A kind of electrolytic copper foil additive and electrolytic copper surface treatment process

An electrolytic copper foil and surface treatment technology, which is applied in the field of electrolytic copper foil additives and electrolytic copper surface treatment technology, can solve the problem of limited performance improvement of copper foil anti-peel strength, oxidation resistance, etc., which cannot meet environmental protection, harmlessness and reliability. Continuous development, limited improvement of copper foil oxidation resistance and anti-stripping performance, etc., to achieve the effect of improving oxidation resistance and anti-stripping ability, easy operation and implementation, and non-corrosion operation implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

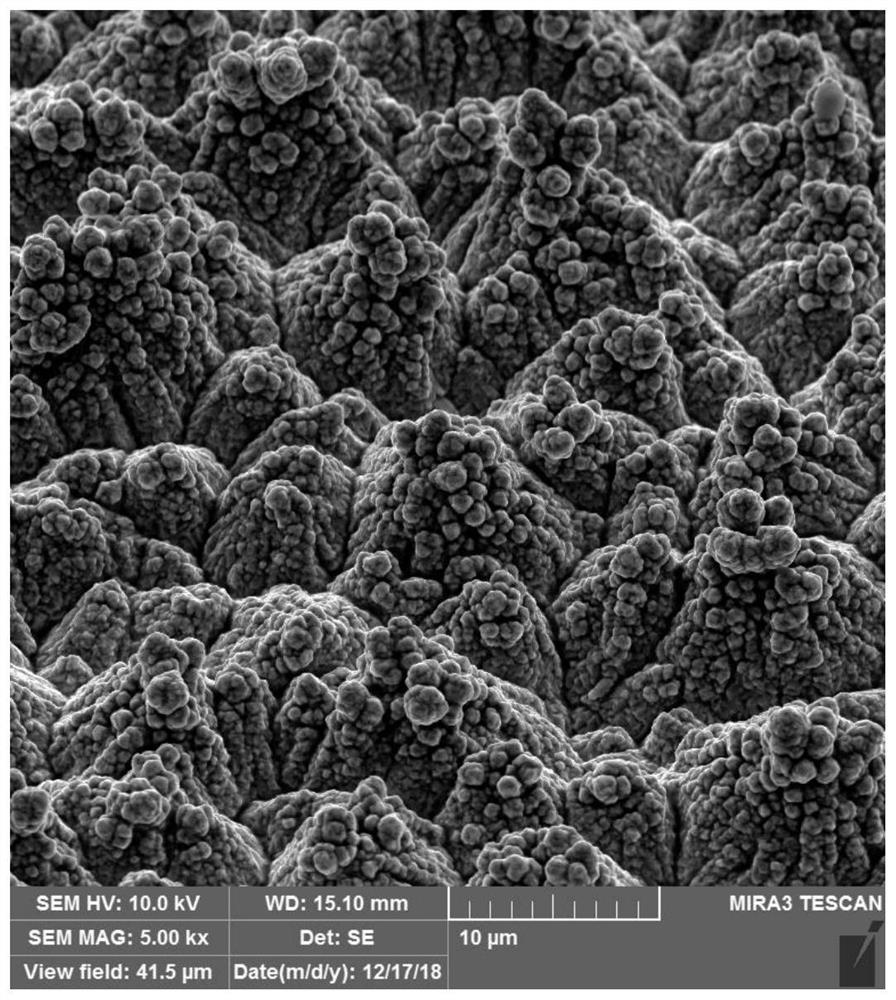

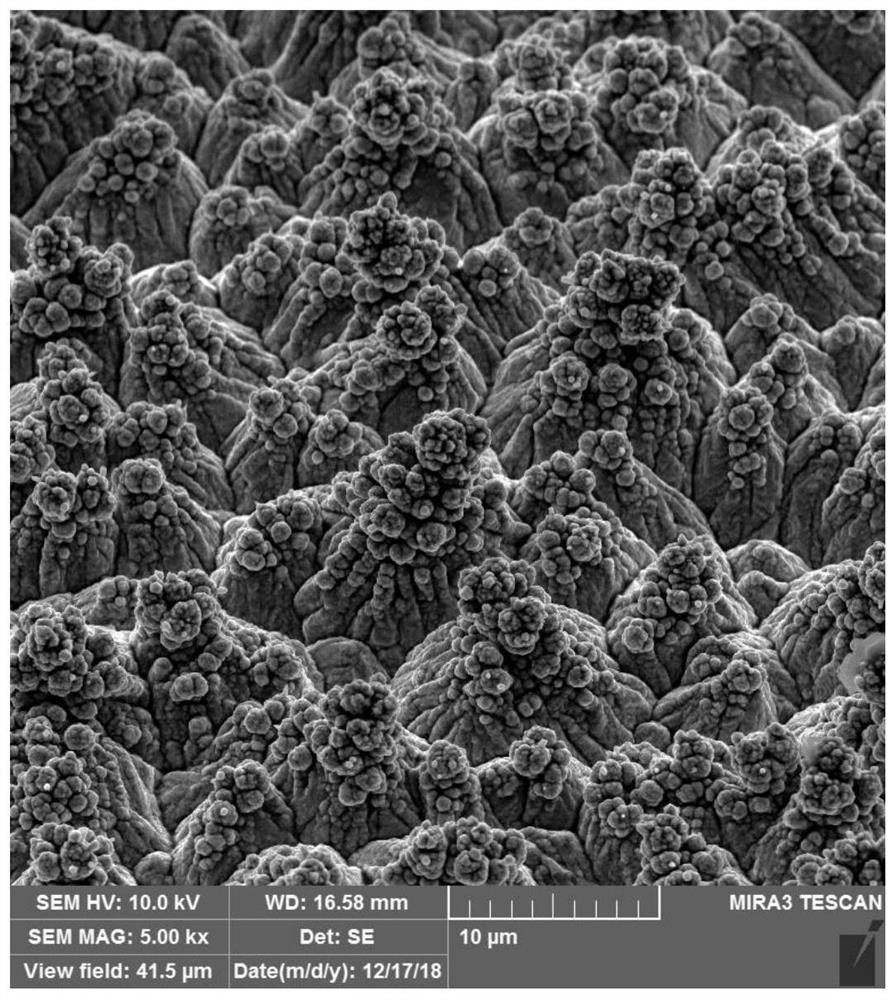

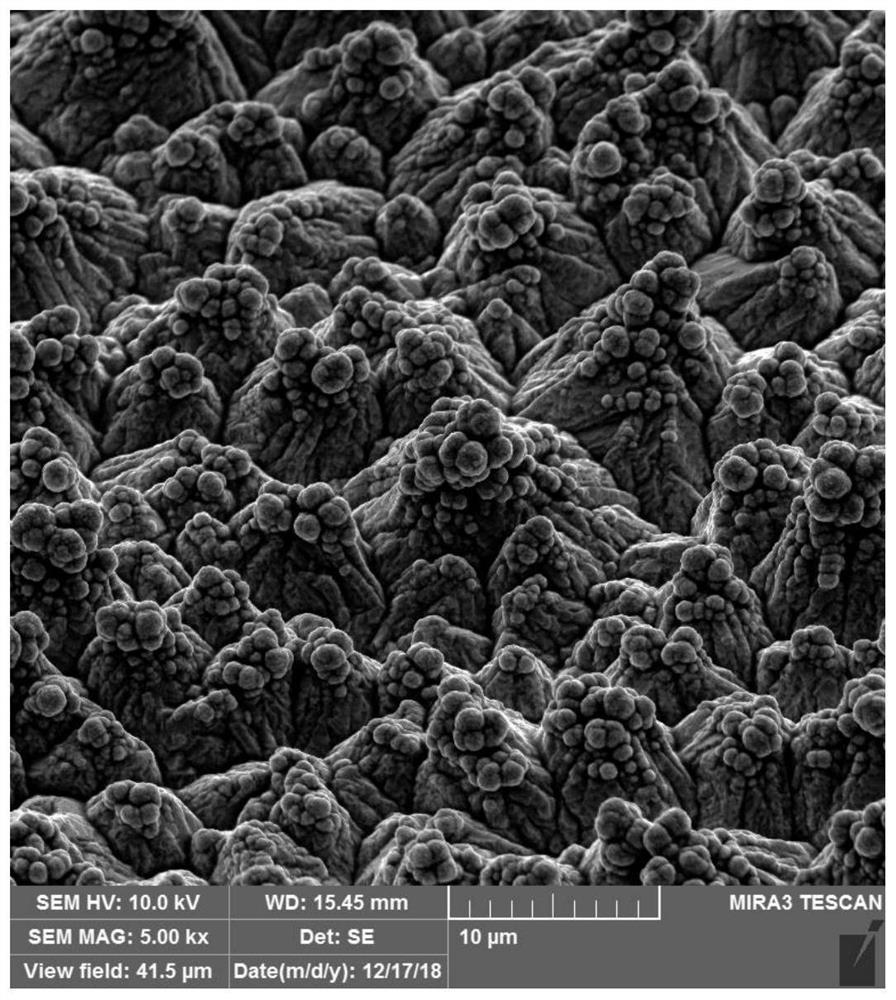

Image

Examples

Embodiment 1

[0031] An additive for electrolytic copper foil, comprising sodium phosphotungstate, polyethylene glycol and sodium polydithiodipropane sulfonate, the content of the sodium phosphotungstate in the electroplating solution is 100mg / L; the polyethylene glycol is The content in the electroplating solution is 80mg / L; the content of the sodium polydisulfide dipropane sulfonate in the electroplating solution is 200mg / L;

