Patents

Literature

35results about How to "Play the role of corrosion inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

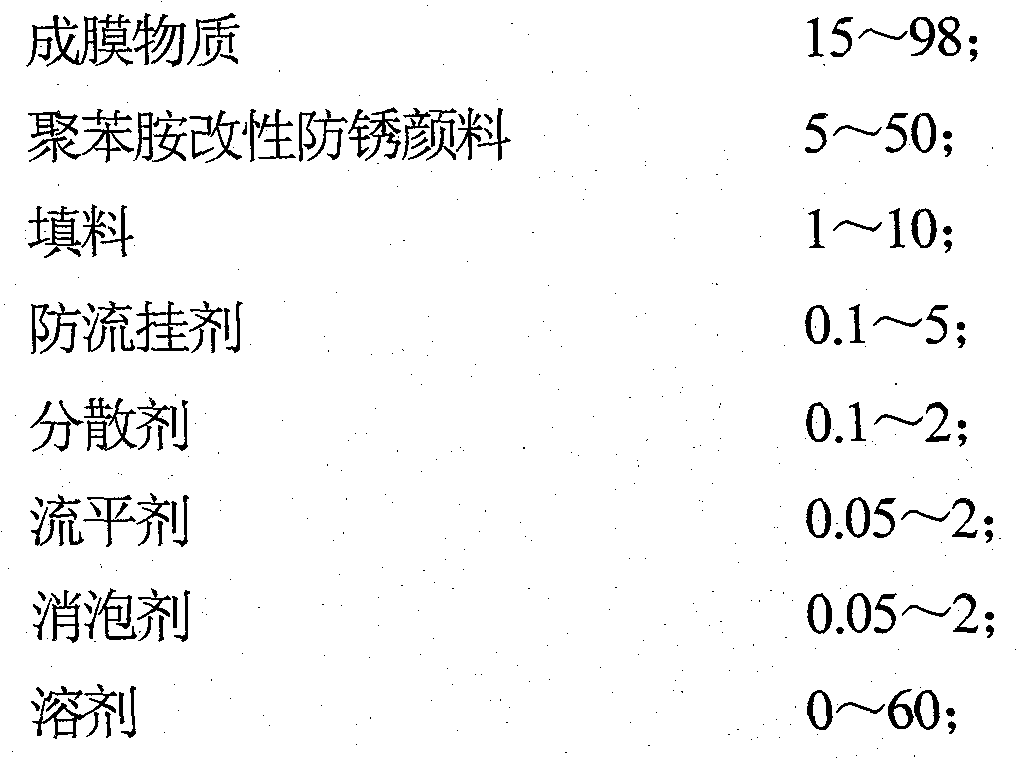

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

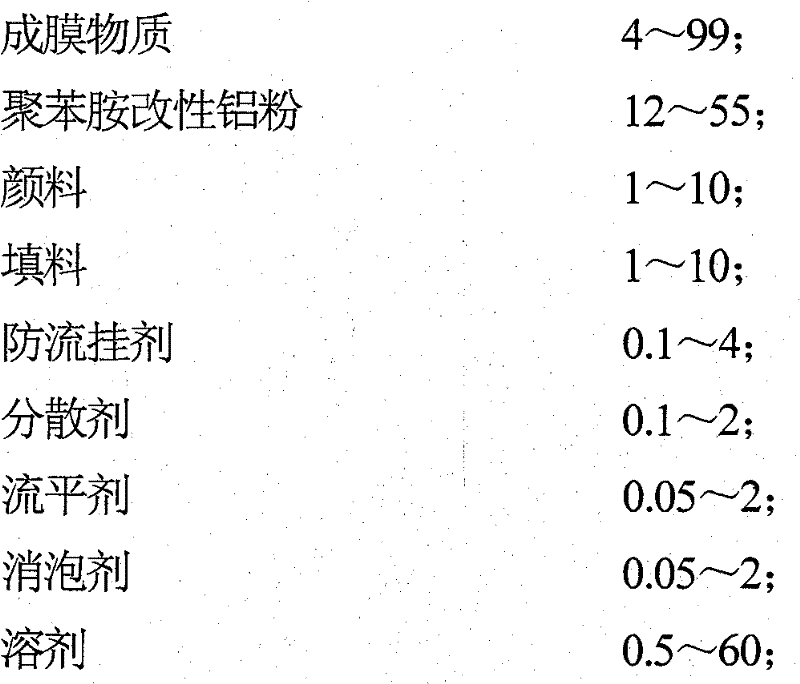

Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

ActiveCN101643619AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPetrochemicalCorrosion

The invention relates to coating technology, in particular to an environment-friendly polyaniline modified aluminium powder anti-corrosive coating and a preparation method thereof to solve the problemthat the prior aluminium powder coating has poor corrosion resistance, and is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating comprises a film forming matter, polyaniline modified aluminium powder and the like. A polyaniline coating layer is formed on the surface of the aluminium powder by an oxidative polymerization method; the treated aluminium powder has passivating effect on metal; and a phytic coating layer on the surface of the aluminium powder also has corrosion inhibiting effect on the metal. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Polyaniline modified glass flake heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN101643615AAchieve passivationImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified glass flake heavy-duty anti-corrosive coating and a preparation method thereof to solve the problems that when theprior glass flake anti-corrosive coatings are constructed, most of the glass flake anti-corrosive coatings require to coat primer on the surface of steel or other metal matrix to improve the corrosionresistance and prevent corrosion between the coat and the interface of the matrix, and the like. The polyaniline modified glass flake heavy-duty anti-corrosive coating comprises epoxy resin, a polyaniline modified glass flake, an amine curing agent and the like. A polyaniline coating layer is formed on the surface of the glass flake by an oxidative polymerization method; the glass flake after thetreatment has the passivating effect on metal; and a phytic coating layer on the surface of the glass flake also has the corrosion inhibiting effect on the metal. The polyaniline modified glass flakeheavy-duty anti-corrosive coating has strong corrosion resistance and permeability resistance, can be applied to heavy-duty anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like, and is particularly suitable for protecting wave splashing zones and tidal difference zones.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

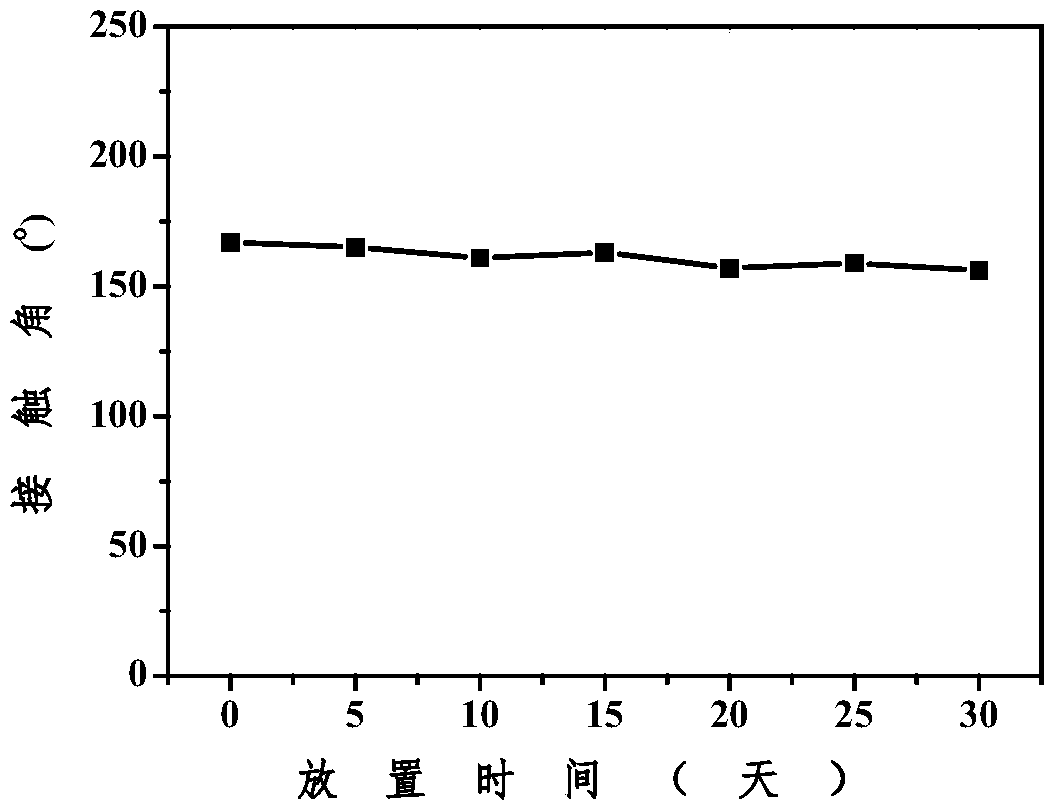

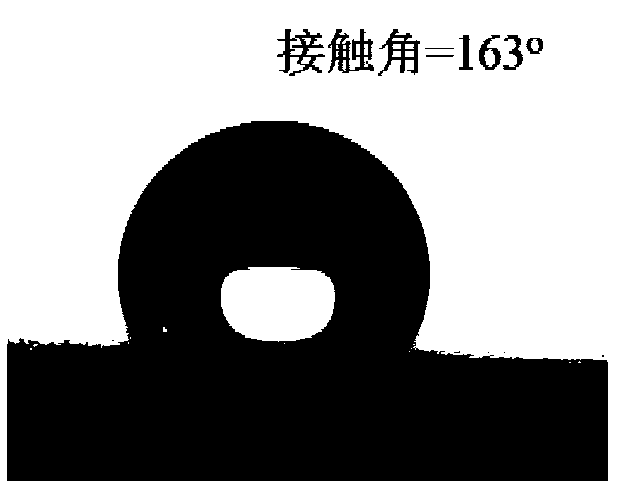

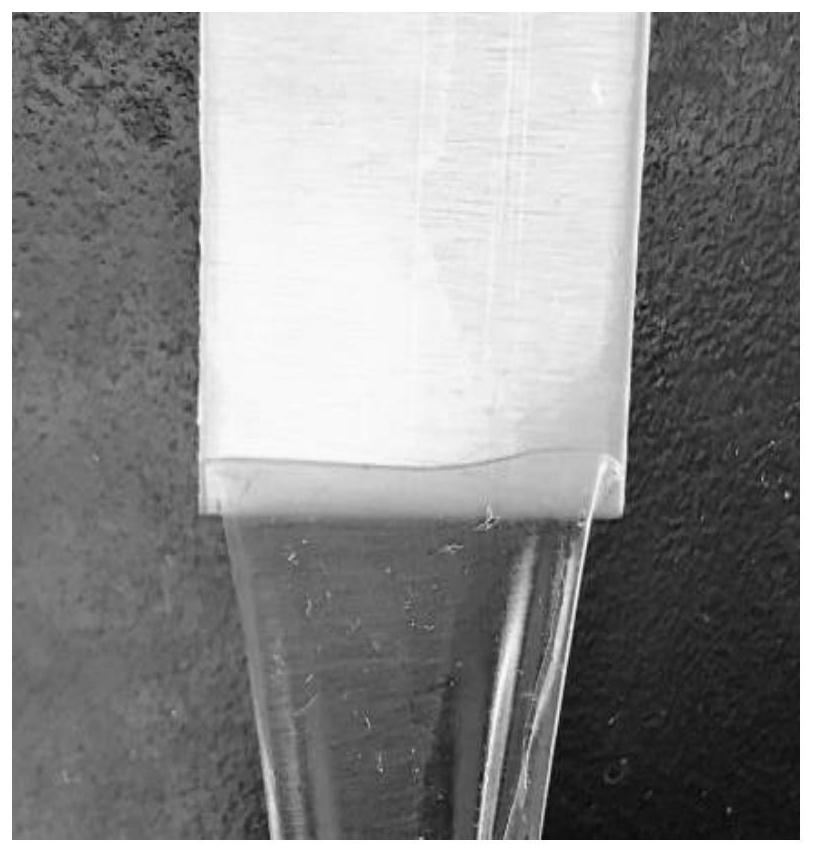

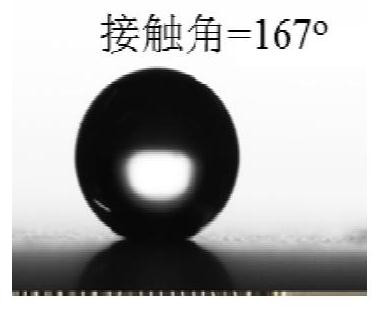

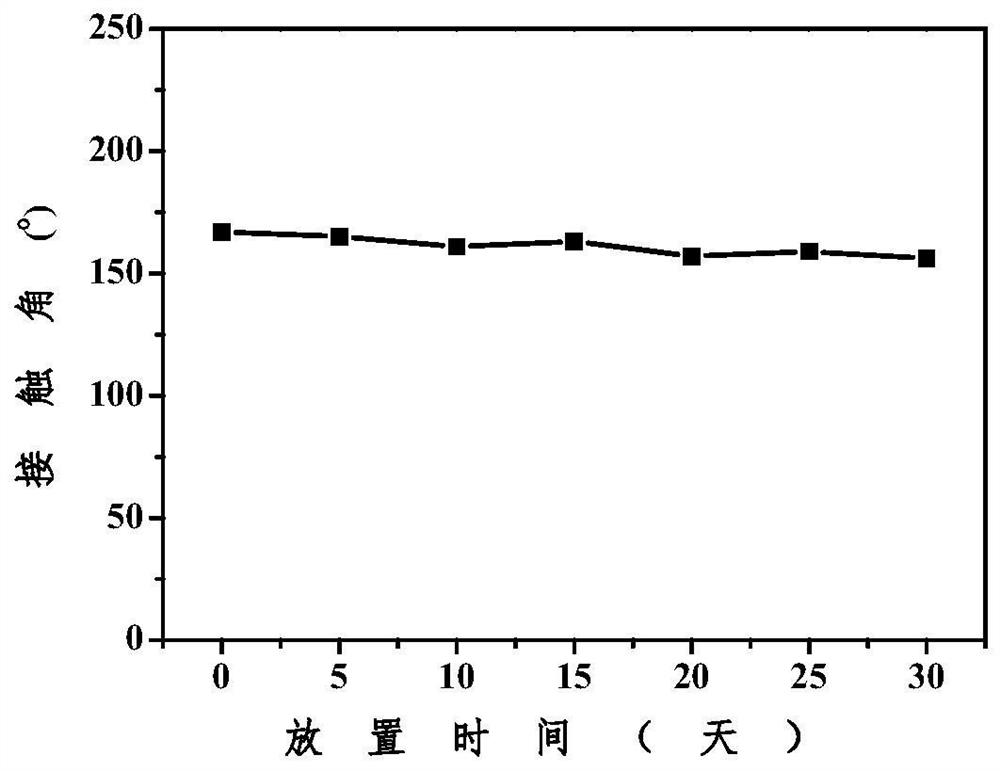

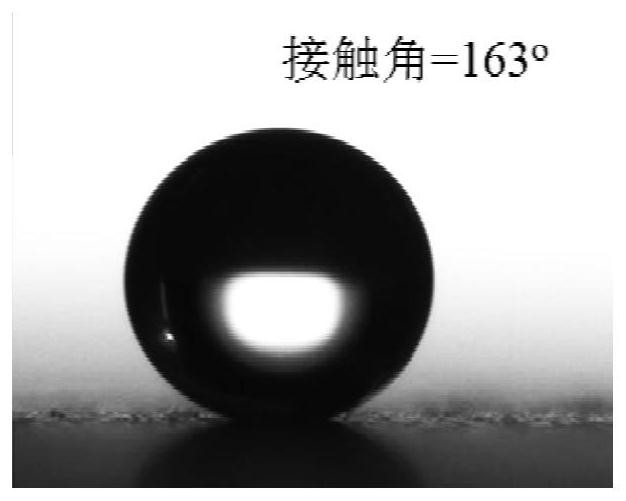

Method for building super-hydrophobic coating on metal surface

ActiveCN109127328AShape constraintsMild conditionsPretreated surfacesCoatingsRoom temperatureAqueous solution

