A kind of cyanide-free copper plating electroplating solution applicable to wide ph and wide current density range and preparation method thereof

A current density, cyanide-free copper plating technology, applied in the field of cyanide-free copper plating solution, cyanide-free copper plating solution and its preparation, can solve the problem of poor bonding between the coating and the substrate, unstable operation of the plating solution, and solution pH Narrow range and other problems, to avoid continuous adjustment or even scrapping, improve the tolerance of solution operation, and facilitate production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

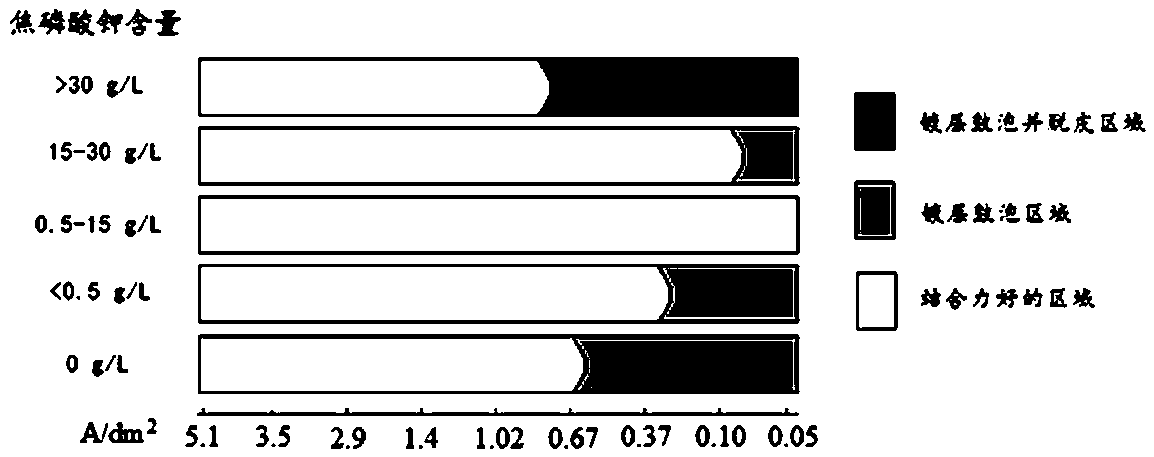

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1:

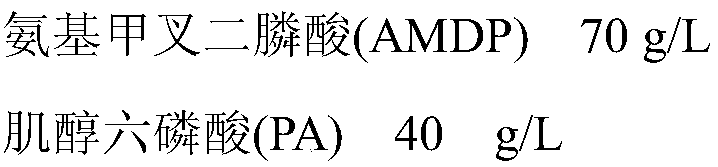

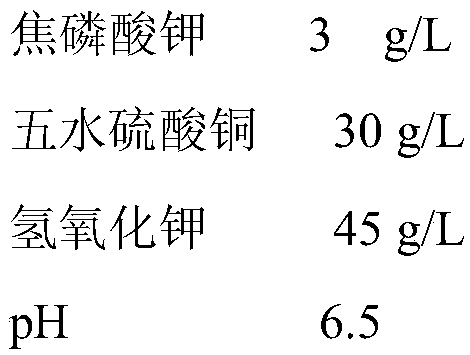

[0022] Prepare the cyanide-free copper plating bath with wide pH and wide current density according to the following ratio.

[0023]

[0024]

[0025] Dissolve and mix the weighed methylene diphosphonic acid and copper sulfate pentahydrate with deionized water respectively. Add potassium hydroxide solution during stirring and stir thoroughly. If the pH is too high due to the addition of potassium hydroxide, adjust the pH to The specified pH value.

[0026] In the resulting solution, adjust the temperature of the solution to 30°C and set the cathode current density to 1A / dm 2 The copper plating layer of about 5 microns is plated on the steel wire substrate with a diameter of 2 mm, and the electroplating time is 15 minutes. The bonding force is tested by the winding method according to ASTM B452-2002.

Embodiment 2

[0028] Prepare the cyanide-free copper plating bath with wide pH and wide current density according to the following ratio.

[0029]

[0030] Dissolve and mix the weighed methylene diphosphonic acid and copper chloride dihydrate in deionized water respectively, add sodium hydroxide solution during stirring and stir thoroughly. If the pH is too high due to the addition of potassium hydroxide, adjust with sulfuric acid To the specified pH value.

[0031] In the resulting solution, adjust the temperature of the solution to 50°C and set the cathode current density to 0.5A / dm 2 The copper plating layer of about 5 microns is plated on the steel wire substrate with a diameter of 2 mm, and the electroplating time is 30 minutes. The bonding force is tested by the winding method according to ASTM B452-2002.

Embodiment 3

[0033] Prepare a cyanide-free copper plating bath with a wide pH range according to the following ratio

[0034]

[0035]

[0036] Dissolve and mix the weighed methylene diphosphonic acid and copper chloride dihydrate in deionized water respectively, add sodium hydroxide solution during stirring and stir thoroughly. If the pH is too high due to the addition of potassium hydroxide, adjust with sulfuric acid To the specified pH value.

[0037] In the obtained solution, adjust the temperature of the solution to 55℃, and set the cathode current density to 2A / dm 2 The copper plating layer of about 5 microns is plated on the steel wire substrate with a diameter of 2 mm, and the electroplating time is 7 minutes. The bonding force is tested by the winding method according to ASTM B452-2002.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com