[0032] The present invention also provides a surface treatment process for electrolytic copper foil, comprising the following steps:

[0033] Step 1. Pickling: Dilute the concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10wt%, pump it into the pickling tank, place the copper foil in the pickling tank for 3 seconds, and clean the surface of the copper foil with deionized water after soaking;

[0034] Step 2, roughening: the cleaned copper foil enters a roughening tank filled with a roughening solution to electroplate a microcrystalline rough...

Embodiment 2

[0040] An additive for electrolytic copper foil, comprising sodium phosphotungstate, polyethylene glycol and sodium polydithiodipropane sulfonate, the content of the sodium phosphotungstate in the electroplating solution is 120mg / L; the polyethylene glycol is The content in the electroplating solution is 120mg / L; the content of the sodium polydisulfide dipropane sulfonate in the electroplating solution is 300mg / L;

[0041] The present invention also provides a surface treatment process for electrolytic copper foil, comprising the following steps:

[0042] Step 1, pickling: dilute the concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10wt%, pump it into the pickling tank, place the copper foil in the pickling tank and soak for 5s, and after soaking, clean the surface of the copper foil with deionized water;

[0043] Step 2, roughening: the cleaned copper foil enters a roughening tank filled with a roughening solution to electroplate a microcrystalline rou...

Embodiment 3

[0049] An additive for electrolytic copper foil, comprising sodium phosphotungstate, polyethylene glycol and sodium polydithiodipropane sulfonate, the content of the sodium phosphotungstate in the electroplating solution is 150mg / L; the polyethylene glycol is The content in the electroplating solution is 120mg / L; the content of the sodium polydisulfide dipropane sulfonate in the electroplating solution is 150mg / L;

[0050] The present invention also provides a surface treatment process for electrolytic copper foil, comprising the following steps:

[0051] Step 1. Pickling: Dilute the concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10wt%, pump it into the pickling tank, place the copper foil in the pickling tank for 3 seconds, and clean the surface of the copper foil with deionized water after soaking;

[0052] Step 2, roughening: the cleaned copper foil enters a roughening tank filled with a roughening solution to electroplate a microcrystalline roug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com