Patents

Literature

33results about How to "Plating solution formula is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

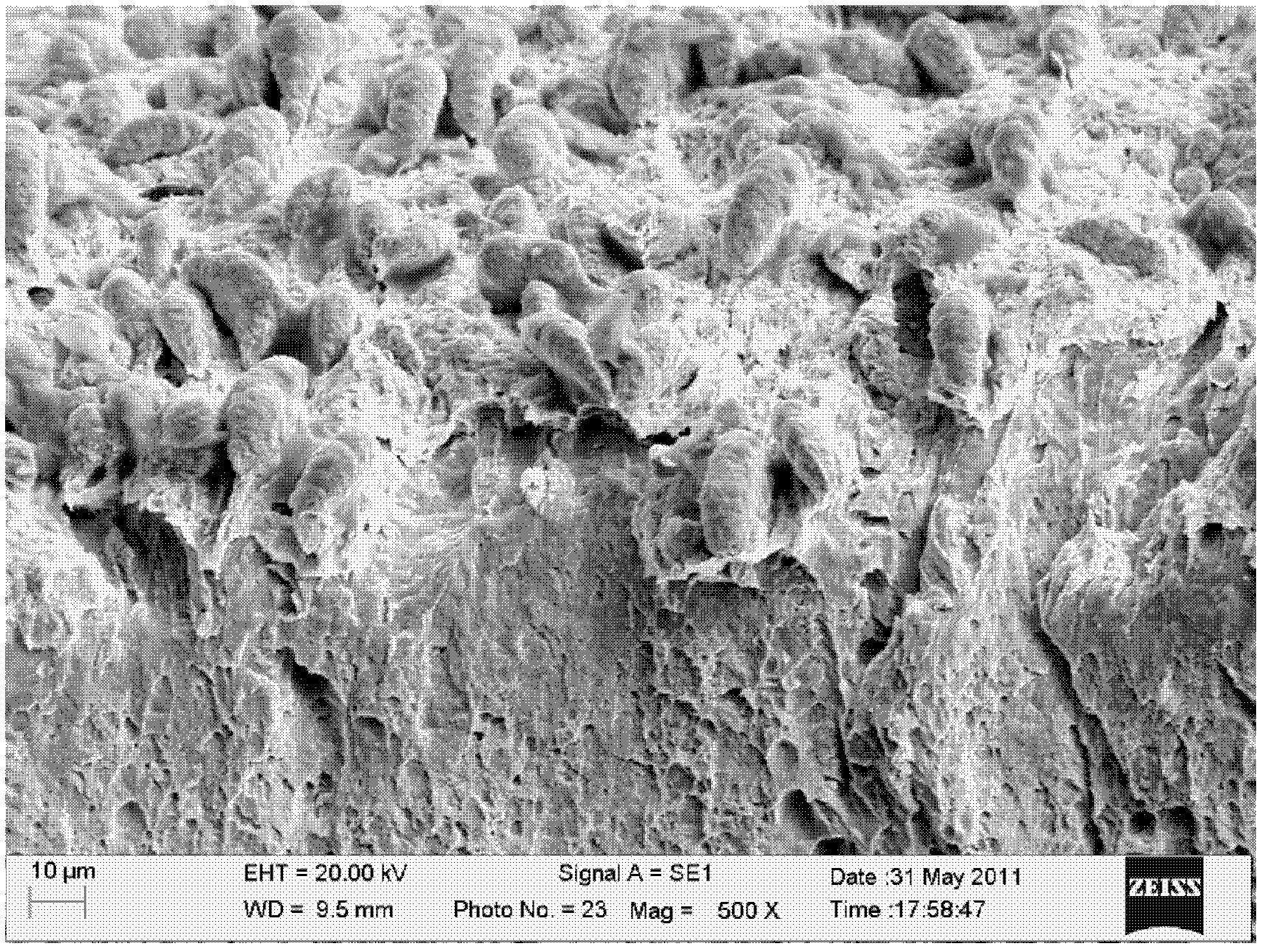

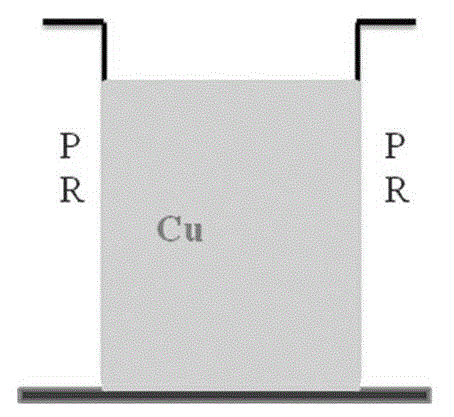

Micro-pore electroplated copper filling method for three-dimensional (3D) copper interconnection high aspect ratio through-silicon-via technology

InactiveCN103361694ALow costFast hole fillingCellsSemiconductor/solid-state device manufacturingMethane sulfonateInterconnection

The invention discloses a micro-pore electroplated copper filling method for a three-dimensional (3D) copper interconnection high aspect ratio through-silicon-via technology. The micro-pore electroplated copper filling method comprises the following steps of: 1, preparing an electroplating solution of a copper methane sulfonate system; 2, wetting micro pores of the through-silicon-via technology through electroplating pretreatment; 3, electrifying and slotting, and increasing the ultralow current diffusion step, so that the copper ion and additives are reasonably distributed on the surfaces and inside the micro pores through the through-silicon-via technology; 4, connecting a silicon wafer where the through-silicon-via technology is positioned with a cathode of a power supply, so that the electroplating surface of the wafer is completely soaked in the electroplating solution, step-by-step current electroplating is performed under the condition that the cathode is rotated or stirred, and the electroplating conditions comprise the current density of 0.01-10A / dm<2> and the temperature of 15-30 DEG C; and 5, completely and thoroughly washing the wafer by using deionized water, performing spin-dry or blow-dry. The provided micro-pore electroplated copper filling method for the 3D copper interconnection high aspect ratio through-silicon-via technology is high in pore filling speed and thin in surface copper, hole and crack risks are avoided, and complete filling of high-difficulty hole with the depth-to-width ratio of more than 10:1 can be realized.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Plating solution and plating method of cyanide-free plating silver

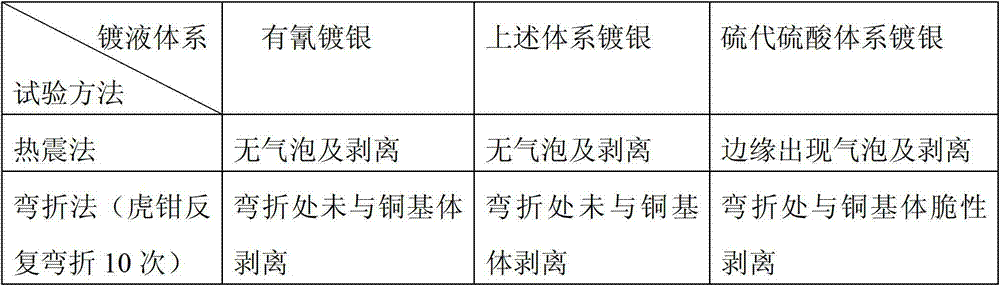

The invention discloses a plating solution and a plating method of cyanide-free plating silver. 20-60g silver nitrate, 70-90g ammonium acetate, 70-110g nicotinic acid, 60-90g potassium carbonate, 40-70g potassium hydroxide, 0.2-1.2g o-benzoyl sulfimide sodium and 0.16-0.64g polyethylene glycol are contained in 1L of the plating solution with a pH value of 9-10. According to the plating solution and the plating method of the cyanide-free plating silver, the plating solution does not contain cyanide ions; the pollution of wastewater treatment is reduced; the injury to a human body due to precious metal plating is reduced; a formula of the plating solution is simple, and easy to control; compared with other cyanide-free plating, the current density is higher; and the deposition efficiency of a silver coating can be improved. With the adoption of pulse plating, a coating that is small in coating stress and good in compactness and brightness, and combines with a matrix well can be obtained.

