Stabilizer for electroplating brightening tin and tin alloy and preparation method thereof

A tin alloy and stabilizer technology, applied in the field of stabilizer preparation, can solve the problems of inability to effectively suppress tetravalent tin, the appearance of the coating layer is foggy, the cathode current efficiency is reduced, etc., and achieves rich deep drawing performance, uniform and bright appearance. , the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

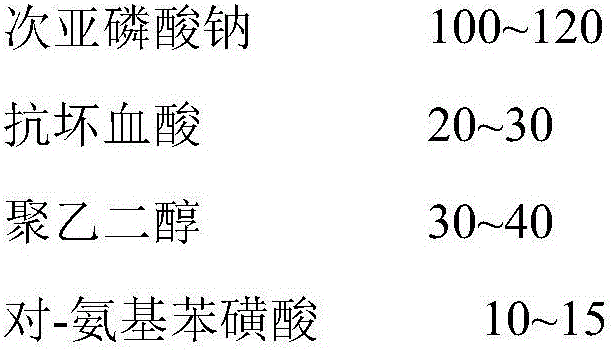

Method used

Image

Examples

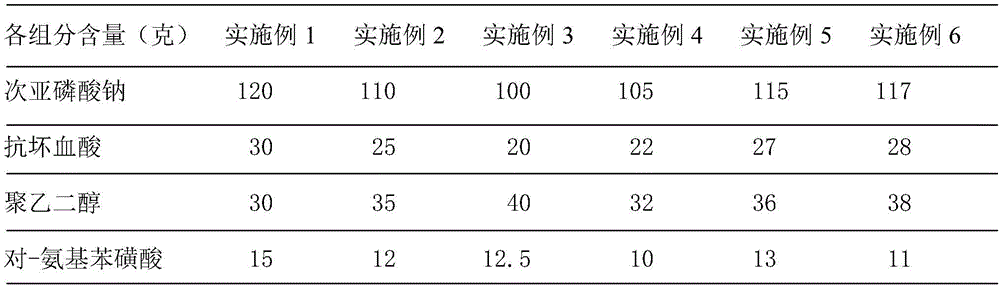

Embodiment 1

[0025] a) Weigh 30 grams of polyethylene glycol (M=6000), put it into a container, add about 600 ml of distilled water, heat, stir until completely dissolved; b) add 120 grams of hypophosphorous acid to the solution of a Sodium, stir until completely dissolved; c) add 30 grams of ascorbic acid in the above liquid, stir until completely dissolved; d) add 15 grams of p-aminobenzenesulfonic acid in the above liquid, stir until completely dissolved; e) add Distill water to 1000ml, stir well, and serve.

Embodiment 2

[0027] The amount of each component added is as described in Table 1, and the preparation steps are as follows: a) polyethylene glycol (M=8000) is put into a container, and about 600 ml of distilled water is added, heated and stirred until completely dissolved; b) Add sodium hypophosphite to the solution of a, stir until completely dissolved; c) add ascorbic acid to the above liquid, stir until completely dissolved; d) add p-aminobenzenesulfonic acid to the above liquid, stir until completely dissolved ; e) add distilled water to 1000 ml, stir evenly, and serve.

Embodiment 3

[0029] The amount of each component added is as described in Table 1, and the preparation steps are as follows: a) polyethylene glycol (M=6000) is put into a container, and about 600 ml of distilled water is added, heated and stirred until completely dissolved; b) In the solution of a, add sodium hypophosphite, stir until completely dissolved; c) add ascorbic acid to the above liquid, stir until completely dissolved; d) add p-aminobenzenesulfonic acid to the above liquid, stir until completely Dissolve; e) add distilled water to 1000 ml, stir evenly, and serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com