A method of hydrothermal treatment to improve the high temperature oxidation resistance of titanium-based alloys

A high-temperature oxidation-resistant, titanium-based alloy technology, which is applied in the coating process of metal materials, can solve the problems of insufficient high-temperature oxidation resistance of titanium-based alloys, reduce the mechanical properties and pollution of titanium-based alloys, and avoid the decline of mechanical properties , Improve high temperature oxidation resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

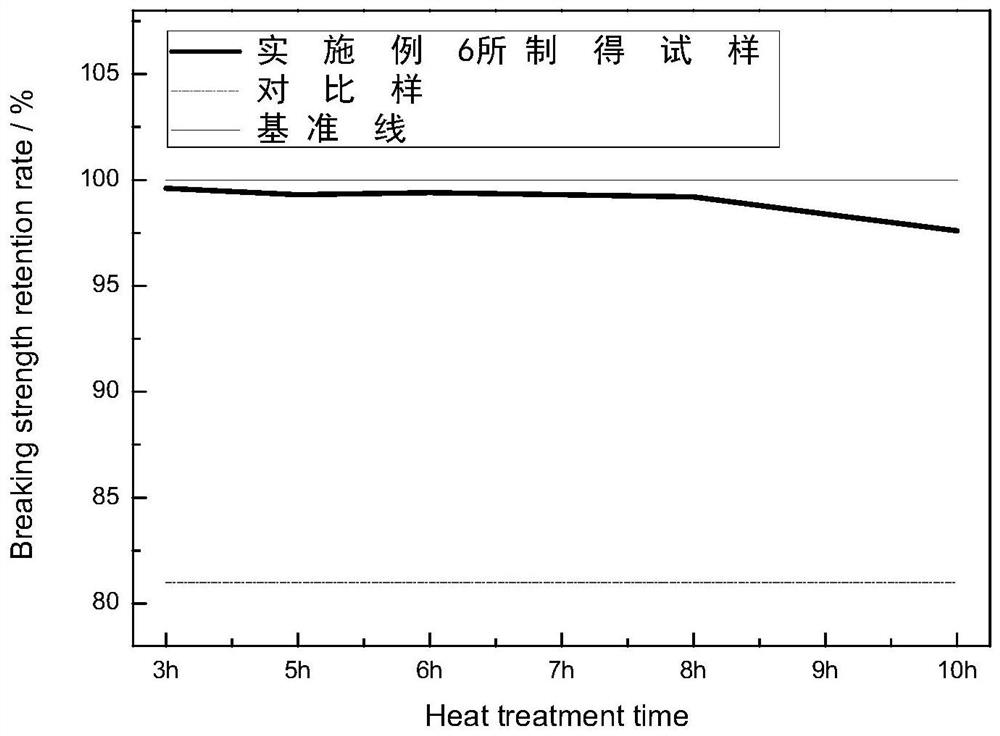

Examples

Embodiment 1

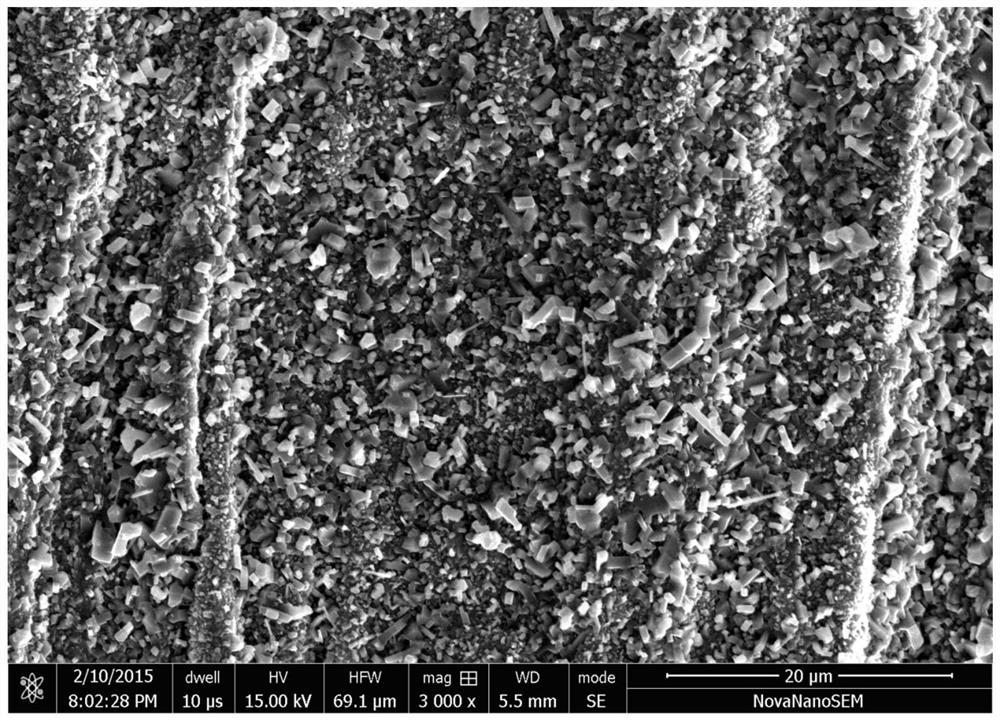

[0048] First, carry out conventional pretreatment on titanium-based alloys: grind the Ti-Al alloy sample (titanium-aluminum atomic ratio is 1:1) with sandpaper to remove surface oxides, then ultrasonically clean it in acetone and ethanol for 10 minutes, and finally use hot air Drying can obtain the pretreated titanium-based alloy. Dissolve ammonium fluoride, potassium fluoride and sodium fluoride in deionized water at a molar ratio of 10:1:2 and stir at room temperature for 2 hours to prepare a salt solution with a total concentration of halogen salt of 2 wt%. Immerse the titanium-based alloy in a salt solution, place it in a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, put it in an oven, and conduct a hydrothermal treatment at a temperature of 140°C for 6 hours. After completion, it is cooled naturally, rinsed with deionized water, and dried in the air. Finally, a titanium-aluminum alloy sample containing F on the surface was obtained. Subsequently, the...

Embodiment 2

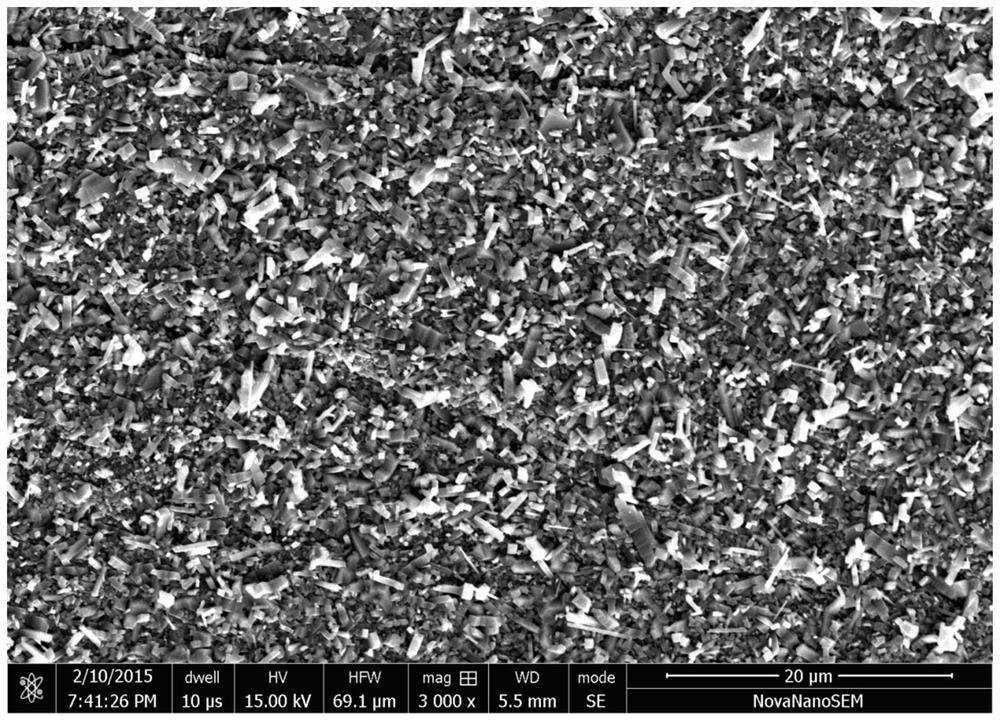