Owner:XI AN JIAOTONG UNIV +1

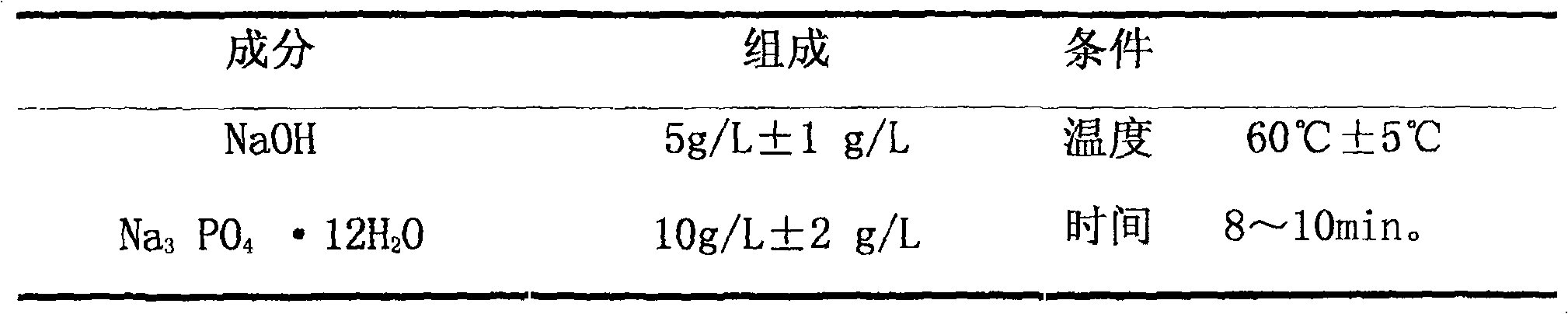

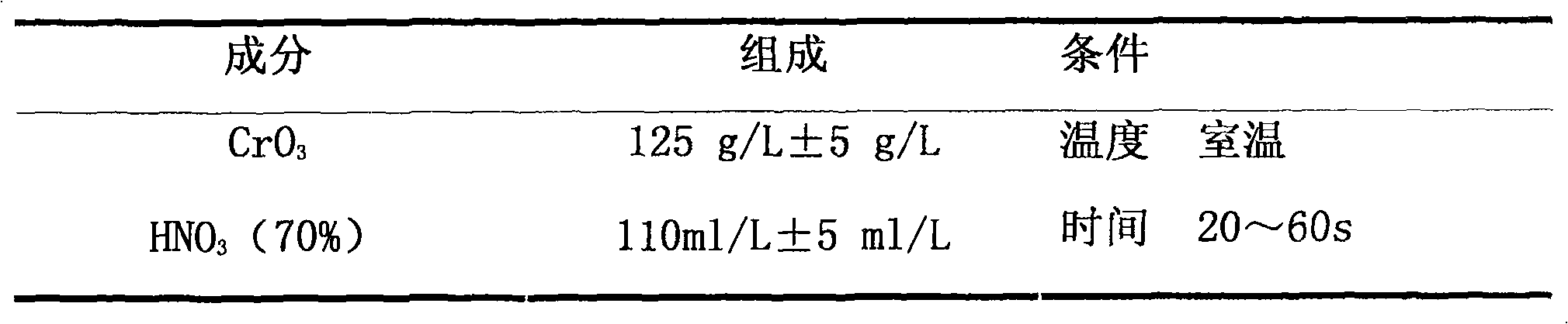

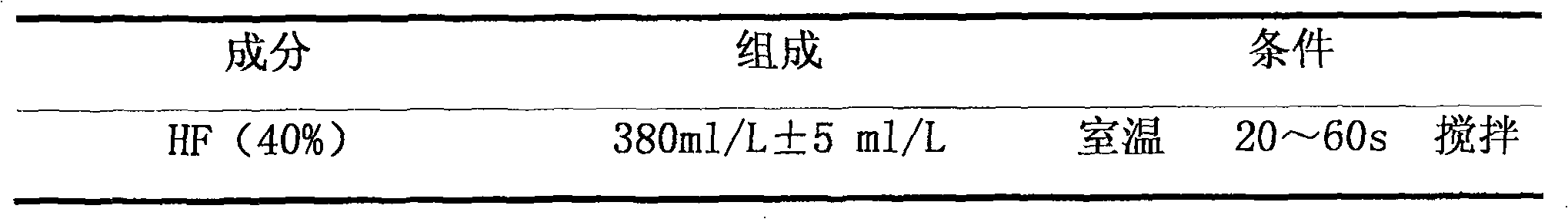

Surface chemical plating Ni-P process using nickel sulfate as main salt

InactiveCN101187020ALow costPlating solution formula is simpleLiquid/solution decomposition chemical coatingEvery HourSulfate

The invention relates to a chemical Ni-P plating technique on the surface of magnesium alloy which takes nickel sulfate (NiSO4, 6H20) as the main salt. The technique process is as follows, ultrasonic cleaning, alkali cleaning, acid cleaning, activation, and chemical nickel phosphorus plating (water cleaning is employed among steps), dispensations of plating solution are NiSO4, 6H2O (20 grams per liter), HF (40%, 12 milliliter per liter), Na3C6H5O7, 2H2O (20 grams per liter), NH4HF2 (10 grams per liter), NH3, H20 (25%, 30 milliliters per liter), and NaH2PO2, H2O (20 grams per liter), and the plating temperature is 88 +-2 DEG C. The plating speed on the surface of magnesium alloy is 20 micrometers per hour, and the plated rigidity is 300-500 HV. The invention is low in cost and simple in plating solution dispensation, and is applicable to the magnesium alloy in Mg-Al-Zn series (AZ series).

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method of monopulse cyanide-free silver electroplating

The invention discloses components and a technology of a monopulse cyanide-free silver electroplating solution. The components and the technology are characterized in that: cyanide-free silver electroplating solution mainly comprises silver nitrate, hydantoin and derivatives thereof, potassium pyrophosphate, potassium sulfate, hydrochloric acid, deionized water, and the like. Operation conditions are that the pH value of the electroplating solution is 6-10 and that the temperature of the electroplating solution is 20-40 DEG C. A finely crystallized silver plating can be obtained through electroplating on pure copper or a copper alloy by utilizing of monopulse electroplating and by controlling the pulse width, the pulse duty cycle, the average pulse current density and the pulse working time. The electroplating solution is simple in formula, easy to control, strong in throwing power and in covering power and high in batch production stability. The plating is finely crystallized, and is good in appearance color. The plating is free from peeling, falling off and stripping. The technology can replace cyanide silver electroplating technologies, is environmental-friendly and pollution-free, and reduces damage of silver electroplating to operators.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Cu-Zn-Sn ternary alloy cyanide-free imitation gold plating solution and use method thereof

The invention discloses a Cu-Zn-Sn ternary alloy cyanide-free imitation gold plating solution and a use method thereof. In the plating solution, copper sulfate, zinc sulfate and stannous sulfate are used as main salts, potassium pyrophosphate is used as a main complexing agent, ethylene diamine, potassium citrate and nitrilotriacetic acid are used as auxiliary complexing agents, sulfuric acid is used as an antioxidant and an anti-hydrolysis agent for stannous ions, and potassium hydroxide is used as a regulator for regulating the pH value of the plating solution. The operating conditions are as follows: the cathode current density is 1.0-3.0A / dm2, the pH value is 8.0-10.0, the temperature of the plating solution is room temperature, the plating time is 60-90s, the mechanical stirring or cathode movement is adopted, the anode material is 316L stainless steel, and the plating process is carried out on the substrate of a plating bright nickel layer. The invention has simple formula of the plating solution, easy control, wide process parameter range, fine crystal, good appearance color, stable plating solution, long service life, strong uniformly plating capacity and covering capacity, and high stability in batch production. The technology can replace the cyanide imitation gold plating process to be used as the plating process for imitating 9K, 18K or 24K gold on surfaces of decorative articles such as jewelry, clocks, handicraft articles and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of electroplated cadmium coating for metalwork

The invention relates to a preparation method of an electroplated cadmium coating for metalwork, belonging to the field of chemical industry, and comprising the following steps of: degreasing and cleaning metalwork to be electroplated by an ultrasonic cleaner, then finely sanding the metalwork, cleaning the surface of the metalwork with clear water and alcohol in sequence, drying the metal surface to remove the alcohol from the surface of the metalwork; and electroplating by a plating solution composed of cadmium sulfate, nickel sulfate, potassium hydroxide, a complexing agent and an auxiliary complexing agent. The preparation method provided by the invention has the advantages that the metalwork is easy to treat, the formula of the plating solution is simple, operation and maintenance are easy, harmful substances such as cyanogen and the like are not contained, and environmental protection is benefited. In addition, the bonding quality between a plated coating and a substrate is good without cracking or damage.