The invention relates to a method for building a super-hydrophobic coating on a metal surface. The method comprises the steps that metal base materials are cleaned in a lye solution at 50-70 DEG C andan acid solution at 50-70 DEG C to remove grease on the surface; chemical etching treatment is carried out on the metal surface by using an aqueous hydrochloric acid solution at room temperature for5-15 minutes; and hydrophobic substance with low-surface-energy is assembled onto the metal surface after the chemical etching treatment, and then solidification treatment is carried out. According tothe method for building the super-hydrophobic coating on the metal surface, the super-hydrophobic coating is built on the metal surface, the used preparation method has no special restrictions on theshape of metal, and coating can be carried out on the surface of a test piece with complicated shape. The method does not require special equipment, has simple process, easy operation and mild condition, is especially suitable for metal parts with irregular shape such as heat exchanger fins, and is easy for industrialized mass production. After the gained coating is placed for a long period, preferable super-hydrophobic performance is still maintained.

Owner:XI AN JIAOTONG UNIV

Preparation method of multifunctional oxyamide for oil field and application thereof

The invention discloses a preparation method of multifunctional oxyamide for an oil field and an application thereof. Long-chain fatty acid amide is prepared by taking natural oil as a raw material, and then oxyamide is prepared through an addition reaction by taking an aldehyde compound as a hydroxylation reagent. The oxyamide is used as a crude oil additive, so that the viscosity and condensation point of the crude oil can be reduced; meanwhile, through the coordination of nitrogen and oxygen atoms with metal, the oxyamide is adsorbed to the metal surface and forms an organic protection layer to realize a corrosion inhibition effect.

Owner:XI'AN PETROLEUM UNIVERSITY

Novel stainless steel pickling-passivating solution and pickling-passivating process thereof

InactiveCN105331989ANo irritating smellImprove protectionMetallic material coating processesGallic acid esterThiourea

The invention discloses novel stainless steel pickling-passivating solution. The novel stainless steel pickling-passivating solution comprises the following components in parts by weight: 30-40 parts of hydrogen peroxide, 20-30 parts of hydrofluoric acid, 5-15 parts of citric acid, 3-7 parts of thiourea derivatives, 2-8 parts of octaphenyl polyoxyethyiene, 50-80 parts of deionized water, 1-5 parts of a silane coupling agent, 5-10 parts of polyaspartic acid, 3-8 parts of polyacrylamide, and 5-12 parts of gallic acid. The invention further discloses a pickling-passivating process thereof. The stainless steel pickling-passivating solution does not contain nitric acid and inorganic strong acid, can achieve integration of a pickling function and a passivating function, and can effectively improve the corrosion resistance of stainless steel surfaces; the process is simple and has no special requirements on operation environment; and the stainless steel pickling-passivating solution is widely applicable to elimination for iron rust, welding spots, oil stain, and black and yellow oxide skins generated during the processes of formation, assembly, welding and the like, and comprehensive passivation for stainless steel workpieces.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

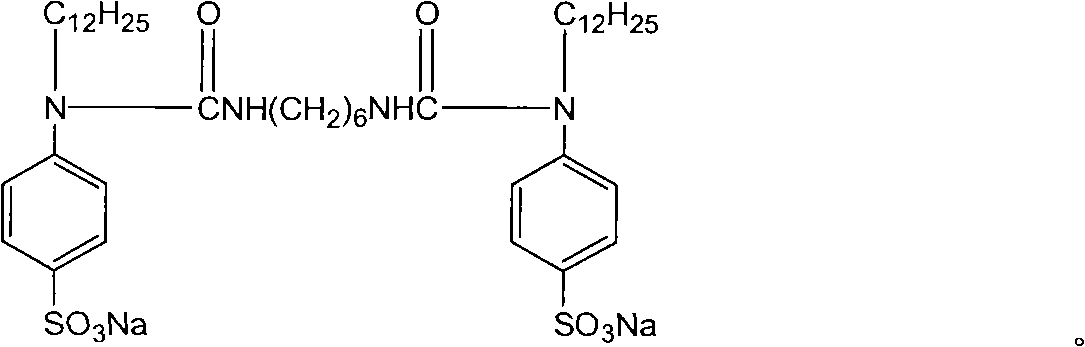

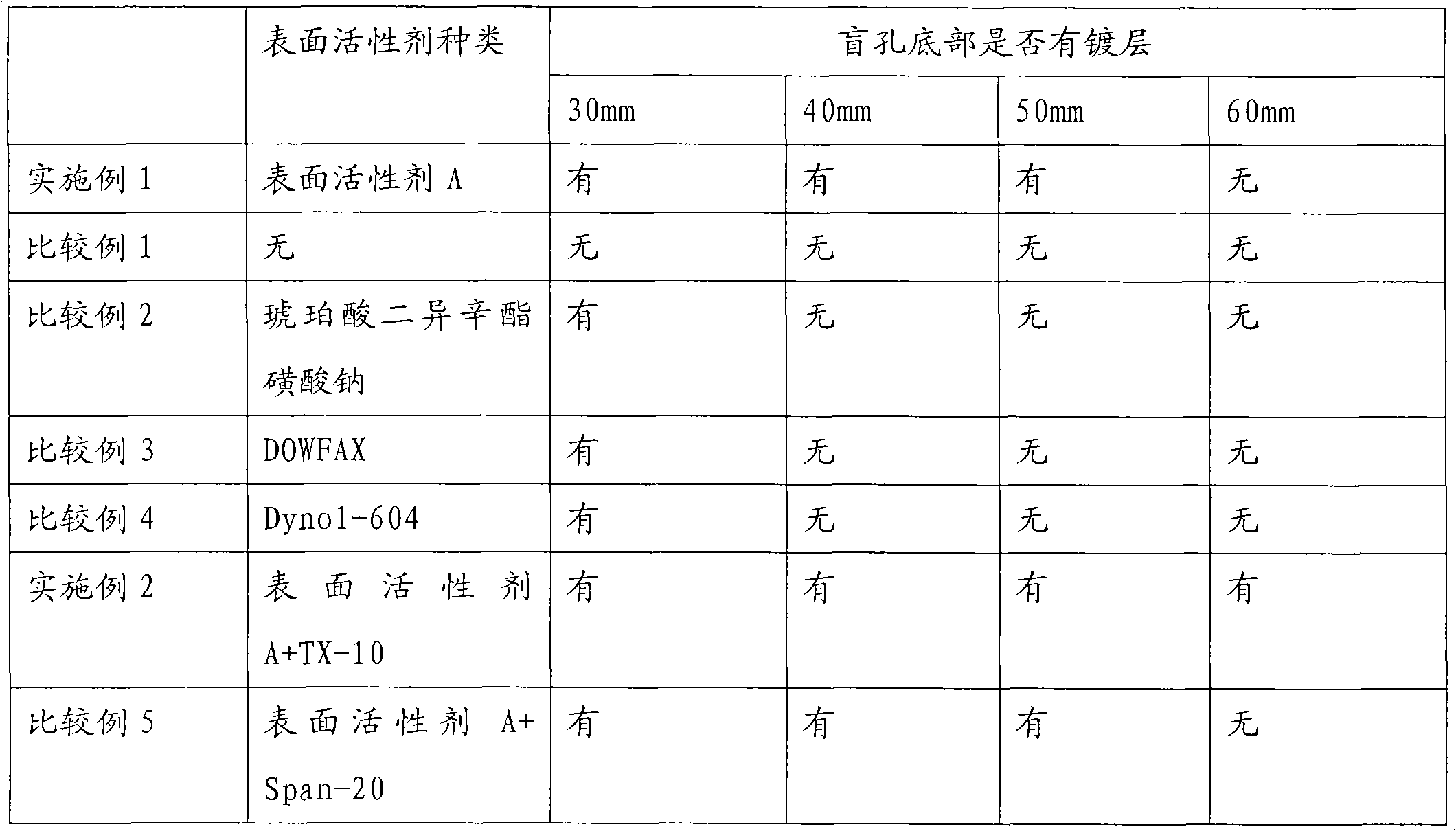

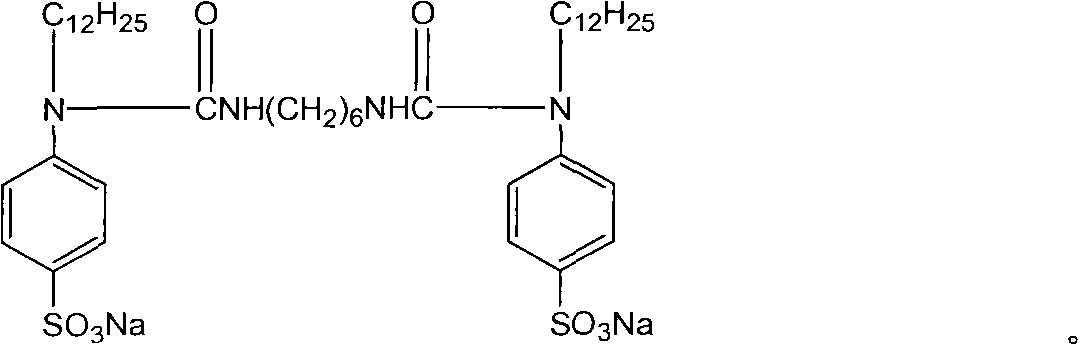

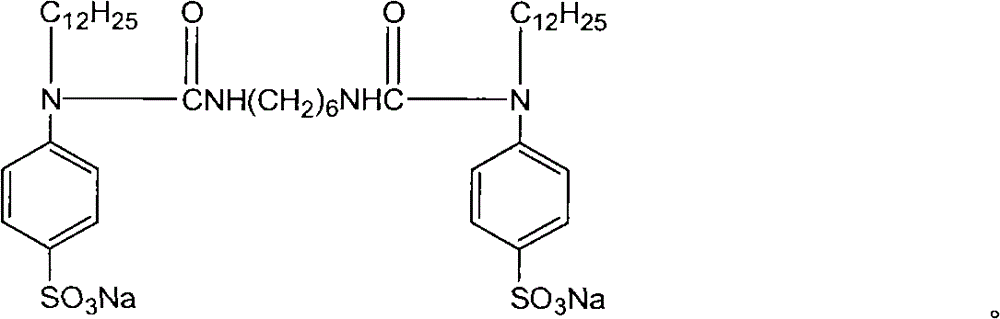

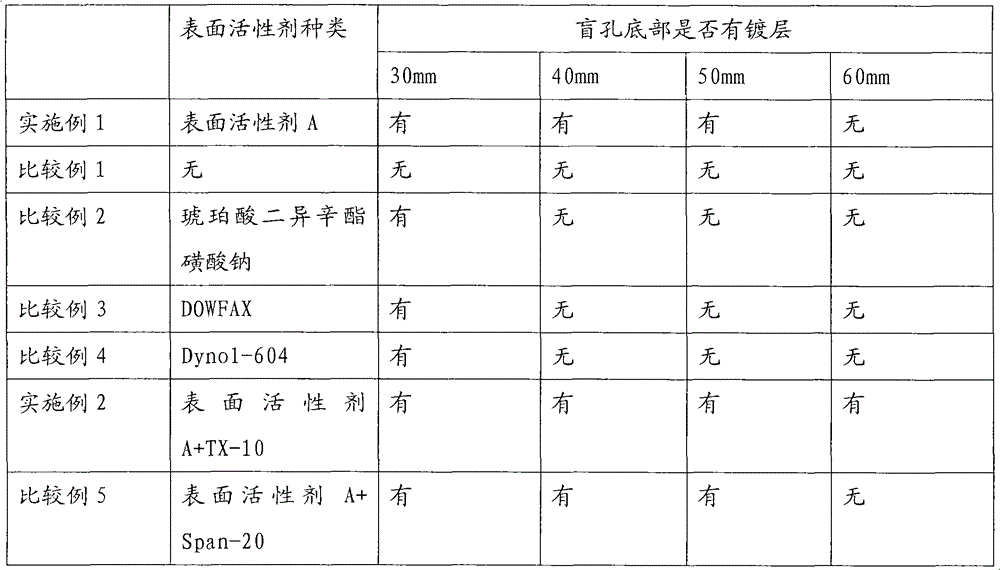

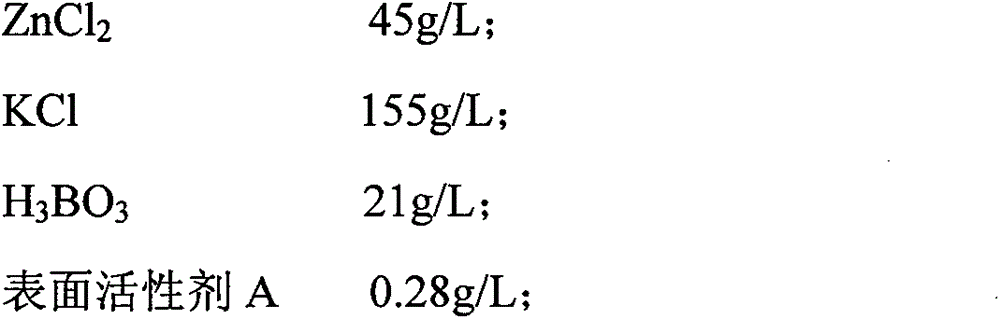

Method for electrogalvanizing on surface of zinc alloy workpiece with blind holes

ActiveCN102560567AImprove deep plating abilityPlay the role of corrosion inhibitionElectrogalvanizationZinc alloys

The invention discloses a method for electrogalvanizing on the surface of a zinc alloy workpiece with blind holes. The method has extremely good blind hole deep plating performance and can prevent corrosion of zinc alloy. An electrogalvanizing solution used in the invention comprises ZnCl2, KCl, H3BO3 and surfactant A, with the balance being water.

