Electroplating solution for surface of zinc alloy workpiece with blind hole

A workpiece surface and zinc alloy technology is applied in the field of electro-galvanizing solution on the surface of zinc alloy workpieces containing blind holes. Complete effect of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

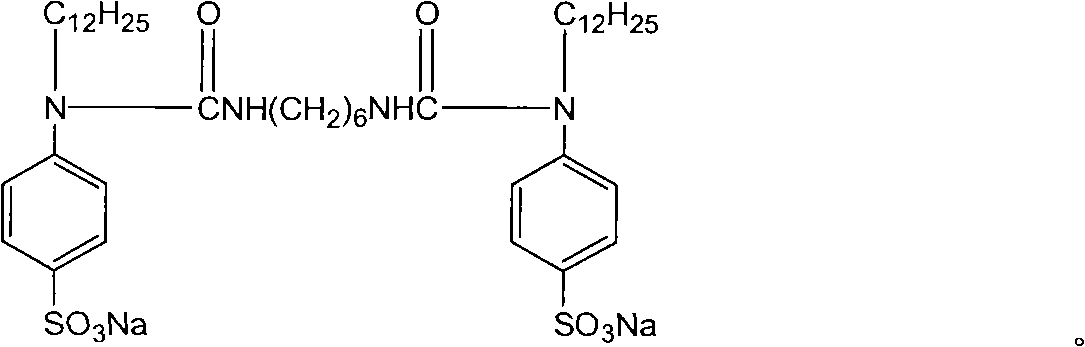

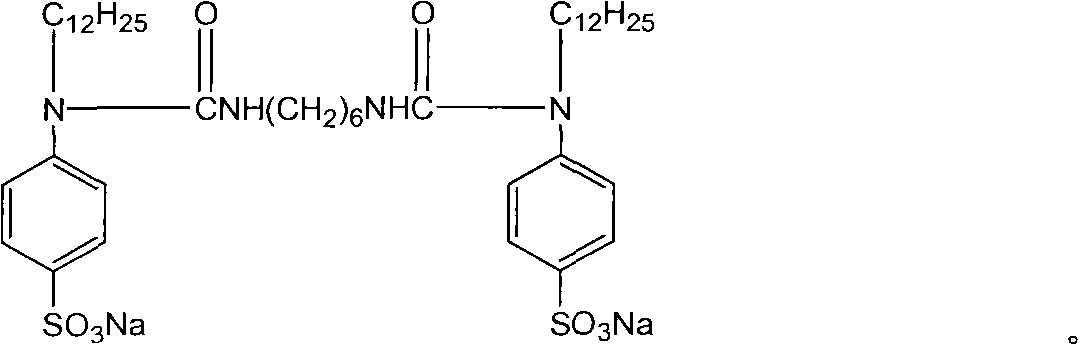

Embodiment 1

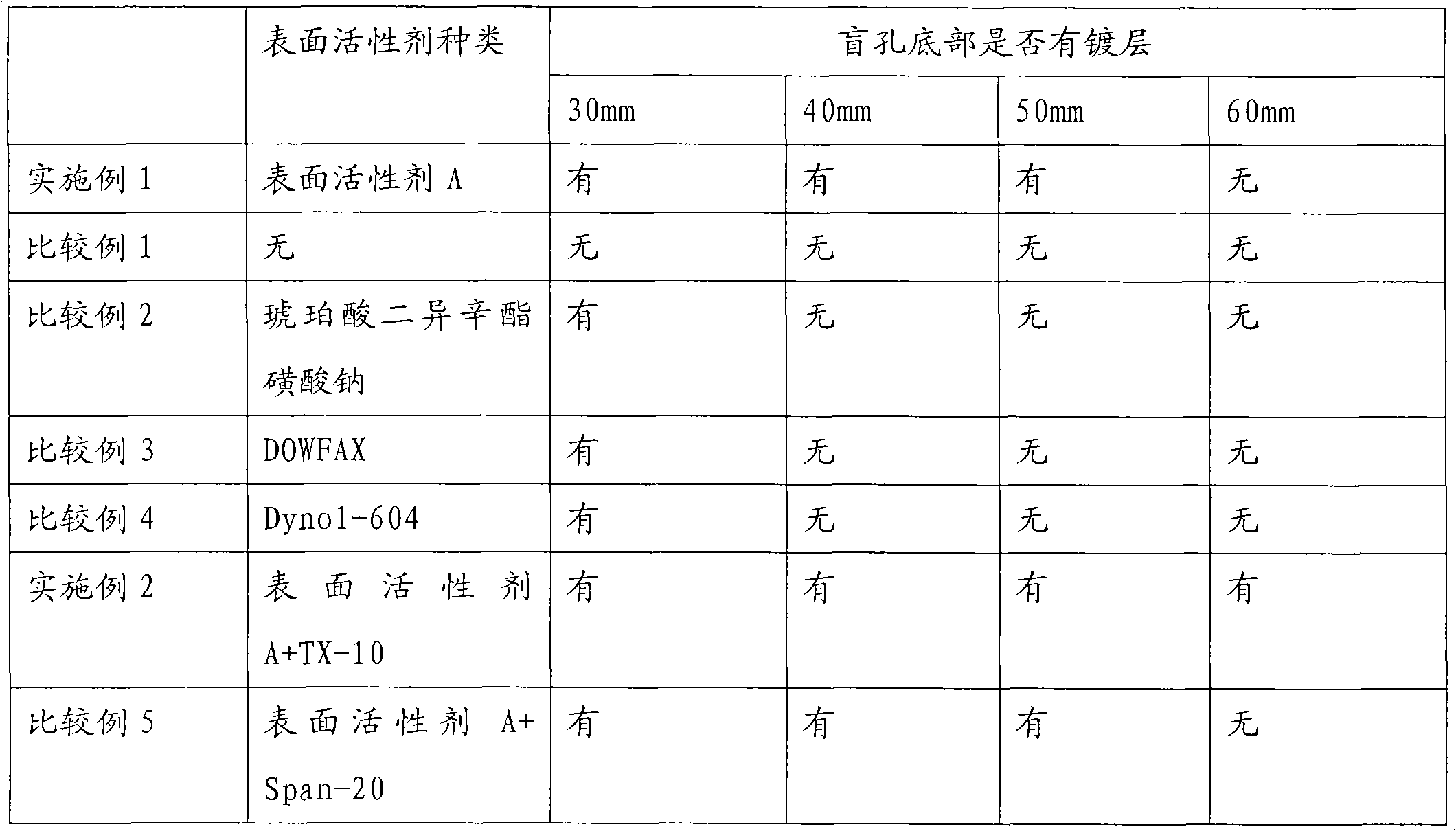

[0033] Zinc alloy die-casting parts with different depths of blind holes were used as workpieces to be plated. The blind holes were circular holes with a diameter of 10 mm and depths of 30 mm, 40 mm, 50 mm and 60 mm, respectively.

[0034] The electroplating process is: degreasing, water washing, rust removal, water washing, electrogalvanizing, water washing, drying, and detecting whether a coating is formed on the inner wall of the blind hole. The composition of the electroplating solution is: ZnCl 2 45g / L; KCl 155g / L; H 3 BO 3 21g / L; Surfactant A 0.28g / L, the balance is water. Solution temperature 25°C, cathode current density 1A / dm 2 , pH value = 5.5, electroplating time 60min. The resulting coating has good compactness, good gloss and good corrosion resistance. Plating is formed on all inner walls of blind holes with a depth of 30mm, 40mm, and 50mm, but no plating is formed on the bottom of a blind hole with a depth of 60mm

Embodiment 2

[0048] Zinc alloy die-casting parts with different depths of blind holes were used as workpieces to be plated. The blind holes were circular holes with a diameter of 10mm and depths of 30mm, 40mm, 50mm, and 60mm, respectively.

[0049] The electroplating process is: degreasing, water washing, rust removal, water washing, electrogalvanizing, water washing, drying, and detecting whether a coating is formed on the inner wall of the blind hole. The composition of the electroplating solution is: ZnCl 2 45g / L; KCl 155g / L; H 3 BO 3 21g / L; Surfactant A 0.28g / L; TX-10 0.15g / L, the balance is water. Solution temperature 25°C, cathode current density 1A / dm 2 , pH value = 5.5, electroplating time 60min. Coatings are formed on all inner walls of blind holes with different depths, and the obtained coatings have good compactness, good gloss and good corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com