A method for constructing superhydrophobic coatings on metal surfaces

A super-hydrophobic coating and metal surface technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of difficult surface treatment and complex structure of aluminum fins, and achieve low cost and engineering Ease of application and mild results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

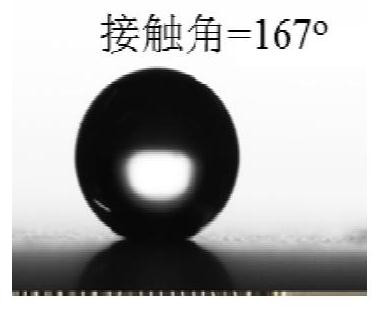

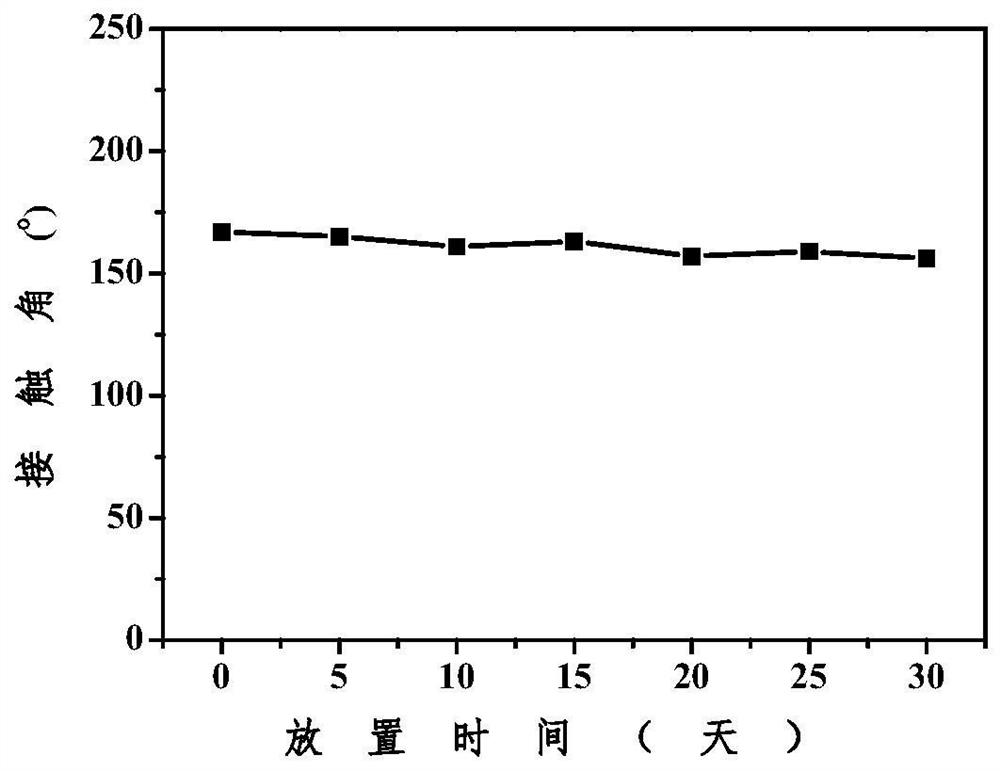

Embodiment 1

[0039] Clean the aluminum fin heat exchanger (take the size of 205mm*45mm*210mm as an example) with alkaline solution at 70°C for 0.5min. 2 CO 3 and Na 3 PO 4 Added to water to prepare, and Na 2 CO 3 The concentration is 0.01mol / L, Na 3 PO 4 The concentration is 0.01mol / L, and then washed with 70°C acid solution for 2min, the acid solution is made by adding Mn(H 2 PO 4 ) 2 and HNO 3 Added to water, Mn(H 2 PO 4 ) 2 The concentration is 0.002mol / L, HNO 3 The concentration is 0.02mol / L, and then rinsed with deionized water and ethanol and dried; the aluminum fin heat exchanger is immersed in a hydrochloric acid aqueous solution with a concentration of 0.5mol / L for 15 minutes, and the etching is carried out at room temperature. The heat exchanger etched by hydrochloric acid aqueous solution was rinsed with deionized water and ethanol in turn, and then dried; the heat exchanger etched by hydrochloric acid aqueous solution was placed in a 2 mmol / L ethanol solution of st...

Embodiment 2

[0043] Clean the aluminum fin heat exchanger (take the size of 205mm*45mm*210mm as an example) with alkaline solution at 50°C for 3 minutes. 2 CO 3 Added to water to prepare, and Na 2 CO 3 The concentration is 0.01mol / L, and then washed with 50 ℃ acid solution for 2min, the acid solution is made by adding Mn(H 2 PO 4 ) 2 、H 3 PO 4 and HNO 3 Added to water, and Mn(H 2 PO 4 ) 2 The concentration is 0.001mol / L, H 3 PO 4 The concentration is 0.02mol / L, HNO 3 The concentration is 0.02mol / L, then rinse with deionized water and ethanol and dry; immerse the aluminum fin heat exchanger in a hydrochloric acid aqueous solution with a concentration of 2mol / L and etch for 5min, and the etching is carried out at room temperature. The heat exchanger etched by the aqueous solution was rinsed with deionized water and ethanol in turn, and then dried; the heat exchanger etched by the hydrochloric acid aqueous solution was placed in a 5 mmol / L ethanol solution of stearic acid, and se...

Embodiment 3

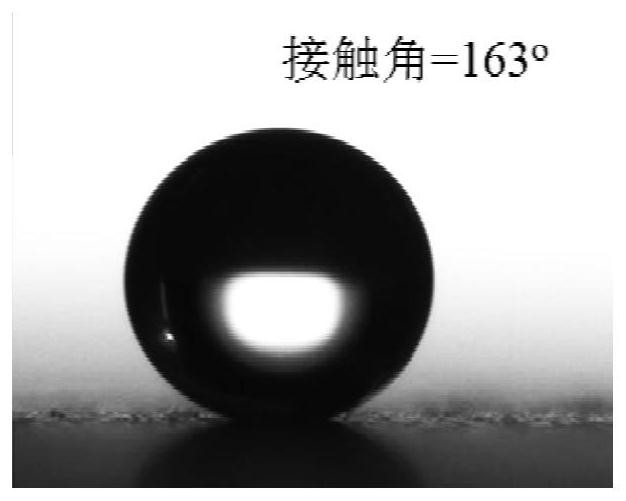

[0046] Clean the aluminum fin heat exchanger (take the size of 205mm*45mm*210mm as an example) with alkaline solution at 60°C for 3 minutes, and pass the alkaline solution through Na 3 PO 4 Added to water to prepare, and Na 3 PO 4 The concentration is 0.02mol / L, and then washed with 60 ℃ acid solution for 3min, the acid solution is made by adding Mn(H 2 PO 4 ) 2 and H 3 PO 4 Added to water, Mn(H 2 PO 4 ) 2 The concentration is 0.0015mol / L, H 3 PO 4 The concentration is 0.04mol / L, and then rinsed with deionized water and ethanol and dried; the aluminum fin heat exchanger is immersed in a hydrochloric acid aqueous solution with a concentration of 1mol / L for etching for 10min, and the etching is carried out at room temperature. The heat exchanger etched by the aqueous solution was rinsed with deionized water and ethanol in turn and then dried; In the ethanol solution of oxysilane, self-assemble at room temperature for 1 hour, rinse with deionized water after taking it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com