper plating in the holes, thereby greatly enhancing the uniformity of the plating solution. Plating ability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Snow making apparatus and method

ActiveUS8376245B2Reduce energy consumptionPrevent freezingRecreational ice productionLighting and heating apparatusWater flowPhysics

A low energy snow making gun having at least one but preferably three operational stages each having at least one pair of small aperture water outlets which are oriented at a divergent angle to generate a respective pair of narrow angled water droplet streams which do not interfere with each other until they have reached a distance from the gun. A second pair of water outlets may be provided on each stage with each pair on each stage oriented at a divergent angle to maintain singularity of the streams over a distance thereby increasing the throwing power of the gun.

Owner:RATNIK IND

Method of filling through-holes

InactiveUS9598787B2Formation is also reduced and inhibitedImprove throwing powerLiquid/solution decomposition chemical coatingPrinted element electric connection formationNitrogenCopper

The methods inhibit or reduce dimpling and voids during copper electroplating of through-holes with flash copper layers in substrates such as printed circuit boards. An acid solution containing reaction products of aromatic heterocyclic nitrogen compounds and epoxy-containing compounds is applied to the through-holes of the substrate followed by filling the through-holes with copper using a copper electroplating bath which includes additives such as brighteners and levelers.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

A kind of cyanide-free sulfite gold plating solution and its application

The invention relates to the field of gold plating, and discloses a cyanide-free sulfite gold plating solution and an application thereof. The cyanide-free sulfite gold plating solution contains gold sulfite, alkali metal sulfite, and 3-nitrobenzenesulfonic acid Salts, organic polyamines, organic phosphonates, polyol compounds, high molecular polymers containing imines, and thiourea compounds. The cyanide-free sulfite gold plating solution provided by the present invention contains a current efficiency stabilizer with excellent properties, which participates in the reduction process of the cathode during the gold plating process, and prevents the occurrence of chemical side reactions, thereby improving the current efficiency, which is obviously beneficial Improve the throwing ability of the plating solution. And it improves a series of problems such as the inaccurate prediction of the amount of gold plating caused by the low current and unstable current efficiency, the relatively poor dispersion ability of the plating solution and the low current density.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

Acid electroplating galvanizing bath additive and its application method

The invention discloses an additive for an acidic electro-galvanizing bath and an application method thereof. The components of the additive and their weight percentages are as follows: 10-90% of long-chain alkane benzene sulfonate or / and heterocyclic organic amine; 10 ~90% water or / and ethanol. This additive improves the brightness and flatness of the galvanized layer, and has good dispersion and coverage capabilities. Adding this additive to the acidic plating solution can obtain high temperature in a wide temperature range and a large current density range The surface performance of the electro-galvanized layer improves the throwing ability of the galvanizing process, and also reduces the corrosion of the acid bath to the electro-galvanized equipment; the additive of the present invention has the advantages of less dosage, high efficiency, non-toxic and odorless, and completely water-soluble , wide application range and other advantages; the application method of this additive is simple, directly add 50-1000ppm of this additive to the acidic electro-galvanizing bath for electro-galvanizing, and you can obtain electro-plating with good surface properties, small internal stress of the coating, and high corrosion resistance Zinc layer and short processing time.

