A kind of preparation method and application of bimetallic Cu-BI electrocatalytic denitrification electrode

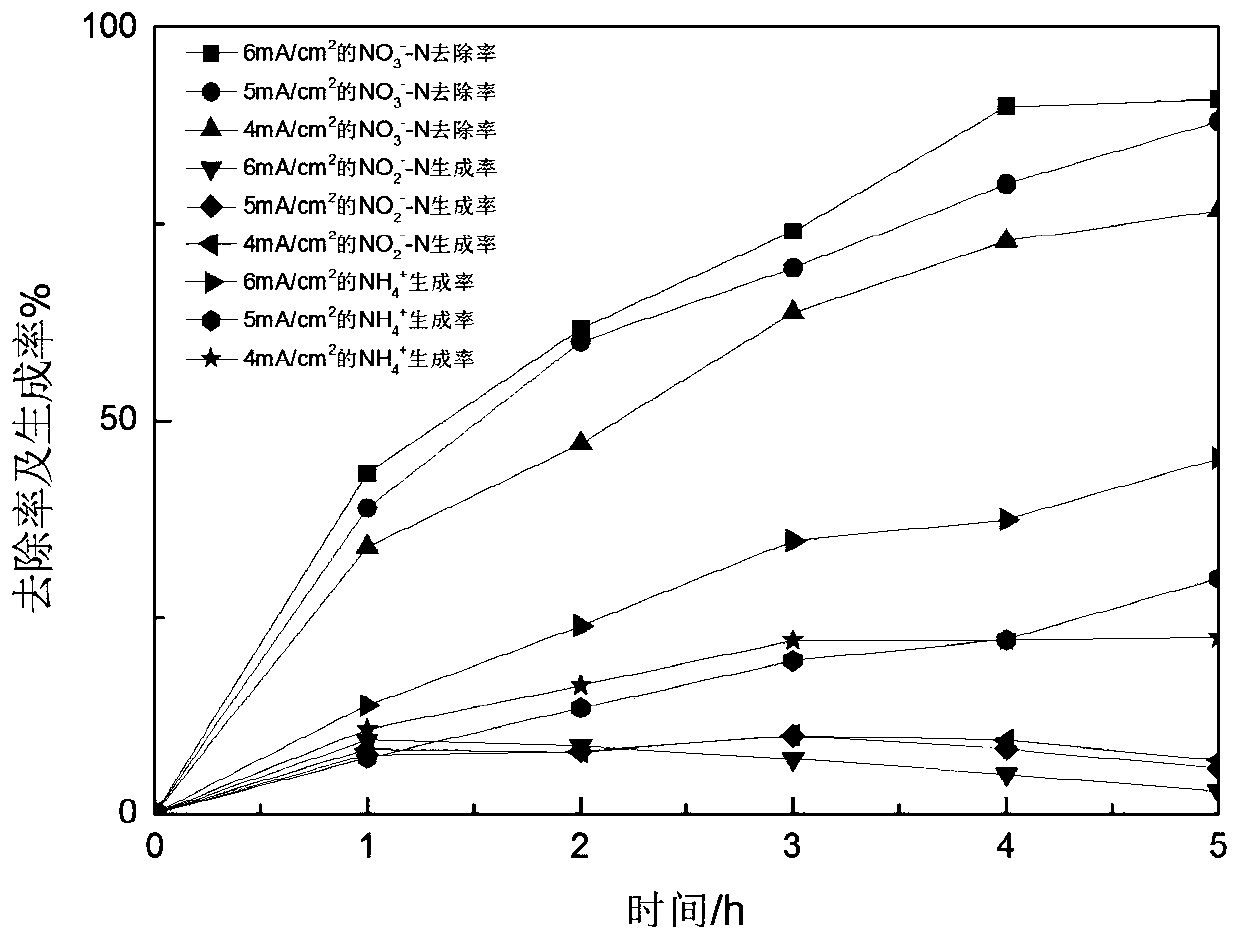

An electrocatalytic and bimetallic technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as unsatisfactory wastewater treatment effects, and achieve easy scale electrode preparation and methods Simple, controllable, rough-surfaced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention is a method for preparing a bimetallic Cu-Bi electrocatalytic denitrification electrode, the steps of which are as follows:

