High-performance electrochemical capacitor plate material and preparation method thereof

An electrochemical and capacitor technology, applied in the field of electrochemical capacitors, can solve the problems of unfavorable silicon-based integrated circuit technology, limited capacitance capacity, low electrolyte wettability, etc., and achieve the effect of cheap drugs, easy realization, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

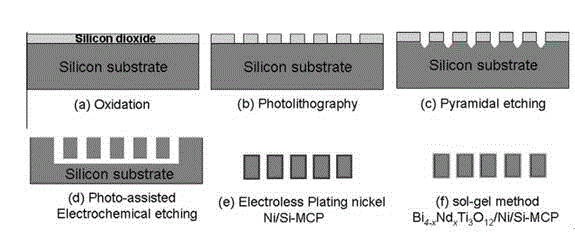

[0041] 1) Preparation of silicon microchannels:

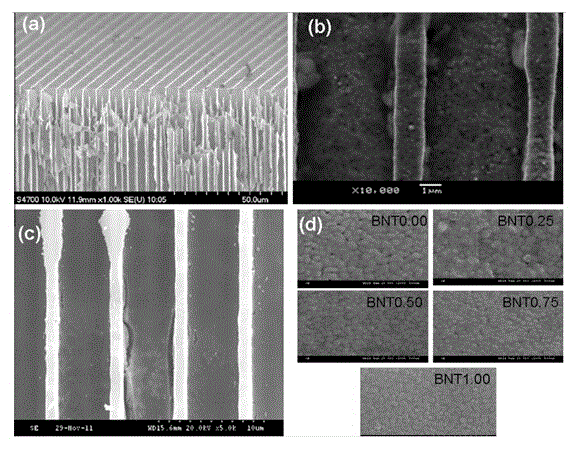

[0042] The preparation process of the electrochemical etching microchannel based on the MEMS process has been described in detail in the patent application 200610025900.7. The microchannel holes are disk-shaped, with a diameter distribution of 5 microns and a depth of about 200 microns. Its etching depth and width can be controlled by etching time, etchant concentration, temperature, etching voltage and light irradiation intensity.

[0043] 2) Preparation of Ni / Si-MCP:

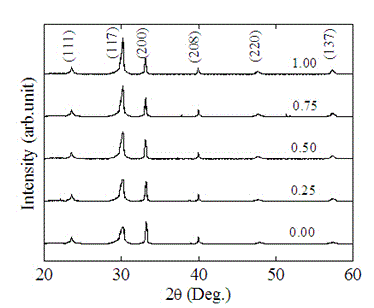

[0044] With the silicon microchannel as the substrate, after the surface pretreatment, the nickel single film is ring-coated on the inner wall of each channel by the electroless plating method to form a nickel / silicon microchannel nanocomposite structure. Surface pretreatment refers to: soaking with 1% polyethylene glycol octyl phenyl ether solution for 30s; the formula of electroless nickel plating solution is: nickel sulfate hexahydrate with a concentration...

Embodiment 2

[0059] 1. Preparation of silicon microchannels:

[0060] The preparation process of the electrochemical etching microchannel based on the MEMS process has been described in detail in the patent application 200610025900.7. The microchannel holes are disk-shaped, with a diameter distribution of 5 microns and a depth of about 200 microns. Its etching depth and width can be controlled by etching time, etchant concentration, temperature, etching voltage and light irradiation intensity.

[0061] 2. Preparation of Ni / Si-MCP:

[0062] The silicon microchannel is used as the substrate, and after surface pretreatment, a thin layer of metal nickel is coated on the inner wall of each channel by electroless plating to form a nickel / silicon microchannel nanocomposite structure. Surface pretreatment refers to: soaking with 1.5% polyethylene glycol octylphenyl ether solution for 40s; the formula of electroless nickel plating solution is: nickel sulfate hexahydrate with a concentration of 1....

Embodiment 3

[0074] 1. Preparation of silicon microchannels:

[0075] The preparation process of electrochemical etching microchannels based on MEMS technology has been described in detail in the patent application 200610025900. The microchannel holes are disk-shaped, with a diameter distribution of 5 microns and a depth of about 200 microns. Its etching depth and width can be controlled by etching time, etchant concentration, temperature, etching voltage and light irradiation intensity.

[0076] 2. Preparation of Ni / Si-MCP:

[0077]The silicon microchannel is used as the substrate, and after surface pretreatment, a thin layer of metal nickel is coated on the inner wall of each channel by electroless plating to form a nickel / silicon microchannel nanocomposite structure. Surface pretreatment refers to: soaking with 1.5% polyethylene glycol octyl phenyl ether solution for 50s; the formula of electroless nickel plating solution is: nickel sulfate hexahydrate with a concentration of 1.0 mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com