Patents

Literature

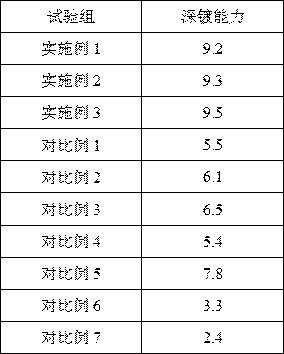

63results about How to "Improve deep plating ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

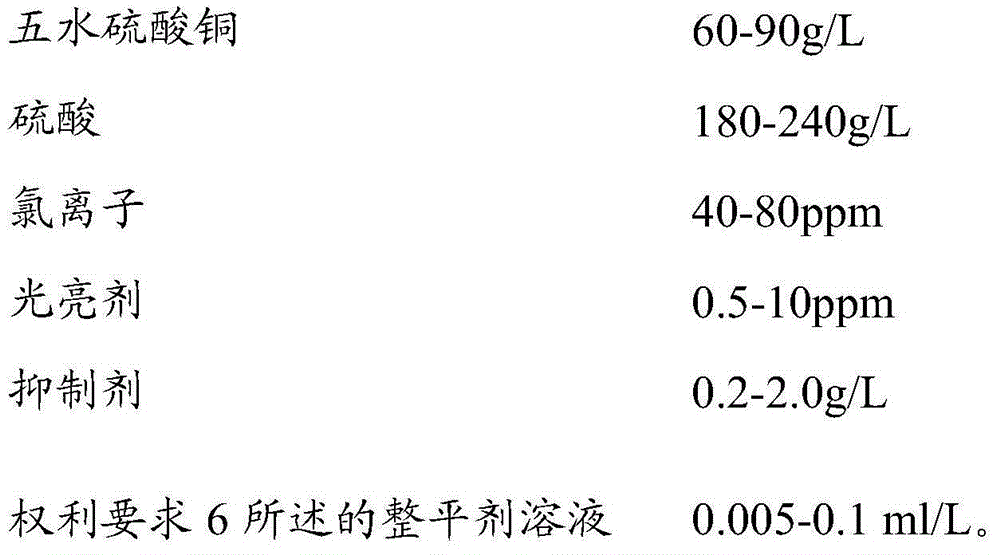

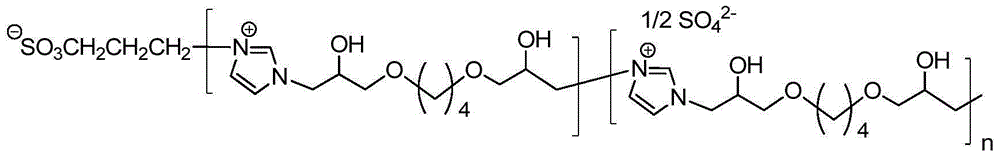

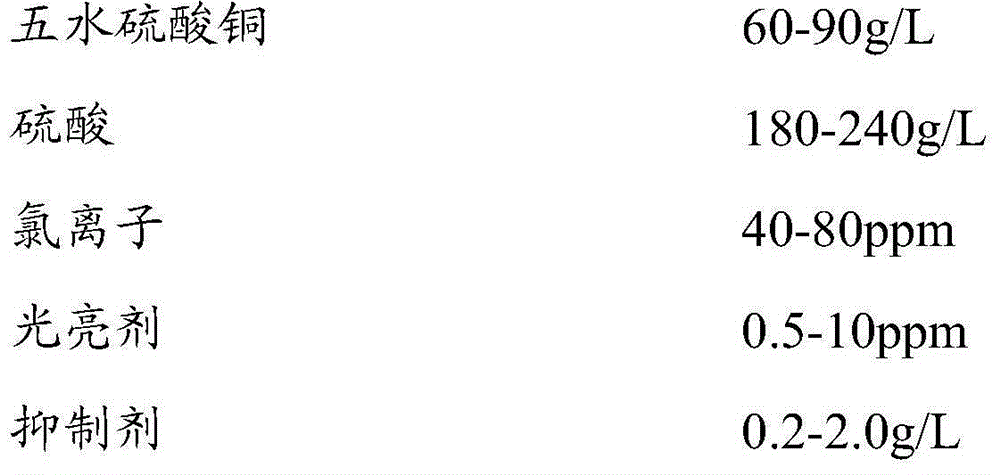

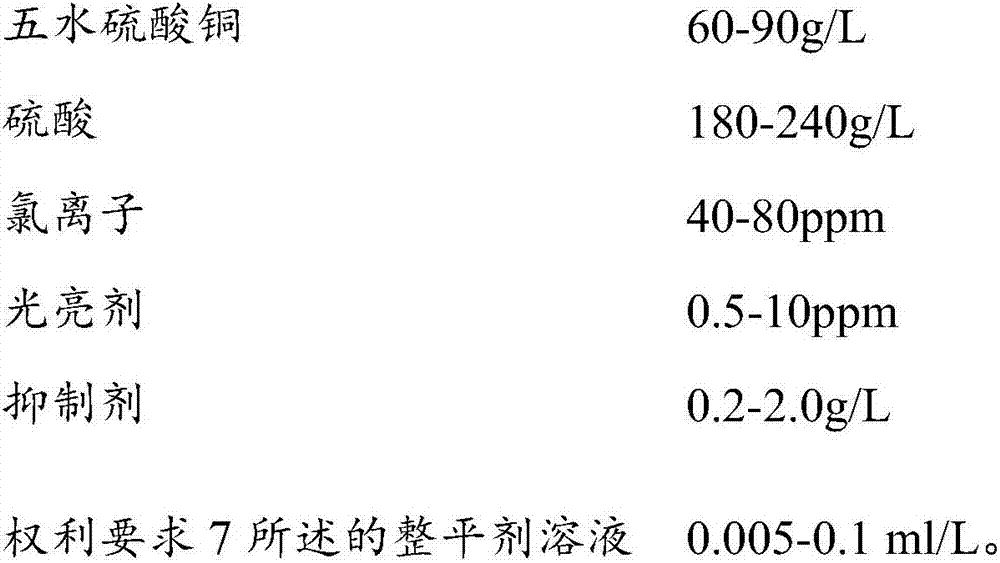

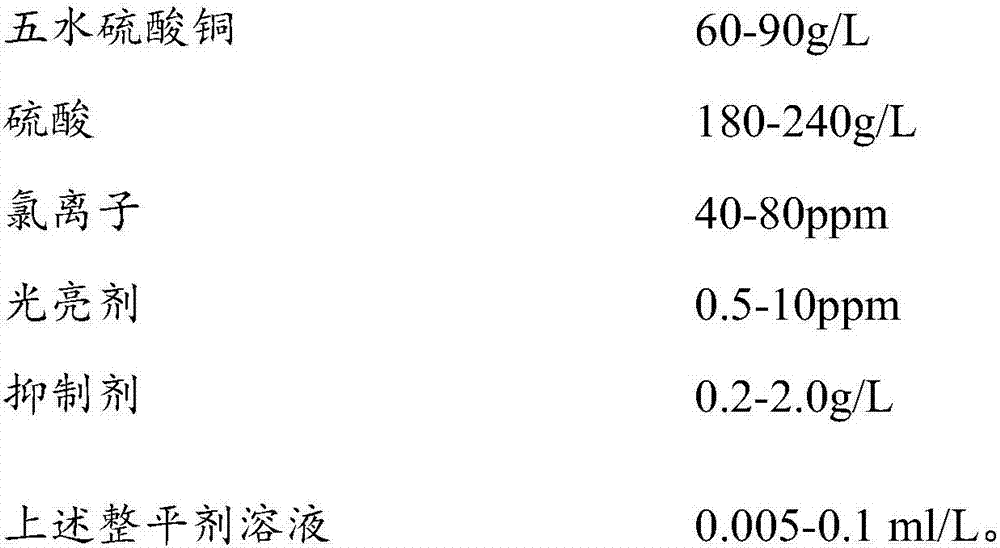

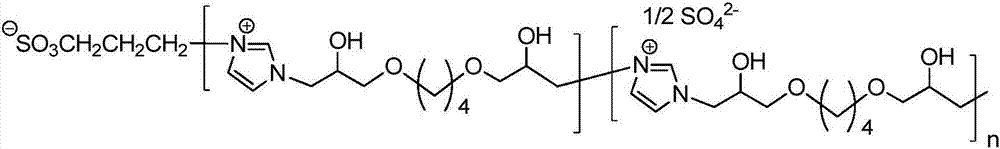

Leveling agent solution and preparation method and application thereof

ActiveCN105002527AHas a leveling effectHas a bright effectAlkyl transferNitrogenous heterocyclic compound

