Copper plating additive suitable for printed circuit board and copper electroplating solution

A technology for printed circuit boards and additives, used in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of poor deep plating ability of electroplating solution, and achieve strong deep plating ability, reduce difficulty, and uniform distribution of ions in the coating layer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

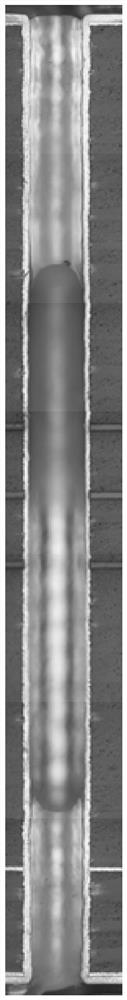

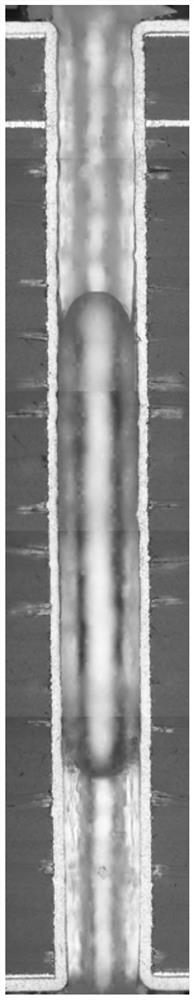

Image

Examples

Embodiment 1

[0055] The application discloses an electroplating copper plating solution suitable for encapsulating carrier boards and printed circuit boards. The electroplating copper plating solution consists of the following components in a concentration ratio:

[0056] Sulfuric acid 200g / L;

[0057] Copper sulfate pentahydrate 70g / L;

[0059] Copper plating additive 50ml / L;

[0060] The balance is pure water, wherein the chloride ions are derived from hydrochloric acid.

[0061] Copper plating additives consist of the following components in concentration ratio:

[0062] Brightener 30mg / L;

[0063] Leveling agent 50mg / L;

[0064] Wetting agent 20g / L;

[0065] The balance is pure water.

[0066] Wherein the brightener is sodium polydithiodipropane sulfonate, the leveling agent is polyethylene oxide polypropylene oxide monobutyl ether, and the wetting agent is polyethylene glycol 6000.

Embodiment 2

[0068] The difference from Example 1 is that the concentration ratio of the brightener in Example 2 is 1 mg / L.

Embodiment 3

[0070] The difference from Example 1 is that the concentration ratio of the brightener in Example 3 is 25mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| evenness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com