Owner:UNIV OF SCI & TECH BEIJING

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

Additive B capable of controlling TSV deep hole copper plating crystallization and growth mode and application of additive B

The invention discloses an additive B capable of controlling the TSV deep hole copper plating crystallization and the growth mode and an application of the additive B. The additive B comprises, by weight, 1%-10% of one of polyethylene glycol and polyvinyl alcohol with the molecular weight being 200 to 20,000 or the mixture of polyethylene glycol and polyvinyl alcohol with different molecular weights, 0.01%-10% of an EO-PO-EO-quaternary ammonium compound, 0.1%-5% of a thioimidazole compound, 0.1%-10% of polyethylenimine and derivative thereof and the balance water. By means of the additive B, the TSV deep hole electroplating copper filling mode can be changed, the crystal habit of copper is changed, and thus defect-free micro protrusion filling along holes of TSV micro holes can be achieved; the copper crystallization shape and the hole opening growth mode are effectively controlled, the surface copper thickness is reduced, TSV deep hole opening micro protrusions are also reduced, hence, the subsequent CMP processing pressure is lightened, the subsequent processing cost is lowered, and the yield and the production efficiency are greatly improved.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

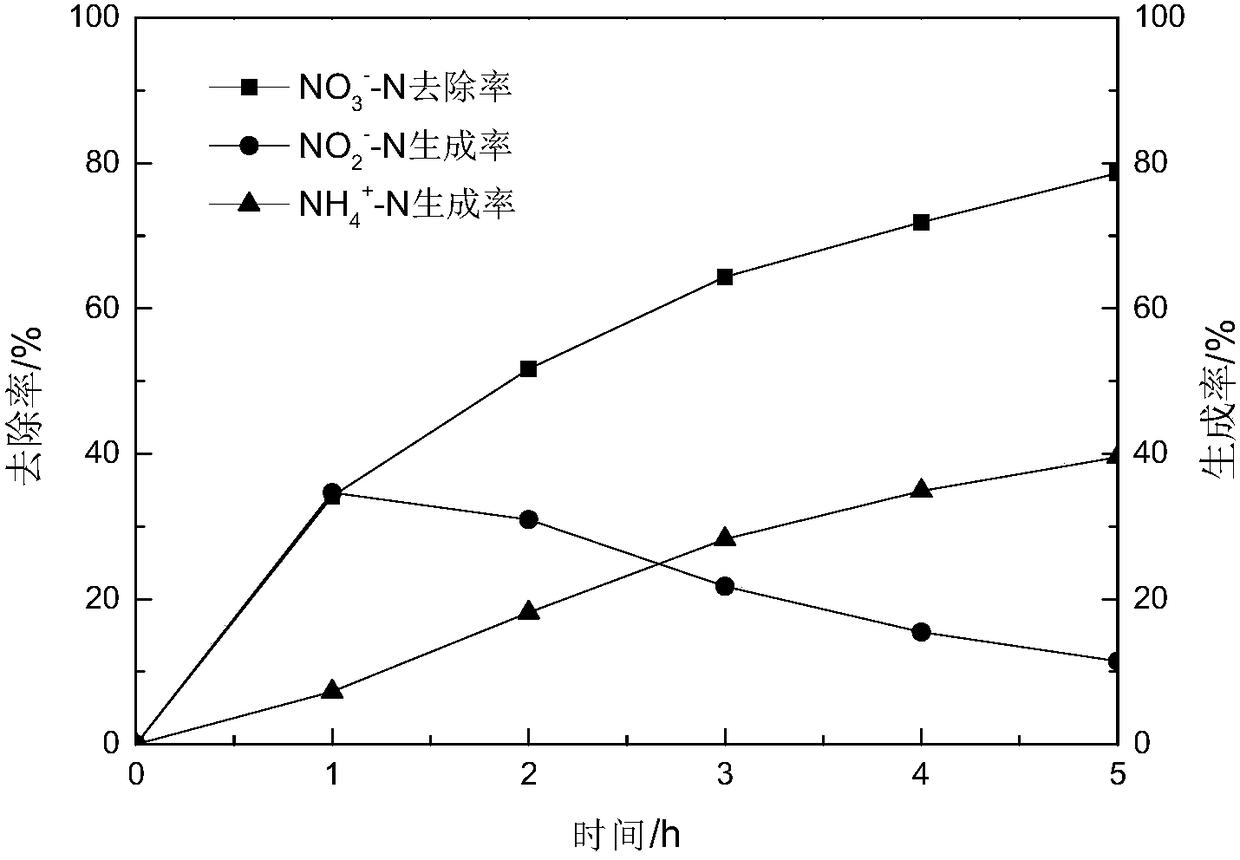

Cu-Sn-Bi electrode with high catalytic activity, and preparation method and application thereof

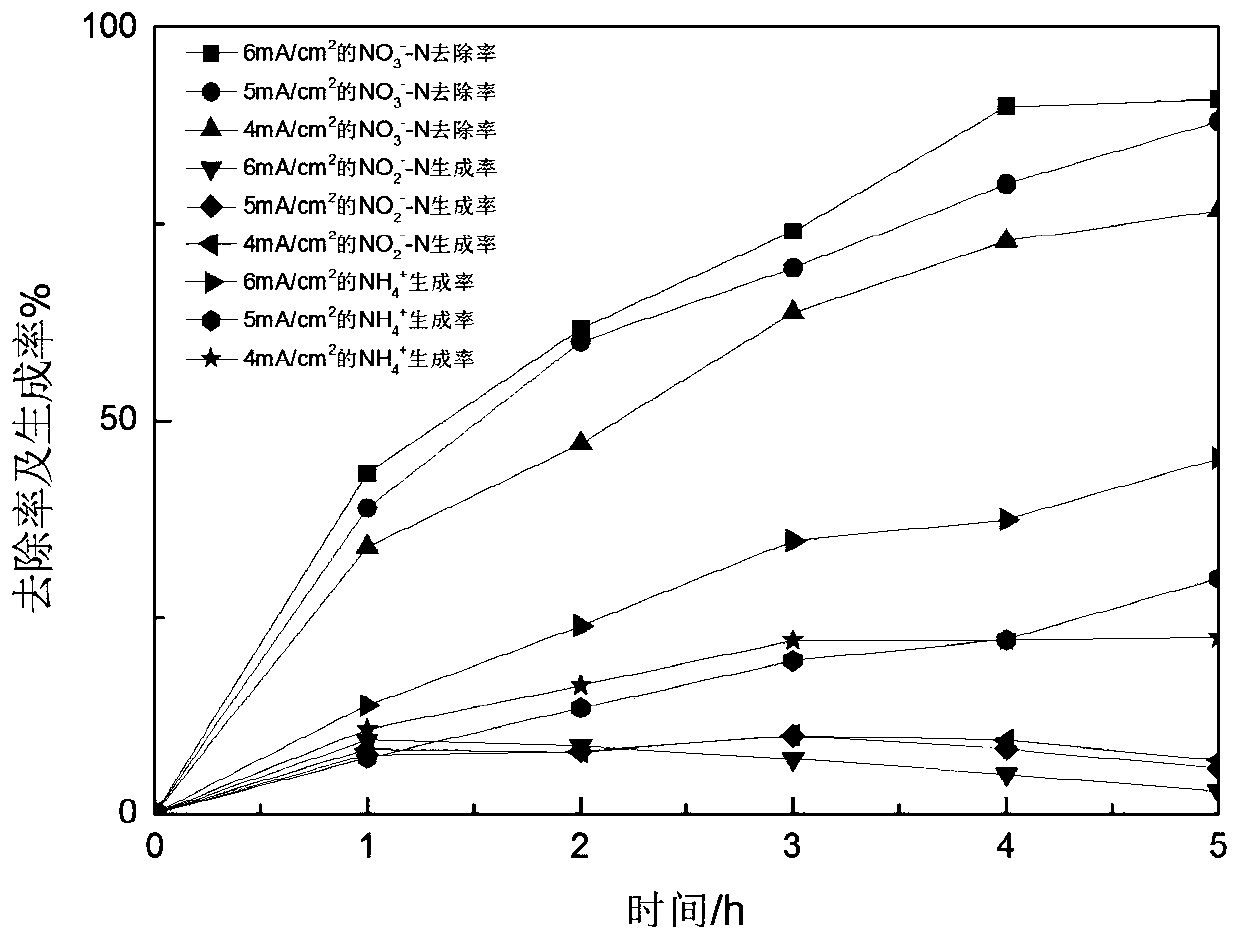

PendingCN108467091ACorrosion resistanceImprove stabilityWater contaminantsWater/sewage treatmentPolymer scienceNitrate

The invention provides a Cu-Sn-Bi electrode with high catalytic activity, and a preparation method and an application thereof. The electrode is prepared by dissolving the following components in deionized water by mass: 56 to 61 g / L of Bi(NO3)3.5H2O, 37 to 52.3 g / L of CuP2O7, 2.6 to 4.3 g / L of SnP2O7, 45 to 65 g / L of KCl, 45 to 65 g / L of NaKC4H4O6.4H2O, 85 to 92 g / L of EDTA-2Na, 118 to 123 g / L ofC7H6O6S.2H2O, 220 to 250 g / L of K4O7P2, 26 to 31 g / L of Na2HPO4 and 25 to 30 g / L N(CH2COOH)3. The process for preparation of the electrode provided by the invention has the following advantages: plating can be performed at a room temperature; working conditions are easy to maintain; a plating liquid has a simple formula with commonly-used chemicals with low price; no secondary synthesis is required; an obtained electrode plating layer is firmly bonded with a substrate; and the surface of the electrode is uniform. The Cu-Sn-Bi electrode provided by the invention has higher corrosion resistanceand good electrical conductivity, is used in the process of nitrate degradation, and has high catalytic efficiency.