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

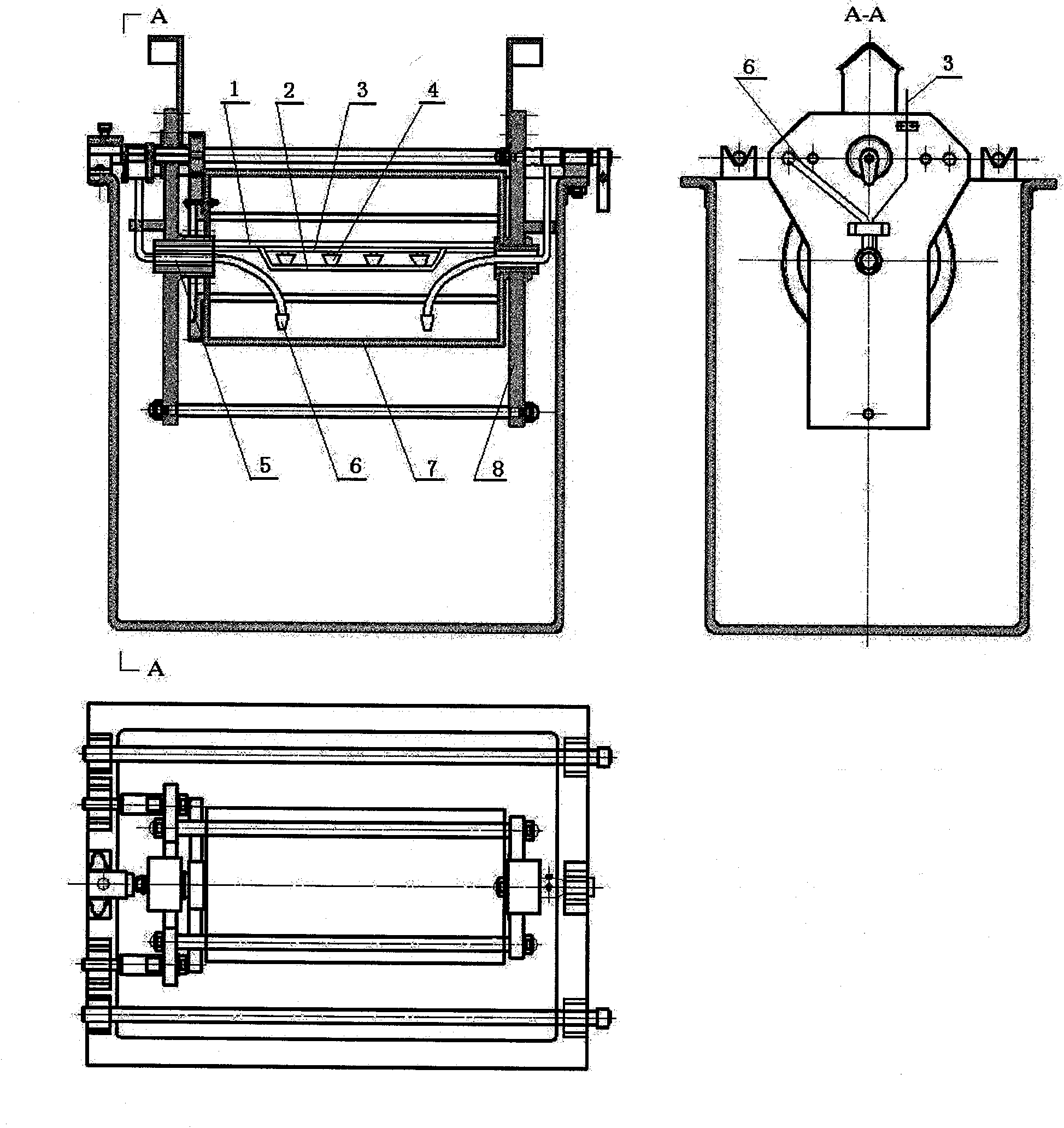

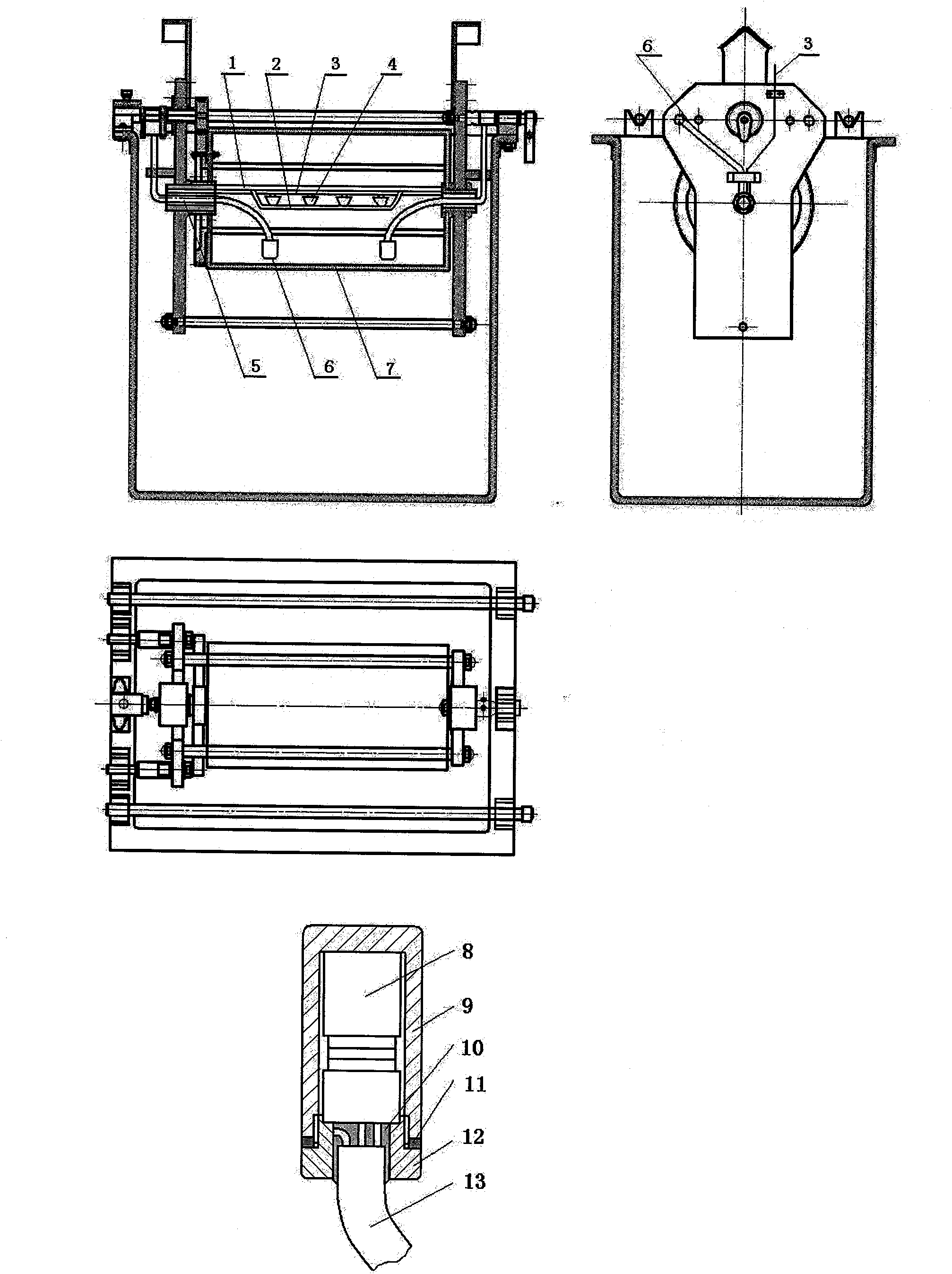

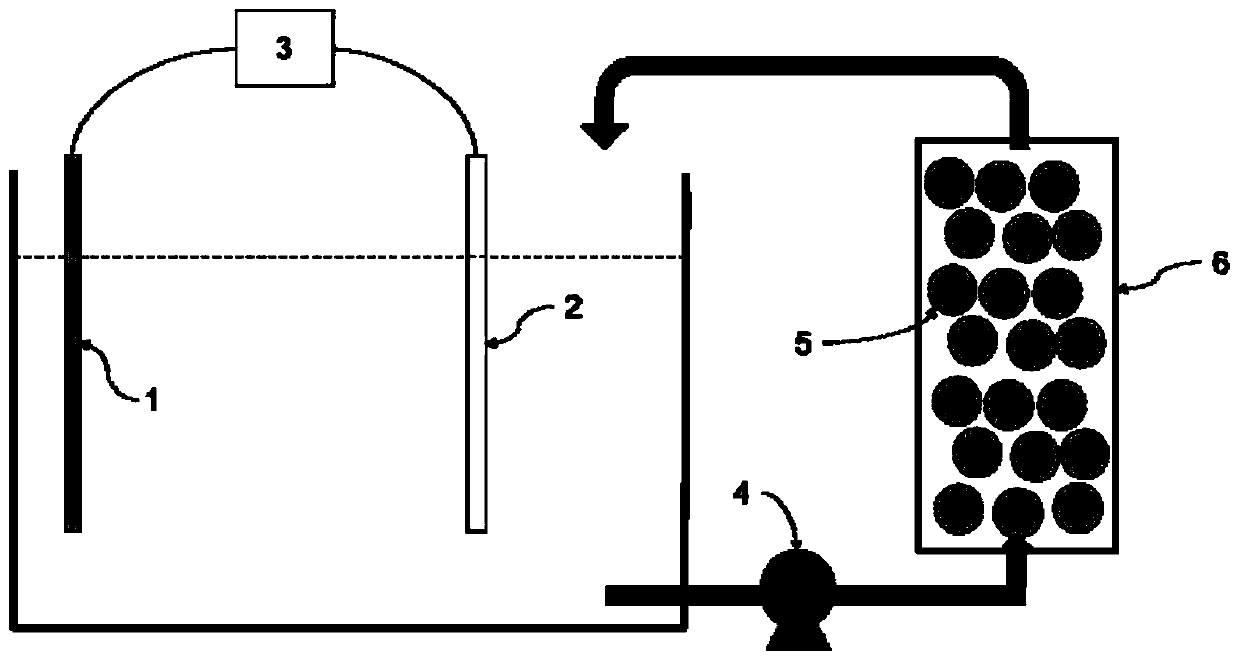

Ultrasonic barrel plating technique and device thereof

InactiveCN101838831ACompact structureGood dispersionElectrolysis componentsDynamic balanceEngineering

The invention relates to a barrel plating device with the function of ultrasonic vibration, aiming at overcoming the defects that as plating solution is limited by a roller cavity when passing in and out a roller in the traditional barrel plating device, the plating layer effect of micropore and deep-hole parts is poor, and the like. The device mainly comprises a plating bath, an electrode, the roller, an ultrasonic generator and the like, wherein the ultrasonic generator is installed inside a fixed hollow shaft or a hollow electrode in the center of the roller, so that ultrasonic vibration can be effectively generated in the plating process, the dynamic balance of the plating solution is realized, and the deep plating effect and the compactness of a plating layer are improved.

Owner:HANGZHOU AMAER TECH +1

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

Electroplating liquid and electroplating method thereof

The invention provides electroplating liquid and an electroplating method thereof. The electroplating liquid comprises the following components including, by mass concentration, 0.3-25 g / L of tetravalent vanadium, 4-10 g / L of divalent iron, 0.3-5 g / L of ferric iron, 100-250 g / L of copper sulfate, 50-210 g / L of sulfuric acid and 30-150 mg / L of chloride. According to the electroplating liquid, the mass concentrations of the tetravalent vanadium, the divalent iron, the ferric iron, the sulfuric acid, the copper sulfate and the chloride are adjusted, and a vanadium system is combined with an ironsystem to give play to higher deep plating capacity. The electroplating method is simple in operation and high in speed, electroplating can be completed within 20-120 minutes generally, the plate faceplating layer thickness is small, and reduction treatment does not need to be treated; and the plate face plating layer thickness is evenly distributed, and the production efficiency of a circuit board is improved.

