Preparation method of electroplated cadmium coating for metalwork

A technology for metal parts and preparation steps is applied in the field of preparing a cadmium layer for electroplating on metal parts, which can solve the problems of high toxicity of cyanide, and achieve the effects of simple processing, tight bonding and simple plating solution formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

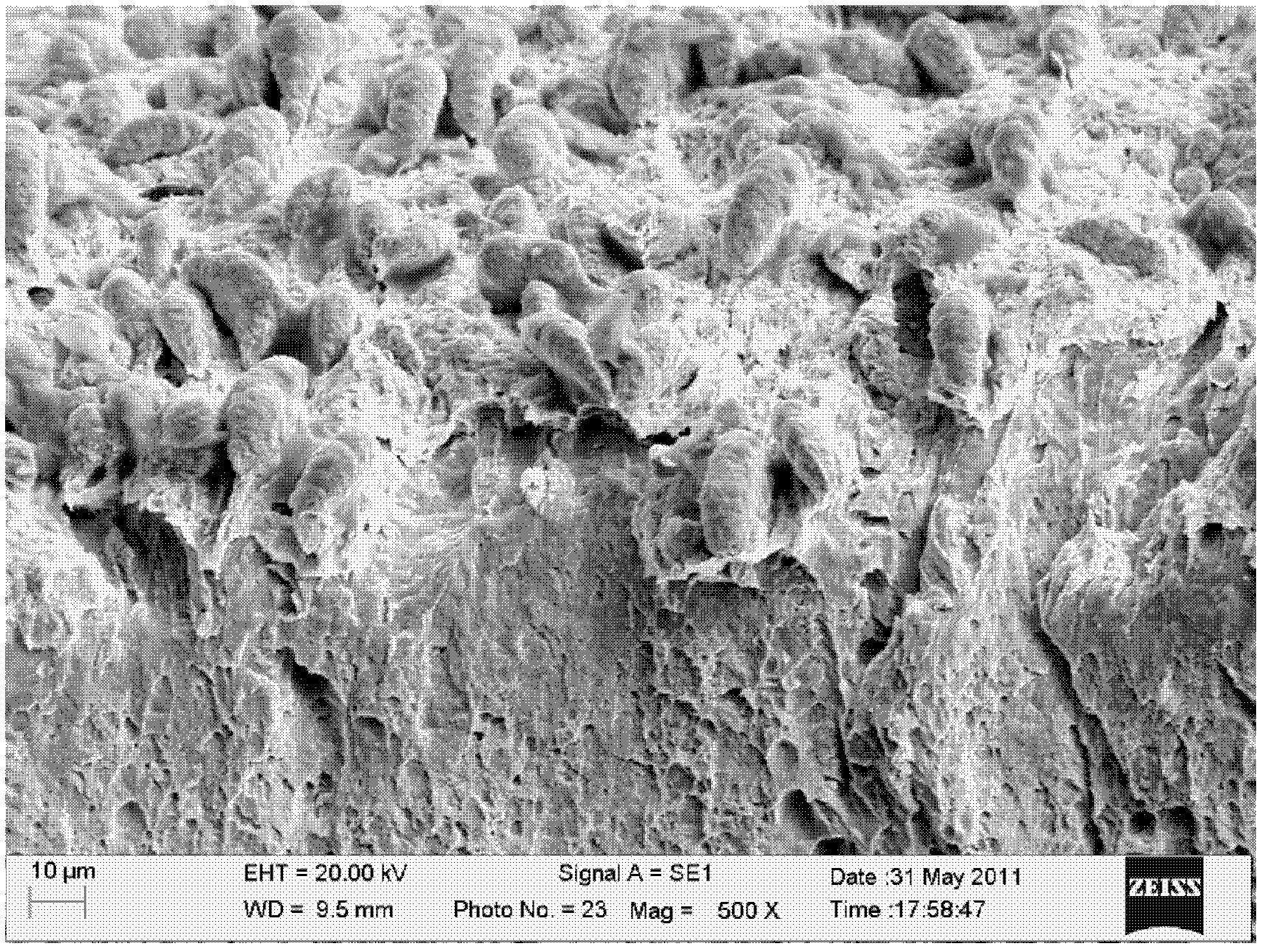

Image

Examples

Embodiment 1

[0032] a) The composition of the plating solution is as follows:

[0033] The concentration of cadmium sulfate is 25g / L, the concentration of nickel sulfate is 0.6g / L, the concentration of potassium hydroxide is 60g / L, the concentration of complexing agent ethylenediaminetetraacetic acid is 80g / L, the auxiliary complexing agent ethylene diamine The concentration of amine was 3ml / L.

[0034] b) Plating solution preparation method:

[0035] After dissolving the ethylenediaminetetraacetic acid and ethylenediamine with deionized water, stir evenly. Add cadmium sulfate and nickel sulfate in turn, add potassium hydroxide to adjust the pH value to 8-9, and add deionized water to the required volume. The temperature for solution preparation was 25°C. Cadmium sulfate, nickel sulfate, and potassium hydroxide are all commercially available.

[0036] c) Plating treatment before electroplating:

[0037] Use an ultrasonic cleaning machine to degrease and clean the surface of the metal ...

Embodiment 2

[0043] a) The composition of the plating solution is as follows:

[0044] The concentration of cadmium sulfate is 25g / L, the concentration of nickel sulfate is 0.4g / L, the concentration of potassium hydroxide is 55g / L, the concentration of complexing agent ethylenediaminetetraacetic acid is 75g / L, the auxiliary complexing agent ethylene diamine The concentration of amine was 4ml / L.

[0045] b) Plating solution preparation method:

[0046] After dissolving the ethylenediaminetetraacetic acid and ethylenediamine with deionized water, stir evenly. Add cadmium sulfate and nickel sulfate in turn, add potassium hydroxide to adjust the pH value to 8-9, and add deionized water to the required volume. The temperature for solution preparation was 28°C. Cadmium sulfate, nickel sulfate, and potassium hydroxide are all commercially available.

[0047] c) Plating treatment before electroplating:

[0048] Use an ultrasonic cleaning machine to degrease and clean the surface of the metal ...

Embodiment 3

[0054] a) The composition of the plating solution is as follows:

[0055] The concentration of cadmium sulfate is 28g / L, the concentration of nickel sulfate is 0.5g / L, the concentration of potassium hydroxide is 60g / L, the concentration of complexing agent ethylenediaminetetraacetic acid is 80g / L, the auxiliary complexing agent ethylene diamine The concentration of amine was 4ml / L.

[0056] b) Plating solution preparation method:

[0057] After dissolving the ethylenediaminetetraacetic acid and ethylenediamine with deionized water, stir evenly. Add cadmium sulfate and nickel sulfate in turn, add potassium hydroxide to adjust the pH value to 8-9, and add deionized water to the required volume. The temperature for solution preparation was 35°C. Cadmium sulfate, nickel sulfate, and potassium hydroxide are all commercially available.

[0058] c) Plating treatment before electroplating:

[0059] Use an ultrasonic cleaning machine to degrease and clean the surface of the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com