High-impermeability concrete and preparation method thereof

A concrete and high-resistance technology, applied in the field of building materials, can solve the problems of difficulty in effectively improving the impermeability of concrete, the reduction of the strength of impermeable concrete, and the uncoordinated shrinkage speed of concrete, so as to improve the compressive strength and impermeability, improve The effect of impermeability, stability and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of high impermeability concrete, its preparation method comprises following preparation steps:

[0035] S1. Melt blending 3 g of silane coupling agent, 45 g of ethylene-vinyl acetate copolymer, and 10 g of nano-alumina at 280° C. for 2 hours to prepare a blend;

[0036] S2. Mix the blend material with 300g cement, 120g water, 80g fly ash, and 880g crushed stone to make impermeable concrete; the silane coupling agent used is vinyltriethoxysilane; the ethylene-vinyl acetate copolymer used The mass percentage of vinyl acetate in the product is 14wt%; the average particle size of the nano-alumina used is 50nm; the cement used is Portland cement; the crushed stone used is crushed stone A with a particle size of 4-6mm.

Embodiment 2-9

[0038] Examples 2-9 are all based on Example 1, and differ from Example 1 only in that the composition of raw materials is different, see Table 2 for details.

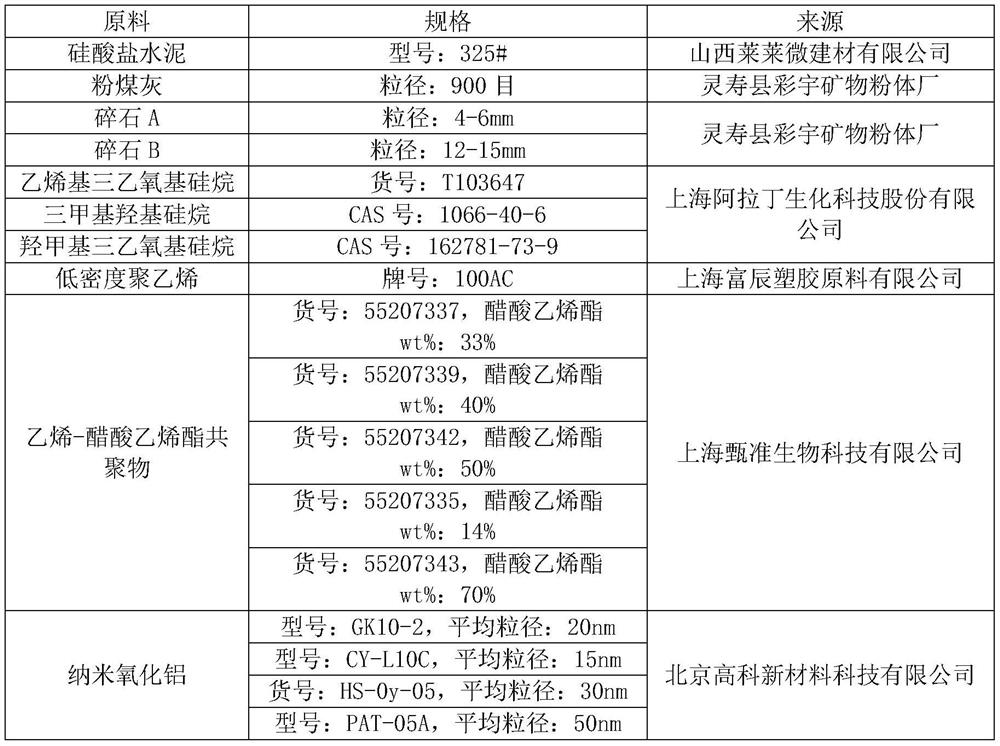

[0039] Table 2. Embodiment 1-9 raw material composition

[0040]

Embodiment 10

[0042] Example 10 is based on Example 9, and differs from Example 9 only in that the silane coupling agent used is trimethylhydroxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com