Owner:南通东湖国际商务服务有限公司

High-efficiency grey water dispersing agent

ActiveCN103086524BEnhanced inhibitory effectGood dispersionScale removal and water softeningHigh concentrationPhosphate

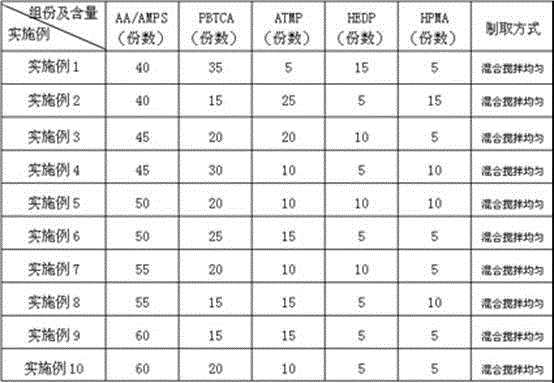

The invention relates to a high-efficiency grey water dispersing agent which is a composition consisting of 40-60 percent of acrylic acid-2-polyscrylide-2-methyl acrylsulfonate, 15-35 percent of 2-phosphate-1,2,4-tricarboxylic acid butane, 5-25 percent of amino trimethylene phosphonic acid, 5-15 percent of hydroxyethylidene-1,1-diphosphonic acid and 5-15 percent of hydrolytic polymaleic anhydride. The dispersing agent is stable in property under the conditions of 40MPa and 250 DEG C, has a high dispersing capacity at the high temperature of 300 DEG C, has a good dispersing function on high-basicity, high-hardness, high-PH value and high ash content and high concentration multiple under the required high-concentration times in a water-coal-slurry pressurization and gasification device, can effectively delay the scale forming tendency and is applicable to a circulating cooling water system in industries such as power, metallurgy and papermaking. The addition in a water system is determined according to the water quality and working conditions, and the amount is 50-80mg / l according to the flow sum of a low-pressure grey water pump and a high-pressure grey water pump.

Owner:JIANGSU TIANMAI CHEM CO LTD +1

Acid pickling technology for welding wire steel surface pretreatment

The invention discloses an acid pickling technology for welding wire steel surface pretreatment. An acid pickling solution adopted in the acid pickling technology is prepared from, by mass, 8%-16% of sulfuric acid, 4%-10% of hydrochloric acid, 0.5%-1% of fatty alcohol-polyoxyethylene ether, 1%-2% of thiourea and the balance water. The acid pickling technology comprises the following steps that 1, welding wire steel is immersed into clear water with the temperature ranging from 55 DEG C to 60 DEG C to be soaked for 5 minutes to 8 minutes; 2, the acid pickling solution is prepared and then poured into an acid pickling tank; 3, the welding wire steel soaked in the clear water is put into the acid pickling tank to be subjected to acid pickling, wherein the acid pickling temperature ranges from 20 DEG C to 35 DEG C, and the acid pickling time ranges from 30 minutes to 40 minutes; 4, the welding wire steel obtained after acid pickling is washed with clear water and then coated with boric acid for rust prevention. According to the acid pickling technology, sulfuric acid and hydrochloric acid are adopted to be cooperatively used, the acid pickling time is short, and steel scale cinder can be removed more effectively; fatty alcohol-polyoxyethylene ether not only achieves an corrosion inhibition effect, but also can generate a layer of foam with the acid pickling solution in the acid pickling process, therefore, the condition that acid mist is volatilized into space to generate pollution is prevented, and the environment is protected.

Owner:哈焊所华通(常州)焊业股份有限公司

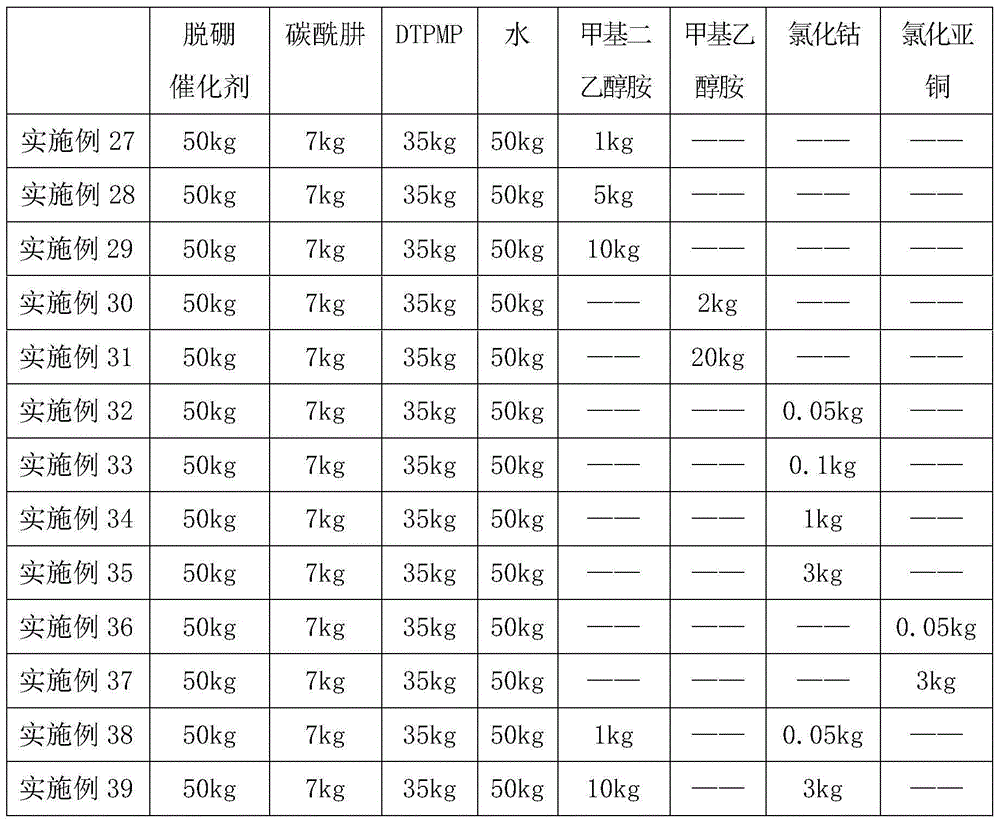

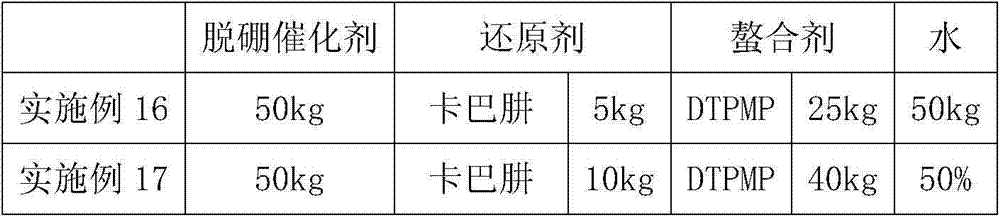

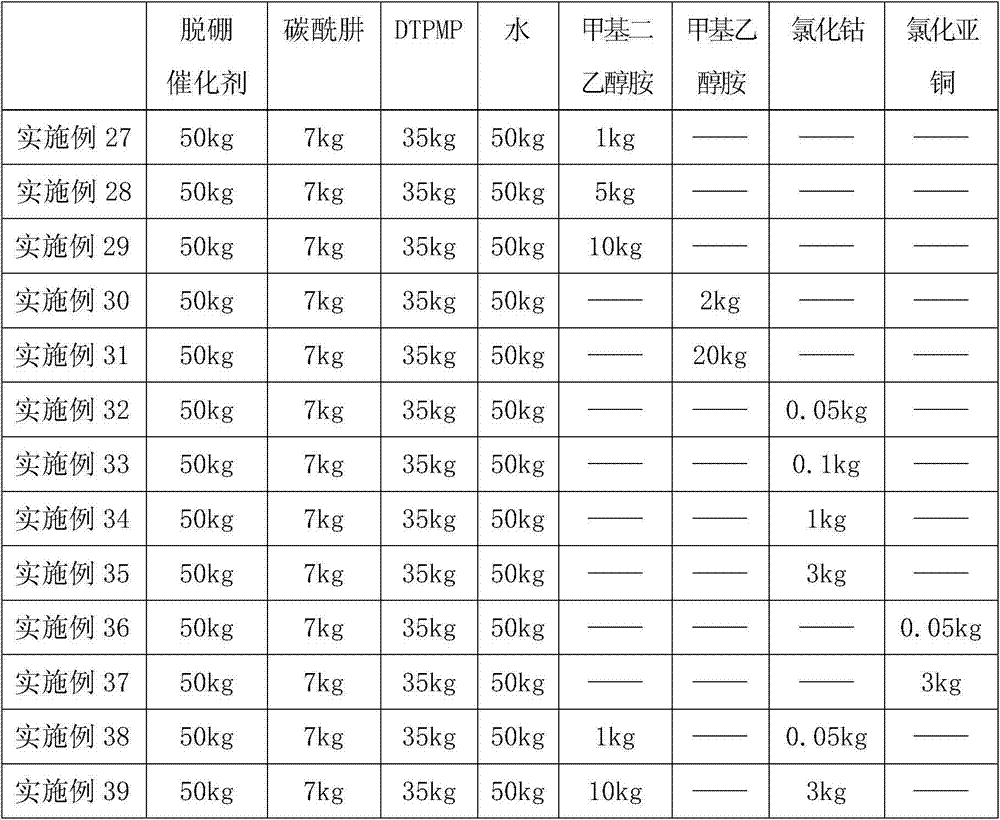

Selective high-molecular fracture catalyst as well as preparation method and application thereof

ActiveCN103480419BImprove efficiencyCross-linking instabilityOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatmentPhosphateActivation energy

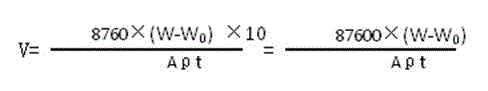

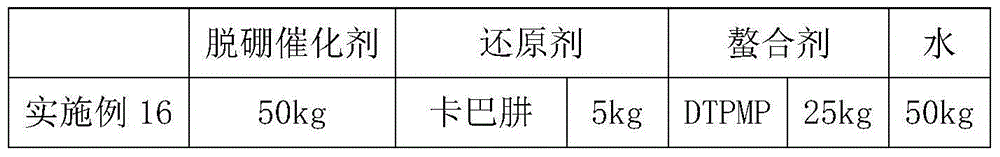

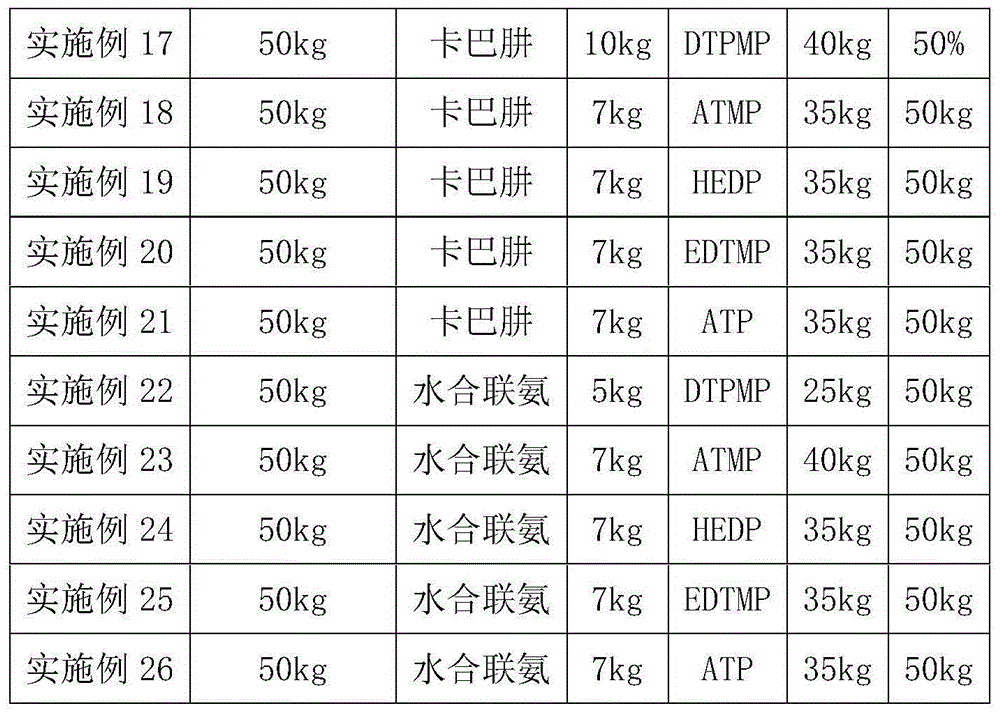

The invention discloses a selective high-molecular fracture catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: filling water into a reaction kettle and increasing the temperature to 50 DEG C; adding an organic phosphate chelating agent in to the reaction kettle and reacting for 1 h; adding a reducing agent and reacting for 30 min; finally, adding a boron removal catalyst, increasing the reaction temperature to 50 to 90 DEG C, and reacting for 3 h. The selective high-molecular fracture catalyst provided by the invention is mainly applied to gel breakage of fracturing fluid in an oil field, and the usage amount is 0.05 to 0.1% of the total mass of the fracturing fluid. The selective high-molecular fracture catalyst has the beneficial effects that gel can be broken radically, the price is reasonable, and the catalyst does not have corrosivity and is free from influence of a great amount of co-existence salt; all ingredients contained in the product supplement one another, the boron removal catalyst lowers the activation energy of boron to ensure that the fracturing fluid is unstable in boron cross-linking performance and is degraded unceasingly so as to achieve the effects of hydration and gel breakage at last, the reducing agent can lower activation energy and serves as a low-temperature activating agent to prevent oxygen corrosion, and the organic phosphate chelating agent can prevent scaled and treated water from being compatible with follow-up water.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Selective high-molecular fracture catalyst as well as preparation method and application thereof

