Method of filling through-holes

a technology of through-holes and copper plating, which is applied in the direction of liquid/solution decomposition chemical coatings, coatings, printed circuit manufacturing, etc., can solve the problems of copper plating's tendency to fill through-holes, the difficulty of copper plating's high aspect ratio, and the way it tends to fill, so as to reduce or inhibit the formation of dimples and voids, good through-hole filling, and the effect of improving throwing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Comparative

[0030]Two FR4 / glass-epoxy coupons 5 cm wide, 15 cm long and 100 μm thick with a plurality of through-holes were provided by Tech Circuit. The through-holes had an average diameter of 100 μm. The coupons contained a layer of electroless copper on one side and on the walls of the through-holes. The thickness of the copper layer on each coupon was 0.3 μm. The two coupons were pre-cleaned using a conventional copper cleaner. One coupon was placed into a dessicator. The other coupon was then placed in a plating cell which contained a copper electroplating bath with a formula as shown in Table 1.

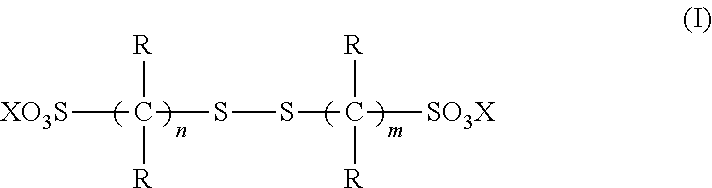

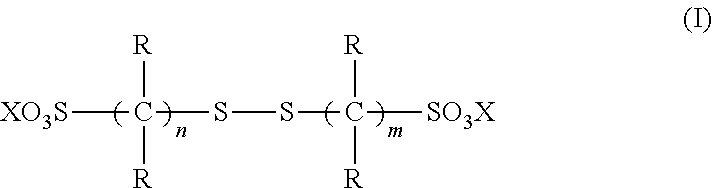

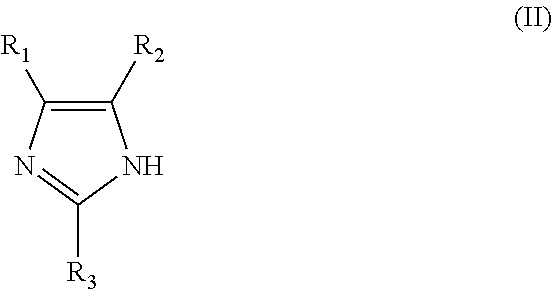

TABLE 1COMPONENTAMOUNTCopper sulfate pentahydrate220g / LSulfuric acid40g / LChloride ion from hydrochloric acid50ppmPolyethylene glycol2g / L4-phenylimidazole / imidazole / 1,4-butandiol50mg / Ldiglycidyl ether copolymerBis-sodium sulfopropyl)-disulfide10mg / L

[0031]The coupon was connected to a conventional DC rectifier. The counter electrode in each plating cell was an insoluble. The plating bath ...

example 2

Comparative

[0033]Three FR4 / glass-epoxy coupons 5 cm wide, 15 cm long and 100 μm thick with a plurality of through-holes were provided by Tech Circuit. The through-holes had an average diameter of 100 μm. The coupons were processed through electroless copper using CIRCUPOSIT™ 880 Electroless Process plating formulations and method. The thickness of the electroless copper layer on each coupon was 0.3 μm. Each coupon was cleaned and electroplated with a flash copper layer 5 μm thick as described in Example 1 above. Each coupon was then placed in a dessicator during the interim before further processing to discourage any oxide formation on the copper.

[0034]Upon removal of the coupons from the dessicator, they were cleaned using a conventional copper cleaner to remove any possible oxide layer and have a clean copper surface for plating. Each coupon was then placed into separate plating cells with a fresh copper electroplating bath having the formulation in Table 1. The plating baths were...

example 3

[0035]Three FR4 / glass-epoxy coupons 5 cm wide, 15 cm long and 100 μm thick with a plurality of through-holes were provided by Tech Circuit. The through-holes had an average diameter of 100 μm. The coupons had a layer of electroless copper 0.3 μm thick. Each coupon was cleaned and electroplated with a flash copper layer 5 μm thick as described in Example 1 above. The coupons were stored in a dessicator prior to further treatment and plating.

[0036]Upon removal from storage, the flashed coupons were cleaned to remove any oxide layer and have a clean copper surface for plating. After cleaning, one coupon was transferred to a plating bath having the formula of Table 1. The second coupon was first immersed in an aqueous solution of 5.5 ppm bis(3-sulfopropyl)disulfide, sodium salt (SPS) and 10 wt % sulfuric acid for two minutes and then transferred into the copper electroplating bath. Copper electroplating was done at a current density of 1.5 A / dm2 with continuous air agitation of the bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com