Autumn and winter socks with high wear resistance and skid resistance

A high wear-resistant and anti-skid technology, applied in socks, pantyhose, clothing, etc., can solve problems affecting blood circulation, etc., and achieve the effect of improving warmth retention, good effect, and improving covering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

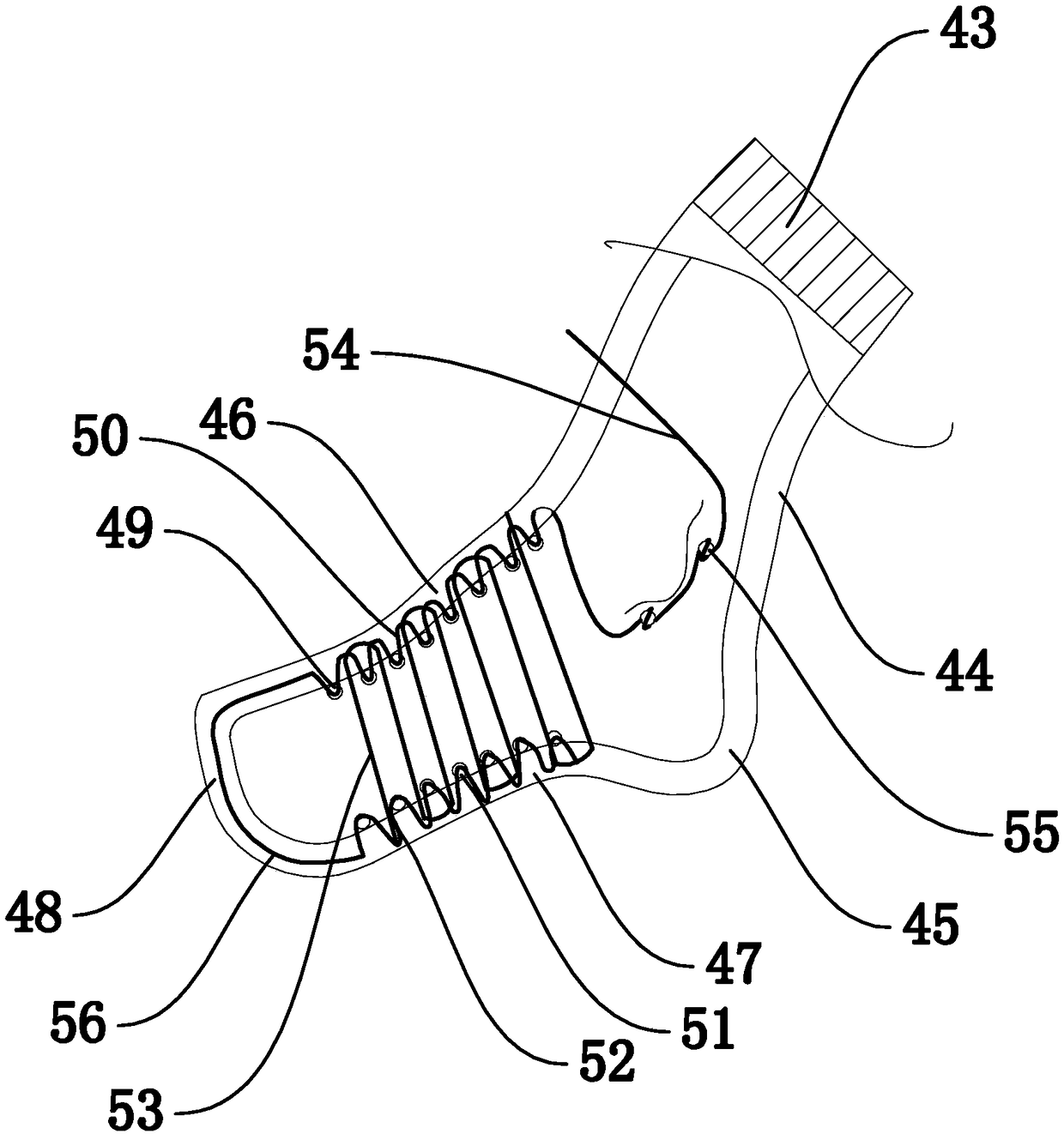

[0036] like figure 1 As shown, the present invention provides a kind of high wear-resistant non-slip autumn and winter socks, comprising a sock body, the sock body includes a sock opening 43, a sock tube 44, a sock heel 45, a sock face 46, a sock bottom 47 and a sock toe 48, and the sock face 46 is provided with There are a plurality of upper anti-slip knots 49 and many upper wear-resistant ropes 50, the upper anti-slip knots 49 are formed on the inside of the sock face 46, and the upper wear-resistant ropes 50 are interwoven on the sock face 46 and pass through the upper anti-skid knots 49; There are a plurality of lower anti-slip knots 51 and a plurality of lower wear-resistant ropes 52, and the lower ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com