A kind of plating solution and electroplating method for electroplating pure tin on copper wire

A copper wire and plating solution technology, applied in the field of electroplating, can solve the problems of uneven electroplating coating, uneven surface, affecting the solderability of the soldering layer, etc., and achieve the effects of simple formula, wide application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

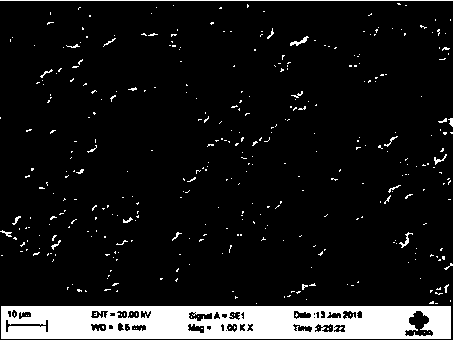

Image

Examples

Embodiment 1

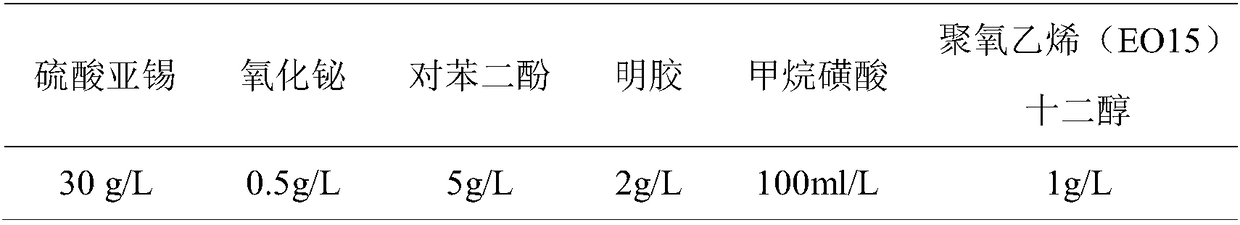

[0035] Table 1

[0036]

[0037] A kind of electroplating method of electroplating pure tin on copper wire, the pH of described plating solution is 1.0, and contains composition in table 1 in every 1L plating solution, prepare 1L plating solution and copper wire electroplating as follows:

[0038] Step 1. Preparation of plating solution:

[0039] a. Measure 100mL of methanesulfonic acid into deionized water and stir;

[0040] B, take by weighing the bismuth oxide of 0.5g, be dissolved in the solution that step a is prepared, stir;

[0041] c, take by weighing the hydroquinone of 5g, be dissolved in the solution that step b is prepared, stir;

[0042] d, take by weighing 1g of polyoxyethylene (EO15) lauryl alcohol, be dissolved in the solution that step c is prepared, stir;

[0043] E, take by weighing the stannous sulfate of 30g, be dissolved in the solution that step d is joined, stir;

[0044] f. Weigh 2g of gelatin, dissolve it in hot water at 50°C, make it fully dis...

Embodiment 2

[0049] Table 2

[0050]

[0051] A kind of electroplating method of electroplating pure tin on copper wire, the pH of described plating solution is 1.0, and contains composition in table 2 in every 1L plating solution, prepare 1L plating solution and copper wire electroplating as follows:

[0052] Step 1. Preparation of plating solution:

[0053] a. Measure 110mL of methanesulfonic acid into deionized water and stir;

[0054] b, take 1g of bismuth oxide, dissolve in the solution prepared in step a, and stir;

[0055] c, take the hydroquinone of 6g, be dissolved in the solution that step b is prepared, stir;

[0056] d, weigh 0.5g of OP emulsifier, dissolve in the solution prepared in step c, and stir;

[0057] E, take by weighing the stannous sulfate of 35g, be dissolved in the solution that step d is joined, stir;

[0058] f. Weigh 3g of gelatin, dissolve it in hot water at 60°C, make it fully dissolved, then add it to the solution prepared in step e, stir, and finally...

Embodiment 3

[0062] table 3

[0063]

[0064] A kind of electroplating method of electroplating pure tin on copper wire, the pH of described plating solution is 1.0, and contains composition in table 3 in every 1L plating solution, prepare 1L plating solution and copper wire electroplating as follows:

[0065] Step 1. Preparation of plating solution:

[0066] a. Measure 120mL of methanesulfonic acid into deionized water and stir;

[0067] B, take by weighing the bismuth oxide of 1.8g, be dissolved in the solution that step a is prepared, stir;

[0068] c, take by weighing the hydroquinone of 8g, be dissolved in the solution that step b is prepared, stir;

[0069] d. Weigh 1g polyoxyethylene (EO15) lauryl alcohol and 1g OP emulsifier, dissolve in the solution prepared in step c, and stir;

[0070] E, take by weighing the stannous sulfate of 40g, be dissolved in the solution that step d is joined, stir;

[0071] f. Weigh 4g of gelatin, dissolve it in hot water at 58°C, make it fully dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com