Owner:GUANGDONG SKYCHEM TECH LTD

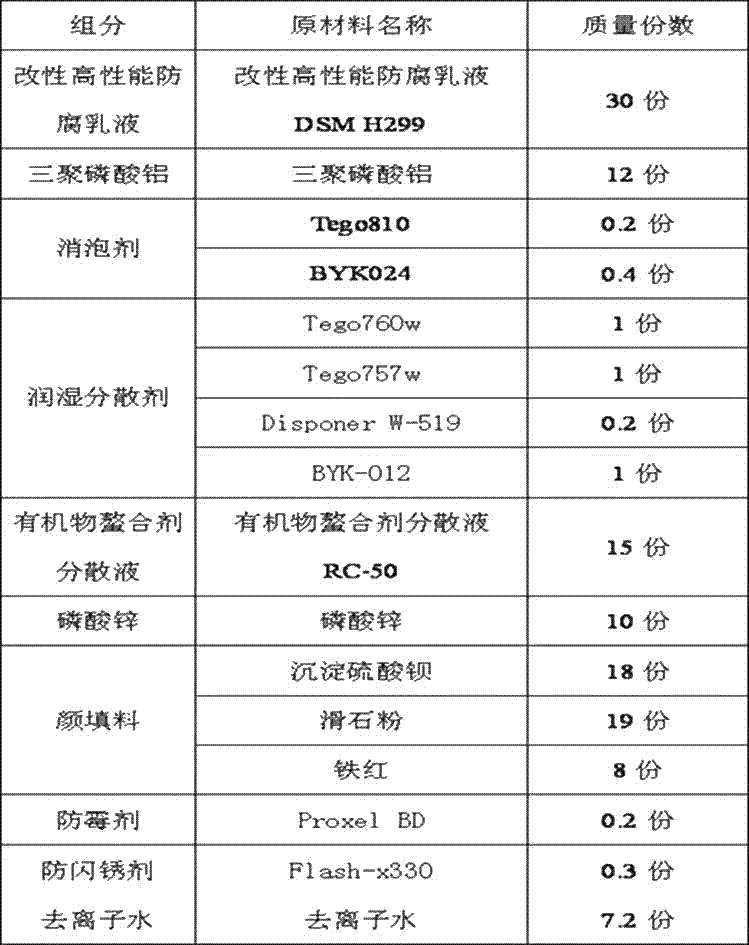

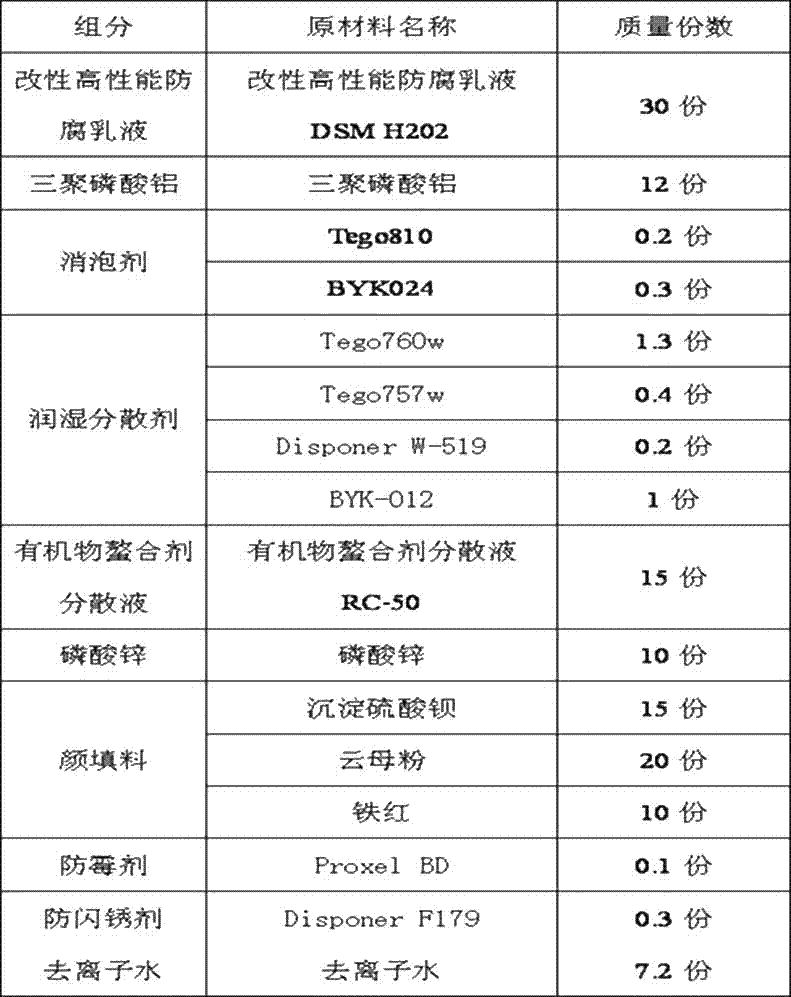

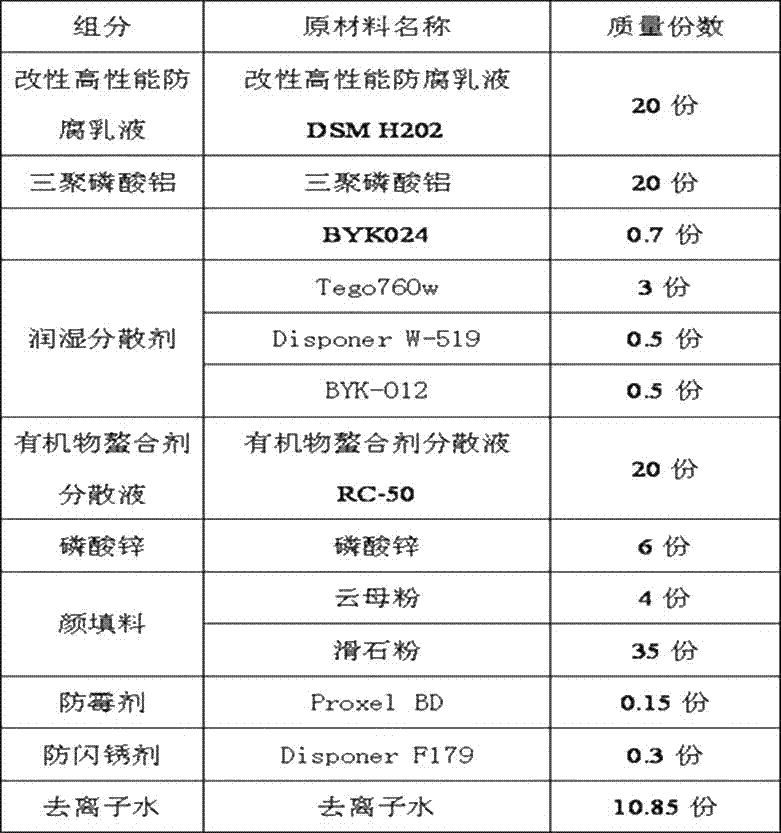

Long-acting waterborne over-rust corrosion protective coating and preparation method thereof

InactiveCN107312460AIncrease crosslink densityHigh film strengthFireproof paintsAnti-corrosive paintsWater basedTectorial membrane

The invention discloses a long-acting waterborne over-rust corrosion protective coating. The long-acting waterborne over-rust corrosion protective coating comprises the following components by weight: 20-35 parts of modified high-performance anti-corrosive emulsion, 10-20 parts of aluminum triphosphate, 6-12 parts of zinc phosphate, 0.1-0.8 part of defoamer, 2-4 parts of wetting dispersant, 10-20 parts of organic chelating agent dispersing agent, 37-45 parts of pigment and filler, 0.1-0.2 part of mildew preventive, 0.2-0.3 part of anti-flash-rust agent, and 7-12 parts of deionized water. The invention provides the long-acting waterborne over-rust corrosion protective coating, the rust is converted into a mode of a dense protective film within a short period of time by improving the crosslinking density and the strength of a film and promoting the rapid dispersing and chelating of the rust, so that the durability, the salt spray resistance and the adhesive force of the coating are improved obviously.

Owner:洛阳双瑞防腐工程技术有限公司

Method for acquiring complexing agent special for zinc-nickel alloy plating

The invention relates to a method for extracting complexing agent special for zinc nickel alloy plating, which has the steps as follows: (1) deionized water of 150ml is injected into a reaction vessel provided with a warming device and an agitating device and is heated until the temperature reaches 15 DEG C to 40 DEG C, and then organic-amine simple complexing agent (the quantity of which is 50g to 150g) or alkanolamine simple complexing (the quantity of which is 50g to 150g) is added by inches; (2) propylene oxide whose quantity is 50g to 100g or epoxy chloropropane whose quantity is 50g to 100g is added into the dissolved complexing agent solution in the temperature of 60 DEG C to 70 DEG C, and the production which is obtained after the reaction can be used as the complexing agent for plating zinc nickel alloy. The method has the beneficial effects that: (1) The quality fraction of nickel in the alloy cladding layer can be controlled in a less range (7 to 14 percent in general), and better maneuverability is realized; (2) by using the complexing agent, the deepening plating ability of the plating solution is greatly enhanced in a higher operating temperature, the operation range of the technology is widened and the production cost is reduced; the method is provided with real popularizing signification in the circumstance that the power source is increasingly strained and the energy conservation and carbon emission reduction are advocated at present.

Owner:杭州东方表面技术有限公司

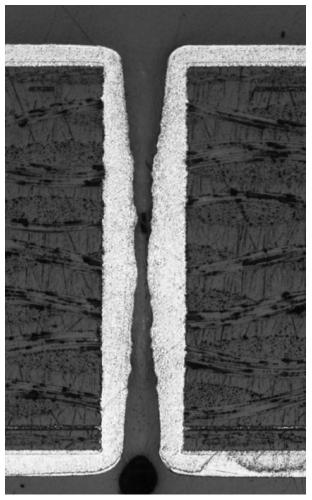

VCP copper plating process for flexible printed circuit board

InactiveCN110318079AImprove deep plating abilityImprove qualityPrinted circuit manufactureChemistryCopper plating

The invention provides a VCP copper plating process for a flexible printed circuit board. The VCP copper plating process comprises the following steps of firstly, cleaning a vertical continuous copperplating tank; continuously washing with deionized water, adding the deionized water, copper sulfate pentahydrate, sulfuric acid, hydrochloric acid and a copper-plated additive (polyethylene glycol, sodium polythiodipropionate and Janus Green) into the copper plating tank, starting a circulation filter pump, inputting the to-be-electroplated flexible circuit board into the tank, and starting the current; after electroplating, taking out the circuit board, and cleaning the circuit board with water; and after blow-drying by hot air, transferring the circuit board into a pattern transferring procedure. According to the vertical continuous (VCP) copper plating process for the flexible printed circuit board, after the flexible circuit board is plated copper, the flexibility is stronger and theexpansion shrinkage of the flexible circuit board is smaller, and the deep plating capability of a through hole is higher, so that the bending resistance of the flexible circuit board is greatly improved, the film alignment in subsequent pattern transfer is facilitated, etching of the flexible circuit board with high-density line width / line distance (0.05 mm / 0.05 mm) is more facilitated, the product quality and the product reliability are improved, the production process is pollution-free, and the process is suitable for industrial production.