Owner:武汉钢铁有限公司

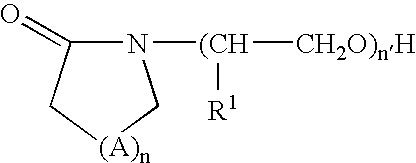

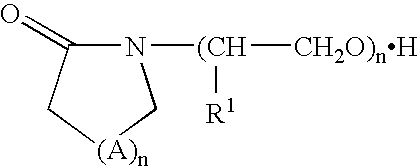

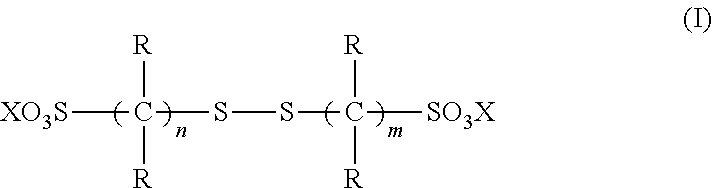

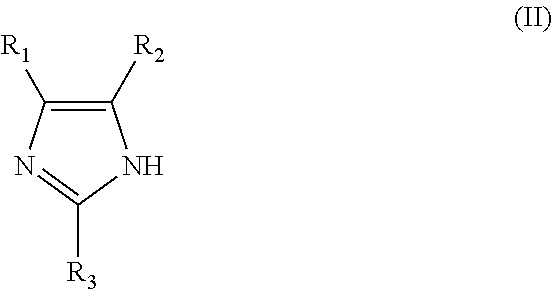

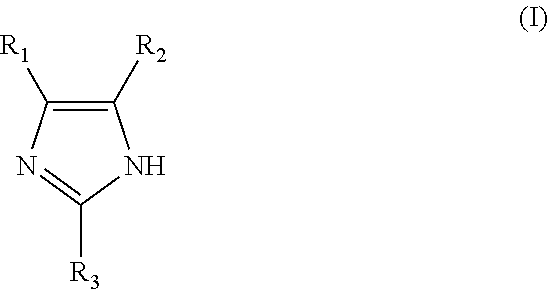

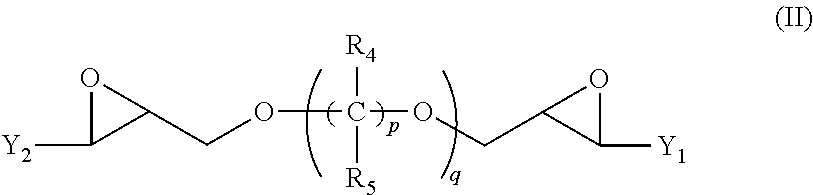

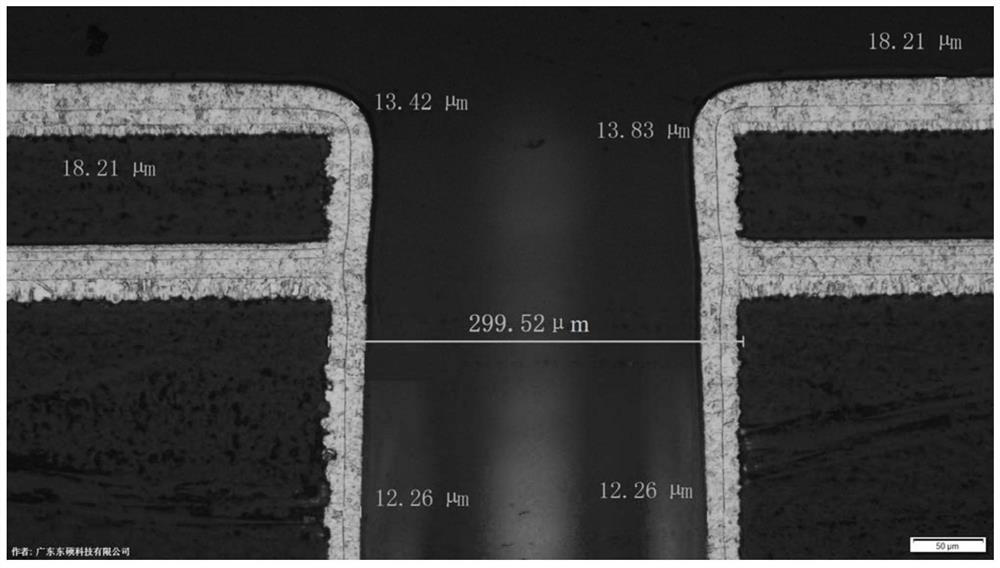

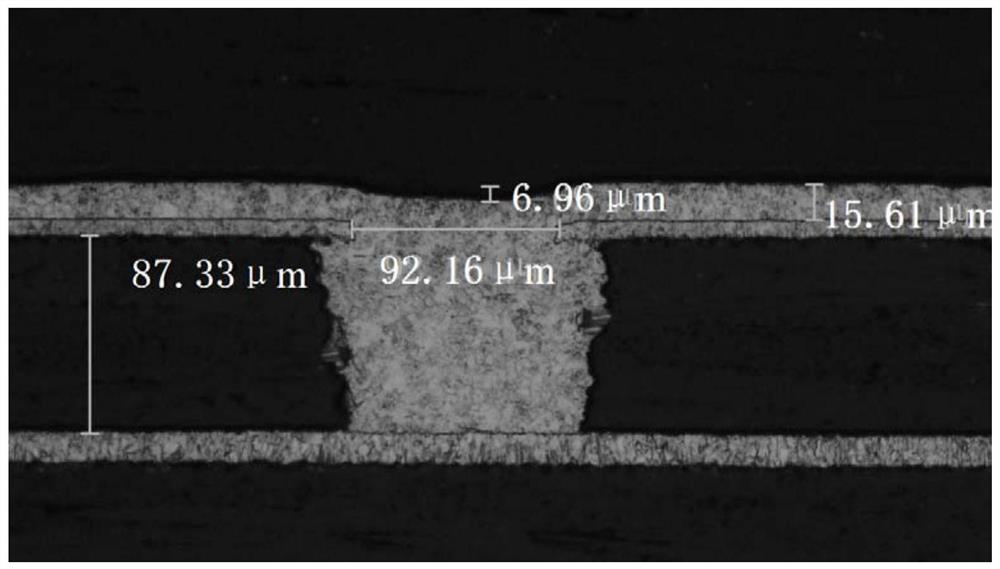

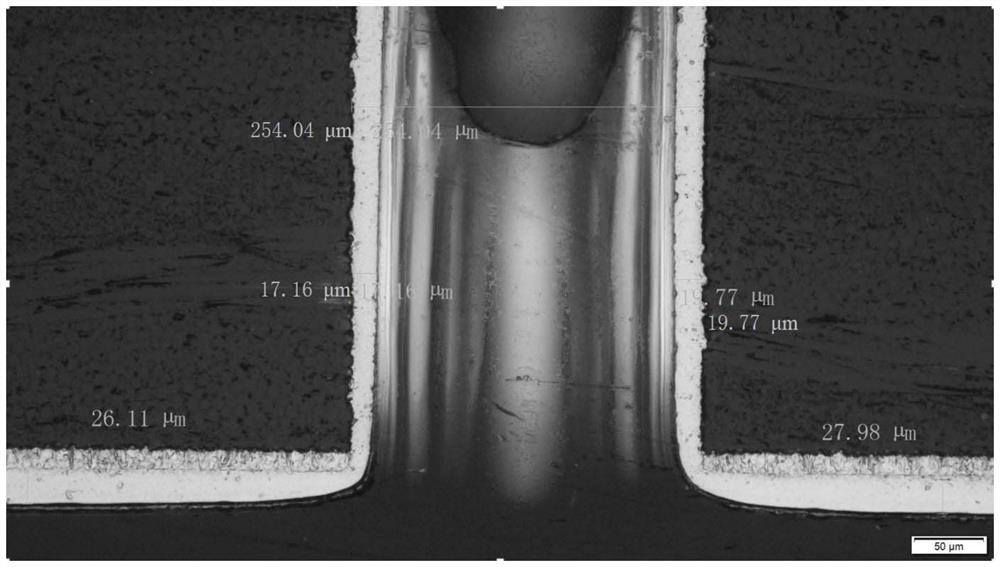

Leveler and electroplating solution containing same

ActiveCN110129841BImprove throwing powerImprove the thin problemOrganic chemistryEpoxide CompoundBis epoxide

The invention relates to a leveling agent and an electroplating solution containing the same, wherein the leveling agent includes functional components, and the functional components are reaction products formed by reacting imidazole compounds, tertiary amine compounds and epoxy compounds. The leveling agent can be better applied to the co-plating process of through-blind holes, and can effectively avoid the problem that the plating layer inside the through-hole and the corner of the through-hole opening is too thin.