[0053] First, carry out conventional pretreatment on titanium-based alloys: use sandpaper to polish the 3Ti-Al alloy sample (titanium-aluminum atomic ratio is 3:1) to remove surface oxides, then ultrasonically clean it in acetone and ethanol for 10 minutes, and finally use hot air Drying can obtain the pretreated titanium-based alloy. Dissolve ammonium fluoride, potassium fluoride and sodium fluoride in deionized water at a molar ratio of 20:1.5:2 and stir at room temperature for 2 hours to prepare a salt solution with a total concentration of halogen salt of 2 wt%. Immerse the titanium-based alloy in a salt solution, place it in a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, put it in an oven, and conduct a hydrothermal treatment at a temperature of 180°C for 10 hours. After completion, it is cooled naturally, rinsed with deionized water, and dried in the air. Finally, a titanium-aluminum alloy sample containing F on the surface was obtained. Subsequent...

Embodiment 3

[0057] First, carry out conventional pretreatment on titanium-based alloys: use sandpaper to polish the 3Ti-Al alloy sample (titanium-aluminum atomic ratio is 3:1) to remove surface oxides, then ultrasonically clean it in acetone and ethanol for 10 minutes, and finally use hot air Drying can obtain the pretreated titanium-based alloy. Dissolve ammonium fluoride, potassium fluoride and sodium fluoride in deionized water at a molar ratio of 20:1.5:1 and stir at room temperature for 2 hours to prepare a salt solution with a total concentration of halogen salt of 2 wt%. Immerse the titanium-based alloy in a salt solution, put it in a polytetrafluoroethylene-lined stainless steel hydrothermal kettle, put it in an oven, and conduct a hydrothermal treatment at a temperature of 150°C for 10 hours. After completion, it is cooled naturally, rinsed with deionized water, and dried in the air. Finally, a titanium-aluminum alloy sample containing F on the surface was obtained. Subsequently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com