Additive B capable of controlling TSV deep hole copper plating crystallization and growth mode and application of additive B

An additive and copper plating technology, which is applied in the field of additive B to change the TSV micropore copper plating filling method and crystallization, can solve problems such as different filling effects, and achieve the effects of reducing subsequent process costs, simple formula, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Additive B: Add 20g of polyethylene glycol 6000 to 973.8g of ultrapure water, stir at 40°C for 15min; then, add 1g of PO-EO quaternary ammonium compound and 0.2g of mercaptoimidazole while stirring Sodium propanesulfonate, 5 g of low molecular weight polyethyleneimine (Lupasol G35). After continuous stirring for 1 h, the plating solution was prepared for electroplating.

[0031] Preparation of plating solution: In the ultrapure copper methanesulfonate electroplating solution, add additives A at 3ml / L and B at 5ml / L in sequence, and stir for 30min.

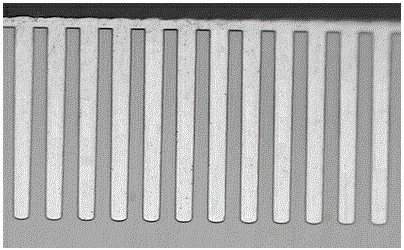

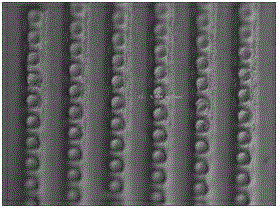

[0032] Take the 20×100μm hole pattern as an example:

[0033] Pretreatment conditions: under the condition of vacuum degree of 0~0.2 torr, keep vacuuming for 5 minutes, soak in pure water for 1-10 minutes;

[0034] Basic plating solution ratio: Cu=80g / L H=20g / L

[0035] Additive ratio: A:B=3:5

[0036] Experimental conditions: Temperature=22-25 ℃ Flow=15 L / min Cathode speed=50 RPM

[0037] Electroplating ...

Embodiment 2

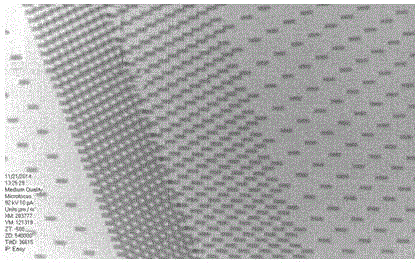

[0039] Take the 6×60μm hole pattern as an example:

[0040]Preparation of Additive B: Add 10g polyethylene glycol 200 and 1g polyethylene glycol 2000 to 978g ultrapure water, stir at 40°C for 15min; then, add 5g of PO-EO quaternary ammonium salt while stirring Compounds, 5 g of high molecular weight vinylimine homopolymer (Lupasol G100) and 1 g of water-soluble 2-mercaptobenzimidazole. After continuous stirring for 1 h, the plating solution was prepared for electroplating.

[0041] Plating solution preparation: Add 2ml / L Xinyang Additive A and 10ml / L Additive B to the basic copper methanesulfonate plating solution, and start electroplating after stirring for 30 minutes.

[0042] Pretreatment conditions: under the condition of vacuum degree of 0~0.2 torr, vacuumize for 5 minutes, soak in pure water for 1-10 minutes;

[0043] VMS ratio: Cu=110g / L H=15g / L

[0044] Additive ratio: A:B=2:10

[0045] Experimental conditions: Temperature=22-25 ℃ Flow=15 L / min Cathode speed=50 RPM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com