Electroplating solution for cyanide-free electroplating of tin bronze for iron and steel parts and its preparation method and electroplating method

A technology of tin electroplating and electroplating solution, which is applied in the field of electroplating tin bronze, can solve the problems of insufficient uniformity and smoothness of the coating layer, poor deep plating ability and throwing ability of the electroplating solution, and influence on the popularization and application of the electroplating solution, so as to improve the deep plating ability and plating The effect of rapid rise and cathodic polarization is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

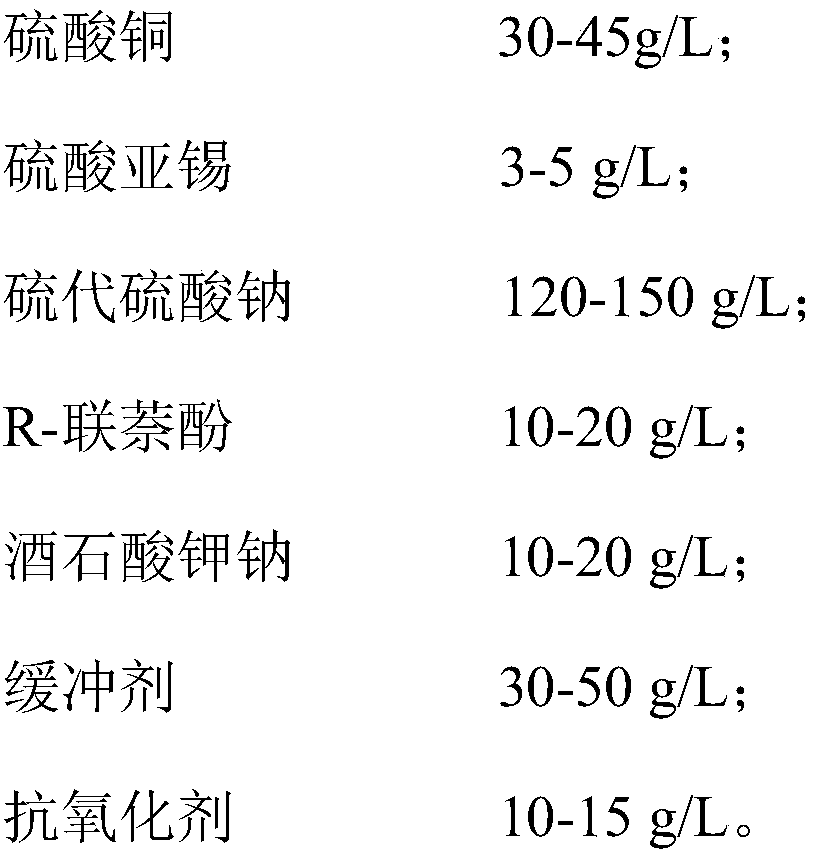

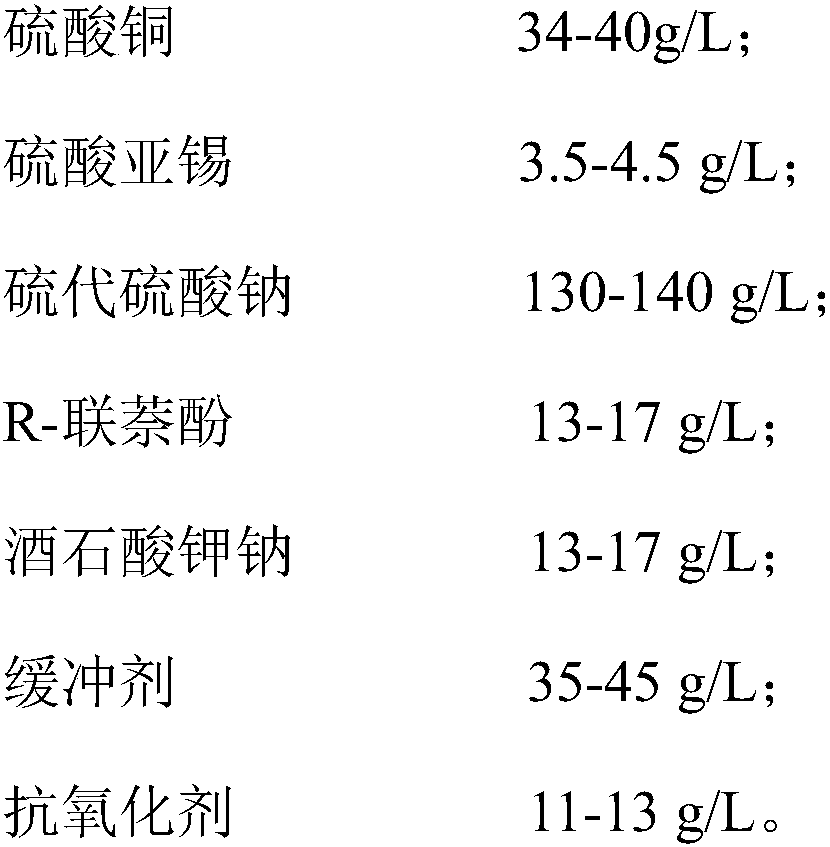

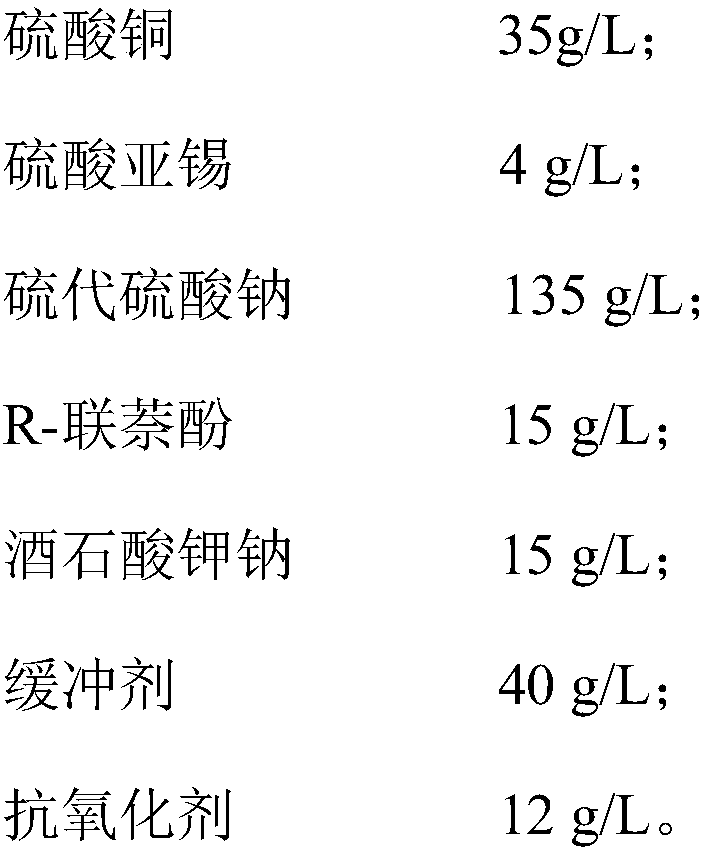

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are provided below to specifically describe the present invention. It is necessary to point out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Some non-essential improvements or adjustments made by the embodiments to the present invention still belong to the protection scope of the present invention.

[0039] 1. the electroplating solution of the iron and steel part cyanide-free electroplating tin-bronze in embodiment 1-5 and comparative example 1-8 all adopts following method preparation:

[0040] a. Dissolve sodium thiosulfate, potassium sodium tartrate and half of buffering agent in warm water at 30-35°C, and then dissolve copper sulfate under stirring;

[0041] b. Add the other half of the buffer, measure the pH value of the solution with pH test paper, adjust the pH to 8-9 with sodium hydroxide or phosphoric acid, and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com