Owner:东莞市斯坦得电子材料有限公司

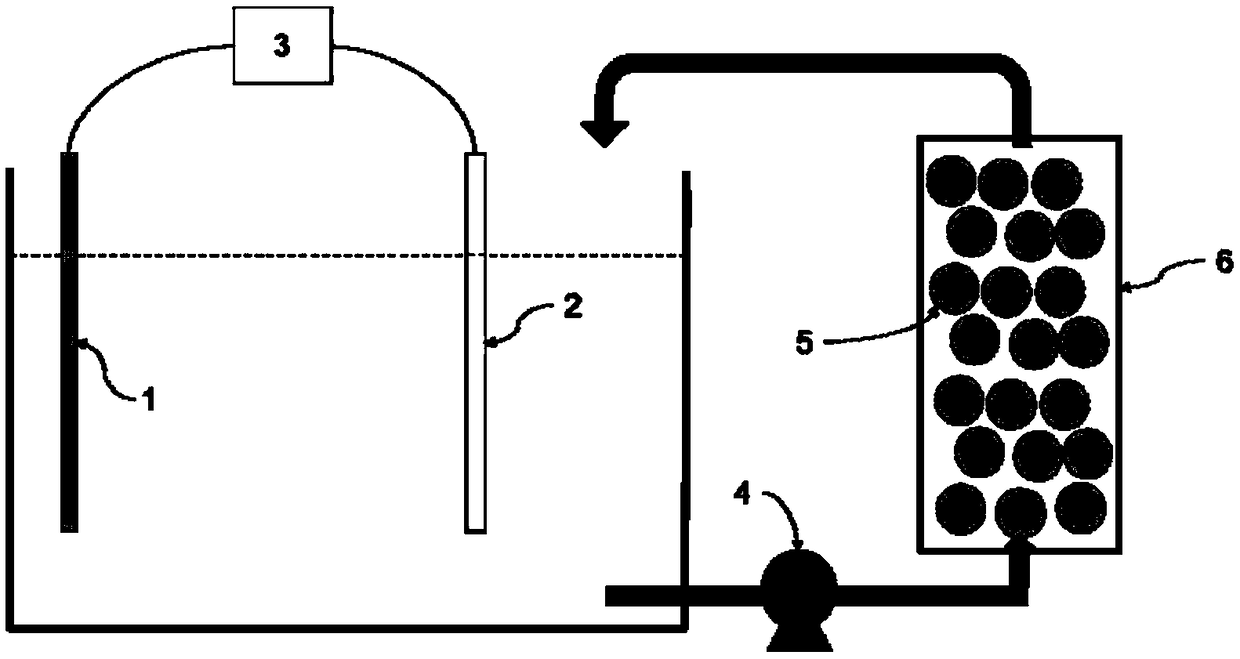

Method for improving deep plating capacity of electrocoppering

ActiveCN108203836AImprove deep plating abilityGood for uniformity controlCellsMineralogySulfuric acid

The invention discloses a method for improving deep plating capacity of electrocoppering. The method comprises the steps of A, preparing an electroplating solution including copper sulfate, sulfuric acid, sodium nitrite, 3-oxo-cyclobutylcarboxylic acid, manganese disodium EDTA trihydrate, 4-methyl-2-oxovaleric acid sodium, a brightening agent, a smoothening agent, a modifying agent and the balancewater; B, pouring the electroplating solution into an electroplating bath; and vertically arranging a circuit substrate into the electroplating bath; C, performing the first-stage electroplating; D,performing the second-stage electroplating; and E, performing the third-stage electroplating. With the adoption of the method, the shortages in the prior art can be solved; and the deep plating capacity of electrocoppering is improved.

Owner:艾威尔电路(深圳)有限公司

Deep hole nickel electroplating plating solution and preparation method thereof

The invention discloses a deep hole nickel electroplating plating solution, a preparation method and an electroplating method, and belongs to the technical field of nickel electroplating. The problemsthat in the prior art, nickel sulfate and nickel sulfamate based plating solution can not be used for deep hole plating are solved. The deep hole nickel electroplating plating solution comprises thenickel sulfate, nickel chloride, a boric acid, a dodecylbenzene sulfonic acid, sodium citrate, an ammonium sulfate, a hydroxypropyl pavement agent and a PS reagent; and the nickel electroplating plating solution comprises 200 - 300 g / L of the nickel sulfate, 30 - 50 g / L of the nickel chloride, 30 - 50 g / L of the boric acid, 0.006 - 0.10 g / L of the dodecylbenzene sulfonic acid, 50 - 90 g / L of the sodium citrate, 5 - 20 g / L of the ammonium sulfate, 0.11 - 1.10 ml / L of the hydroxypropyl pavement agent, and 0.001 - 0.10 g / L of the PS reagent. According to the deep hole nickel electroplating plating solution, the electroplating operation of the irregular deep hole in a battery shell is realized.

Owner:CENT IRON & STEEL RES INST

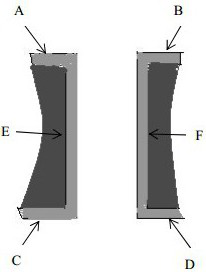

Efficient gun barrel bore chromium plating additive and plating solution thereof

The invention discloses an efficient gun barrel bore chromium plating additive and a plating solution thereof. The additive mainly comprises methyl sulfonic salt, sodium bromide and magnesium sulfate, and the plating solution mainly comprises CrO3, H2SO4, Fe3+ and Cr3+. By applying the additive and the plating solution to gun barrel bore chromium plating, qualified rate of gun barrel bore chromium coatings can be improved significantly, current efficiency is improved and can reach 20%-27%, chromium coating deposition velocity is increased and is 2-3 times of that of traditional hard chromium plating, gun barrel bore chromium plating time is shortened, and energy consumption in the chromium plating process is reduced. In the aspect of chromium coating performances, chromium coating hardness is enhanced beneficially, chromium loss rate after shooting of a gun barrel is decreased, chromium coating quality is improved remarkably, the chromium coatings are fine, and bright and uniform in thickness, throwing power of the plating solution is high, cone difference is reduced, inner wall chromium plating of deep-barrel parts can be completed only one-time plating to enable cone difference thereof to meet process standards, reversing chromium plating is not needed, chromium plating efficiency is improved greatly, time is saved, and cost of deep-barrel inner wall chromium plating is lowered. The additive is fluoride-free, small in anodic corrosion and capable of effectively protecting anodes.

Owner:欧忠文 +1

Hole metallizing method for circuit board with high ratio of thickness to radial dimension

InactiveCN106535501AReduce pollutionControllable surfaceVacuum evaporation coatingSputtering coatingCopperElectroplating

The invention provides a hole metallizing method for a circuit board with a high ratio of thickness to radial dimension, and solves problems that there is no tin layer for protecting the hole bottom after etching, there is no copper in the hole and thereby the circuit board is caused to be discarded because a metalized back drill hole with the high ratio of thickness to radial dimension is relatively deep and a tin layer is difficult to set at the bottom of the hole in a coating manner after pattern electroplating. Therefore, the invention proposes the method for improving the no-copper condition of a metalized back drill hole of the circuit board with the high ratio of thickness to radial dimension. The invention can effectively control the thickness of hole wall copper, and the thickness can be controlled. The method can avoid the material waste caused by the normally-used thick copper technology in the prior art, can enable the surface copper layer of the hole wall to be uniform in thickness, enables the surface to be flat, and can meet the requirements of the performances of a precise circuit element circuit board. The method is simple, is advanced in technology, improves the electroplating current density, shortens the electroplating time, improves the deep electroplating capability, and effectively reduces the pollution caused by electroplating.

