Potassium chloride cyanide-free titanium alloy plating solution, its preparation method and electroplating process

A technology of potassium chloride and titanium alloy, which is applied in the field of potassium chloride cyanide-free titanium alloy electroplating and electroplating, and can solve the problems of low stability of the plating solution, many inclusions, and decreased corrosion resistance of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

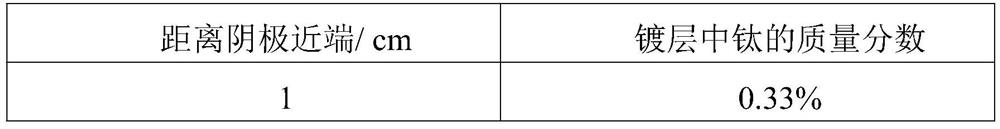

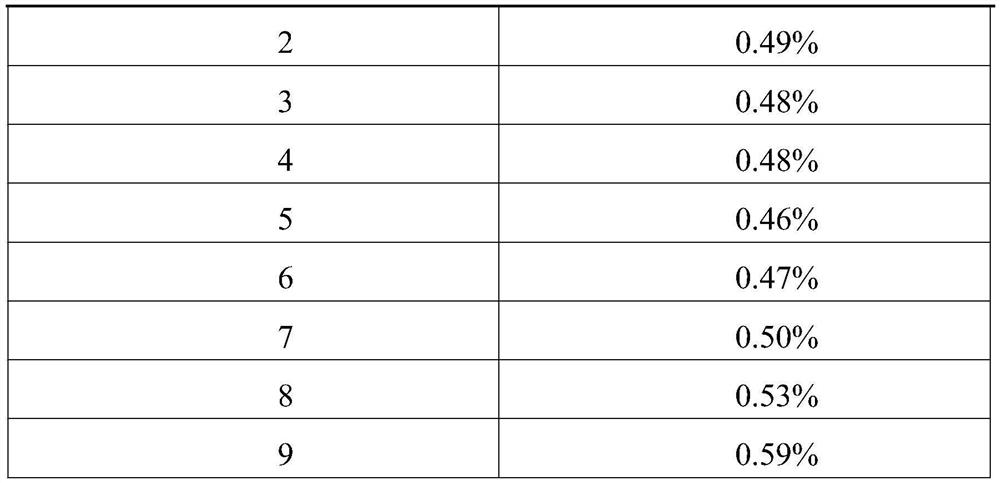

[0048] The potassium chloride cyanide-free cadmium titanium alloy plating solution composition and the concentration of the present embodiment are as follows:

[0049] Cadmium chloride 30g / L, potassium chloride 150g / L, complexing agent 130g / L, sodium fluoride 3g / L, titanium salt supplement 5mL / L, brightener 2mL / L, auxiliary agent 30mL / L Dose 10mL / L;

[0050] The displacement agent contains water-soluble propargyl amide polymer with a mass concentration of 8-12g / L, sodium dimethylbenzenesulfonate with a mass concentration of 50-80g / L, and a product model of polyoxyethylene PE 600 Ether phosphate 80~120mL / L. Add 8-12g of water-soluble propargyl amide polymer, 80-120mL of polyoxyethylene ether phosphate with a mass concentration of sodium dimethylbenzene sulfonate of 50-80g and product model PE 600 into 500mL of water, stir well and add water to 1000mL.

[0051] The complexing agent is composed of three components A, B and C, wherein component A is nitrilotriacetic acid, compo...

Embodiment 2

[0084] The composition and concentration of the barrel plating potassium chloride cyanide-free cadmium titanium alloy plating solution of the present embodiment are as follows:

[0085] Cadmium chloride 25g / L, potassium chloride 180g / L, complexing agent 100g / L, sodium fluoride 1g / L, titanium salt replenisher 2mL / L, brightener 2mL / L, auxiliary agent 30mL / L, position Dose 5ml / L;

[0086]The mass concentration of the water-soluble propargyl amide polymer contained in the moving agent is 5-10g / L, the mass concentration of sodium dimethylbenzenesulfonate is 70-100g / L, and the product model is polyoxyethylene PE 600 Ether phosphate 100~150mL / L. Add 5-10g of water-soluble propargyl amide polymer, 70-100g of sodium dimethylbenzene sulfonate, and 100-150mL of polyoxyethylene ether phosphate ester of product model PE 600 into 500mL of water, stir well and add water to 1000mL.

[0087] The preparation method of the complexing agent, brightener, auxiliary agent and titanium salt replen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com