Owner:SHENYANG POLYTECHNIC UNIV

Lead-free electroless tin plating solution

InactiveCN102994994AEnables continuous autocatalytic depositionReduce typesLiquid/solution decomposition chemical coatingSolubilityPorosity

The invention relates to a lead-free electroless tin plating solution. The lead-free electroless tin plating solution is characterized by comprising the following components: 20 to 30g / L of stannous mono-sulphate, 60 to 120g / L of thiourea, 15 to 25g / L of citric acid, 20 to 50g / L of sulfur dioxide, 3 to 5g / L of ethylene diamine tetraacetic acid, 0.01 to 0.05g / L of polyethylene glycol, 20 to 55m / L of 98% of concentrated sulfuric acid, 0.5 to 1.0g / L of gelatin, and the balance of regulator. The lead-free electroless tin plating solution has the advantages that few categories of chemical materials are used and cost is low; the tin can be continuously deposited at a high speed on copper and a copper alloy substrate, thus semi-bright chemical coatings with different thicknesses can be produced, and the flatness of the chemical coatings can be improved; and the lead-free electroless tin plating solution is remarkable in grain refinement, low in porosity, simple in formula of plating solution, easy to control, stable in plating solution, long in service life and high in stability in batch production; and polyethylene glycol is a nontoxic and nonirritating substance with high water solubility, and can be combined with other materials without producing harmful substances.

Owner:NANTONG HUIFENG ELECTRONICS TECH

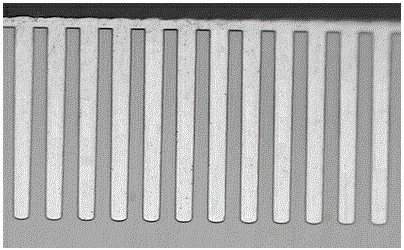

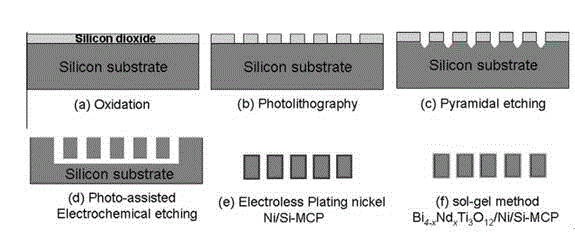

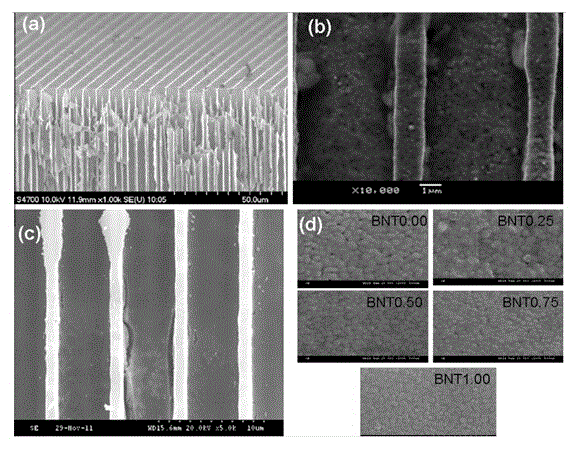

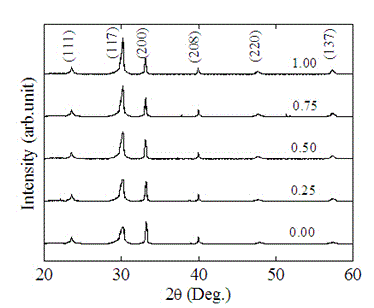

High-performance electrochemical capacitor plate material and preparation method thereof

InactiveCN104952628AObvious advantagesRegular and uniform pore sizeHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePath length

The invention discloses a high-performance electrochemical capacitor plate material and a preparation method thereof, and belongs to the field of capacitor manufacture. The high-performance electrochemical capacitor plate material is silicon micro-channel supported neodymium-doped bismuth titanate, and adopts the structure that a neodymium-doped bismuth titanate thin film layer is generated on the inner wall of a three-dimensional silicon micro-channel plate through vacuum filtration and high-temperature oxidation to be used as an electrochemical capacitor active layer. The preparation method of the high-performance electrochemical capacitor plate material comprises the following steps: preparing the three-dimensional silicon micro-channel plate by adopting an electrochemical method, then, depositing a nickel layer by adopting a electroless plating method, preparing a nano-neodymium-doped bismuth titanate thin film layer by adopting a sol-gel method, and finally, performing rapid thermal annealing in an oxygen atmosphere, so as to form a neodymium-doped bismuth titanate / silicon micro-channel composite structure material. The high-performance electrochemical capacitor plate material provided by the invention provides a short transmission / diffusion path length, has larger specific area, and is conductive to obtaining higher energy density and power density.

Owner:QIQIHAR UNIVERSITY

A kind of method of single-pulse cyanide-free electroplating silver

The invention discloses components and a technology of a monopulse cyanide-free silver electroplating solution. The components and the technology are characterized in that: cyanide-free silver electroplating solution mainly comprises silver nitrate, hydantoin and derivatives thereof, potassium pyrophosphate, potassium sulfate, hydrochloric acid, deionized water, and the like. Operation conditions are that the pH value of the electroplating solution is 6-10 and that the temperature of the electroplating solution is 20-40 DEG C. A finely crystallized silver plating can be obtained through electroplating on pure copper or a copper alloy by utilizing of monopulse electroplating and by controlling the pulse width, the pulse duty cycle, the average pulse current density and the pulse working time. The electroplating solution is simple in formula, easy to control, strong in throwing power and in covering power and high in batch production stability. The plating is finely crystallized, and is good in appearance color. The plating is free from peeling, falling off and stripping. The technology can replace cyanide silver electroplating technologies, is environmental-friendly and pollution-free, and reduces damage of silver electroplating to operators.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Stabilizer for electroplating brightening tin and tin alloy and preparation method thereof

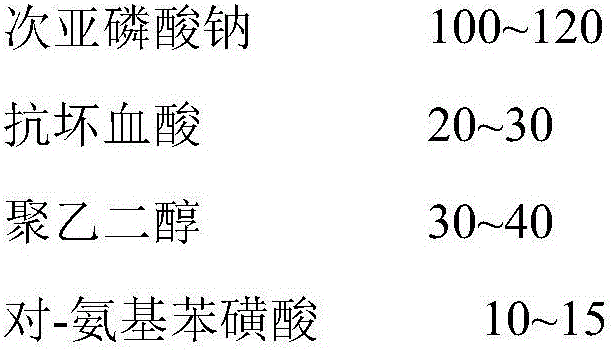

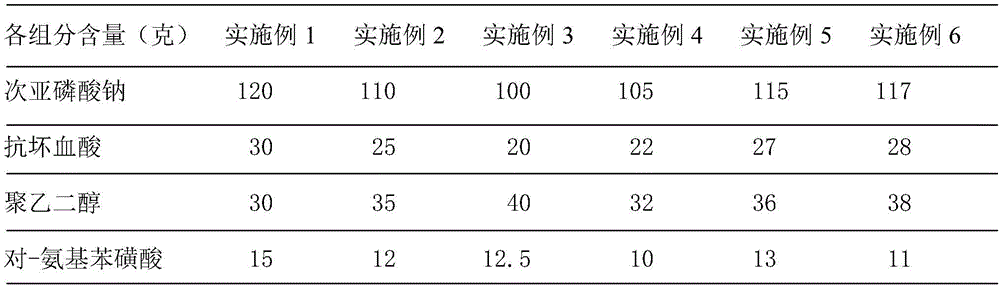

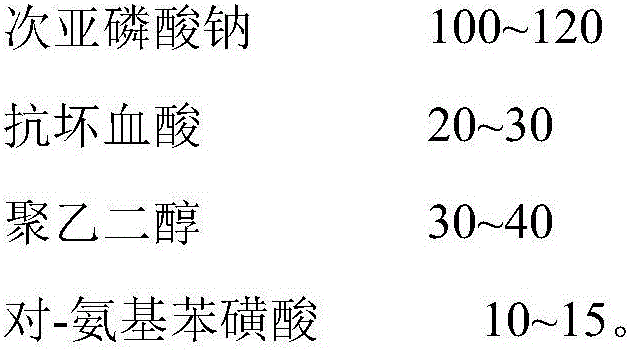

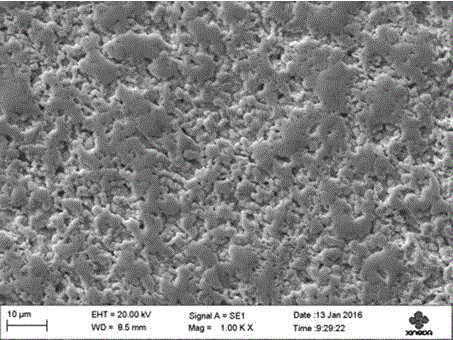

InactiveCN106521570AImprove coverageImprove the corrosion resistance of the nickel layerCorrosionPolyethylene glycol

