Pipe composition with high heat resistance and creep resistance and preparation method thereof

A creep-resistant, high-heat-resistant technology, applied in the field of high-heat-resistant and creep-resistant pipe compositions and its preparation, can solve the problem of reduced creep resistance and wear resistance of polyethylene materials, low Vicat softening temperature, and reduced Material performance and other issues, to achieve the effect of improving processing performance, improving creep resistance performance, and the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

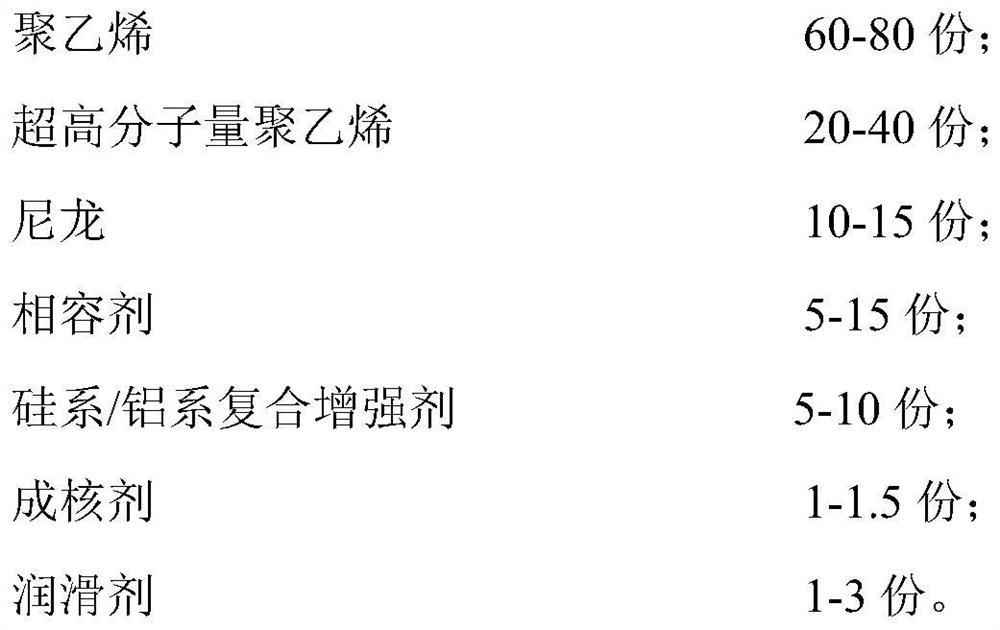

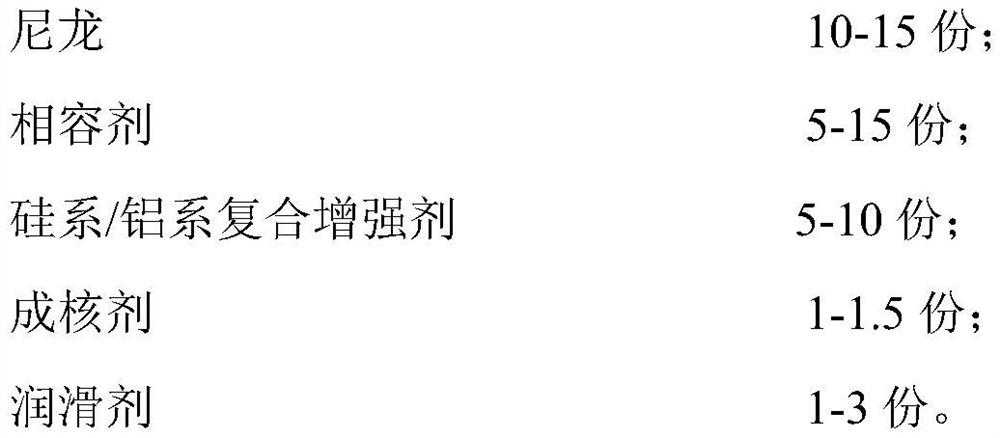

Method used

Image

Examples

Embodiment 1-5

[0039] The preparation method of embodiment 1-5 and comparative example 1-4 is as follows:

[0040] (1) The preparation method of the silicon-based / aluminum-based composite reinforcing agent is as follows: firstly, the natural silica and aluminum oxide are ground into nanoscale, and the particle size is 60 nanometers; then according to the mass ratio of natural silica: aluminum oxide=1: Weigh it in a ratio of 2, put it into a high-speed mixer, add 1.5% of the total amount of the mixture of vinyltrimethoxysilane coupling agent, mix at a high speed, the mixing speed is 1000 rpm, the mixing temperature is 90°C, and the mixing time is 6 minutes , release the material.

[0041] (2) Dry the nylon in an oven at 95°C for 4 hours, take it out, and set aside.

[0042] (3) Weigh polyethylene, ultra-high-density polyethylene, nylon, silicon-based / aluminum-based composite reinforcing agent, compatibilizer and other additives in proportion and add them to the mixer for high-speed stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com