Owner:GUANGDONG TONESET SCI & TECH

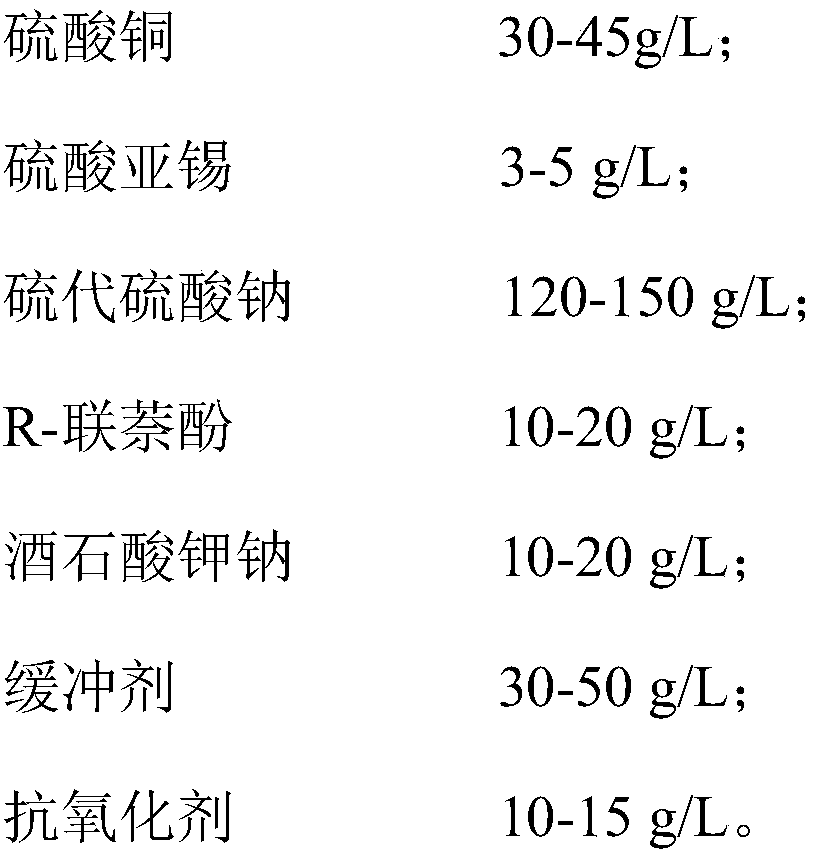

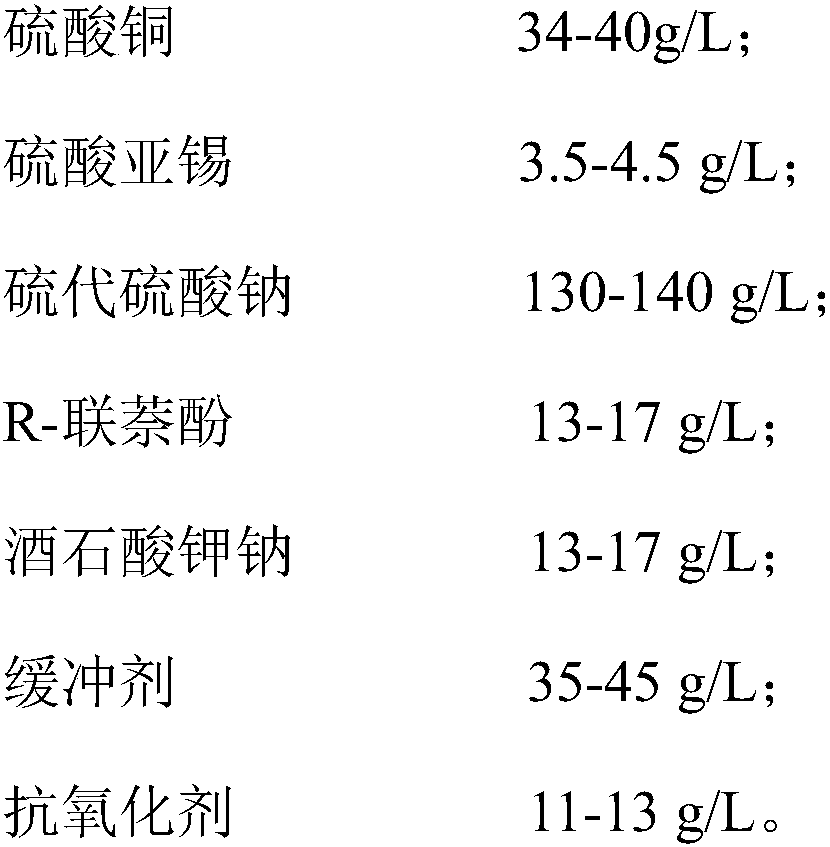

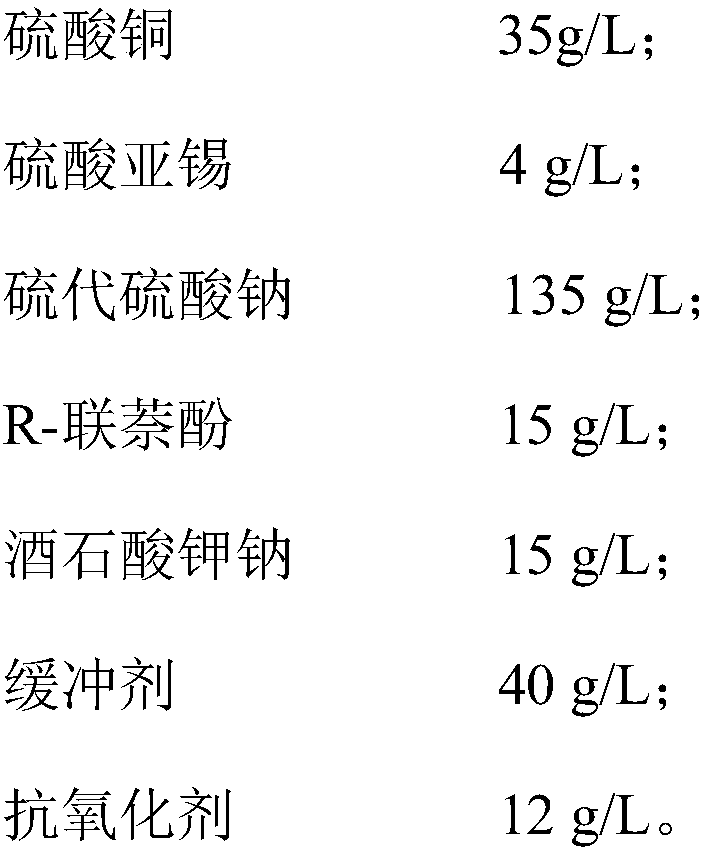

Electroplating solution for cyanide-free electroplating of tin bronze for iron and steel parts and its preparation method and electroplating method

The invention discloses a cyanide-free tin-bronze electroplating solution for steel parts, and a preparation method and an electroplating method thereof, and relates to the technical field of tin-bronze electroplating. The tin-bronze electroplating solution comprises 30-45 g / L of copper sulfate, 3-5 g / L of tin sulfate, 120-150 g / L of sodium thiosulfate; 10-20 g / L of R-binaphthol, 10-20 g / L of potassium sodium tartrate, 30-50 g / L of buffering agents and 10-15 g / L of antioxidants according to the mass concentration; and the cyanide-free tin-bronze electroplating solution for the steel parts adopts water as solvents. The invention further discloses the preparation method and the electroplating method of the cyanide-free tin-bronze electroplating solution for the steel parts. The cyanide-freetin-bronze electroplating solution for the steel parts, prepared with the above preparation method, is used for electroplating according to the electroplating method provided by the invention; coatings obtained by electroplating are distributed evenly and smoothly, and are large in thickness and high in glossiness; and the adhesive force between the coatings and the substrate of the steel parts isimproved obviously, and the electroplating solution, and the preparation method and an electroplating method thereof have wide application prospects.

Owner:湖南金泰环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com