ActiveCN103480419AImprove efficiencyCross-linking instabilityOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatmentPhosphateActivation energy

The invention discloses a selective high-molecular fracture catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: filling water into a reaction kettle and increasing the temperature to 50 DEG C; adding an organic phosphate chelating agent in to the reaction kettle and reacting for 1 h; adding a reducing agent and reacting for 30 min; finally, adding a boron removal catalyst, increasing the reaction temperature to 50 to 90 DEG C, and reacting for 3 h. The selective high-molecular fracture catalyst provided by the invention is mainly applied to gel breakage of fracturing fluid in an oil field, and the usage amount is 0.05 to 0.1% of the total mass of the fracturing fluid. The selective high-molecular fracture catalyst has the beneficial effects that gel can be broken radically, the price is reasonable, and the catalyst does not have corrosivity and is free from influence of a great amount of co-existence salt; all ingredients contained in the product supplement one another, the boron removal catalyst lowers the activation energy of boron to ensure that the fracturing fluid is unstable in boron cross-linking performance and is degraded unceasingly so as to achieve the effects of hydration and gel breakage at last, the reducing agent can lower activation energy and serves as a low-temperature activating agent to prevent oxygen corrosion, and the organic phosphate chelating agent can prevent scaled and treated water from being compatible with follow-up water.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618BAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

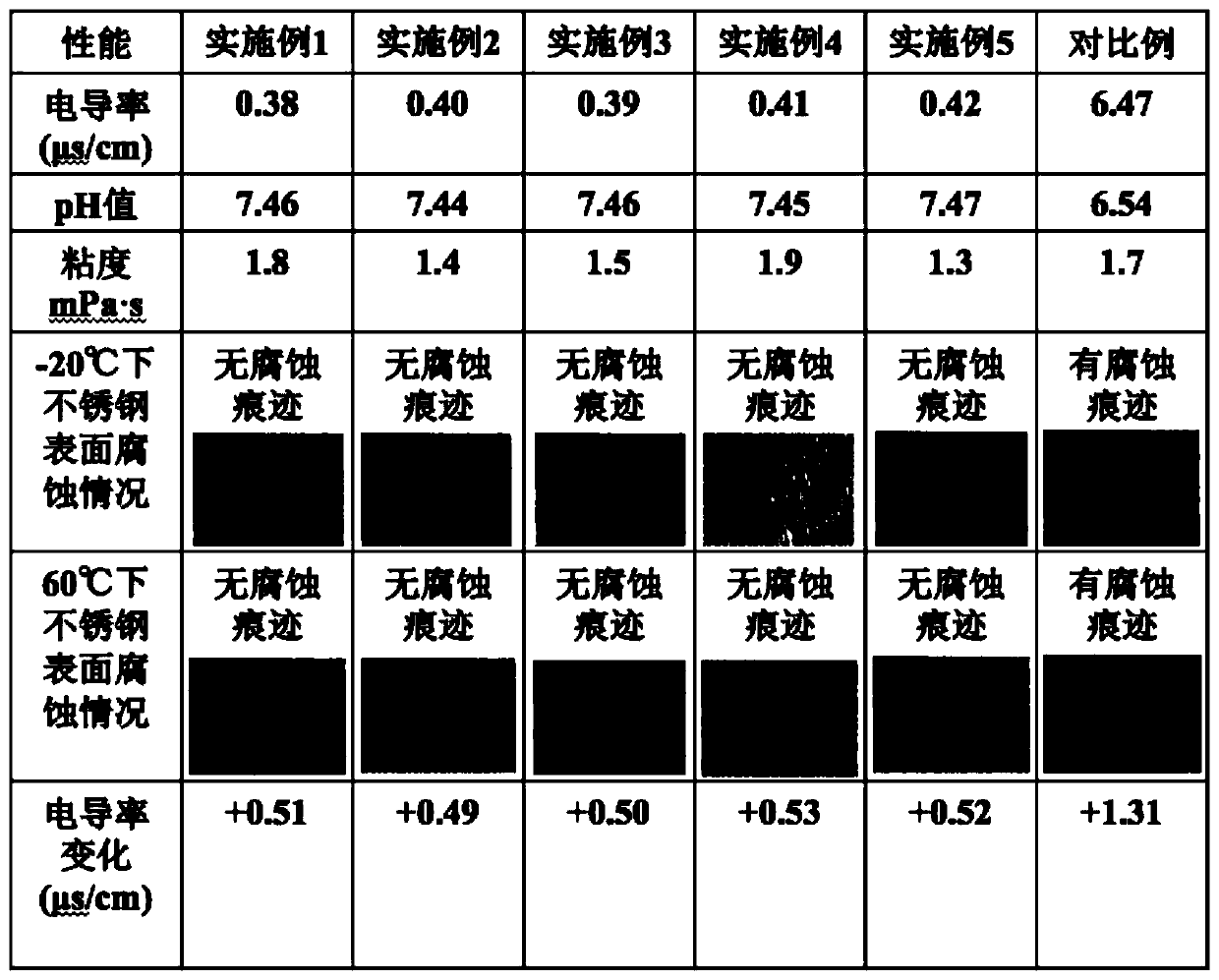

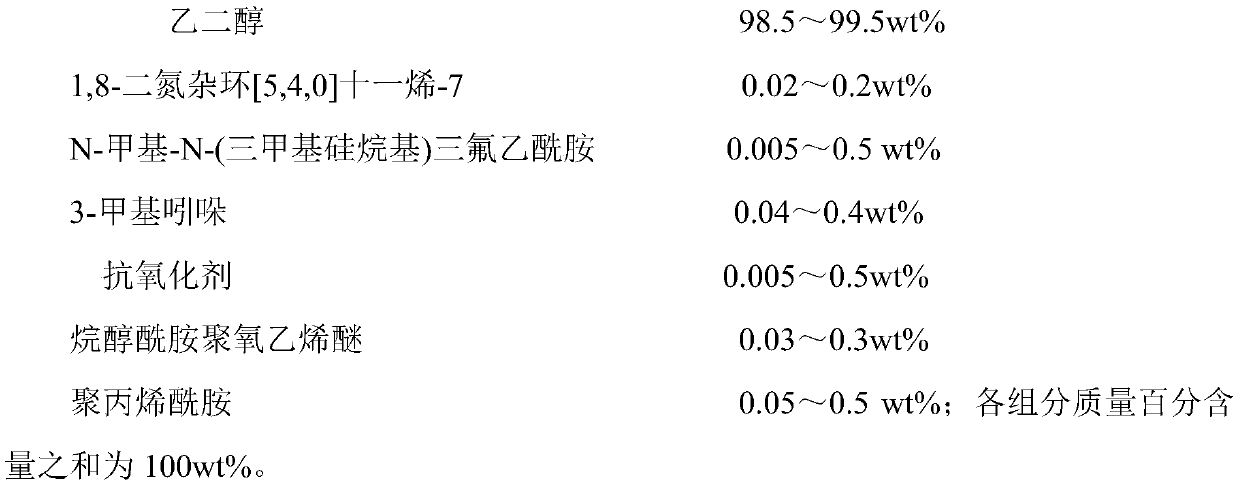

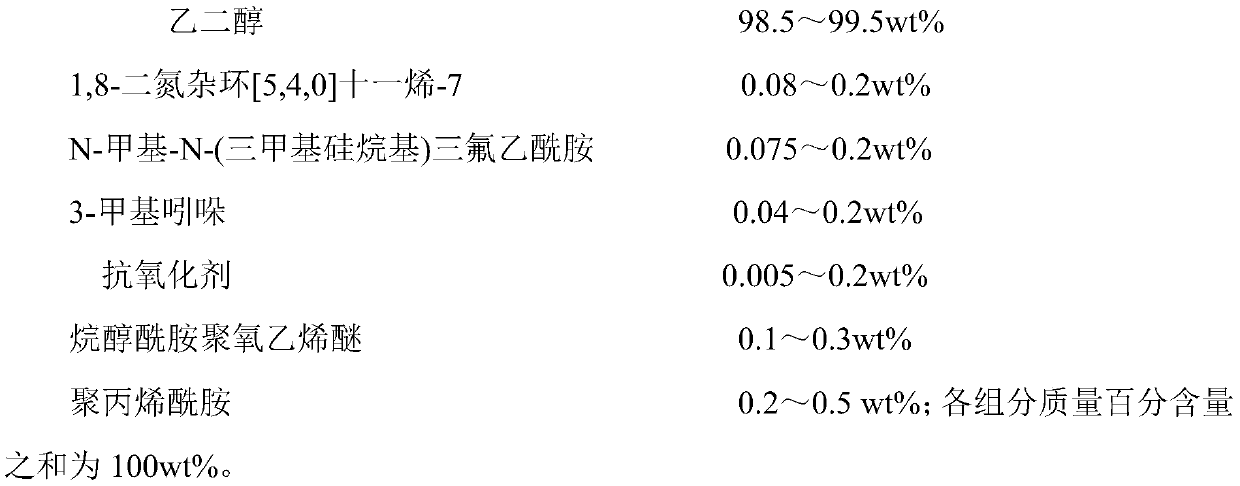

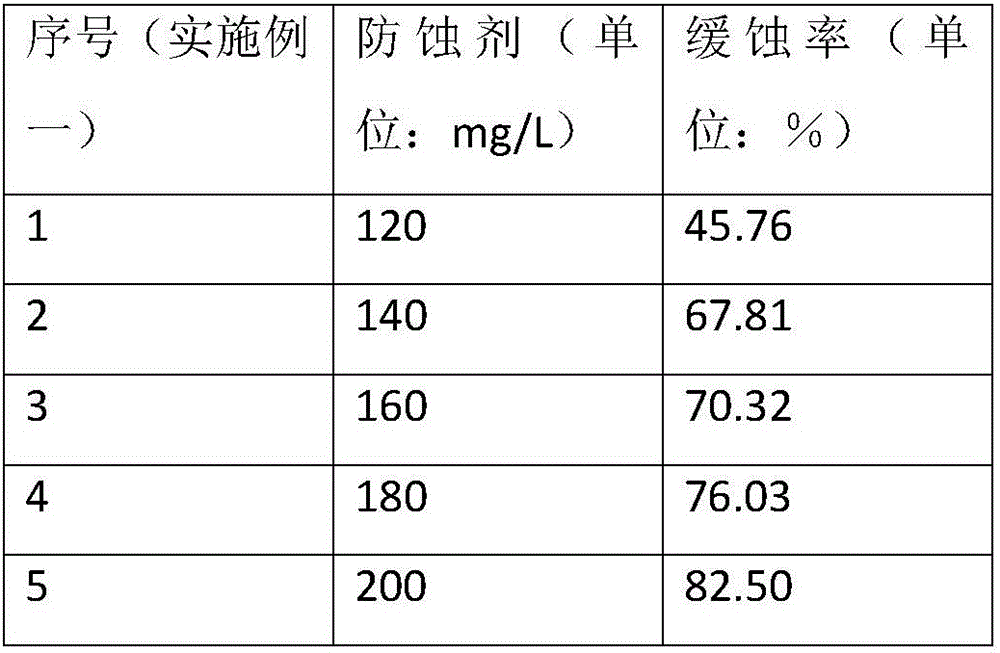

High-temperature corrosion-resistant fuel cell engine antifreeze and preparation method thereof

InactiveCN110055039ALowering the freezing pointAvoid corrosionHeat-exchange elementsFuel cellsTrimethylsilyl

The invention provides a novel high-temperature corrosion-resistant fuel cell engine antifreeze. The high-temperature corrosion-resistant fuel cell engine antifreeze comprises, by weight, 98.5-99.5wt%of glycol and 0.5-1.5wt% of an additive, wherein the additive includes, by weight, 0.02-0.2wt% of 1,8-heterocyclic(5,4,0) undecene-7, 0.005-0.5wt% of N-methyl-N-(trimethylsilyl) trifluoroacetamide, 0.04-0.4wt% of 3-methyl indole, 0.05-0.5wt% of dipyridamole, 0.03-0.3wt% of alkanolamide polyoxylene ether and 0.05-0.5wt% of polyacrylamide. A new additive formula without using water is adopted as the substrate, the conductivity of the antifreeze is reduced, and the stainless steel is protected from corrosion at high temperature; the antifreeze is low in cost, simple in preparation process and suitable for fuel cell vehicles.

