Method for producing melt-blown nonwoven down dual constituent thermal insulating interlining

A non-woven, two-component technology, applied in the direction of non-woven fabrics, textiles and paper, can solve the problems of weakened resilience of thermal insulation wadding, poor strength of microfibers, and reduced thermal performance, etc., to increase vertical and horizontal tension, Improve the heat retention rate and improve the effect of heat retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

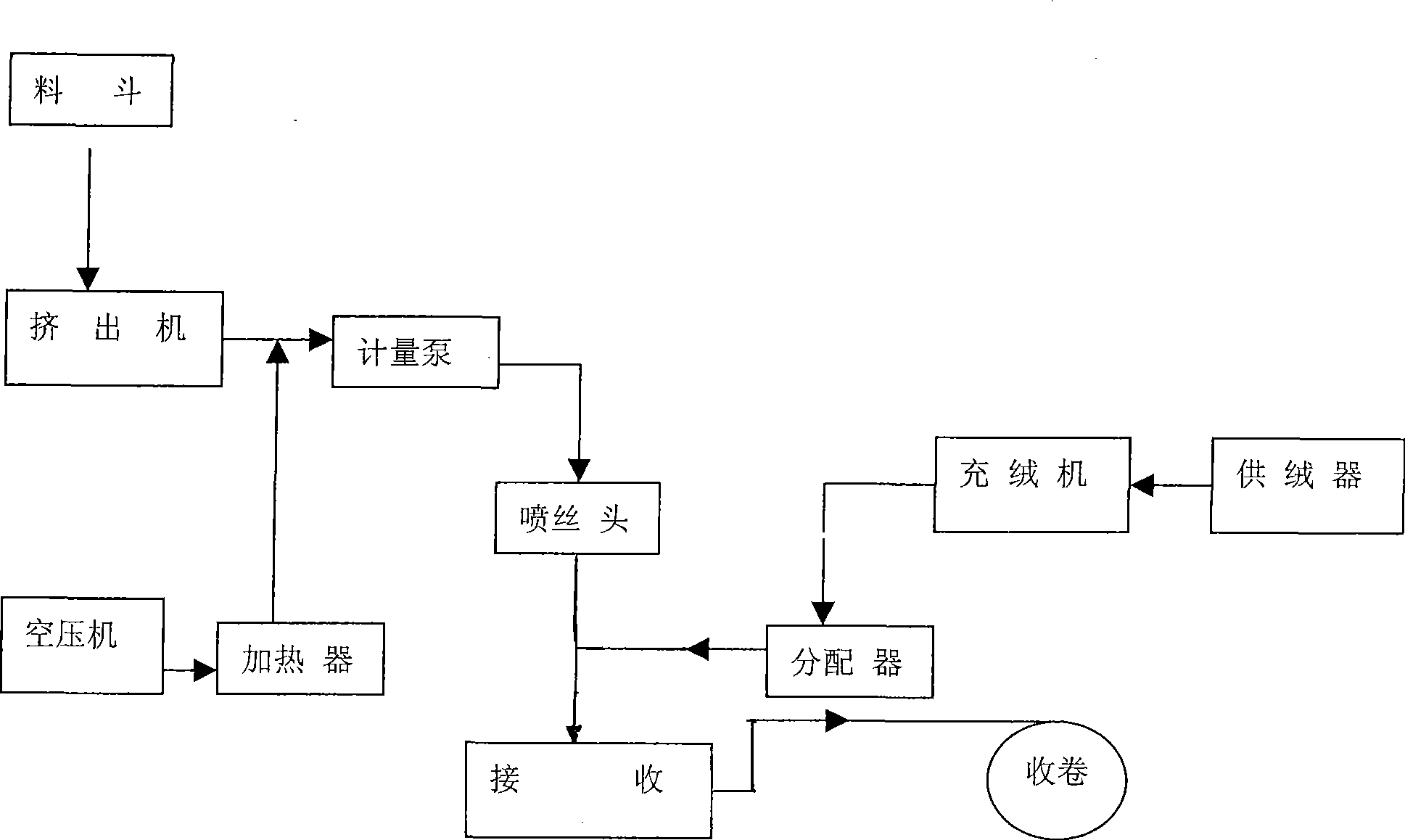

[0009] Referring to the accompanying drawings, the present invention provides a preparation method in which the two components are prepared separately and then combined together. The production process of non-woven flakes includes raw material feeding, melt metering and draw-spinning melt-blowing. The specific preparation method of the non-woven fiber is as follows: the polymer resin chip in the hopper is sent into the melting device, heated to a molten state; then sent into the extruder, and extruded through the spinneret hole. The diameter of the spinneret hole used is 0.28mm, and the diameter range of the extruded fiber is 0.5-5μm; the extruded fiber filaments are stretched into ultra-fine fibers under the action of the hot air heated by the heater; The fiber filaments are processed into superfine fibers with a diameter range of 0.5-2.5 μm. It is metered into the spinneret by the metering pump, and the molten short fiber is sprayed out from the spinneret to the fiber spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com