Surface chemical plating Ni-P process using nickel sulfate as main salt

A technology of surface chemistry and nickel sulfate, applied in the field of low-cost technology, can solve the problem of high cost of Ni-P plating process, and achieve the effect of low cost and simple plating solution formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] l. Treatment before plating.

[0020] The pre-plating treatment of the workpiece includes four steps of surface ultrasonic cleaning, alkali cleaning, acid cleaning and activation, with water washing in between.

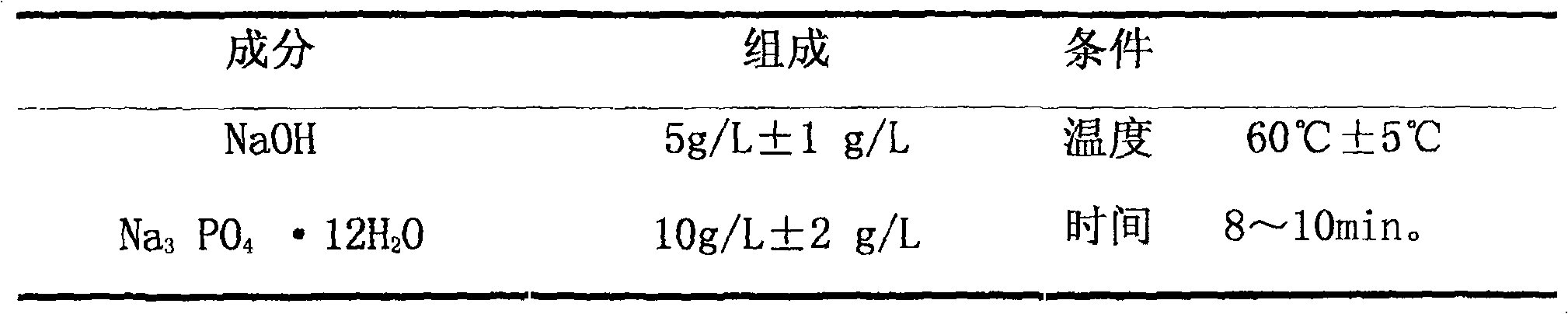

[0021] The formula of alkaline lotion is shown in Table 1:

[0022] Table 1

[0023]

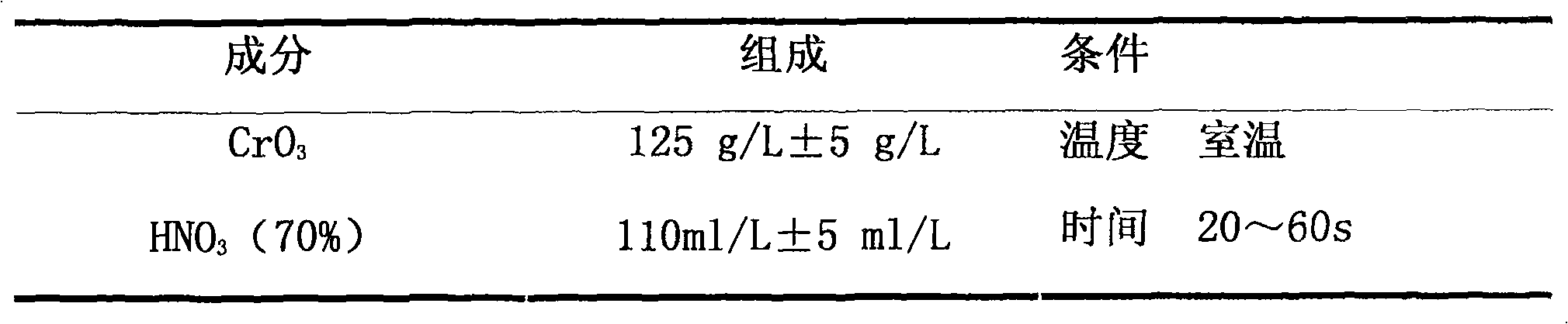

[0024] The acid lotion formula is shown in Table 2

[0025] Table 2

[0026]

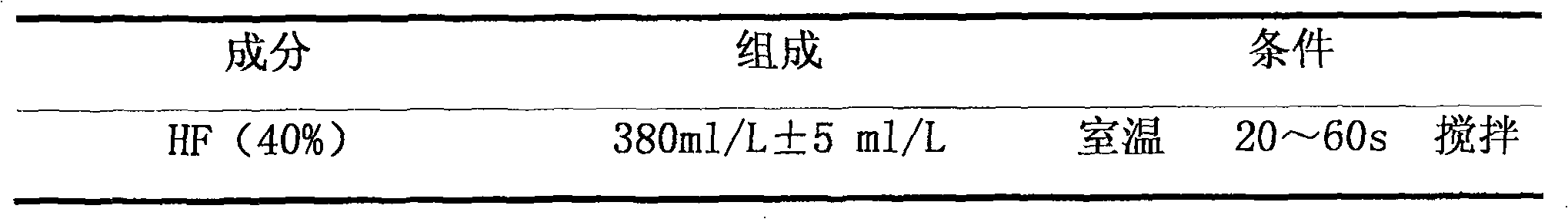

[0027] The activation solution formula is shown in Table 3

[0028] table 3

[0029]

[0030] 2. Plating solution formula and plating conditions

[0031] The bath formula and plating conditions are shown in Table 4

[0032] Table 4

[0033]

[0034] The plating solution is prepared by one-step acid plating solution. The principle is to directly prepare electroless nickel plating solution according to the formula. The specific operation steps are as follows:

[0035] (1) Measure the nickel sulfate, reducing agent (sodium hypophosphite), complexing agent (sodium citrate), and buffer (ammonium hydrogen fluoride) accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com