Owner:SHANGHAI UNIV +1

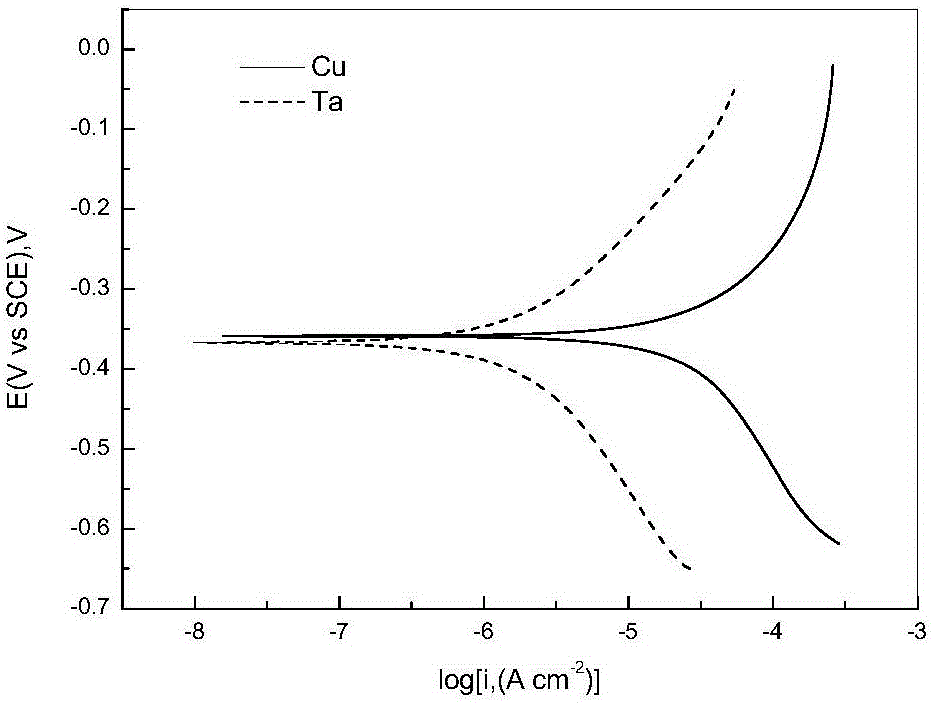

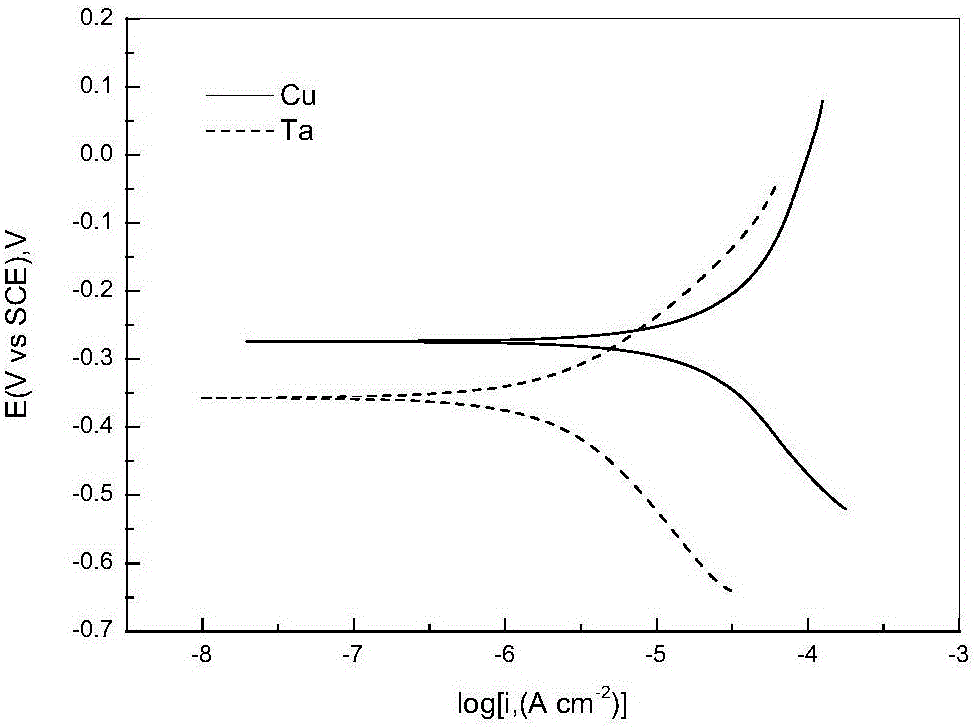

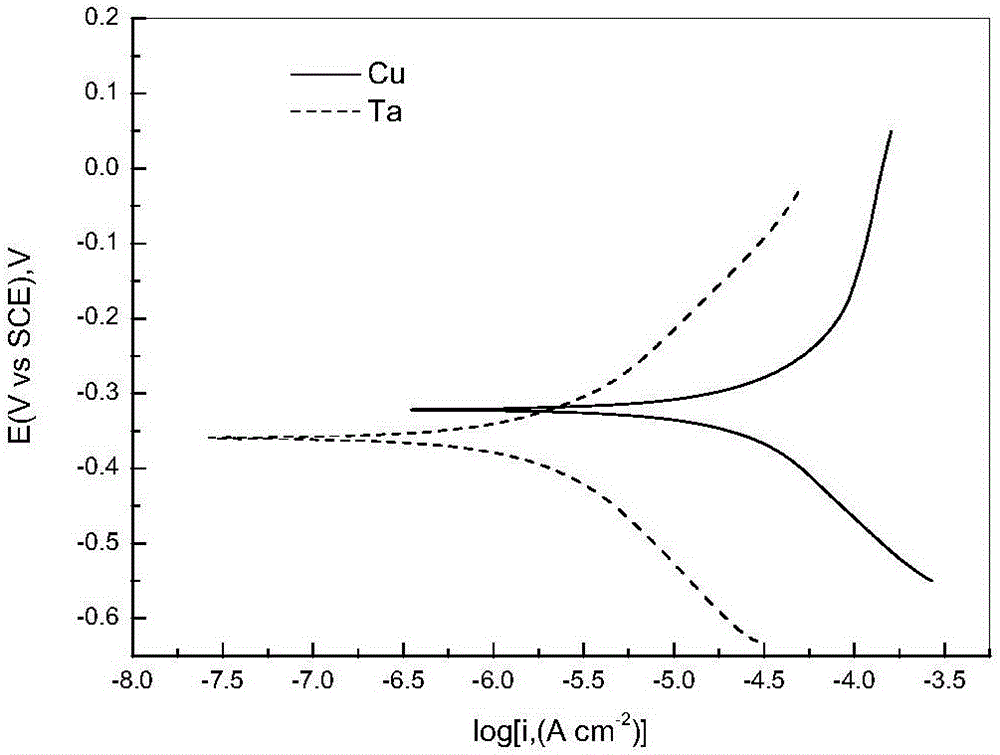

Application of alkaline polishing solution in inhibition of galvanic couple corrosion of copper-tantalum barrier layer

ActiveCN106244028AConducive to reasonable configurationThe defect of poor customer service stabilityPolishing compositionsEthylenediaminePotential difference

The invention belongs to the field of chemically mechanical polishing, and in particular, relates to an application of an alkaline polishing solution in inhibition of galvanic couple corrosion of a copper-tantalum barrier layer; the alkaline polishing solution takes a polyhydroxy polyamino compound as a chelating agent and a pH regulator; the mass percentage of the polyhydroxy polyamino compound in the alkaline polishing solution is 0.1%-2%, and the pH value of the alkaline polishing solution is 9-10.5; the polyhydroxy polyamino compound is formed by mixing one or more of hydroxyethyl ethylenediamine, tetrahydroxyethyl-ethylene diamine and triethanolamine. The special hydroxyl and amino containing compound is added in the alkaline polishing solution to be used as a chelating agent, the chelating agent makes the potential of copper in the polishing solution reduced, a passivation layer is formed on the surface of tantalum, and the potential of tantalum in the polishing solution is reduced in a smaller degree, so that the purpose of reducing the potential difference between copper and tantalum is achieved, the corrosion current is reduced, and the corrosion rate is controlled.

Owner:HEBEI UNIV OF TECH

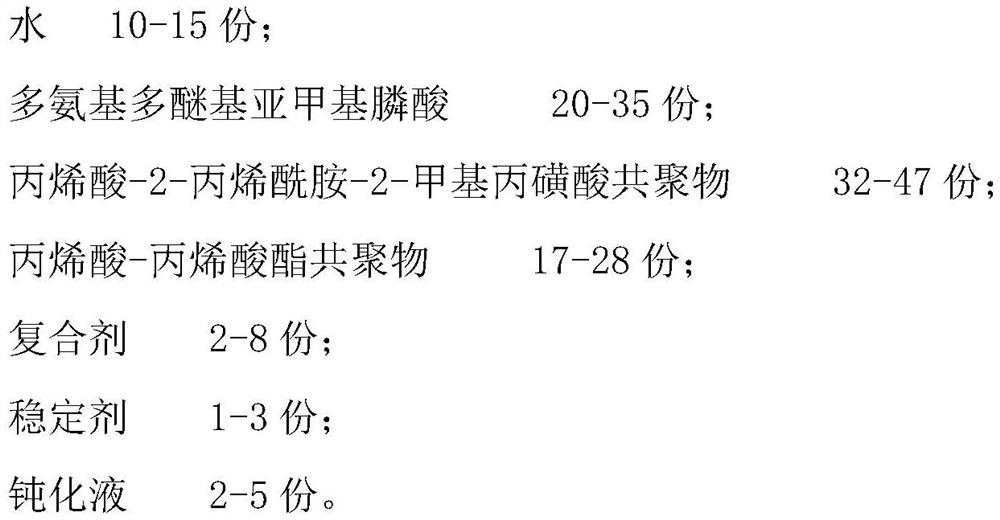

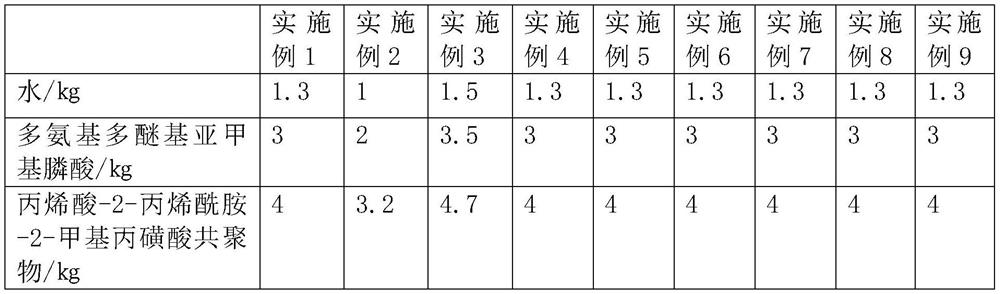

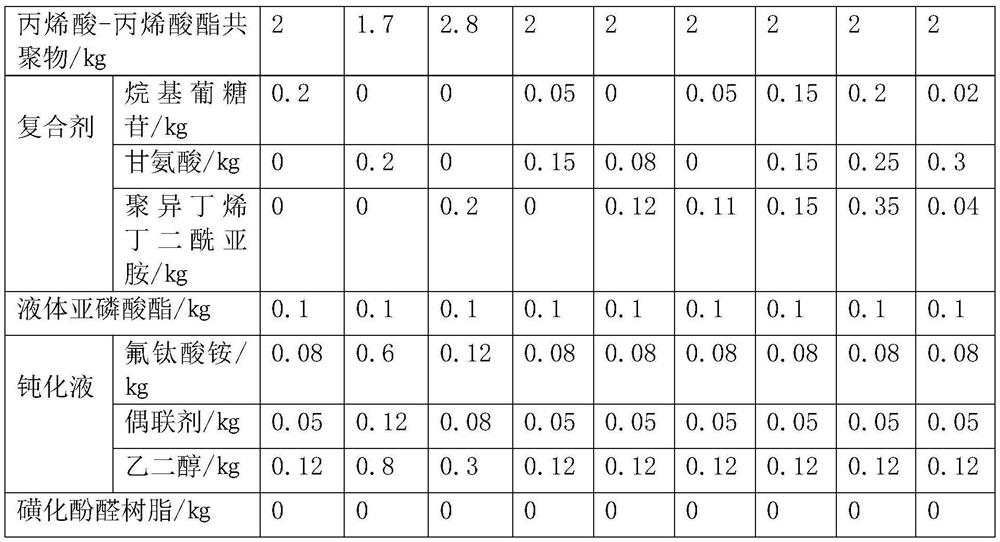

Coal chemical industry grey water scale inhibitor

PendingCN112194261AImprove thermal stabilityReduce decompositionSpecific water treatment objectivesScale removal and water softeningMeth-Greywater

The invention discloses a coal chemical industry grey water scale inhibitor, and belongs to the technical field of grey water scale inhibitors. The coal chemical industry grey water scale inhibitor comprises the following components by weight: 10-15 parts of water; 20-35 parts of polyamino polyether methylene phosphonic acid; 32-47 parts of an acrylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer; 17-28 parts of an acrylic acid-acrylate copolymer; 2-8 parts of a compounding agent; 1-3 parts of a stabilizer; and 2-5 parts of a passivation solution. The scale inhibitor of the invention has the advantages of being stable at high temperature, high in scale inhibition rate and good in corrosion inhibition.

Owner:上海鲁昕化工科技有限公司

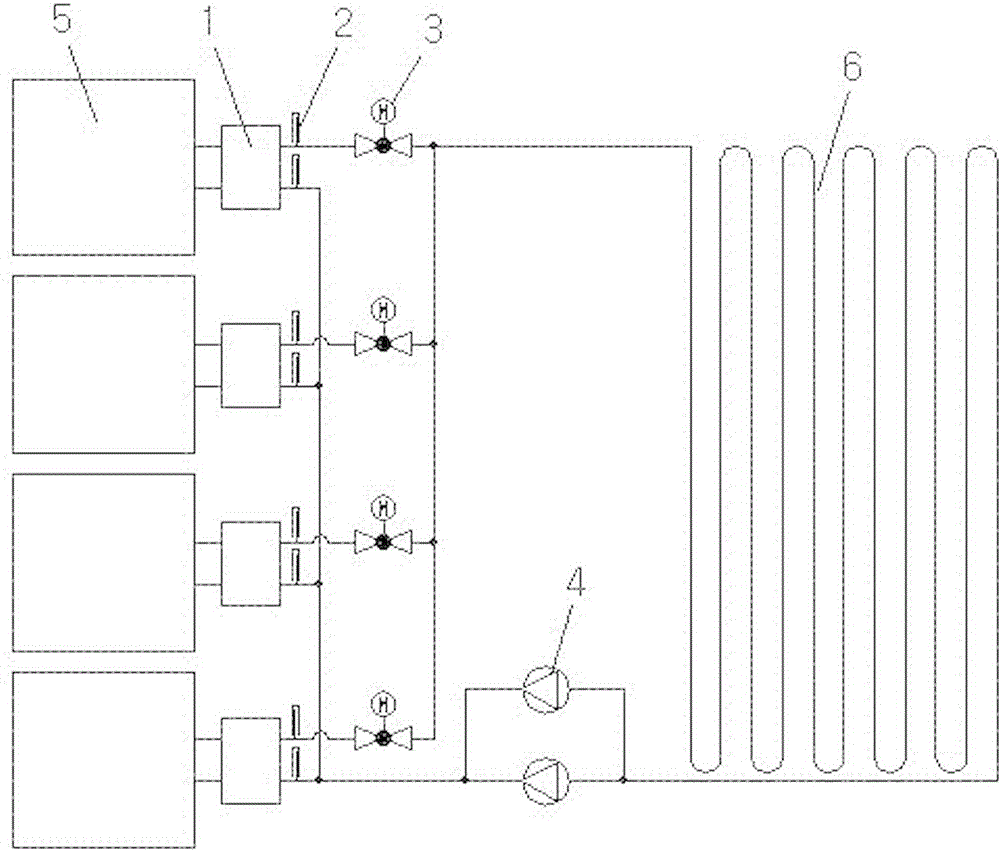

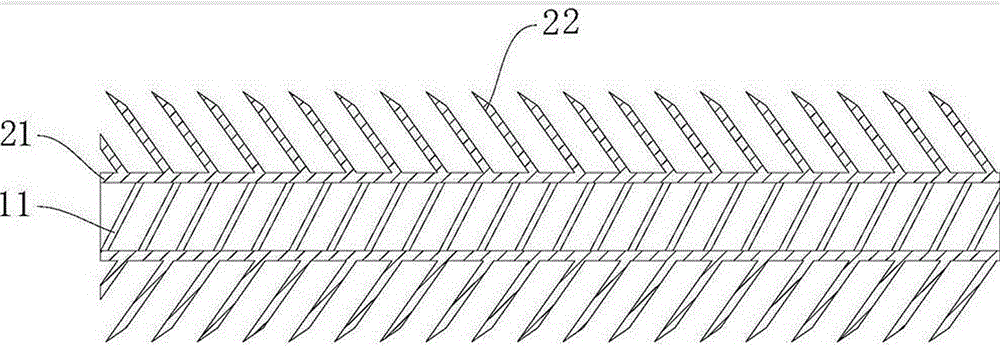

Industrial waste heat floor heating system

InactiveCN106287899AGood corrosion inhibition effectPromote degradationLighting and heating apparatusHot-water central heatingEngineeringAir compressor