A stabilizer for electroplating brightening tin and tin alloy comprises, by weight, 100-120 parts of sodium hypophosphite, 20-30 parts of ascorbic acid, 30-40 parts of polyethylene glycol and 10-15 parts of sulfanilic acid. The molecular weight M of the polyethylene glycol is 6000-12000. A preparation method of the stabilizer for electroplating brightening tin and tin alloy includes the following steps that (a) polyethylene glycol is weighed, distilled water is added to the polyethylene glycol to form a polyethylene glycol solution with the concentration of 5-8%, and heating and stirring are conducted until the polyethylene glycol is completely dissolved; (b) sodium hypophosphite is added and stirred until the sodium hypophosphite is completely dissolved; (c) ascorbic acid is added into the solution and stirred until the ascorbic acid is completely dissolved; (d) sulfanilic acid is added into the solution and stirred until the sulfanilic acid is completely dissolved; and (e) distilled water is supplemented and added to enable the concentration of the polyethylene glycol to be 3-4%, and the operation is competed after uniform stirring. The stabilizer for electroplating brightening tin and tin alloy has the advantages of being high in corrosion resistance, good in covering capacity, good in stability, high in electroplating efficiency and capable of being stored for a long time. A tin plating solution is stable. A clad layer obtained through electroplating is uniform, compact and good in combination force.

Owner:HUBEI UNIV

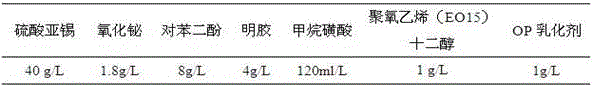

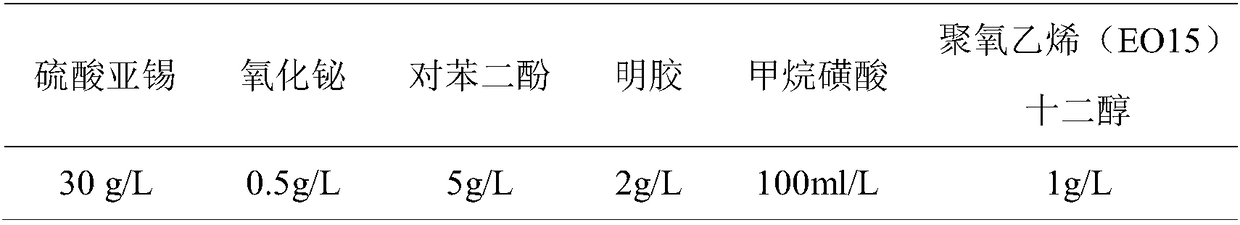

Plating solution formula for electroplating pure tin on copper wire and electroplating method

The invention discloses a plating solution formula for electroplating pure tin on a copper wire and an electroplating method. The pH value of a plating solution is 1.0. The plating solution comprises tin(II) sulfate, an adding agent bismuth oxide, an adding agent nonionic surfactant, a stabilizing agent p-dihydroxybenzene, a brightening agent gelatin and solvent sulphonethane. The electroplating method includes the steps that the copper wire serves as an electroplating cathode after being subjected to alkaline washing to remove oil and subjected to hot water washing, acid pickling, cold water washing and drying, and a titanium plate serves as an electroplating anode; and the current density is 2.5-4 A / dm<2>, the electroplating time is 10 min, and temperature is normal temperature. The plating solution composition is simple and easy to control, waste liquid is environment-friendly and easy to process, the electroplating process is easy to control, and a plating layer is uniform, smooth and good in binding force.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Cyanide-free copper electroplating method for reducing porosity of copper plating layer

The present invention relates to a cyanide-free copper electroplating method for reducing porosity of a copper plating layer. According to the cyanide-free copper electroplating method, a substrate is alternately subjected to a direct current electroplating unit and a pulse electroplating unit, the pH value of the electroplating solution is controlled to 12-13, the temperature is 50-70 DEG C, the cathode current density for copper electroplating in each direct current electroplating unit is 0.5-3.0 A / dm<2>, the electroplating time is 2-3 min, the pulse average current density for copper electroplating in each alternating current electroplating unit is 0.5-3.0 A / dm<2>, the duty ratio is 15%, and the electroplating time is 2-3 min. The plating layer obtained through the method has minimal porosity when the plating layer thickness is 10-20 mum.

Owner:WUXI XINSANZHOU STEEL

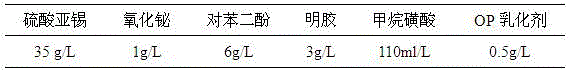

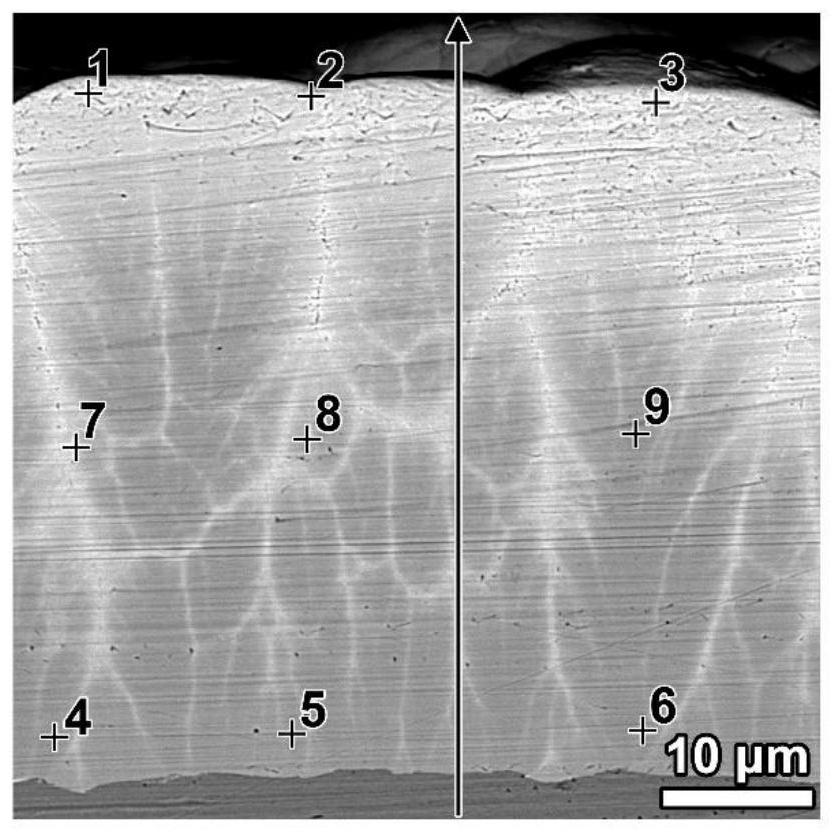

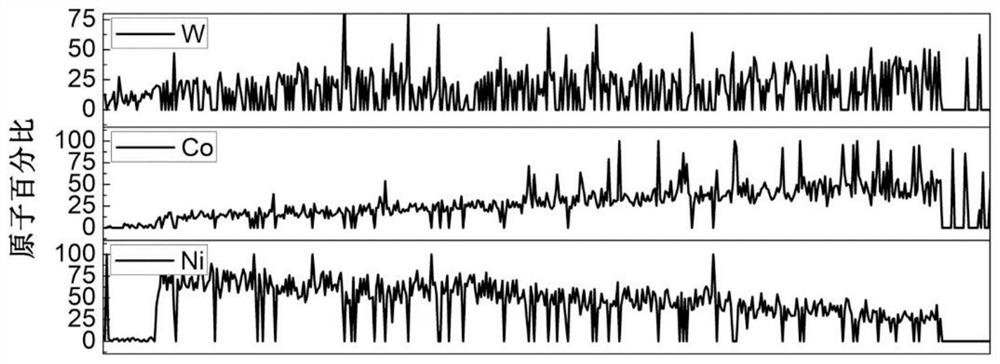

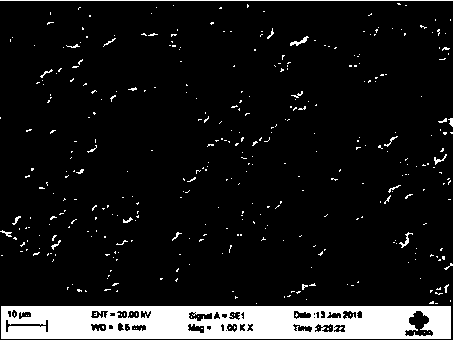

Plating solution of nickel-cobalt-tungsten gradient plating layer, preparation method and electroplating method

