Electro-gas welding device and electro-gas welding method

A gas-electric vertical welding and welding wire technology, which is used in arc welding equipment, welding equipment, welding accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

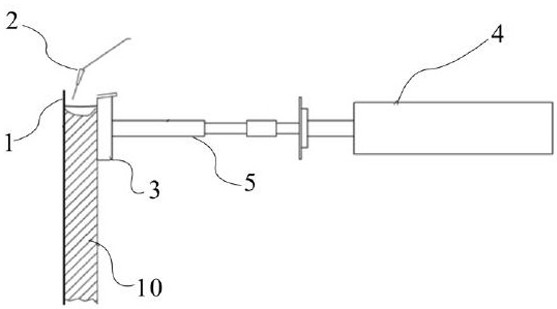

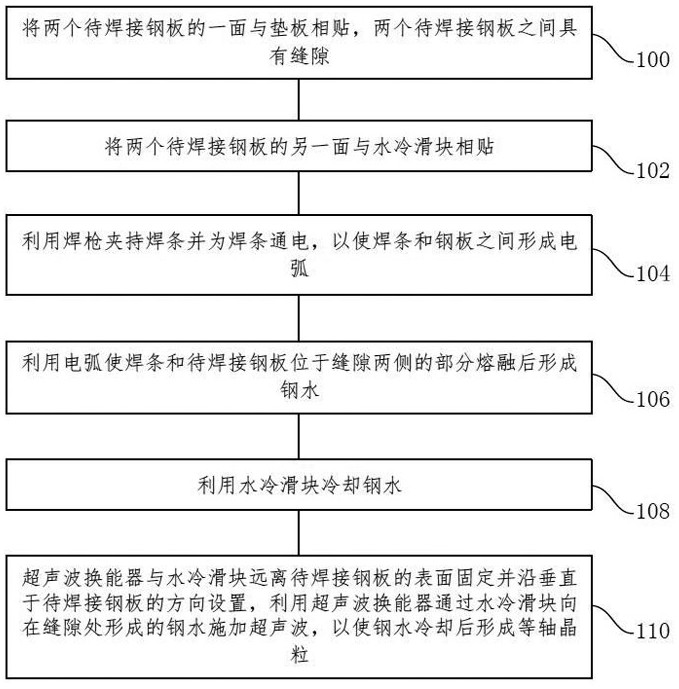

Method used

Image

Examples

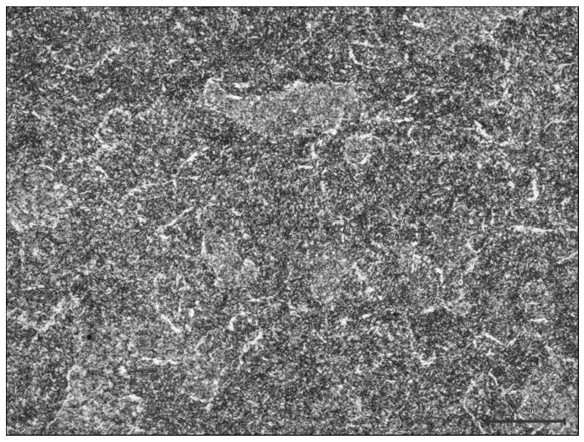

Embodiment

[0085] The thickness of the steel plate to be welded is 40mm, the shielding gas of the welding wire is carbon dioxide, and the flow rate of the shielding gas is 2.2m 3 / h, welding torch voltage 37.5V, welding current 390A, welding speed 0.5mm / s, welding torch swing speed 3mm / s, welding torch swing distance 18mm, dwell time before 0.5s, after 0.5s, wire feeding speed 15m / min; The ultrasonic frequency was 18 Hz, the ultrasonic amplitude was about 150 μm, and the power was 3200 W. After the welding was completed, a steel plate including a weld was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com