The invention discloses a floor heating system, and particularly relates to an industrial waste heat floor heating system. The industrial waste heat floor heating system comprises a high-temperature oil way of an air compressor, a floor heating heat exchange coiler and a circulation water pump and further comprises a set of heat exchangers. A water outlet of the floor heating heat exchange coiler is connected to water inlets of the various heat exchangers through the circulation water pump. Water outlets of the heat exchangers are connected to a water inlet of the floor heating heat exchange coiler through electromagnetic valves. The heat exchangers are internally provided with heat dissipation pipes communicating with the high-temperature oil way of the air compressor, a plurality of cooling fins are arranged on the outer surfaces of the heat dissipation pipes, the cooling fins and the heat dissipation pipes are integrally formed, and the cooling fins incline relative to the axes of the heat dissipation pipes. Spiral grooves are formed in the inner surfaces of the heat dissipation pipes. The spiral grooves coincide with the geometric center axes of the heat dissipation pipes. The outer surfaces of the heat dissipation pipes are further coated with antirust layers. The floor heating system overcomes the technical defects that in the prior art, the heat conversion efficiency is low, and ageing is likely to happen, and the industrial waste heat floor heating system high in heat conversion efficiency and long in service life is provided.

Owner:CHONGQING CECEP SANFENG ENERGY +1

Electroplating solution for surface of zinc alloy workpiece with blind hole

ActiveCN102534699AImprove deep plating abilityPlay the role of corrosion inhibitionElectrogalvanizationZinc alloys

The invention discloses a zinc electroplating solution for the surface of a zinc alloy workpiece with a blind hole. The zinc electroplating solution has an excellent deep plating performance for the blind hole and can prevent zinc alloy from being corroded. The zinc electroplating solution comprises the following ingredients: ZnCl2, KCl, H3BO3, surface active agent A and water in balancing amount.

Owner:SHENZHEN CHENGGONG CHEM

Special scale inhibitor for saline and alkaline land spray irrigation device and preparation method of special scale inhibitor

InactiveCN106219773AReduce corrosionExtended service lifeTreatment using complexing/solubilising chemicalsSodium polyacrylateIon

The invention discloses a special scale inhibitor for a saline and alkaline land spray irrigation device. The special scale inhibitor is prepared from the raw materials in parts by weight, 8-15 parts of hydroxy ethylene sodium phosphate, 3-5 parts of sodium polyacrylate, 1-3 parts of mercaptobenzothiazole sodium, 5-10 parts of sodium hexametaphosphate, 3-7 parts of ethylene diamine tetramethylidene phosphoric acid sodium, 1-2 parts of benzotriazole sodium, 6-15 parts of methyl benzo three nitrogen, 6-10 parts of polyvinylpyrrolidone, 4-8 parts of lignin and the rest water. The lignin is a dispersive scale inhibition material and added into the scale inhibitor, corrosion-inhibition effects of the scale inhibitor are improved, the lignin and the mercaptobenzothiazole sodium are matched to act, the device is effectively protected, ions in water are spread and can flow along with the water, the sodium hexametaphosphate is provided with a plurality of coordinate bonds, the coordinate bonds can simultaneously combine with a plurality of ions, so that descaling can be effectively avoided, and the scale inhibitor is stable in performance and has good heat stability.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

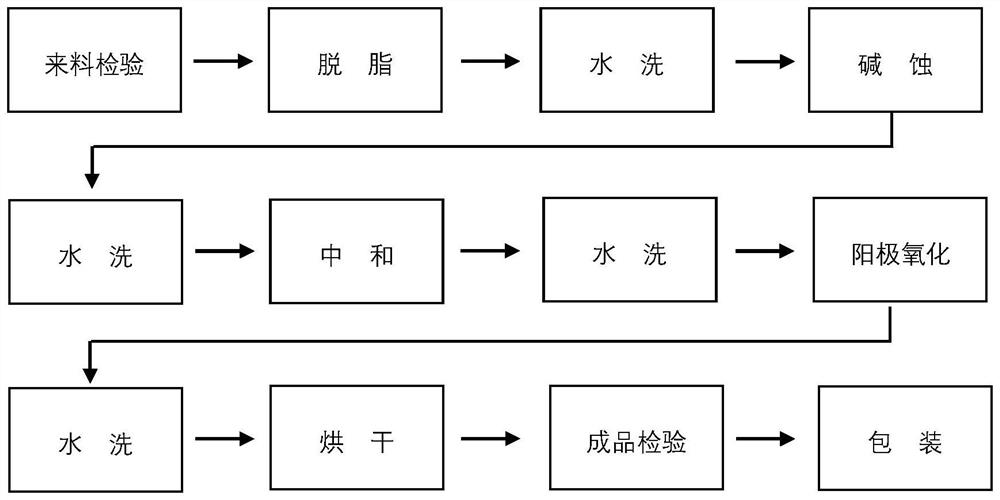

Bonding pretreatment method for aluminum alloy workpiece

ActiveCN113832518AIncrease the degree of ionizationHigh yieldAnodisationMagnesium phosphateO-Phosphoric Acid

The invention provides a thermal control bonding pretreatment method for an aluminum alloy workpiece. The method comprises the following steps: (1) workpiece pretreatment: sequentially carrying out degreasing, water washing, alkali etching, water washing, neutralizing and water washing treatment on the aluminum alloy workpiece; and (2) anodizing treatment: putting the pretreated aluminum alloy workpiece into an anodizing tank to be subjected to anodizing treatment, so as to obtain an oxidation film, wherein the anodizing tank contains an anodizing tank solution, and the anodizing tank solution comprises 50-200 g / L of phosphoric acid, 10-130 g / L of sulfuric acid, 1-15 g / L of cerous sulfate, 10-45 g / L of boric acid and 0.5-20 g / L of magnesium phosphate. The aluminum alloy workpiece treated through the treatment method can meet the requirement for thermal control performance, the sunlight absorptivity of the aluminum alloy workpiece can reach 0.3, and the hemispherical emissivity of the aluminum alloy workpiece can reach 0.4.

Owner:HARBIN INST OF TECH

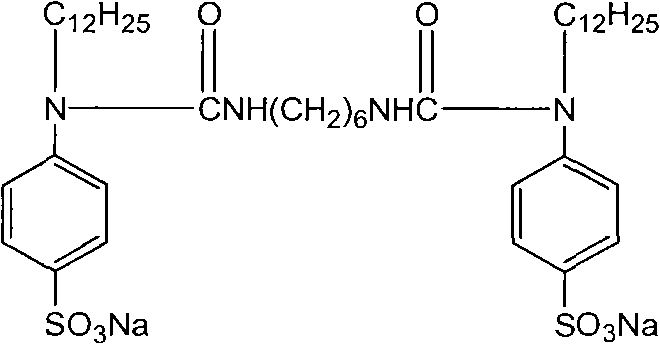

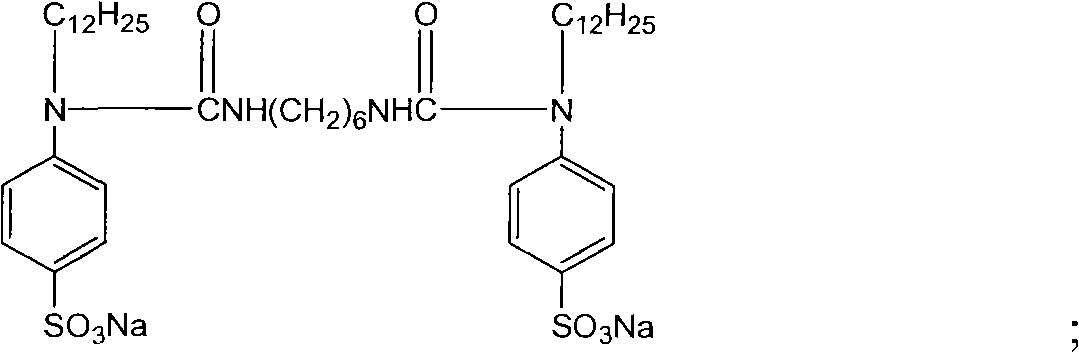

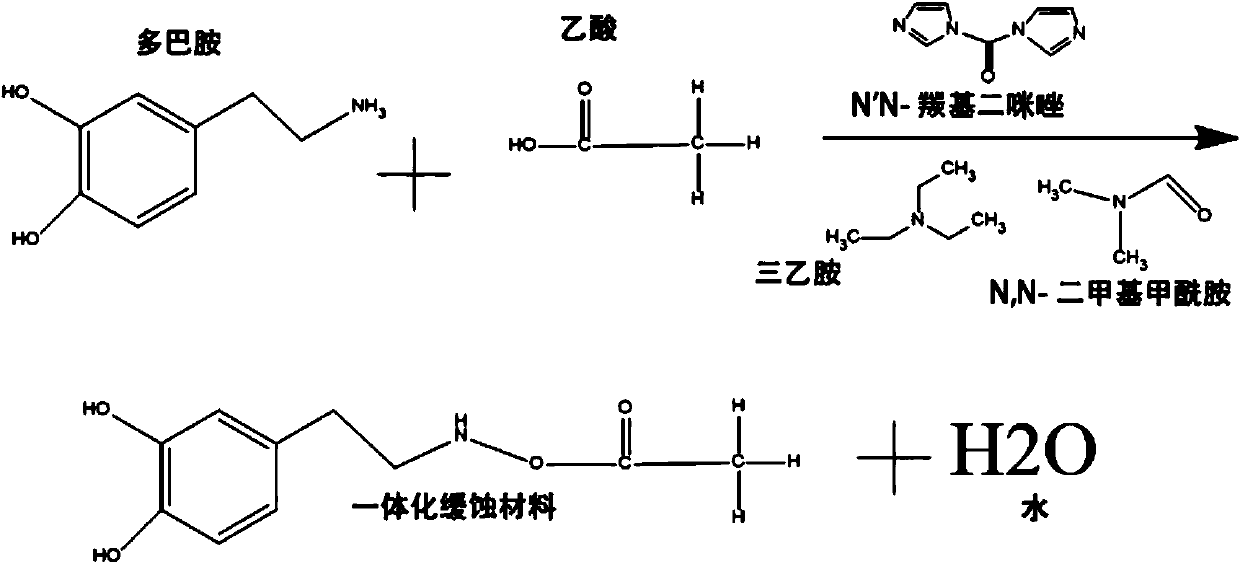

Environment-friendly vapor phase corrosion inhibitor and preparation method thereof

The invention particularly relates to an environment-friendly vapor phase corrosion inhibitor and a preparation method thereof, and belongs to the field of corrosion prevention. The environment-friendly vapor phase corrosion inhibitor comprises the following components in parts by mass: 10-20 parts of an integrated slow-release material, 5-10 parts of phosphoric acid, 5-10 parts of amino acid, 1-5parts of a surfactant, 3-5 parts of phytic acid, 10-20 parts of urea, 1-5 parts of flavone, 5-10 parts of sodium gluconate and 100-150 parts of deionized water, wherein the integrated slow-release material comprises the following components in parts by mass: 15-30 parts of dopamine, 100-200 parts of N, N dimethylformamide, 5-10 parts of N, N'-carbonyl diimidazole, 5-10 parts of triethylamine and6-12 parts of acetic acid. According to the environment-friendly vapor phase corrosion inhibitor provided by the embodiment of the invention, adopted corrosion inhibition additives are environment-friendly and non-toxic materials, replace the traditional imidazoline toxic environment-friendly vapor phase corrosion inhibitor, do not cause harm to the environment and human bodies, and meet the national requirements of green, environment-friendly and sustainable materials.