Owner:奥士康精密电路(惠州)有限公司

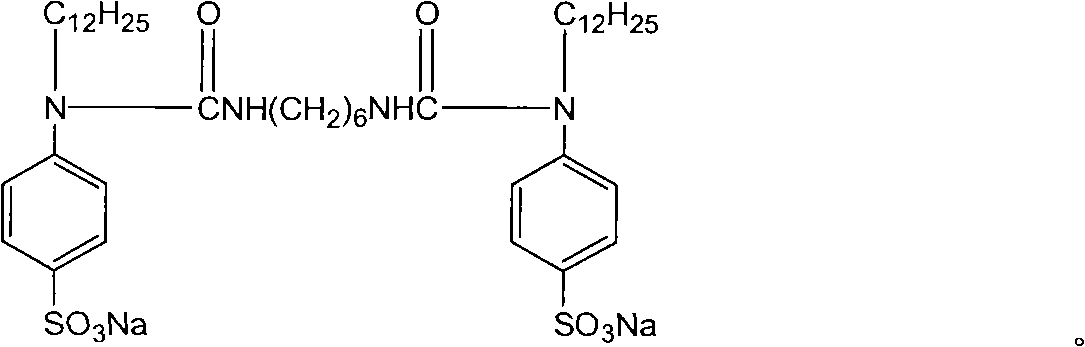

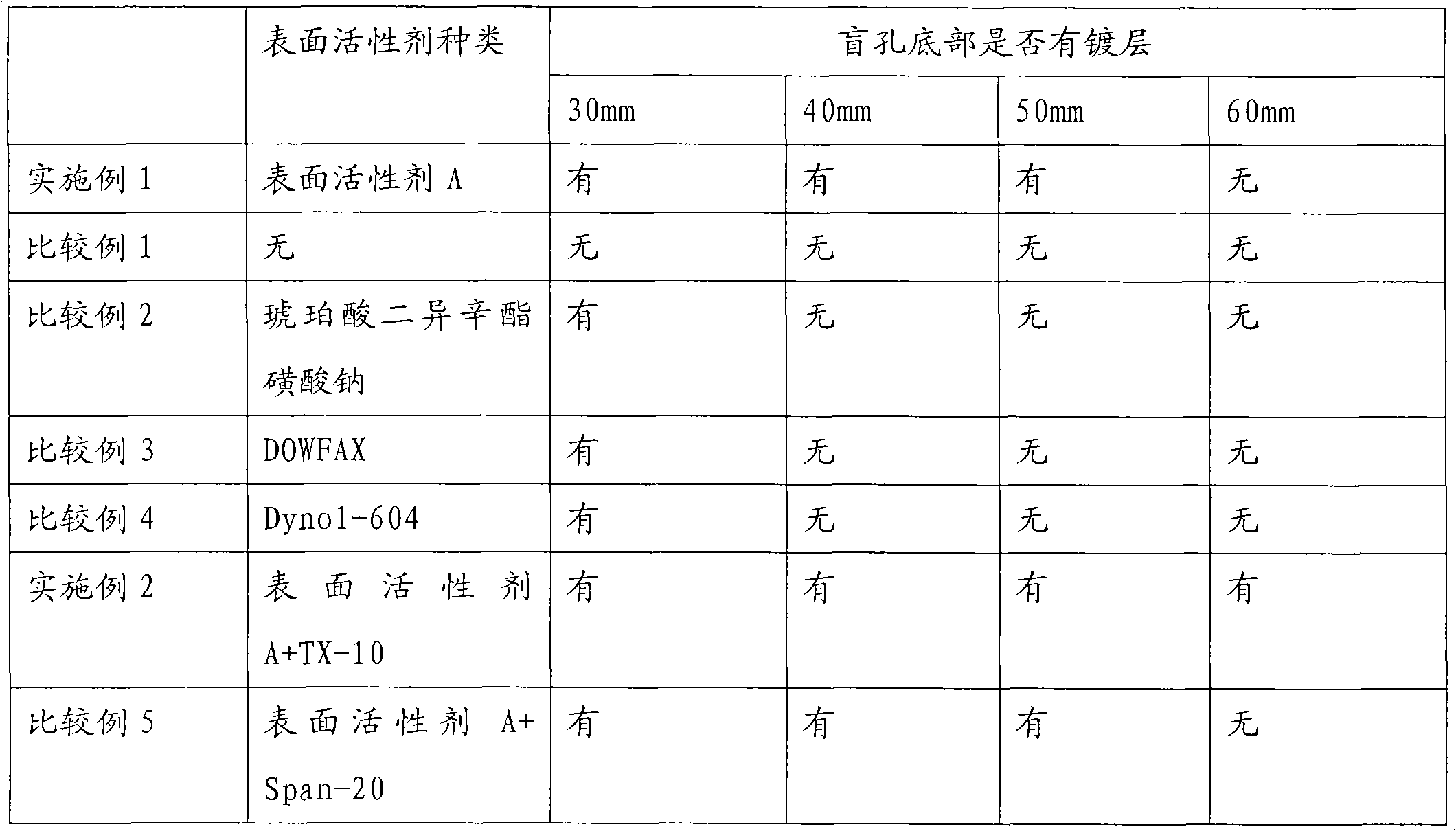

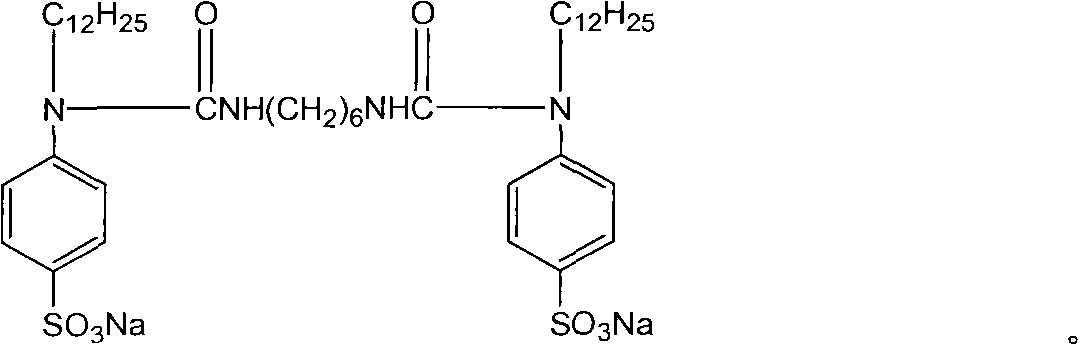

Method for electrogalvanizing on surface of zinc alloy workpiece with blind holes

ActiveCN102560567AImprove deep plating abilityPlay the role of corrosion inhibitionElectrogalvanizationZinc alloys

The invention discloses a method for electrogalvanizing on the surface of a zinc alloy workpiece with blind holes. The method has extremely good blind hole deep plating performance and can prevent corrosion of zinc alloy. An electrogalvanizing solution used in the invention comprises ZnCl2, KCl, H3BO3 and surfactant A, with the balance being water.

Owner:南通东湖国际商务服务有限公司

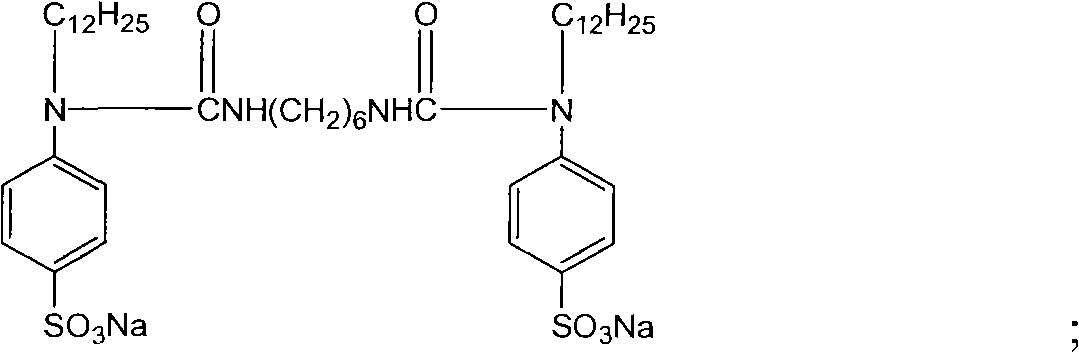

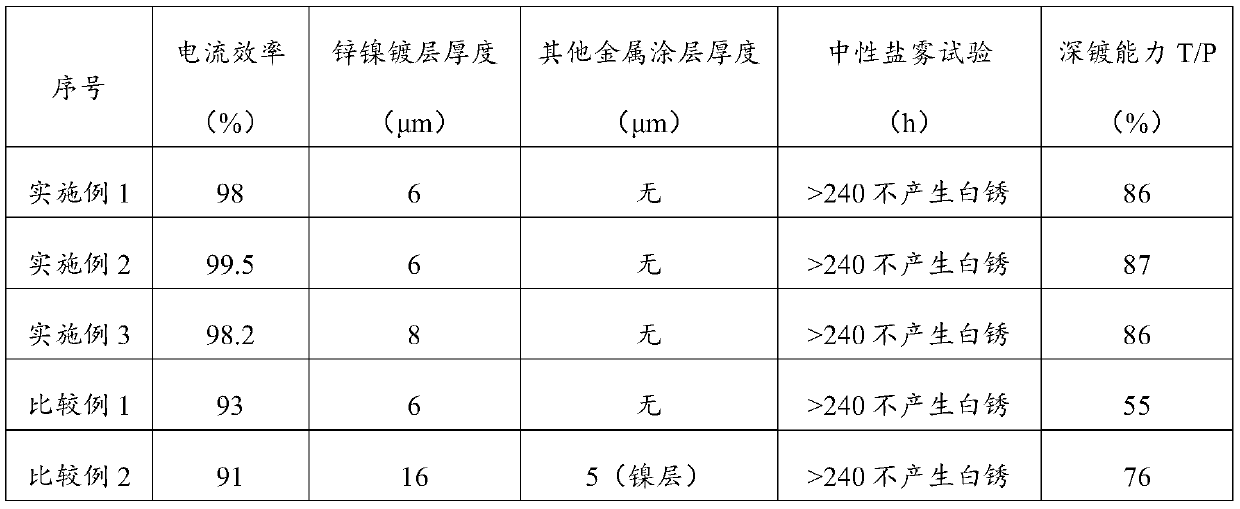

Method for electroplating zinc-nickel alloy, magnet, electroplating solution and purpose of potassium chloride

ActiveCN110983392AImprove deep plating abilityImprove current efficiencyJewelleryElectrogalvanizationNickel alloy

The invention discloses a method for electroplating a zinc-nickel alloy, a magnet, an electroplating solution and a purpose of potassium chloride. The method comprises the following steps of performing pretreatment on a sintered neodymium-iron-boron magnet, to obtain a first magnet; putting the first magnet into the electroplating solution to perform electroplating, to obtain a second magnet, wherein the electroplating solution is prepared from zinc chloride, nickel chloride, potassium chloride, boric acid and water; and performing post treatment on the second magnet, to obtain a sintered neodymium-iron-boron magnet with zinc-nickel alloy plating, wherein the zinc-nickel alloy plating is directly in contact with the surface of the sintered neodymium-iron-boron magnet. By using the method provided in the invention, the hole sealing treatment is not needed to be performed on the magnet; and the current efficiency is high.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

