Precise fitting wrench

A technology of lamination and wrench, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of unusable and inconvenient carrying of ring wrenches, and achieve the effect of improving practicability and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

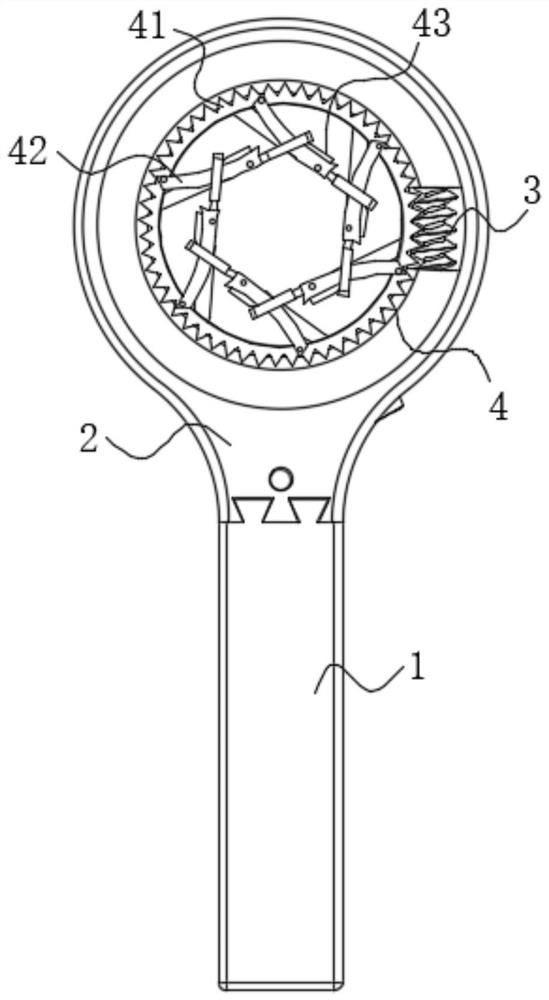

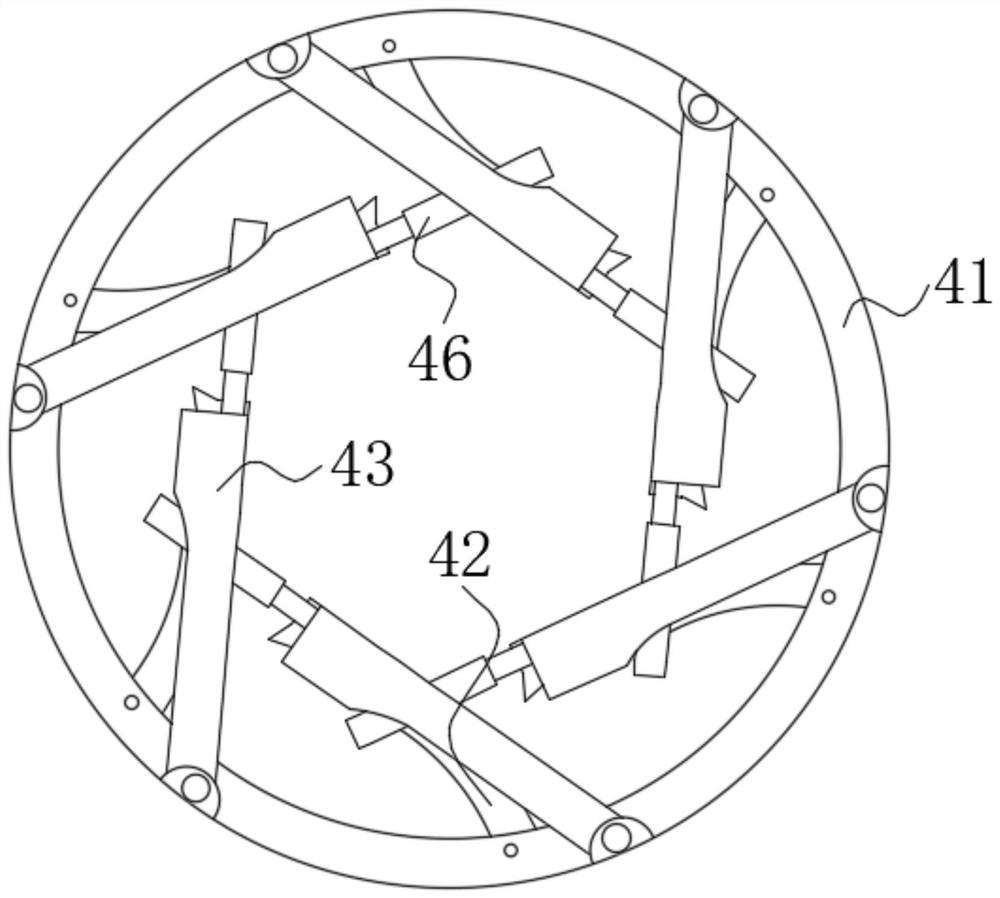

[0020] use Figure 1-Figure 5 A precision fitting wrench according to an embodiment of the present invention will be described as follows.

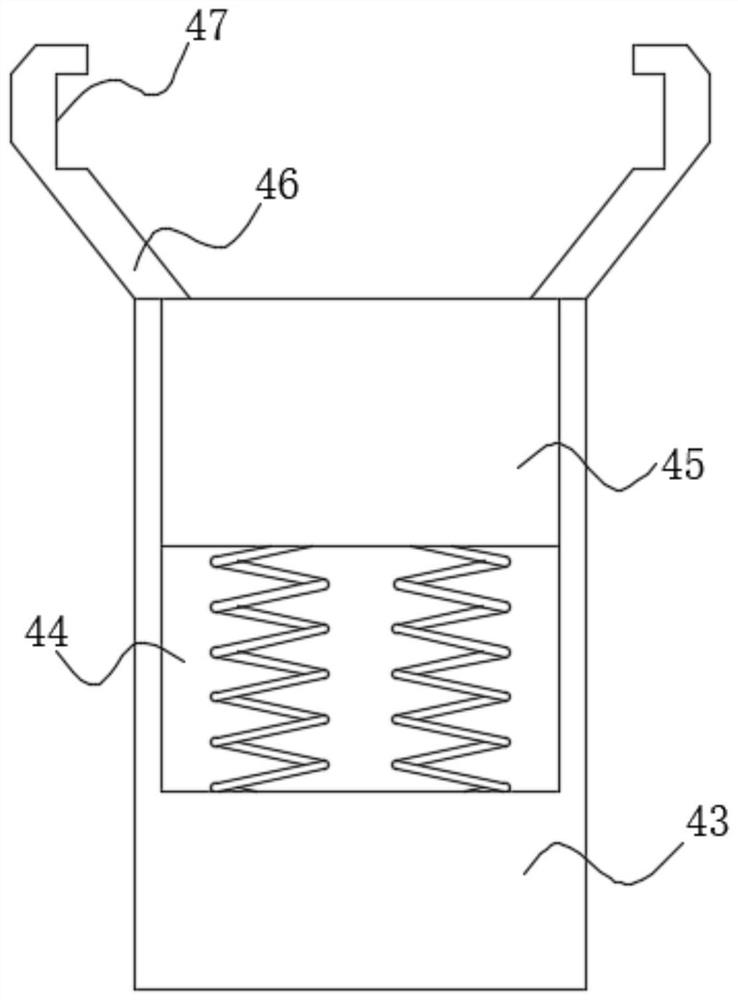

[0021] like Figure 1-Figure 5 As shown, a precision fitting wrench according to the present invention includes a handle 1, a mounting ring 2, an adjusting nut 3 and an adjusting mechanism 4; the upper end of the handle 1 is fixedly connected with a mounting ring 2; the mounting ring An adjusting nut 3 is rotatably installed in the right end wall of 2, and an adjusting mechanism 4 is arranged in the middle of the mounting ring 2; Block 46, snap groove 47, extrusion rod 48 and suction cup 49; the outer surface of the toothed ring 41 is rotatably connected with the adjusting nut 3 through threads, there are two toothed rings 41, and the toothed rings 41 are respectively symmetrically connected to the mounting ring. 2 on the outer surfaces of the front and rear sides, the outer surface of the gear ring 41 is hinged with adjustment plates 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com