Preparation method of fabric with far-infrared warm keeping function

A far-infrared, functional technology, applied in dyeing, fabric surface trimming, weaving, etc., can solve the problems that bamboo charcoal cannot fully exert its efficacy, hard texture, low fiber strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

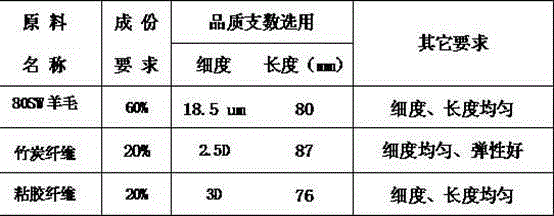

Embodiment 1

[0042] A method for preparing a fabric with far-infrared heat-retaining function, characterized in that it comprises the steps of:

[0043] 1) Preparation of bamboo charcoal fiber

[0044] The fired bamboo charcoal is modified by the atmospheric pressure radio frequency cold plasma technology. The specific process conditions are: the incident power is 110W, the argon flow is 10L / min, the sulfur hexafluoride flow is 15sccm, and the sinking temperature is 140℃, the treatment time is 15 minutes, the bamboo charcoal can be fully etched and embrittled, and then repeatedly ball milled with a planetary ball mill to micronize the bamboo charcoal to obtain a bamboo charcoal powder with a particle size of about 0.1-0.2μm;

[0045] 2) Melt spinning: the bamboo charcoal sub-nanometer micro-powder is evenly blended into the polyester fiber through the melt spinning process, and the addition amount is 10%, and the 3D bamboo charcoal fiber is made with biochemical technology drawing;

[004...

Embodiment 2

[0061] A method for preparing a fabric with far-infrared heat-retaining function, characterized in that it comprises the steps of:

[0062] 1) Preparation of bamboo charcoal fiber

[0063] The fired bamboo charcoal is modified by the atmospheric pressure radio frequency cold plasma technology. The specific process conditions are: the incident power is 110W, the argon flow is 10L / min, the sulfur hexafluoride flow is 15sccm, and the sinking temperature is 140℃, the treatment time is 15 minutes, the bamboo charcoal can be fully etched and embrittled, and then repeatedly ball milled with a planetary ball mill to micronize the bamboo charcoal to obtain a bamboo charcoal powder with a particle size of about 0.1-0.2μm;

[0064] 2) Melt spinning: the bamboo charcoal sub-nanometer micropowder is evenly blended into the polyester fiber through the melt spinning process, and the addition amount is 20%, and the 3D bamboo charcoal fiber is made by drawing yarn with biochemical technology; ...

Embodiment 3

[0080] A method for preparing a fabric with far-infrared heat-retaining function, characterized in that it comprises the steps of:

[0081] 1) Preparation of bamboo charcoal fiber

[0082] The fired bamboo charcoal is modified by the atmospheric pressure radio frequency cold plasma technology. The specific process conditions are: the incident power is 110W, the argon flow is 10L / min, the sulfur hexafluoride flow is 15sccm, and the sinking temperature is 140℃, the treatment time is 15 minutes, the bamboo charcoal can be fully etched and embrittled, and then repeatedly ball milled with a planetary ball mill to micronize the bamboo charcoal to obtain a bamboo charcoal powder with a particle size of about 0.1-0.2μm;

[0083] 2) Melt spinning: The bamboo charcoal sub-nanometer micropowder is evenly blended into the polyester fiber through the melt spinning process, and the addition amount is 15%, and the 3D bamboo charcoal fiber is made by drawing yarn with biochemical technology; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com