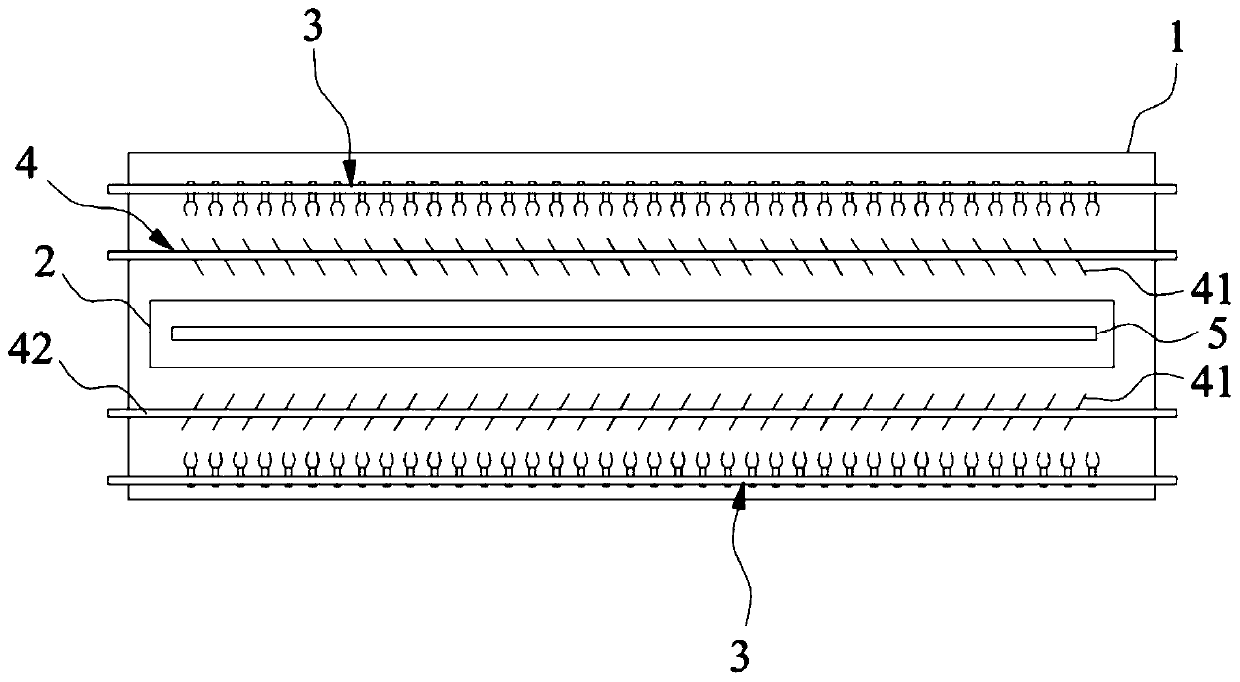

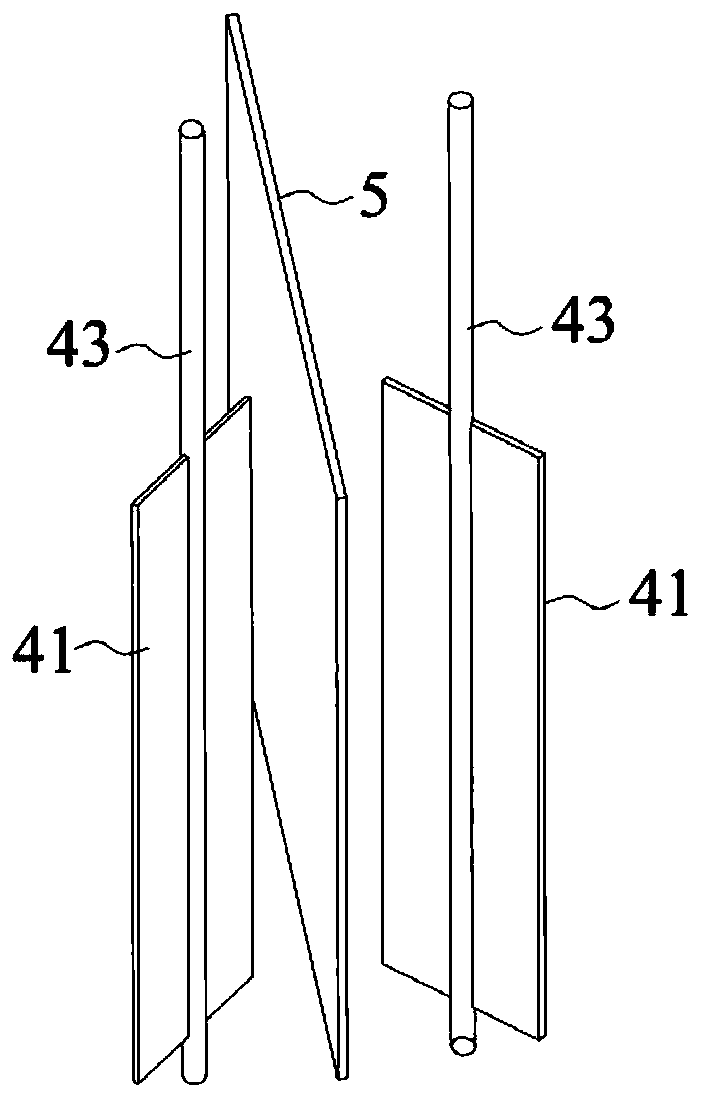

PCB electroplating device

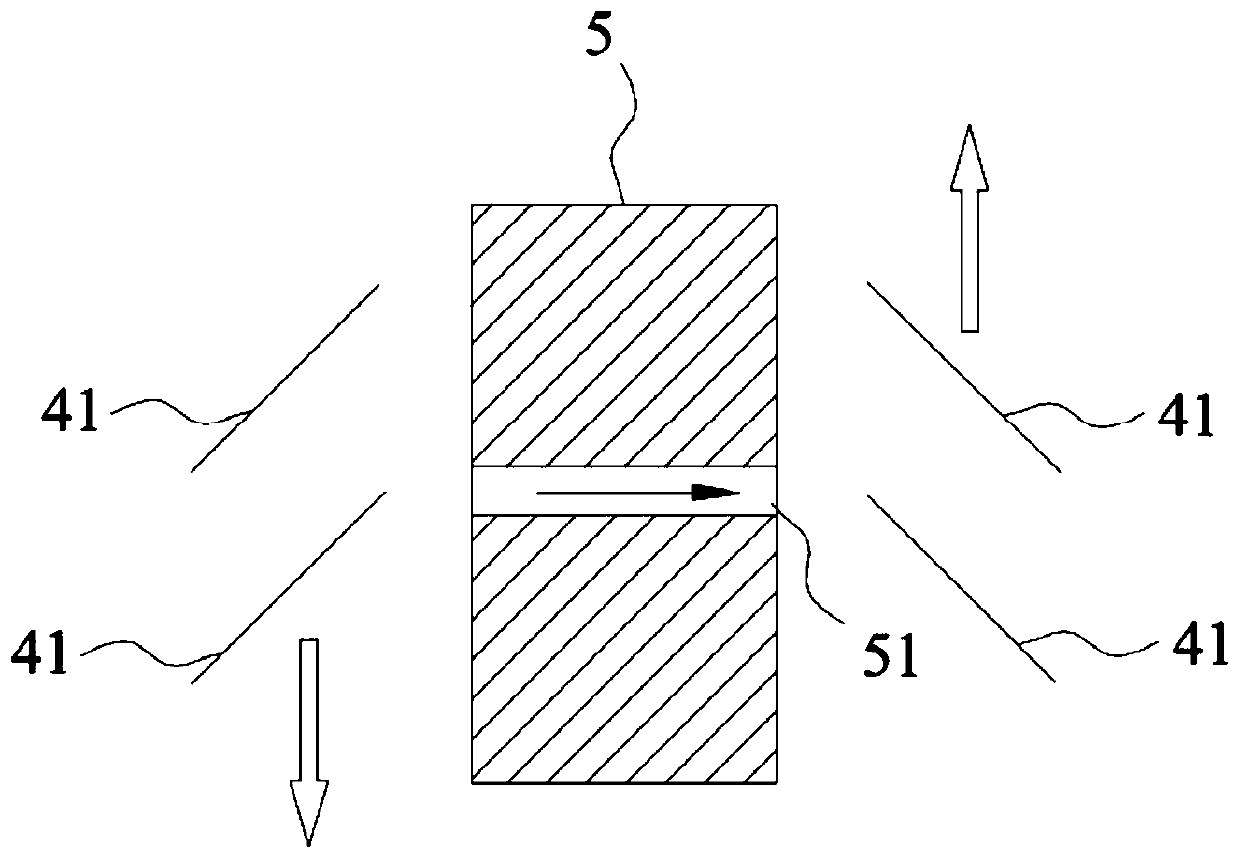

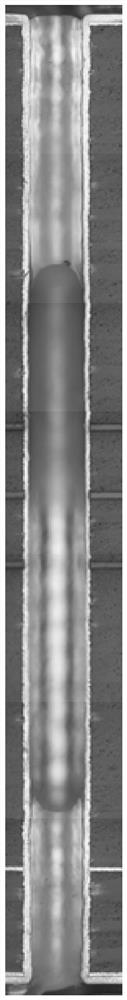

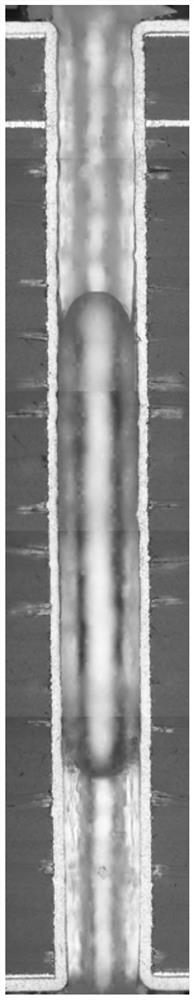

ActiveCN110629263AImprove deep plating abilityIncrease flow rateCellsTanksEngineeringPressure difference

The invention relates to the technical field of PCB electroplating and particularly discloses a PCB electroplating device. The PCB electroplating device comprises an electroplating bath, a clamp, twopositive poles and turbulent flow components. The clamp is used for clamping a PCB and immersing the PCB in an electroplating solution in the electroplating bath in the vertical direction, the two positive poles are placed on both sides of the PCB, and the turbulent flow components are located between the PCB and one of the positive poles. Each turbulent flow component comprises a blade frame andblades mounted on the blade frame. The blade frames drive the blades to swing in a reciprocating manner parallel to the PCB faces in the horizontal direction, and the blades push the electroplating solution, so that a pressure difference is generated between the two plate faces of the PCB, the plating solution is promoted to flow through a drilling hole in the PCB, the flow rate of the plating solution passing through the drilling hole is increased, and the deep plating capacity of the drilling hole is improved; and compared with the prior art, by the adoption of the PCB electroplating device,the deep plating capacity of the PCB with the thickness ratio of equal to or greater than 16:1 can be remarkably improved, higher-power pumping is not needed, and energy waste is relatively saved,

Owner:DONGGUAN SHENGYI ELECTRONICS

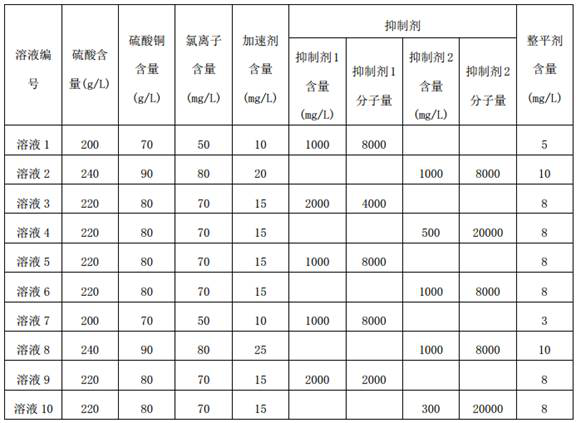

Copper plating additive suitable for printed circuit board and copper electroplating solution

The invention relates to the field of copper plating additives, and particularly discloses a copper plating additive suitable for a printed circuit board and a copper electroplating solution. The copper plating additive comprises the following components according to the concentration ratio: 1-50 mg / L of brightening agent, 1-100 mg / L of leveling agent, 0.5-50 g / L of wetting agent and the balance pure water. The copper electroplating solution comprises the following components according to the concentration ratio: 180-250g / L of sulfuric acid, 50-80g / L of copper sulfate pentahydrate, 40-120ppm of chloride ions, 10-50ml / L of coppering additive and the balance pure water. According to the copper plating additive, the uniformity of a plating layer and the deep plating capacity of a plating solution can be effectively improved, the deep plating capacity TP of a through hole with the aspect ratio being 8 can reach 92.4%, the deep plating capacity TP of a through hole with the aspect ratio being 12 can reach 83.3%, and the electroplating uniformity COV of the printed circuit board can reach 9.5%.

Owner:珠海松柏科技有限公司 +2

Electrolyte for the galvanic deposition of aluminium from aprotic solvents in a plating barrel

InactiveCN101573476AUniform corrosion resistanceImprove deep plating abilityGroup 3/13 element organic compoundsGalvanic depositionSolvent

The invention relates to an electrolyte for the galvanic deposition of al uminium from aprotic solvents, said electrolyte containing a compound of for mula N(R1)4X.(m-n-o)AI (C2H5)3-n AIR2 3-o AIR3 3 (I), wherein R1 is a C1 to C4 alkyl group, X is equal to F, Cl or Br, m is equal to between 1 and 3, pr eferably between 1.7 and 2.3, n is equal to between 0.0 and 1.5, preferably 0.0 and 0.6, o is equal to between 0.0 and 1.5, preferably between 0.0 and 0 .6, and R2 and R3 are a C1 or C3 to C6 alkyl group, R2 differing from R3in a n organic solvent. The invention also relates to a method for producing the electrolyte, a coating method and the coated material parts.