PendingCN114196997AGuaranteed uniformityPlating solution formula is simpleTrisodium citrateAmmonium chloride mixture

The invention discloses a plating solution of a nickel-cobalt-tungsten gradient plating layer, a preparation method and an electroplating method, and relates to the field of preparation of gradient plating layers, and every 1 L of the plating solution comprises 9-18 g of nickel sulfate, 3-6 g of cobalt sulfate, 30-60 g of sodium tungstate, 90-180 g of trisodium citrate, 18-36 g of ammonium chloride and 6-12 g of sodium chloride. Constant-current and direct-current continuous electroplating is adopted, and the problems that in the gradient plating electroplating process, electroplating parameter control is complex, and the requirement for an electroplating power source is high are solved.

Owner:CHINA JILIANG UNIV

Standard aluminum wire electroplating solution formula

The invention discloses a standard aluminum wire electroplating solution formula. The pH of the plating solution is in the range of 5.2 to 5.4, the standard aluminum wire electroplating solution formula comprises the following components of, in parts by weight, 37g-40g of aluminum chloride, 47g-49 g of aluminum oxide, 17g-19g of sodium chloride, 19g-21g of boric acid, 65g-67g of magnesium carbonate, 17g-20g of methyl methacrylate, 13g-15g of potassium carbonate, 12g-15 g of zinc chloride, 6g-8g of copper chloride and 41g-48g of stannous sulfate; 2.5g-3g of additive bismuth oxide, 2.5g-3g of additive nonionic surfactant, 9g-11g of stabilizer hydroquinone, 5g-7g of brightener gelatin and 510g-560g of deionized water. The invention provides the standard aluminum wire electroplating solution formula which is uniform in plating, smooth in surface, high in binding force and good in welding performance.

Owner:江门市顺高电镀有限公司

Standard copper wire electroplating solution formula

The invention relates to a standard copper wire electroplating solution formula which is characterized in that the pH of the electroplating solution is 5.0, the standard copper wire electroplating solution includes 20-30 g of aluminum hydroxide, 20 to 46 g of aluminum oxide, 12-16g of sodium lauryl sulfate, 15-18g of silicic acid, 50-64g of magnesium carbonate, 12-16g of methyl methacrylate, 7-12gof potassium chloride, 3-11g of ferroferric oxide, 2-5g of silver nitrate, 30 40g of tin propane sulfonate; 0.5-2g of additive bismuth oxide; 0.5-2g of additive non-ionic surfactant; 5-8g of stabilizer hydroquinone; 2-4g of brightener gelatin and 300-500g of deionized water. The the standard copper wire electroplating solution has the advantages of simple formula, environmental protection, and good stability, an electroplating process is easy to control, and an electroplated layer is uniform, compact, good in bonding force, and widely used in welding. The electroplating solution does not generate bubbles, and remains clear during the electroplating process.

Owner:如皋市跃天特种标准件有限公司

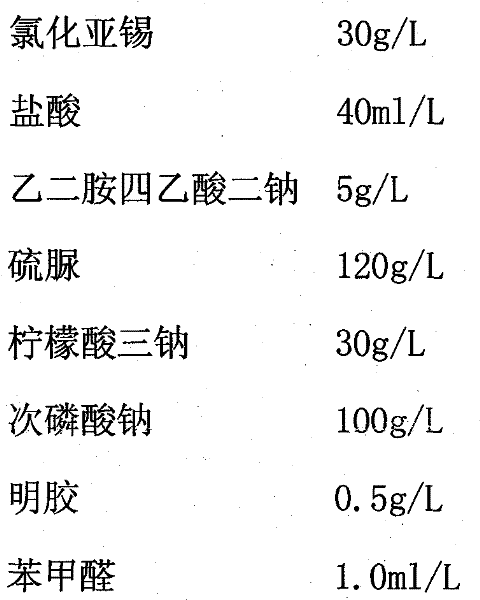

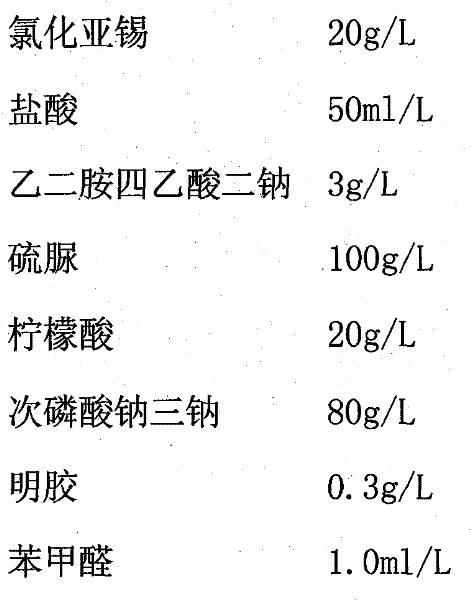

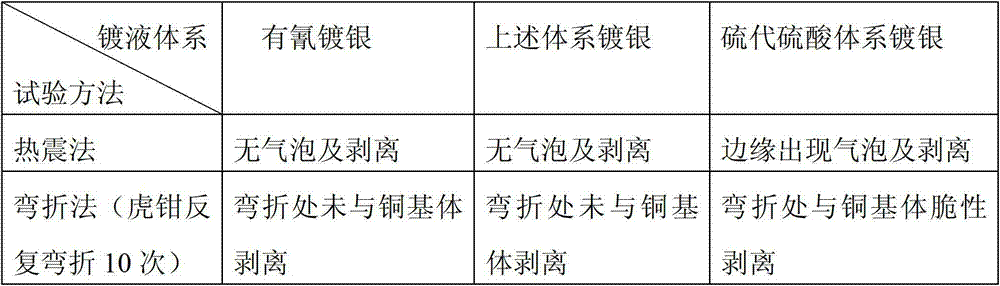

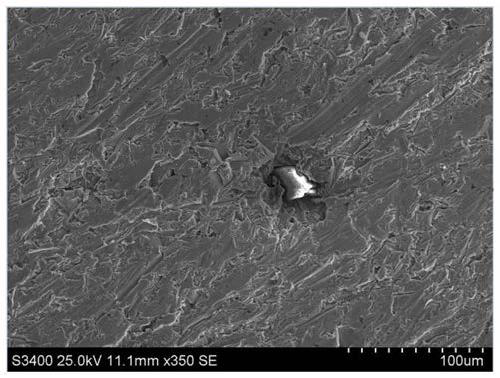

Semi-bright lead-free chemical tinning liquid and using method thereof

InactiveCN101717929BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingThioureaBenzaldehyde

The invention discloses new semi-bright lead-free chemical tinning liquid and a using method thereof. A semi-bright silver tin-copper alloy chemical plating layer is obtained on copper and copper alloy matrix. In the chemical plating liquid, tin sulfate is used as a main salt, thiourea is used as a main complexing agent, citric acid is used as an auxiliary complexing agent, sodium hypophosphite is used as a reducing agent, ethylene diamine tetraacetic acid is used as an antioxidant, sulfuric acid is used as a stabilizing agent, gelatin is used as a leveling agent, and benzaldehyde is used as an auxiliary brightening agent. The pH value of the plating liquid is 0.8 to 2.0, the temperature of the plating liquid is between 80 and 90 DEG C, the carrying capacity of the plating liquid is 0.8 to 1.5dm2 / L, and the mechanical stirring speed is 50 to 100 rpm. The continuous self-catalytic deposition of tin is implemented on the copper and copper alloy matrix, plating layers of different thicknesses can be obtained by controlling the chemical plating time, and the deposition speed is high; crystalline grains are obviously refined, the surface flatness of the plating layer is improved, and the plating surface area is large; the plating layer and the matrix are combined firmly; and after passivating treatment, the change resistance of the plating layer is high. The technology has broad application prospect in products such as deep hole pieces, blind hole pieces, small-sized electronic parts and components which are difficult to process, printed circuit boards (PCB) and the like.