Owner:SHOUGANG CORPORATION

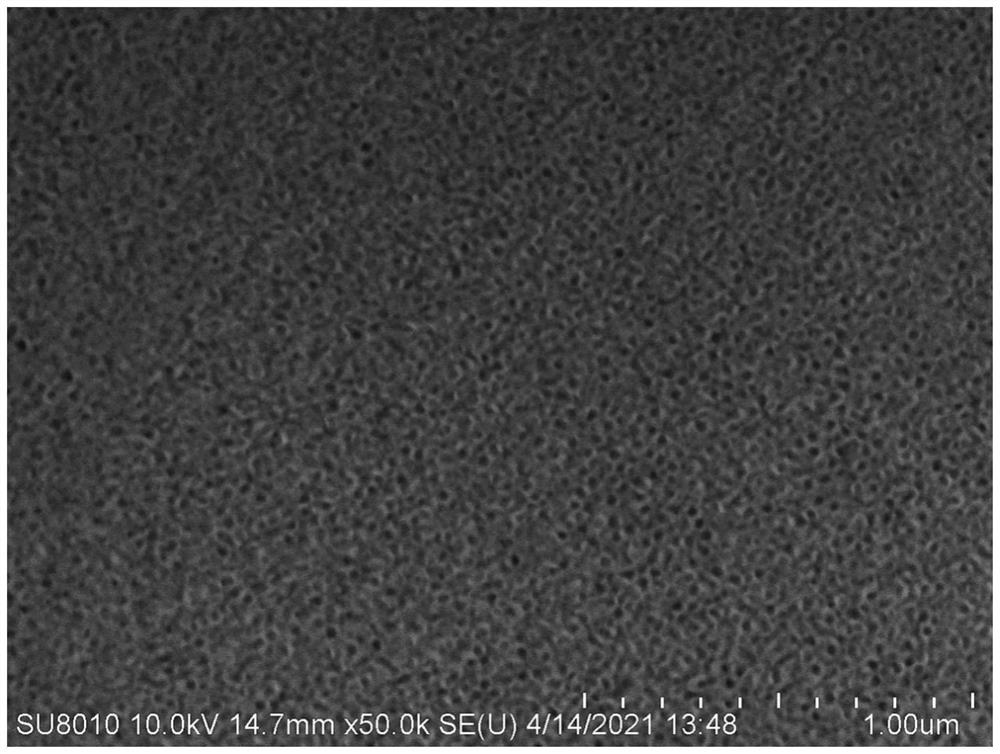

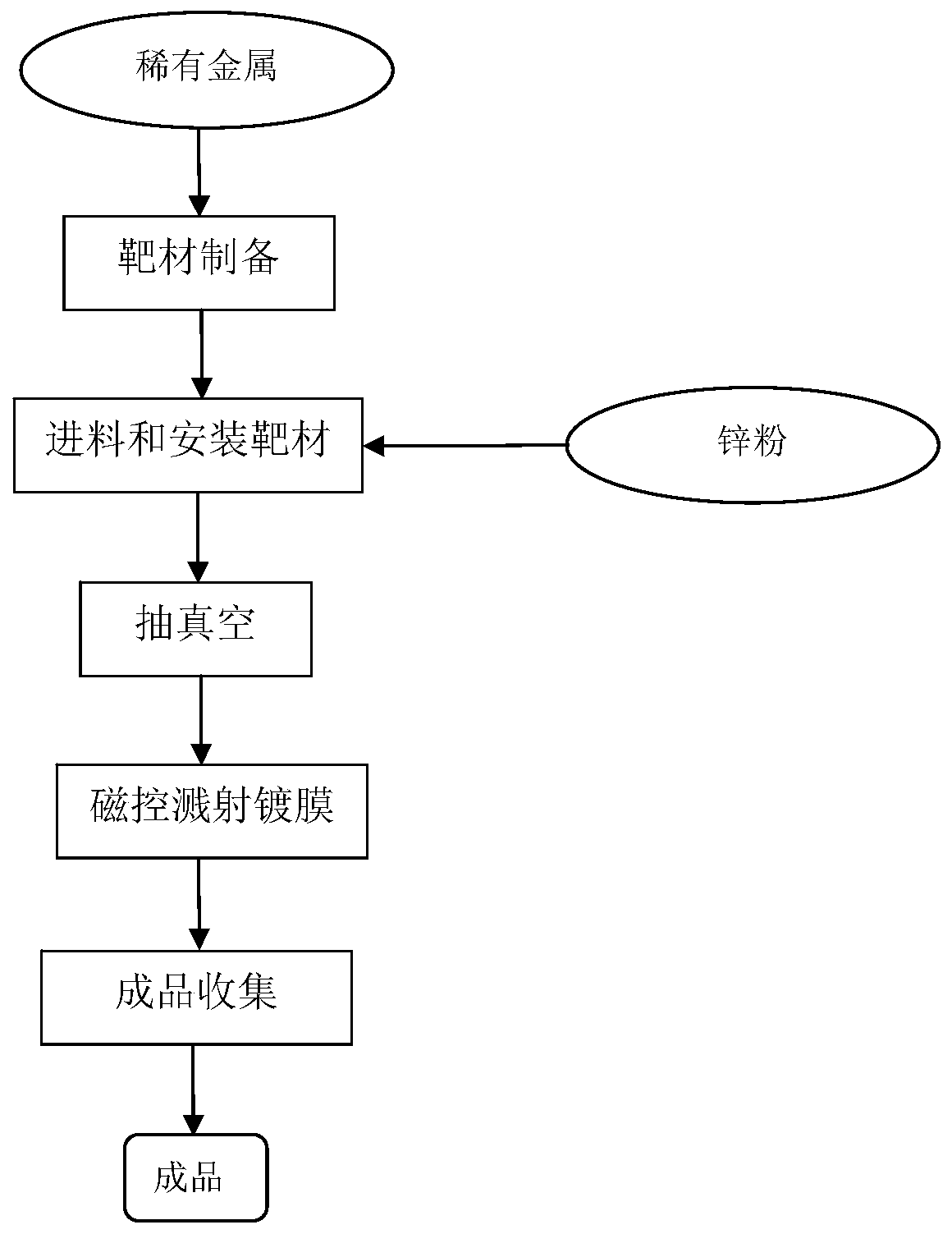

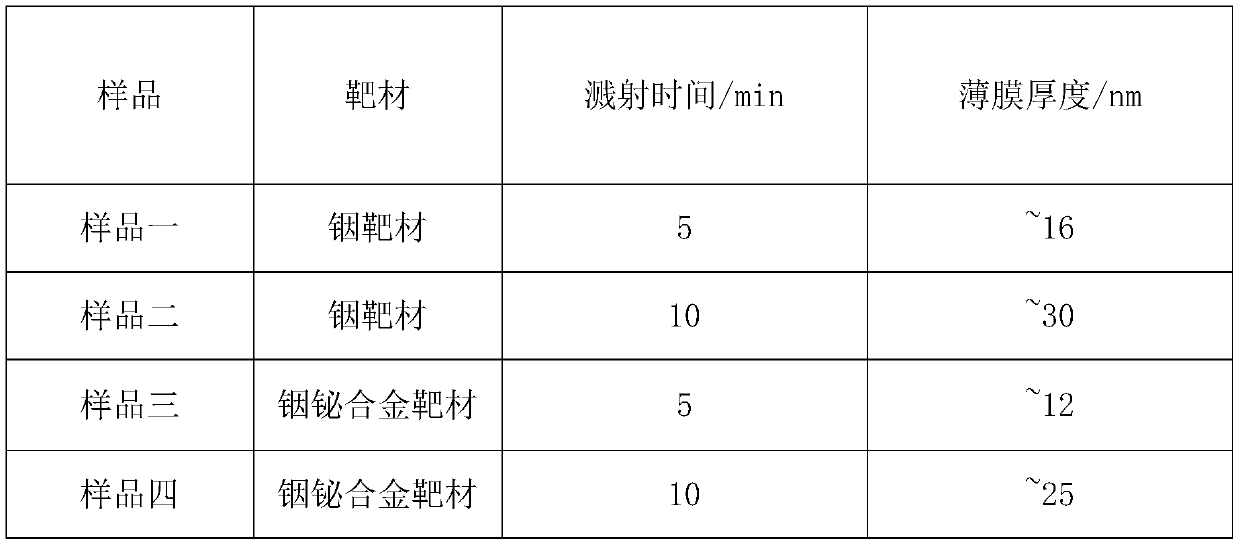

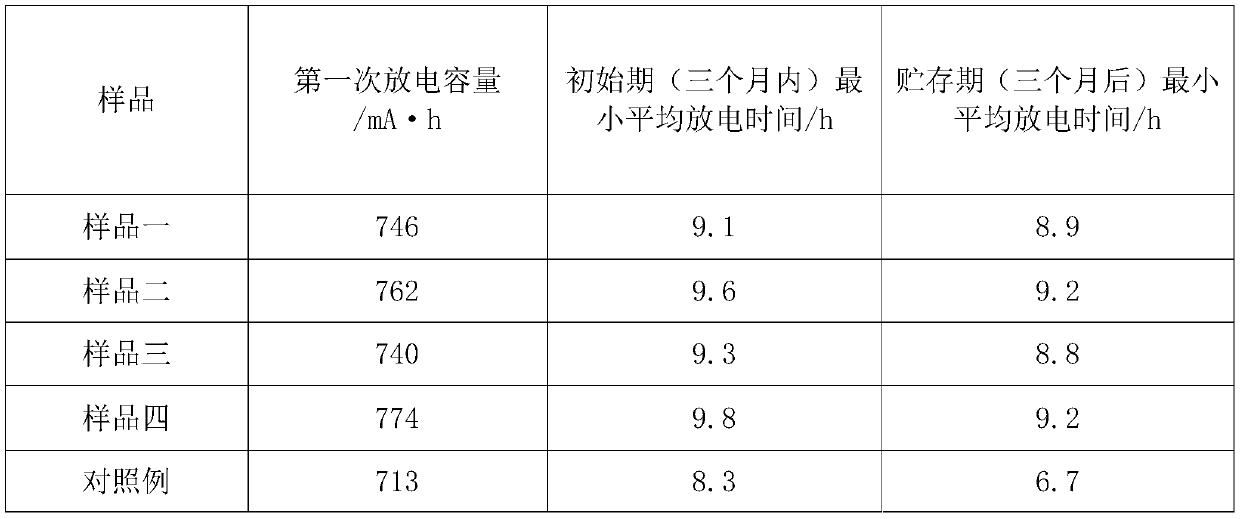

Corrosion-inhibiting zinc powder used for alkaline manganese battery and preparation process for corrosion-inhibiting zinc powder

InactiveCN109735815AImprove battery performanceSlow self-meltingCell electrodesVacuum evaporation coatingIndiumMetal

The invention discloses corrosion-inhibiting zinc powder used for an alkaline manganese battery and a preparation process for corrosion-inhibiting zinc powder, and the zinc powder contains 0.001-0.2wt% of rare metal, wherein the rare metal is coated onto zinc powder through a magnetron sputtering coating method, the rare metal defines a net-shaped rare metal film on the surfaces of particles of zinc powder; and the rare metal comprises indium (In). rare metal which is harmless on environment is coated through the magnetron sputtering coating method to replace existing common mercury and cadmium, so that corrosion-inhibiting zinc powder, which meets environment-friendly requirements, is free of mercury and cadmium, and is good in battery performance, used for the alkaline manganese batteryis formed.

Owner:ZHENGJIANG MUSTANG BATTERY CO LTD

Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

ActiveCN101643619BAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPhytic acidAluminium powder

The invention relates to coating technology, in particular to an environment-friendly polyaniline modified aluminium powder anti-corrosive coating and a preparation method thereof to solve the problem that the prior aluminium powder coating has poor corrosion resistance, and is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating comprises a film forming matter, polyaniline modified aluminium powder and the like. A polyaniline coating layer is formed on the surface of the aluminium powder by an oxidative polymerization method; the treated aluminium powder has passivating effect on metal; and a phytic coating layer on the surface of the aluminium powder also has corrosion inhibiting effect on the metal. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

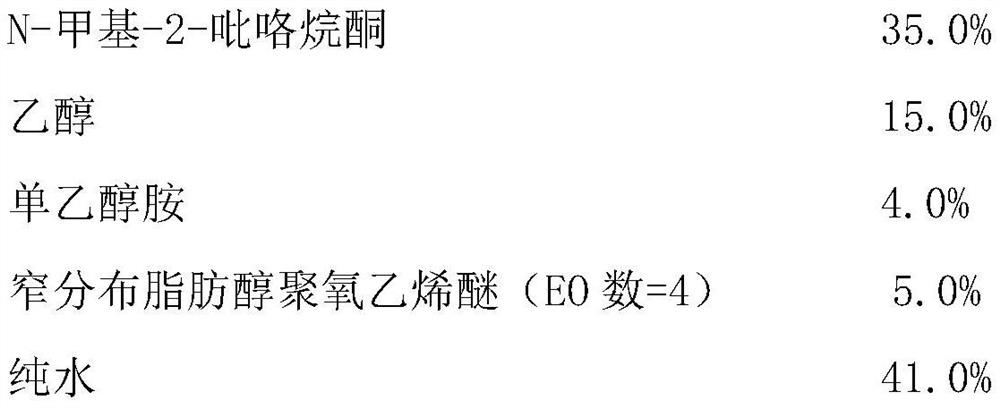

Water-based aircraft paint remover and preparation method thereof

ActiveCN112724735APeel off paint filmPlay the role of corrosion inhibitionChemical paints/ink removersPaint stripperSolvent

The invention discloses a water-based aircraft paint remover and a preparation method thereof, and belongs to the technical field of fine chemical engineering. The paint remover comprises a main solvent, a cosolvent, a penetrating agent, a wetting stripping agent and the like. The wetting stripping agent adopted by the paint remover can form a molecular-level protective layer on the surface of a metal substrate, plays a role in stripping a paint film and inhibiting corrosion, and can protect the surface of the metal substrate while improving the paint removal efficiency. The paint remover has the advantages of small volatilization loss, environmental protection, no pollution, no need of secondary cleaning with gasoline and other organic solvents, no harm to human bodies, and no pollution to the environment. The paint remover has excellent paint removal performance and does not corrode a metal substrate at the bottom of the paint film; and no organic matter is left on the surface of the paint removed metal substrate.

Owner:江苏奥首材料科技有限公司

Polyester heavy-duty anticorrosive coating with polyaniline-modified glass flakes, and preparation method thereof

ActiveCN101643621BAchieve passivationImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsPolyesterPhytic acid

The invention relates to coating technology, in particular to a polyester heavy-duty anticorrosive coating with polyaniline-modified glass flakes, and a preparation method thereof, which solves the problem that the surfaces of steel or other metal substrates need to be coated with primer to increase anti-corrosion performance and prevent coatings and substrate interfaces from being corroded in the construction of most of the prior glass-flake anticorrosive coatings. The polyester heavy-duty anticorrosive coating with polyaniline-modified glass flakes comprises unsaturated polyester resin, thepolyaniline-modified glass flakes, amine curing agent and the like. As polyaniline coating layers are formed on the surfaces of the glass flakes by an oxidative polymerization method, the treated glass flakes have the effect of passivating metal, and phytic-acid coating layers on the surfaces of the glass flakes play a role in inhibiting corrosion of metal. The polyester heavy-duty anticorrosive coating with polyaniline-modified glass flakes has strong corrosion resistance and permeation resistance, can be applied to heavy-duty engineering in the fields of petrochemical industry, wharf facilities, ships and the like, and is particularly applicable to the protection of spray splash areas and tidal range areas.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electroplating solution for surface of zinc alloy workpiece with blind hole

ActiveCN102534699BImprove deep plating abilityPlay the role of corrosion inhibitionElectrogalvanizationZinc alloys

The invention discloses a zinc electroplating solution for the surface of a zinc alloy workpiece with a blind hole. The zinc electroplating solution has an excellent deep plating performance for the blind hole and can prevent zinc alloy from being corroded. The zinc electroplating solution comprises the following ingredients: ZnCl2, KCl, H3BO3, surface active agent A and water in balancing amount.

