A kind of electroplating liquid and electroplating method thereof

An electroplating solution and forward current technology, applied in the field of copper electroplating, can solve the problems of high toxicity, etc., achieve high plating ability, reduce plating hole defects, and thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

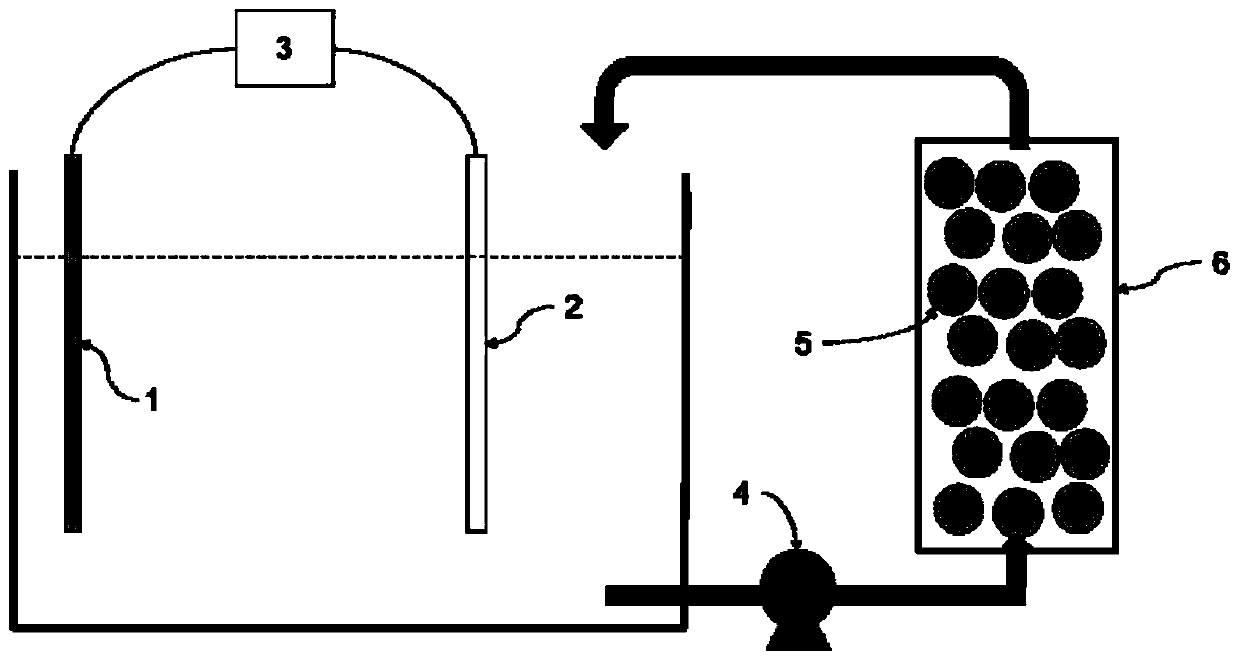

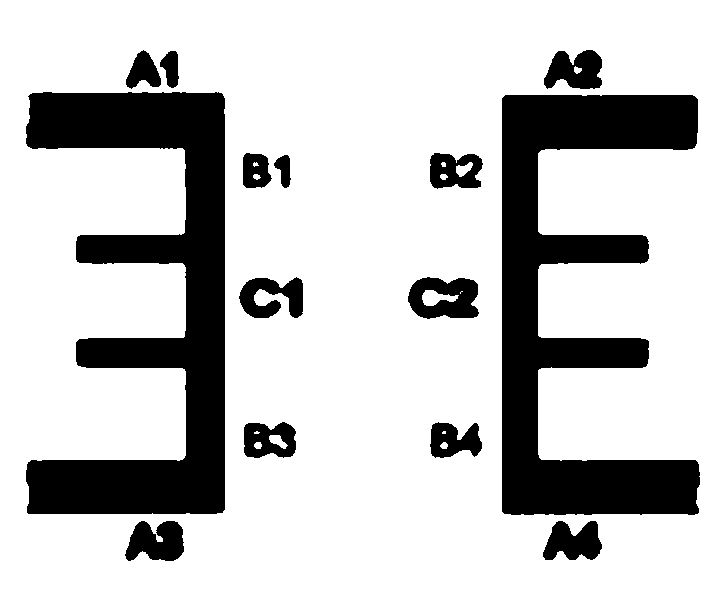

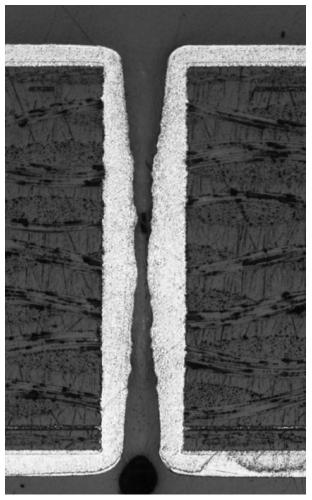

[0058] Embodiment 1 Plated through hole

[0059] The electroplating solution of the present embodiment comprises the following components in terms of mass concentration:

[0060]

[0061]

[0062] Immerse the plate-shaped piece with a through hole on the surface in the electroplating solution, and conduct electroplating after the plate-shaped piece is electrified as the cathode, wherein the aspect ratio (AR) of the through hole is 5, and the forward current density is 9A / dm 2 , the forward current pulse time is 15ms, and the reverse current density is 27A / dm 2 , the reverse current pulse time is 1.5ms, and the electroplating time is 3h. The difference in TP value can be seen more intuitively through long-term electroplating.

Embodiment 2

[0075] Example 2 Plated through hole

[0076] The electroplating solution of the present embodiment comprises the following components in terms of mass concentration:

[0077]

[0078]Immerse the plate-shaped piece with a through hole on the surface into the electroplating solution, wherein the diameter of the through-hole is 300 μm and the hole height is 1500 μm μm, and the plate-shaped piece is used as the cathode to carry out electroplating, wherein the forward current density is 10A / dm 2 , the forward current pulse time is 40ms, and the reverse current density is 30A / dm 2 , the reverse current pulse time is 2ms, and the electroplating time is 60min.

Embodiment 3

[0086] Example 3 Plated Through Holes

[0087] The electroplating solution of the present embodiment comprises the following components in terms of mass concentration:

[0088]

[0089] Immerse the plate-shaped piece with a through hole on the surface into the electroplating solution, wherein the diameter of the through-hole is 300 μm and the hole height is 1500 μm, and the plate-shaped piece is used as the cathode to carry out electroplating after electrification, wherein the forward current density is 10A / dm 2 , the forward current pulse time is 40ms, and the reverse current density is 30A / dm 2 , the reverse current pulse time is 2ms, and the electroplating time is 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com