A high aspect ratio circuit board through-hole electroplating process

A through-hole electroplating, high aspect ratio technology, applied in electrodes, printed circuits, electrical components, etc., can solve the problem of uneven current density distribution in the hole/hole center, uneven copper deposition in the hole/hole center, and long-term products. Reliability risks and other issues, to achieve the effect of improving deep plating capacity, reducing anode oxygen evolution, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

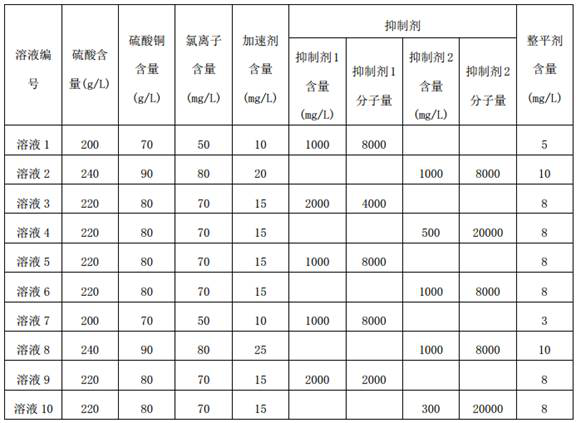

[0030] A copper electroplating solution for high aspect ratio circuit board through-hole electroplating, the copper electroplating solution is composed of the following components: sulfuric acid 200-240g / L, copper sulfate pentahydrate 70-90g / L, chloride ion 50- 80ppm, accelerator 10-20ppm, inhibitor 500-2000ppm, leveling agent 5-10ppm. Described accelerator is isothiourea propanesulfonic acid inner salt, specifically, can select molecular formula to be C 4 H 10 N 2 O 3 S 2 The isothiourea propanesulfonic acid inner salt; the inhibitor is polyethylene glycol or polyethylene glycol ether, the molecular weight of the inhibitor is 4000-20000; the leveling agent is a specific thiadiazole amide compound , the structural formula of the specific thiadiazole amide compound is:

[0031] .

Embodiment 2

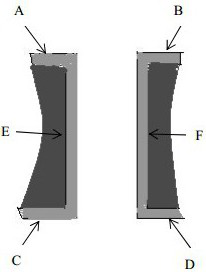

[0033] The through-hole electroplating was performed using the electroplating copper solution suitable for the high aspect ratio circuit board through-hole electroplating process of Example 1, specifically, electroplating using forward and reverse pulse currents. A titanium anode coated with iridium and tantalum is used as the anode, and the electroplating process conditions are: the forward current density is 1.2-1.8 A / dm 2 , the forward and reverse pulse current amplitude ratio is 1:2-1:3; the forward pulse time is 100-200 milliseconds, and the forward and reverse pulse time ratio is 10:1-20:1; during electroplating, the solution temperature is 10 -35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com