Owner:KUNMING UNIV OF SCI & TECH

A kind of plating solution and electroplating method for electroplating pure tin on copper wire

The invention discloses a plating solution and an electroplating method for electroplating pure tin on copper wires, wherein the pH value of the plating solution is 1.0, and it contains stannous sulfate, an additive bismuth oxide, an additive nonionic surfactant, and a stabilizer pair Hydroquinone, brightener gelatin, solvent methanesulfonic acid; electroplating method: copper wire is washed with alkali to remove oil, hot water, pickling, cold water, and dried to make the cathode of the electroplating, and the titanium plate is used as the anode of the electroplating; the current density is 2.5 ‑4A / dm2, the electroplating time is 10min, and the temperature is room temperature. The composition of the plating solution of the invention is simple and easy to control, the waste liquid is environmentally friendly and easy to handle, the electroplating process is easy to control, and the plating layer is uniform and smooth and has good binding force.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Surface chemical plating Ni-P process using nickel sulfate as main salt

InactiveCN100595323CLow costPlating solution formula is simpleLiquid/solution decomposition chemical coatingEvery HourGram

The invention relates to a chemical Ni-P plating technique on the surface of magnesium alloy which takes nickel sulfate (NiSO4, 6H20) as the main salt. The technique process is as follows, ultrasoniccleaning, alkali cleaning, acid cleaning, activation, and chemical nickel phosphorus plating (water cleaning is employed among steps), dispensations of plating solution are NiSO4, 6H2O (20 grams per liter), HF (40%, 12 milliliter per liter), Na3C6H5O7, 2H2O (20 grams per liter), NH4HF2 (10 grams per liter), NH3, H20 (25%, 30 milliliters per liter), and NaH2PO2, H2O (20 grams per liter), and the plating temperature is 88 +-2 DEG C. The plating speed on the surface of magnesium alloy is 20 micrometers per hour, and the plated rigidity is 300-500 HV. The invention is low in cost and simple in plating solution dispensation, and is applicable to the magnesium alloy in Mg-Al-Zn series (AZ series).

Owner:ZHONGYUAN ENGINEERING COLLEGE

Formula of standard bolt electroplating solution

The invention relates to a formula of a standard bolt electroplating solution. The formula of the standard bolt electroplating solution is characterized in that the pH value of an plating solution is5.0, and the plating solution comprises of 20-36 g of aluminum chloride, 20-46 g of aluminum oxide, 12-16 g of sodium hydroxide, 15-18 g of silicic acid, 50-64 g of magnesium carbonate, 12-16 g of methyl methacrylate, 7-12 g of potassium chloride, 3-11 g of zinc chloride, 2-5 g of copper chloride, 30-40 g of stannous sulfate, 0.5-2 g of additive bismuth oxide, 0.5-2 g of an additive nonionic surfactant, 5-8 g of a stabilizer hydroquinone, 2-4 g of a brightener gelatin and 300-500 g of deionized water. According to the method, the formula of the plating solution is simple, environment-friendlyand good in stability, the electroplating technology is easy to be controlled, the electroplated coating is uniform and dense, the binding force is good, and the application is wide in the aspect of welding; and in the electroplating process, the plating solution does not generate bubbles, and the plating solution is kept clear all the time.

Owner:如皋市跃天特种标准件有限公司

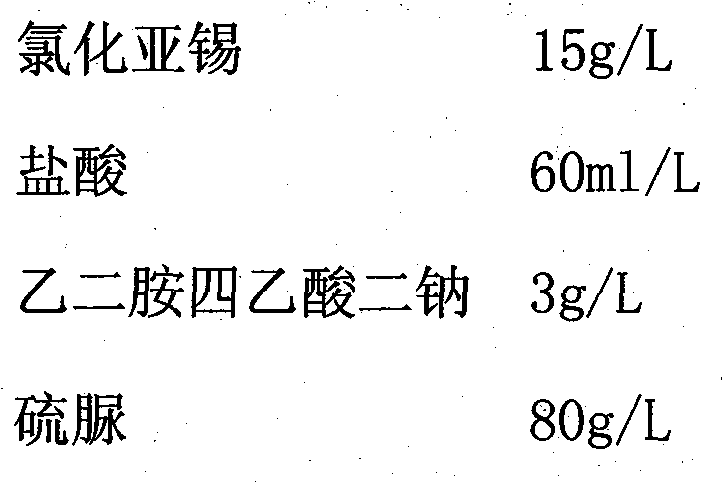

Continuously self-catalyzed deposition chemical plating solution of tin and using method thereof

InactiveCN101724834BEnables continuous autocatalytic depositionFast depositionLiquid/solution decomposition chemical coatingAntioxidantBenzaldehyde

The invention discloses continuously self-catalyzed deposition chemical plating solution of tin and a using method thereof. Half-bright and silvery-white tin-copper alloy deposition layers are obtained on pure copper and a copper alloy substrate. In the chemical plating solution, stannous chloride serves as a main salt, thiourea serves as a main complexing agent, trisodium citrate serves as an auxiliary complexing agent, sodium hypophosphite serves as a reducing agent, disodium ethylene diamine tetraacetate serves as an antioxidant, a hydrochloric acid serves as a stabilizing agent, gelatin serves as a leveling agent and benzaldehyde serves as an auxiliary brightening agent. The using method comprises the following operating conditions that: the pH value of the plating solution is 0.8 to 2.0; the temperature is 80 to 90 DEG C; the loading capacity is 0.8 to 1.5 dm2 / L; and the mechanical stirring speed is 50 to 100 rpm. The continuously self-catalyzed deposition chemical plating solution of the tin and the using method thereof have the advantages of capability of obtaining half-bright and silvery-while tin-copper alloy clad layers with different thicknesses by controlling chemical plating time, high deposition rate, remarkable grain refinement, improvement on surface evenness of the clad layer and batch production stability, secure interface combination, strong change resistance of the clad layer after being passivated, and broad application prospect in the products of deep hole elements, blind hole elements, difficult-to-handle miniature electronic components and parts, printed circuit boards PCBs and the like.

Owner:KUNMING UNIV OF SCI & TECH

A kind of electroplating solution and electroplating method of cyanide-free electroplating silver

The invention discloses a plating solution and a plating method of cyanide-free plating silver. 20-60g silver nitrate, 70-90g ammonium acetate, 70-110g nicotinic acid, 60-90g potassium carbonate, 40-70g potassium hydroxide, 0.2-1.2g o-benzoyl sulfimide sodium and 0.16-0.64g polyethylene glycol are contained in 1L of the plating solution with a pH value of 9-10. According to the plating solution and the plating method of the cyanide-free plating silver, the plating solution does not contain cyanide ions; the pollution of wastewater treatment is reduced; the injury to a human body due to precious metal plating is reduced; a formula of the plating solution is simple, and easy to control; compared with other cyanide-free plating, the current density is higher; and the deposition efficiency of a silver coating can be improved. With the adoption of pulse plating, a coating that is small in coating stress and good in compactness and brightness, and combines with a matrix well can be obtained.

Owner:XI AN JIAOTONG UNIV +1

A kind of preparation method and application of bimetallic Cu-BI electrocatalytic denitrification electrode

ActiveCN108070886BCorrosion resistanceImprove stabilityWater contaminantsWater/sewage treatmentReduction ActivityNitrate salts

Owner:SHENYANG POLYTECHNIC UNIV

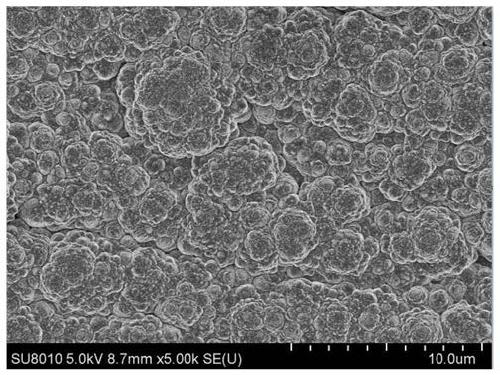

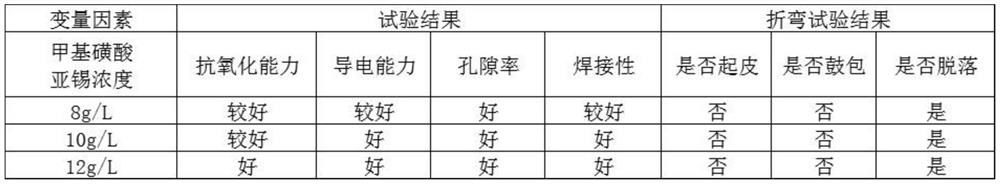

Tin plating solution for copper electronic material as well as preparation method and application method of tin plating solution