Owner:ALUMINAL OBERFLACHENTECHN

Leveling agent solution and its preparation method and application

ActiveCN105002527BGood effectGood deep plating abilityNitrogenous heterocyclic compoundCombinatorial chemistry

The invention relate to a leveling agent solution and a preparation method and application thereof. The leveling agent solution is obtained in the mode that a nitrogenous heterocyclic compound and a diepoxide compound are polymerized and then 1,3-propane sultone is used for an alkylation reaction. The leveling agent solution, a brightener and an inhibitor are used together, and a good electroplating effect can be obtained in electroplating of circuit board through holes.

Owner:GUANGDONG GUANGHUA SCI TECH

Cyanide-free copper electroplating method for reducing porosity of copper plating layer

The present invention relates to a cyanide-free copper electroplating method for reducing porosity of a copper plating layer. According to the cyanide-free copper electroplating method, a substrate is alternately subjected to a direct current electroplating unit and a pulse electroplating unit, the pH value of the electroplating solution is controlled to 12-13, the temperature is 50-70 DEG C, the cathode current density for copper electroplating in each direct current electroplating unit is 0.5-3.0 A / dm<2>, the electroplating time is 2-3 min, the pulse average current density for copper electroplating in each alternating current electroplating unit is 0.5-3.0 A / dm<2>, the duty ratio is 15%, and the electroplating time is 2-3 min. The plating layer obtained through the method has minimal porosity when the plating layer thickness is 10-20 mum.

Owner:WUXI XINSANZHOU STEEL

Electroplating solution for surface of zinc alloy workpiece with blind hole

ActiveCN102534699AImprove deep plating abilityPlay the role of corrosion inhibitionElectrogalvanizationZinc alloys

The invention discloses a zinc electroplating solution for the surface of a zinc alloy workpiece with a blind hole. The zinc electroplating solution has an excellent deep plating performance for the blind hole and can prevent zinc alloy from being corroded. The zinc electroplating solution comprises the following ingredients: ZnCl2, KCl, H3BO3, surface active agent A and water in balancing amount.

Owner:SHENZHEN CHENGGONG CHEM

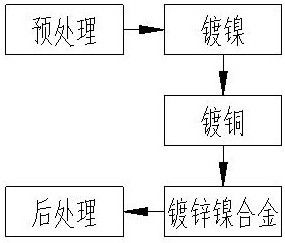

Method for electroplating zinc-nickel alloy on sintered neodymium iron boron

InactiveCN112064076AGood dispersionHarm reductionLiquid applicationElectrogalvanizationCopper plating

The invention discloses a method for electroplating zinc-nickel alloy on sintered neodymium iron boron. The method comprises the following steps that (1) a sintered neodymium iron boron magnet is pretreated to obtain the pretreated magnet; (2) the pretreated magnet is soaked in a solution of 80-85 DEG C for chemical nickel plating for 15-30 minutes; (3) the magnet subjected to nickel plating is subjected to copper electroplating; (4) the magnet subjected to copper electroplating serves as a cathode and is put into a zinc-nickel alloy electroplating solution for electroplating to obtain a zinc-nickel alloy electroplated product; and (5) the electroplated product is subjected to post-treatment. The chemical nickel plating thickness is 2-10 microns, the electrocoppering is alkaline copperingor pyrophosphate coppering, and the electrocoppering thickness is 1-15 microns. The method solves the problems of poor deep plating capability and low corrosion resistance of the neodymium iron boronmagnet, and has the advantages of improving the deep plating capability of the sintered neodymium iron boron magnet, directly forming the zinc-nickel alloy coating on the surface of the sintered neodymium iron boron magnet, improving the current efficiency on the premise of ensuring the corrosion resistance of the magnet, and the like.

Owner:GANZHOU FORTUNE ELECTRONICS

Tin cobalt alloy electroplating liquid with good deep plating capacity and electroplating method thereof

ActiveCN109881224AImprove deep plating abilitySolve difficult technical problemsChlorideSeignette salt

The invention discloses a tin cobalt alloy electroplating liquid with good deep plating capacity and an electroplating method thereof. The tin cobalt alloy electroplating liquid with the good deep plating capacity is prepared from the components: 40-50g / L of stannous chloride, 30-40g / L of cobalt chloride, 60-90g / L of potassium chloride, 10-12g / L of EDTA disodium salt, 5-10g / L of seignette salt, 0.05-0.1g / L of dibenzenesulfonimide, 0.3-0.5g / L of thiophene-2-sulfoacid, 0.1-0.2g / L of coumarin and 0.02-0.05g / L of N,N-diethylamine propargylamine. According to the tin cobalt alloy electroplating liquid with the good deep plating capacity and the electroplating method thereof, a primary brightening agent adopted in the electroplating liquid is a composition of the dibenzenesulfonimide and the thiophene-2-sulfoacid, and a secondary brightening agent is a composition of the coumarin and the N,N-diethylamine propargylamine. The four substances are used as the brightening agents of the electroplating liquid, meanwhile, play the synergistic effect on the aspect of improving the deep plating capacity, and none is dispensable. The deep plating capacity of the electroplating liquid is greatly improved, and the tin cobalt alloy electroplating liquid with the good deep plating capacity is very suitable for plating of workpieces with long pipe shapes.

Owner:昂七化工科技(上海)有限公司

PCB (printed circuit board) isolation graph copper pouring and distributing secondary etching method

InactiveCN108200729AReduce dosageLow densityConductive material chemical/electrolytical removalEtchingCopper pour

The invention relates to the technical field of PCB (printed circuit board) processing, and discloses a PCB isolation graph copper pouring and distributing secondary etching method which includes thesteps: a copper pouring film optimization; b graph transfer; c graph electroplating; d graph etching; e secondary graph transfer; f secondary etching. The method is applicable to secondary etching ofcopper pouring and distributing of PCBs with locally isolated graphs and the copper thickness smaller than 2OZ, production defect rate is greatly reduced, and the method is low in cost, high in efficiency and suitable for large-scale popularization.

Owner:奥士康精密电路(惠州)有限公司

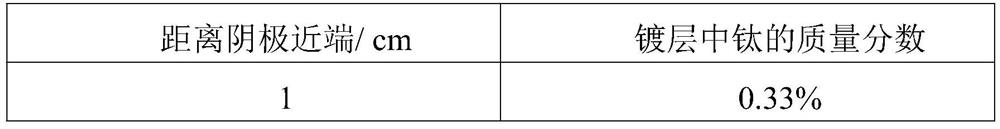

Potassium chloride cyanide-free titanium alloy plating solution, its preparation method and electroplating process

The invention discloses a potassium chloride cyanide-free cadmium titanium alloy plating solution and a preparation method and electroplating process of the potassium chloride cyanide-free cadmium titanium alloy plating solution. The plating solution per liter comprises 20-35g of cadmium chloride, 80-140g of a complexing agent, 120-200g of potassium chloride, 1-5g of sodium fluoride, 2-5mL of a titanium salt supplement, 1-3mL of a brightening agent, 20-40mL of an auxiliary agent and 5-15mL of a displacement agent. According to the electroplating operation conditions, the pH value of the plating solution is 6.5-7.5, plating bath temperature is 20-35 DEG C, the cathode current density is 0.5-2A / dm<2>, and the area ratio of a cathode to an anode is 2:(1-3). The plating solution is stable, convenient to maintain and small in process hydrogen brittleness, and a cadmium titanium alloy coating is excellent in corrosion resistance and good in market prospect.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Manufacturing method for solving nonuniform inflation of copper bath of vertical plating line

InactiveCN113373484ASolve uneven pumpingImprove qualityCellsPrinted element electric connection formationCopper platingManufacturing technology

The invention provides a manufacturing method for solving nonuniform inflation of a copper tank of a vertical plating line, and relates to the technical field of circuit board manufacturing processes. The manufacturing method comprises the following steps that a method for plating copper required by a PCB is selected, an instrument is prepared, a solution is prepared, the solution is put into the instrument, an inorganic additive and an organic additive are added, mixing is carried out after the additives are added, waiting for completion of mixing is carried out, a designed inflating pipe is placed in the instrument, bubbles in the solution are removed, the PCB needing to be plated with copper is soaked in the instrument, and waiting for completion of copper plating is performed. Therefore, the U-shaped inflating pipe is changed into an H shape, due to the fact that connecting ports are located in the middles of the two sides of the H shape, the upward distance or the downward distance of gas is equal, a whole tank body is used for inflating, overall distribution is uniform, the wettability of a copper-plated copper surface and in holes and the bubble removing effect are enhanced, the traditional design of a vertical plating line is changed, the qualified rate of products can be obviously improved, the production quality is improved, the copper plating uniformity is improved, the consumption of copper balls can be reduced, and the cost of the copper balls is saved.