Owner:SHENZHEN CHENGGONG CHEM

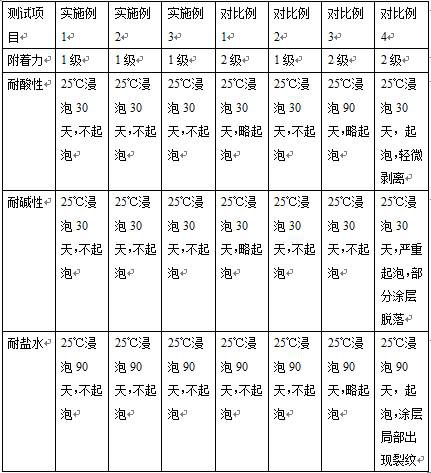

A kind of anticorrosion and antirust paint and preparation method thereof

ActiveCN109021782BEasy curingImprove adhesionAnti-corrosive paintsEpoxy resin coatingsTriethoxysilaneTitanium powder

Owner:福建省艺邦新材料科技有限公司

Polyaniline modified glass flake heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN101643615BAchieve passivationImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified glass flake heavy-duty anti-corrosive coating and a preparation method thereof to solve the problems that when the prior glass flake anti-corrosive coatings are constructed, most of the glass flake anti-corrosive coatings require to coat primer on the surface of steel or other metal matrix to improve the corrosion resistance and prevent corrosion between the coat and the interface of the matrix, and the like. The polyaniline modified glass flake heavy-duty anti-corrosive coating comprises epoxy resin, a polyaniline modified glass flake, an amine curing agent and the like. A polyaniline coating layer is formed on the surface of the glass flake by an oxidative polymerization method; the glass flake after the treatment has the passivating effect on metal; and a phytic coating layer on the surface of the glass flake also has the corrosion inhibiting effect on the metal. The polyaniline modified glass flake heavy-duty anti-corrosive coating has strong corrosion resistance and permeability resistance, can be applied to heavy-duty anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like, and is particularly suitable for protecting wave splashing zones and tidal difference zones.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

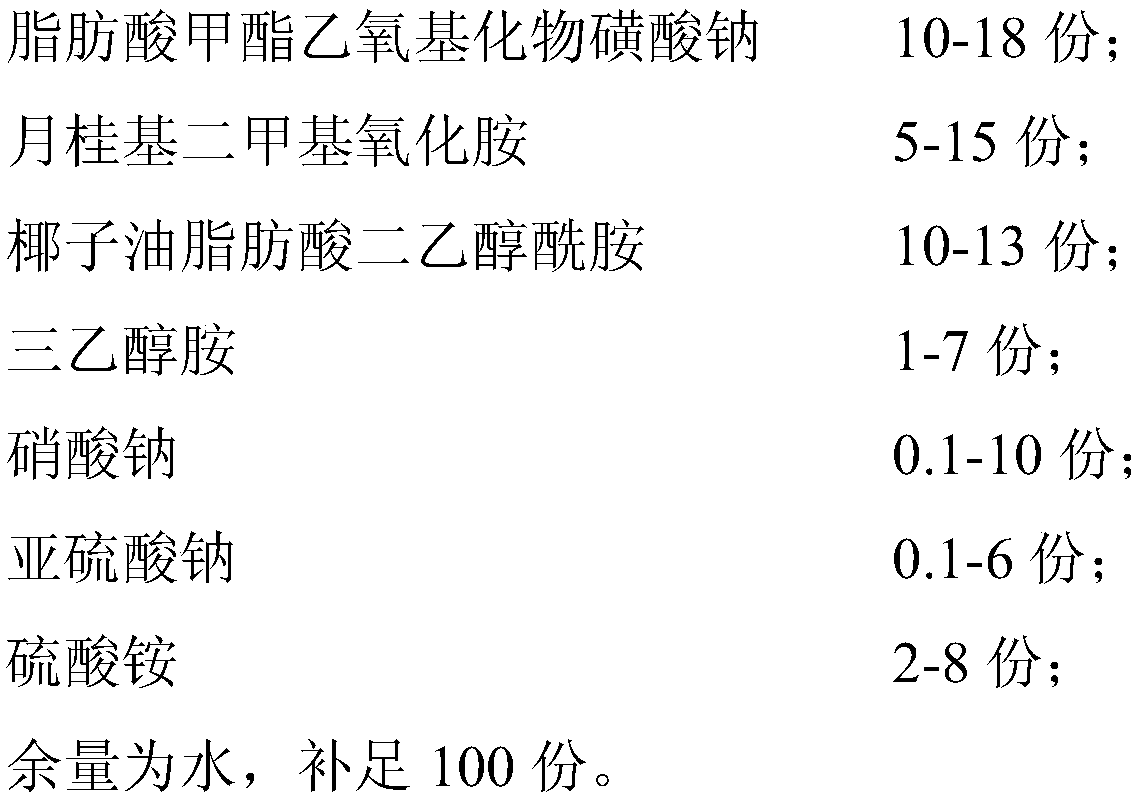

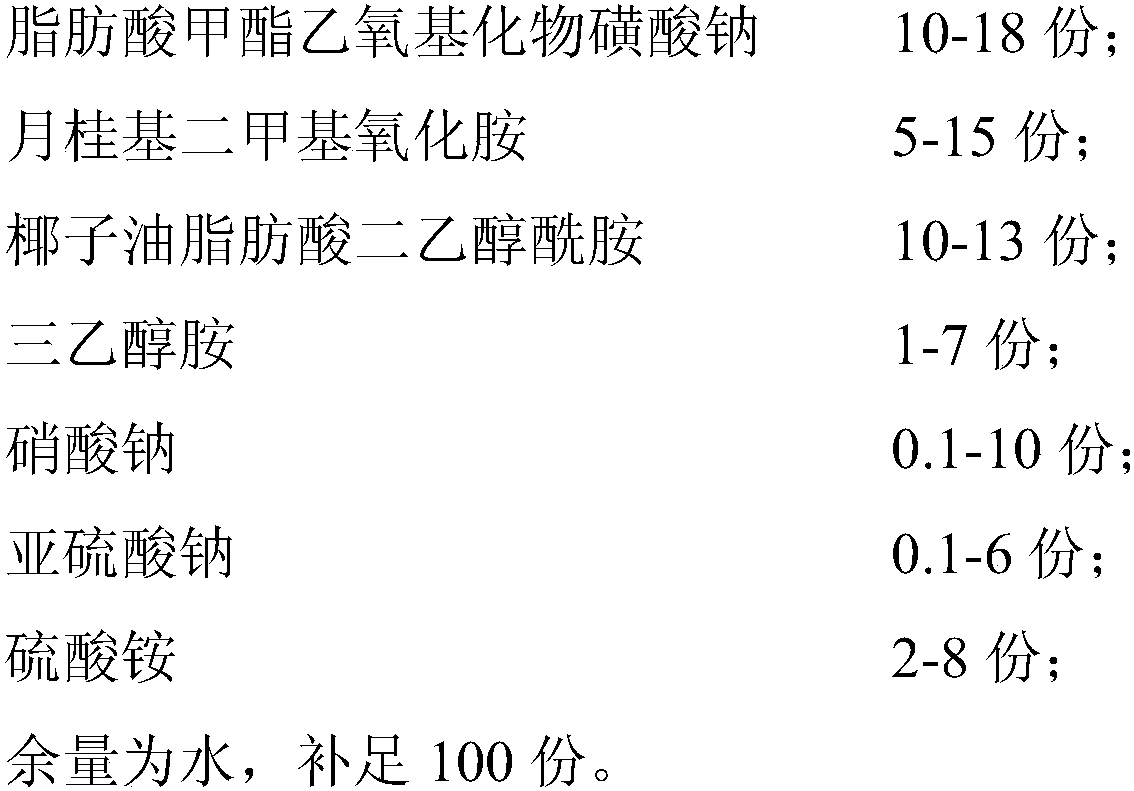

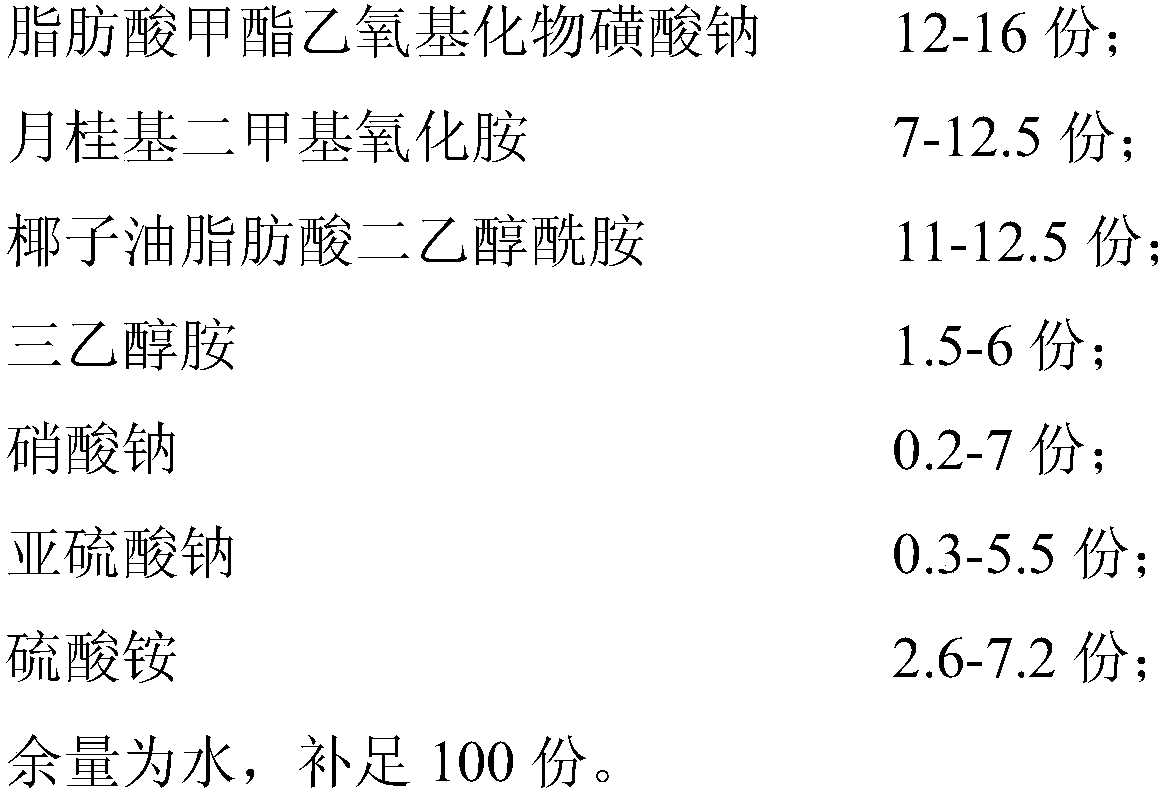

Preparation method of environment-friendly acid-pickling mist-suppressing synergist

The invention relates to a preparation method of an environment-friendly acid-pickling mist-suppressing synergist. The acid-pickling mist-suppressing synergist has the effects of corrosion inhibitionand mist suppression; the fatty acid methyl ester ethoxylate sodium sulfonate, the coconut oil fatty acid diethanolamide and the lauryl dimethyl amine oxide have synergistic effects and are added in the pickling solution to generate a closed foam layer; and the sodium sulfite and the ammonium sulfate can reduce the tension of the acid liquor on the surface of the metal so as to form a molecular film, so that volatilization of the acid mist can be effectively prevented, and the mist-suppressing effect can reach 95% or above. The triethanolamine and the acid liquor can generate a certain chemical reaction, so that the reaction between the acid liquor and the metal is prevented, and the effect of corrosion inhibition is achieved. The synergist is high in corrosion inhibition efficiency and mist-suppressing efficiency, and can reduce the time of the acid pickling process, so that the acid pickling efficiency is improved; moreover, the synergist does not contain chemical reagents capable ofpolluting the environment, and accords with the Chinese requirements of acid pickling and mist-suppressing corrosion inhibitors; and the synergist is simple in preparation process, low in raw material cost and good in economic benefit.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

Wire drawing liquid with good lubrication effect used for stainless steel wire rod and preparation method thereof

InactiveCN104293455AImprove the lubrication effectImprove cooling effectLubricant compositionWater basedTectorial membrane

The invention discloses a wire drawing liquid with good lubrication effect used for a stainless steel wire rod, which is characterized by comprising the following raw materials by weight: 2.5-4 parts of coconut oil fatty acid diethanolamide, 1.5-2.5 parts of octadecane oeoyl sarcosine acid, 2-3 parts of sulfide fatty acid ester, 2-3 parts of calcium sulfide alkylphenol, 1-2 parts of sodium naphthenate, 3-4.5 parts of sodium bicarbonate, 1-2 parts of anti-oxidant DSTP, 5.5-6.5 parts of wool grease, 4.5-6 parts of sodium dodecyl benzene sulfonate, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. According to the invention, the added sulfide fatty acid ester has good lubricity, the employed water base has good heat radiation effect, the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability, and the cooperated surfactant can form a layer of protection film on the surface of metal and has corrosion inhibition effect. The wire drawing liquid with good lubrication effect has excellent cleaning performance, is easily removed after processing, and has advantages of low cost, simple technology and long storage.

Owner:ANHUI TATSU PRECISION ALLOY

A method for constructing superhydrophobic coatings on metal surfaces

ActiveCN109127328BShape constraintsMild conditionsPretreated surfacesCoatingsMetallurgyAqueous solution

The invention relates to a method for building a super-hydrophobic coating on a metal surface. The method comprises the steps that metal base materials are cleaned in a lye solution at 50-70 DEG C andan acid solution at 50-70 DEG C to remove grease on the surface; chemical etching treatment is carried out on the metal surface by using an aqueous hydrochloric acid solution at room temperature for5-15 minutes; and hydrophobic substance with low-surface-energy is assembled onto the metal surface after the chemical etching treatment, and then solidification treatment is carried out. According tothe method for building the super-hydrophobic coating on the metal surface, the super-hydrophobic coating is built on the metal surface, the used preparation method has no special restrictions on theshape of metal, and coating can be carried out on the surface of a test piece with complicated shape. The method does not require special equipment, has simple process, easy operation and mild condition, is especially suitable for metal parts with irregular shape such as heat exchanger fins, and is easy for industrialized mass production. After the gained coating is placed for a long period, preferable super-hydrophobic performance is still maintained.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com