A large-scale steel ingot electroslag thermal capping device and method with evenly distributed heat source

A technology of uniform distribution and steel ingots, applied in the field of electroslag thermal capping devices for large steel ingots, can solve the problems of not being suitable for large steel ingots, low heating efficiency, long current loop, etc. , good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

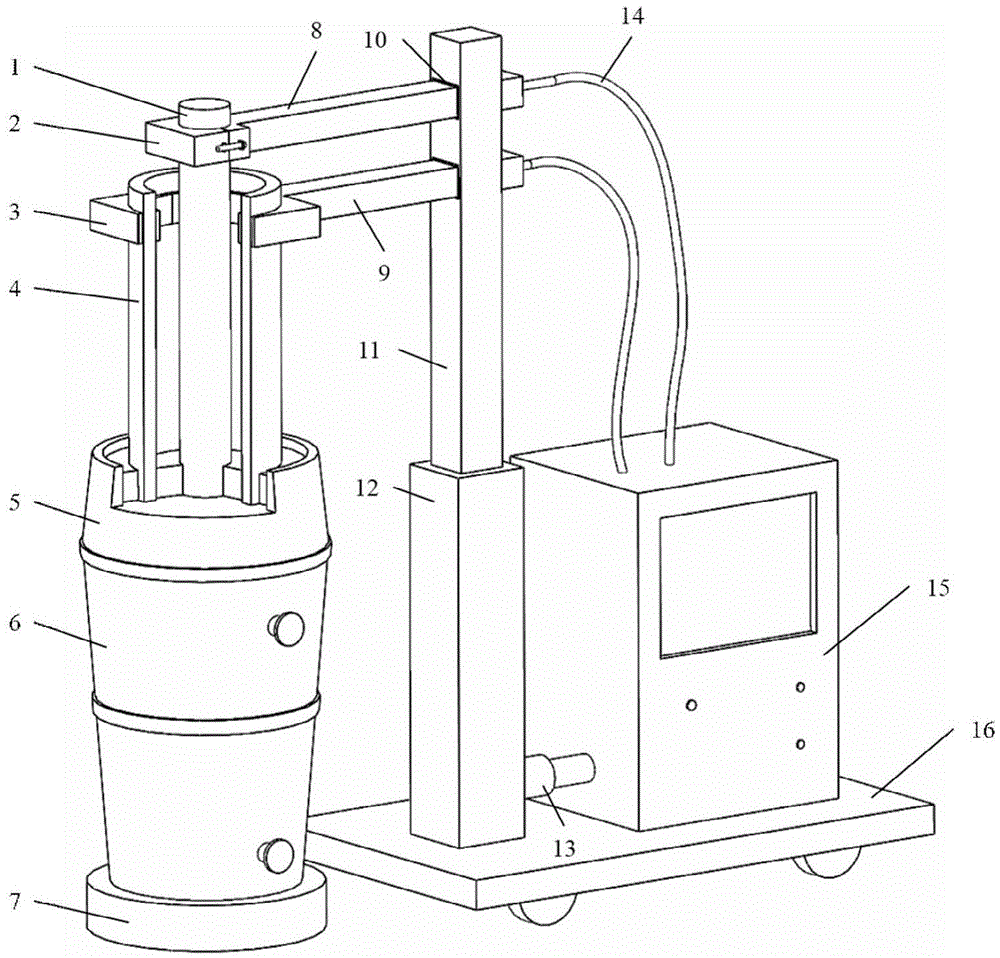

[0041] A large-scale steel ingot electroslag thermal capping device with evenly distributed heat sources, such as figure 1 As shown, it includes hydraulic fixed support 12, hydraulic transmission rod 13, lifting arm 11, control cabinet 15 and trolley 16; hydraulic fixed support 12, control cabinet 15 are all installed on the trolley 16, and lifting arm 11 is inserted into the hydraulic fixed support In the seat 12, the hydraulic fixed support base 12 is connected to the hydraulic transmission rod 13, and the hydraulic transmission rod 13 is connected to the control cabinet 15;

[0042] It also includes an upper holder 2, a lower holder 3, an upper electrode cross arm 8, a lower electrode cross arm 9 and a double-layer graphite electrode pair;

[0043] The inner graphite electrode 1 of the double-layer graphite electrode pair is a solid column, and the outer graphite electrode 4 is a hollow tube. The two electrodes are coaxially aligned and inserted into the liquid pre-slag in ...

Embodiment 2

[0064] A large-scale steel ingot electroslag thermal capping device with evenly distributed heat sources, such as figure 1 As shown, it includes hydraulic fixed support 12, hydraulic transmission rod 13, lifting arm 11, control cabinet 15 and trolley 16; hydraulic fixed support 12, control cabinet 15 are all installed on the trolley 16, and lifting arm 11 is inserted into the hydraulic fixed support In the seat 12, the hydraulic fixed support base 12 is connected to the hydraulic transmission rod 13, and the hydraulic transmission rod 13 is connected to the control cabinet 15;

[0065] It also includes an upper holder 2, a lower holder 3, an upper electrode cross arm 8, a lower electrode cross arm 9 and a double-layer graphite electrode pair;

[0066] The inner graphite electrode 1 of the double-layer graphite electrode pair is a solid column, and the outer graphite electrode 4 is a hollow tube. The two electrodes are coaxially aligned and inserted into the liquid pre-slag in ...

Embodiment 3

[0087] A large-scale steel ingot electroslag thermal capping device with evenly distributed heat sources, such as figure 1 As shown, it includes hydraulic fixed support 12, hydraulic transmission rod 13, lifting arm 11, control cabinet 15 and trolley 16; hydraulic fixed support 12, control cabinet 15 are all installed on the trolley 16, and lifting arm 11 is inserted into the hydraulic fixed support In the seat 12, the hydraulic fixed support base 12 is connected to the hydraulic transmission rod 13, and the hydraulic transmission rod 13 is connected to the control cabinet 15;

[0088] It also includes an upper holder 2, a lower holder 3, an upper electrode cross arm 8, a lower electrode cross arm 9 and a double-layer graphite electrode pair;

[0089] The inner graphite electrode 1 of the double-layer graphite electrode pair is a solid column, and the outer graphite electrode 4 is a hollow tube. The two electrodes are coaxially aligned and inserted into the liquid pre-slag in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com