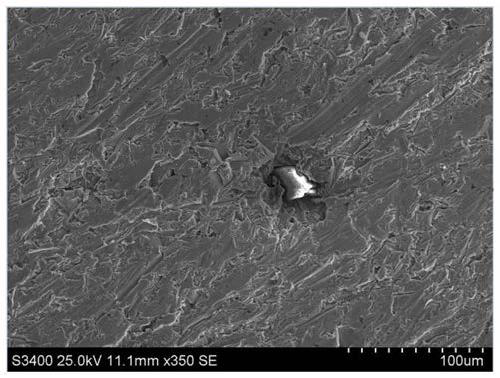

[0031] (1) Pretreatment of the copper substrate: the copper substrate is polished with water-resistant sandpaper, then placed in acetone for 10-15 minutes of ultrasonication, then activated in 10% dilute sulfuric acid solution for 30-45 seconds, washed with distilled water and then used.

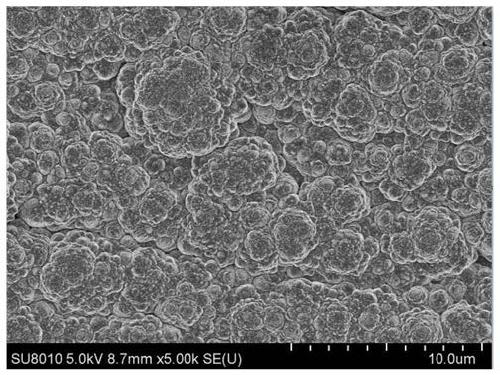

[0032] (1) (2) Plating solution preparation: preparation of Bi 3+ 、Cu 2+ Copper-bismuth plating solution with a mass concentration ratio of 1:1-9. First prepare copper electroplating plating solution, with 35-50g / L copper pyrophosphate as the main salt, 200-240g / L potassium pyrophosphate as complexing agent, add 25-28.3g / L disodium hydrogen phosphate in a water bath at 45-60°C Fully stir in the medium until completely dissolved; prepare bismuth electroplating bath, use 96-97g / L bismuth nitrate as the main salt, 120-125g / L disodium edetate as the...

Embodiment 1

[0038] A preparation method of bimetallic Cu-Bi electrocatalytic denitrification electrode, the steps are as follows:

[0039] (1) Pretreatment of the copper substrate: the copper substrate was polished with water-resistant sandpaper, placed in acetone for 12 minutes, then activated in 10% dilute sulfuric acid solution for 40 seconds, washed with distilled water and then used.

[0040] (2) Preparation of plating solution: prepare copper electroplating plating solution, use 35g / L copper pyrophosphate as the main salt, 200g / L potassium pyrophosphate as complexing agent, add 26g / L disodium hydrogen phosphate and stir fully in a 45°C water bath Until completely dissolved; prepare bismuth electroplating bath, with 96g / L bismuth nitrate as the main salt, 120g / L edetate disodium as the main complexing agent, then add 60g / L potassium chloride, potassium sodium tartrate, 120g / L 5-sulfosalicylic acid until fully stirred evenly. Potassium hydroxide was used to adjust the pH to 8 during...

Embodiment 2

[0043] A preparation method of bimetallic Cu-Bi electrocatalytic denitrification electrode, the steps are as follows:

[0044] (1) Pretreatment of the copper substrate: the copper substrate was polished with water-resistant sandpaper, then placed in acetone for 10 minutes of ultrasonication, then activated in 10% dilute sulfuric acid solution for 30 seconds, washed with distilled water and then used.

[0045] (2) Plating solution preparation: prepare copper electroplating plating solution, use 38.2g / L copper pyrophosphate as the main salt, 206.3g / L potassium pyrophosphate as complexing agent, add 27.3g / L disodium hydrogen phosphate in a 60°C water bath Fully stir until completely dissolved; prepare bismuth electroplating bath, with 96.5g / L bismuth nitrate as the main salt, 121.2g / L edetate disodium as the main complexing agent, then add 60g / L potassium chloride, Potassium sodium tartrate, 120g / L 5-sulfosalicylic acid until fully stirred evenly. Potassium hydroxide was used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com