Owner:ZHUHAI CHINA EAGLE ELECTRONIC CIRCTCUIS CO LTD

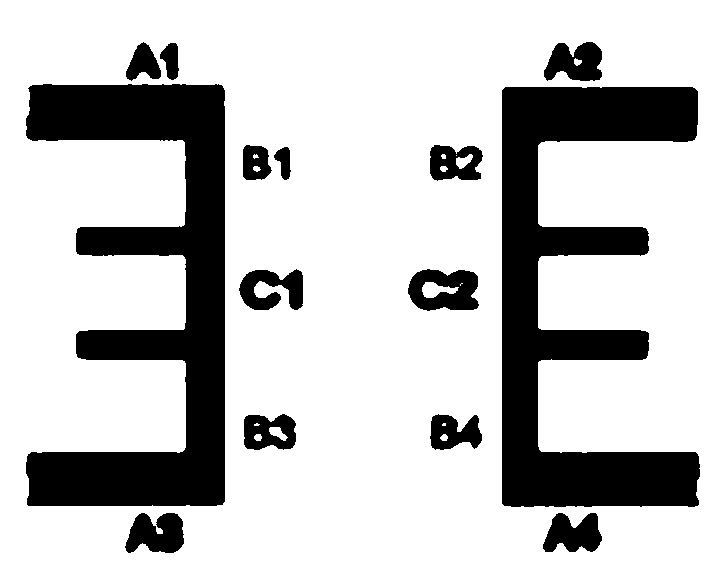

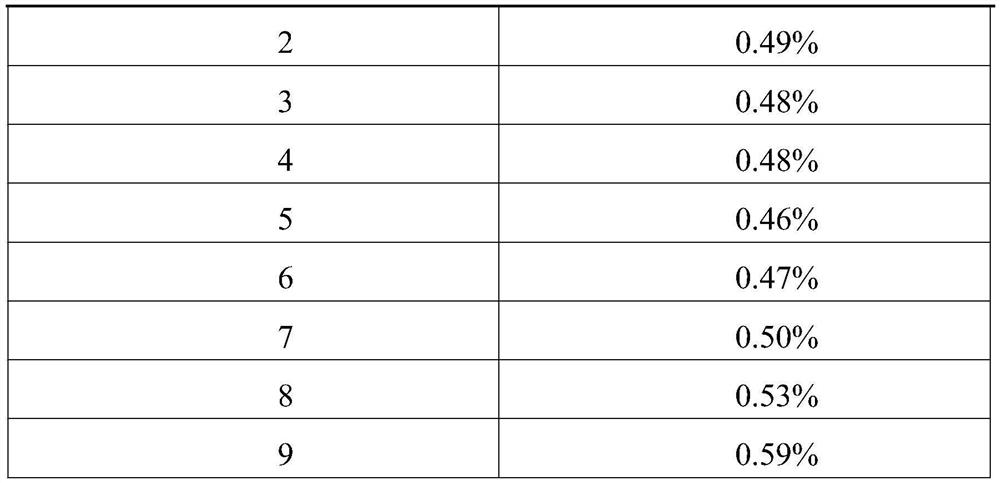

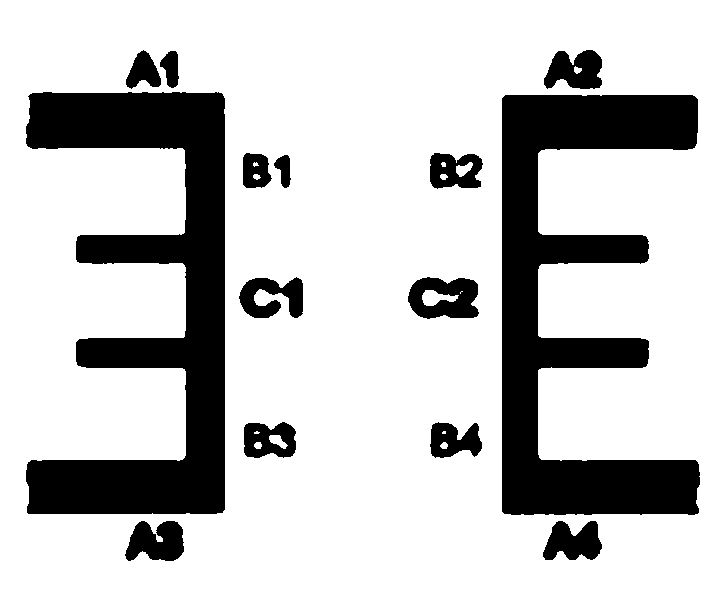

Composite acid system PCB vertical continuous electroplating device and method

ActiveCN104762652ADoes not affect through swapReduce consumptionElectrolysis componentsElectrolysisEngineering

The embodiment of the invention provides a composite acid system PCB vertical continuous electroplating device and a method. The composite acid system PCB vertical continuous electroplating device comprises independent sealed anode chambers separated in an electroplating bath, the independent sealed anode chambers are composed of diaphragm clamping plates for clamping the two sides of a diaphragm, a plurality of side stand plates perpendicular to a copper cylinder groove wall and guide components for guiding an anode power line, and inclined guide separation plates are arranged on the guide components. The diaphragm clamping plates are in bolt connection with the front edges of the side stand plates, and the guide components are located on the front edges of the anode chambers, and fixed to the side stand plates. The sealed anode chambers are symmetrically arranged on the two sides of a copper cylinder. Different acid systems are adopted inside and outside the anode chambers for electrolysis and electroplating, and composite acid system electroplating is formed. The deep electroplating hole penetrating capacity of electroplating equipment is improved, an electroplating layer is even and good in consistency, productivity is large, efficiency is improved, liquid is saved, and production cost is lowered.

Owner:栾善东

Cyanide-free sulfite system electrogilding solution and application thereof

PendingCN113862736AImprove stabilityQuality improvementProcess efficiency improvementGold contentCerium

The invention discloses a cyanide-free sulfite system electrogilding solution and application thereof. The cyanide-free sulfite system electrogilding solution comprises the following raw materials: 10 g / L-30 g / L of gold sulfite (in terms of gold element), 50 g / L-250 g / L of alkali metal sulfite, 130 g / L-280 g / L of an auxiliary complexing agent, 50 g / -120 g / L of conductive salt and 0.08 g / L-1 g / L of a composite additive. The composite additive comprises an organic additive and an inorganic additive, the organic additive at least contains an alcohol additive, and the inorganic additive at least contains any one of antimony, cerium, copper, tellurium and bismuth ions. The cyanide-free sulfite system electrogilding solution researched and developed is high in gold content, simple in component, stable in property, wide in pH value range, good in deep plating capacity, relatively high in cathode current density and high in current efficiency, and can be applied to preparation of a thick gold layer.

Owner:深圳市潮尊珠宝首饰有限公司

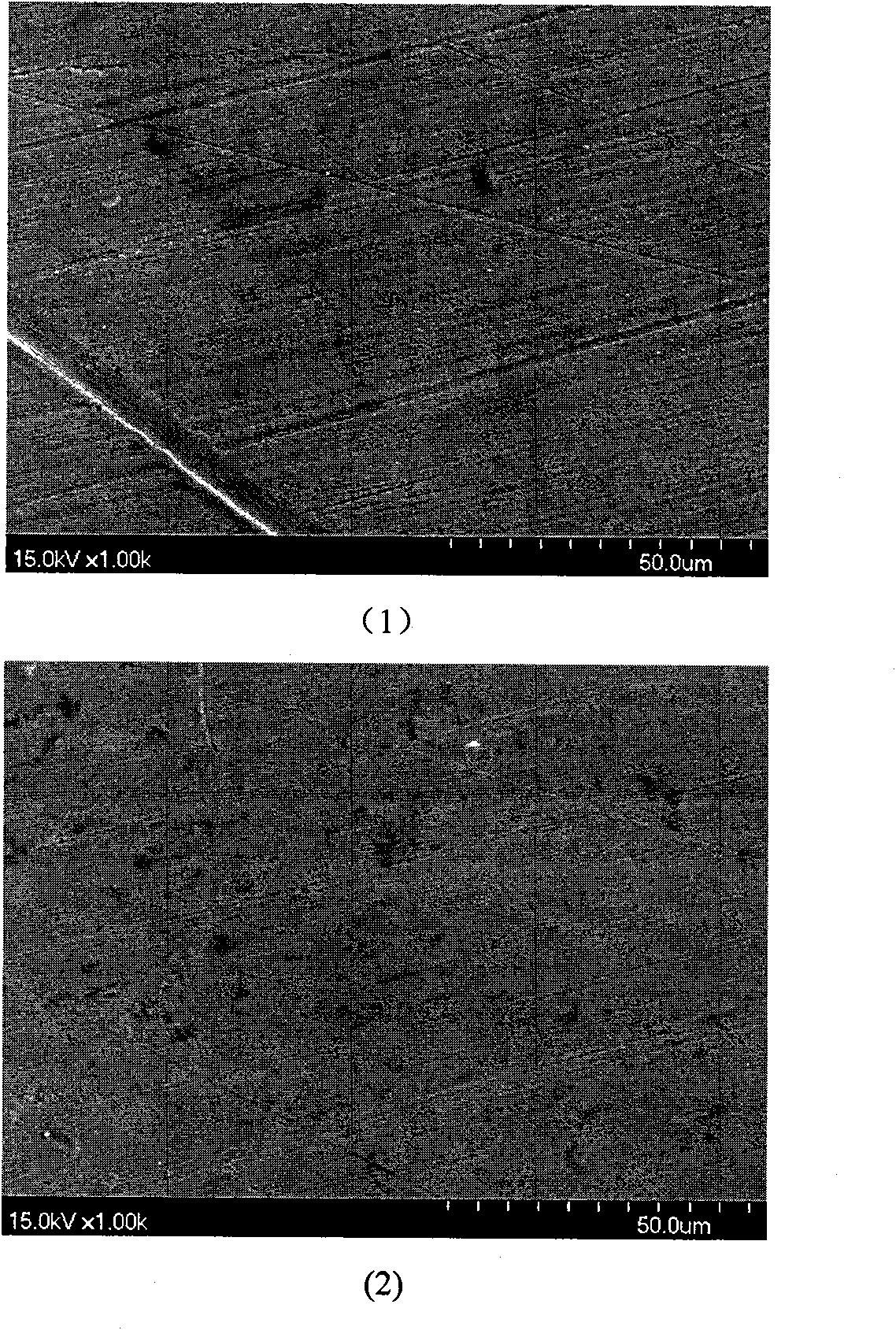

A kind of electrolytic copper foil additive and electrolytic copper surface treatment process

The invention discloses an electrolytic copper foil additive. The electrolytic copper foil additive comprises sodium phosphotungstate, polyethylene glycol and sodium 3,3'-dithiodipropane sulfonate, wherein the content of sodium phosphotungstate in an electroplating liquid is 20-300mg / L; the content of polyethylene glycol in the electroplating liquid is 10-200mg / L; and the content of sodium 3,3'-dithiodipropane sulfonate in the electroplating liquid is 20-300mg / L. According to the electrolytic copper foil additive, sodium phosphotungstate is added and hydrolyzed to obtain phosphotungstate radical, an electrode reaction is accelerated by virtue of the complexing action of phosphotungstic acid, and the covering power of a roughening treatment process and the uniformity of surface crystallization are improved. The invention further provides a surface treatment process for an electrolytic copper foil. The surface treatment process for the electrolytic copper foil comprises the steps of acidpickling, roughening, curing, passivating, silane coupling agent coating and drying; the treated copper foil is good in covering power presentation, a compact roughened layer can be formed, and the anti-oxidation and anti-peeling capacity are improved; the roughness Rz of the surface of the treated copper foil is not greater than 8[mu]m, the Rmax is not greater than 10.0[mu]m, the anti-peeling strength is not less than 2.0kg / cm; and additives containing arsenic, lead and other substances are not used in the treatment process, and the requirements of environment protection and sustainable development are met.

Owner:JIANGXI UNIV OF SCI & TECH +1

A kind of high tg plate production process

ActiveCN107580414BImprove deep plating abilityPrevent protrudingConductive pattern polishing/cleaningGlass fiberPhysical chemistry

Owner:DONGGUAN MEADVILLE CIRCUITS

A high aspect ratio circuit board through-hole electroplating process

ActiveCN114574911BReduce thicknessIncreasing the thicknessPrinted element electric connection formationElectrodesCopper sulfateMaterials science

Owner:SHENZHEN BANMING SCI & TECH CO LTD

A kind of electroplating liquid and electroplating method thereof

ActiveCN108754555BImprove deep plating abilityImprove the plating effectJewelleryPhysical chemistryChloride

The present application provides an electroplating solution and an electroplating method employing the same. The electroplating solution comprises the following components by weight / volume concentration: 0.3-25 g / L of tetralvanadium, 4-10 g / L of ferrous iron, 0.3-5 g / L of ferric iron, 100-250 g / L of copper sulfate, 50-210 g / L of sulfuric acid, and 30-150 mg / L of a chloride.

Owner:GUANGDONG SKYCHEM TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com