PendingCN114574840ATo preventEasy to degradeLiquid/solution decomposition chemical coatingPhosphorous acidMeth-

The invention discloses a copper electronic material tin plating solution, a preparation method and an application method, and the formula of an additive of the copper electronic material tin plating solution comprises the following components: main salt: stannous methanesulfonate with the concentration of 10-13g / L; a hydrolysis agent: 96 to 112 ml / L of methanesulfonic acid; the complexing agent is thiourea with the concentration of 75 g / L or 80 g / L; a tin whisker inhibitor: 0.8-1.2 g / L of silver methanesulfonate; the antioxidant is ethylenediamine tetraacetic acid with the concentration of 3-5g / L; the auxiliary brightening agent is benzaldehyde with the concentration of 0.2 g / L to 0.3 g / L; the reducing agent is at least one of hypophosphorous acid and sodium hypophosphite, and the concentration of the reducing agent is 50-82ml / L; gelatin is also added into the plating solution, and the concentration of the gelatin is 0.2-1.0 g / L; the complex solubilizer is polyalcohol with the concentration of 50 to 500g / L; and the crystal refiner is a polyoxyalkylene ether or amino acid type solution with the concentration of 0.1-10g / L.

Owner:深圳市虹喜科技发展有限公司

Standard nut electroplate liquid formula

The invention relates to a standard nut electroplate liquid formula. The standard nut electroplate liquid formula is characterized in that the pH value of the electroplate liquid is 5.0; the electroplate liquid comprises 20-36g of aluminium hydroxide, 20-46g of aluminium oxide, 12-16g of sodium hydroxide, 15-18g of silicic acid, 50-64g of magnesium carbonate, 12-16g of methyl methacrylate, 7-12g of potassium chloride, 3-11g of ferriferrous oxide, 2-5g of silver nitrate, 30-40g of stannous sulfate, 0.5-2g of additive bismuth oxide; 0.5-2g of additive nonionic surfactant, 5-8g of stabilizer hydroquinone, 2-4g of brightener gelatin, and 300-500g of deionized water. The standard nut electroplate liquid formula is simple, environmentally friendly and excellent in stability; electroplating technology is easy to control; a clad layer produced by electroplating is high in uniformity, densification and binding force; and the standard nut electroplate liquid formula can be widely applied in welding; and bubbles are not produced in the electroplate liquid during electroplating, and the electroplate liquid is always clear.

Owner:如皋市跃天特种标准件有限公司

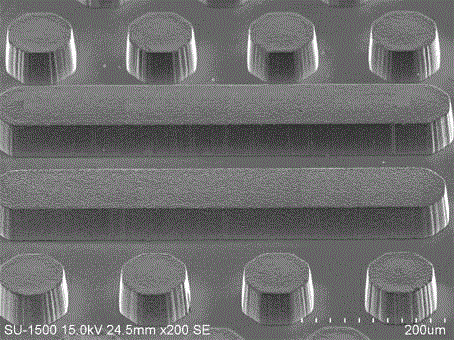

A high-speed bump electroplating method for copper interconnects

ActiveCN103103585BImprove reliabilityImprove uniformityCellsSemiconductor devicesSpeed bumpPolyethylene glycol

The invention discloses a high-speed embossment electroplating method applied to copper interconnection. A sulfonic acid copper system electroplating liquid is adopted to carry out copper column embossment electroplating; the electroplating conditions are as follows: the current density is 1-25A / dm<2>, and the temperature is 15-35 DEG C; the electroplating liquid comprises 160-350g / L high-purity methanesulfonic acid copper salt, 30-180g / L high-purity methanesulfonic acid and 10-80mg / L chloride ions; the electroplating liquid further comprises 1-10ml / L of an accelerator and 1-10ml / L of a leveling agent; the accelerator is UPB3221A and comprises one or a mixture of several of polydithio dipropane sodium sulfonate, alcohlpropane sulfonate, phenyl dithio propane sodium sulfonate, 3-sulfenyl-1-propanesulfonic acid sodium salt and dimethyl-dithio formamide sulfonic acid; and the leveling agent is UPB3221L and comprises one or a mixture of several of polyethylene glycol, a fatty alcohol alkoxy compound, an ethylene oxide-propylene oxide block copolymer of which the molecular weights are respectively 400, 1,000, 6,000 and 20,000. The high-speed embossment electroplating method applied to copper interconnection, disclosed by the invention, ensures that a copper column has good reliability and uniformity, and at the same time has a relatively high electroplating speed.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Cu-Zn-Sn ternary alloy cyanide-free imitation gold plating solution and use method thereof

Owner:KUNMING UNIV OF SCI & TECH

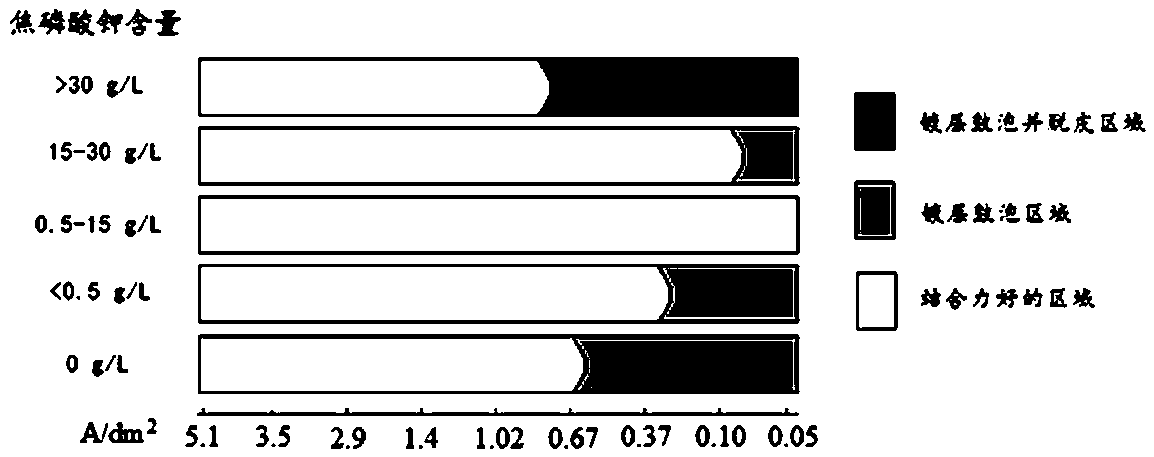

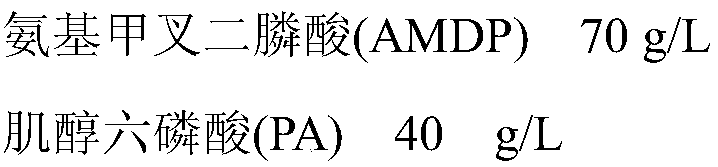

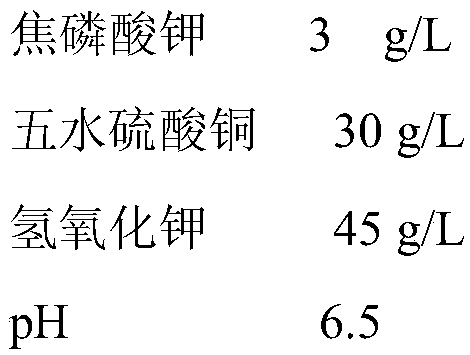

A kind of cyanide-free copper plating electroplating solution applicable to wide ph and wide current density range and preparation method thereof

ActiveCN106521574BImprove deep plating abilityAvoid the problem of constant adjustment or even scrappingCopper platingSquare decimeter

The invention provides a cyanide-free copper-plated electroplating solution suitable for a wide pH range and a wide current density range. The cyanide-free copper-plated electroplating solution comprises amino methylene diphosphonic acid (AMDP) with concentration being 20-90g / L, inositol hexaphosphoric acid (PA) or phytic acid sodium salt hydrate with concentration being 10-70g / L, pyrophosphate with concentration being 0.5-15g / L, and copper salt with concentration being 3-25g / L. The cyanide-free copper-plated electroplating solution provided by the invention has an applicable pH range of 6-13.5, an applicable current density range of 0.2-4 amperes / square decimeter, is simple in formula, is non-toxic, is free of cyanide pollution; and copper is directly plated on iron substrate, a magnesium alloy, zinc or zinc alloy matrix and zinc-immersed aluminum, so that the obtained copper plating is excellent in binding force with the matrix.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com