Descaling mechanism of liquid outlet device, liquid outlet device, shower head and faucet

A technology for showers and liquid nozzles, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of affecting the shape of the liquid, high dependence, insufficient deformation, etc., to achieve the removal of scale and foreign matter, low production accuracy requirements, and coordination Effects with low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

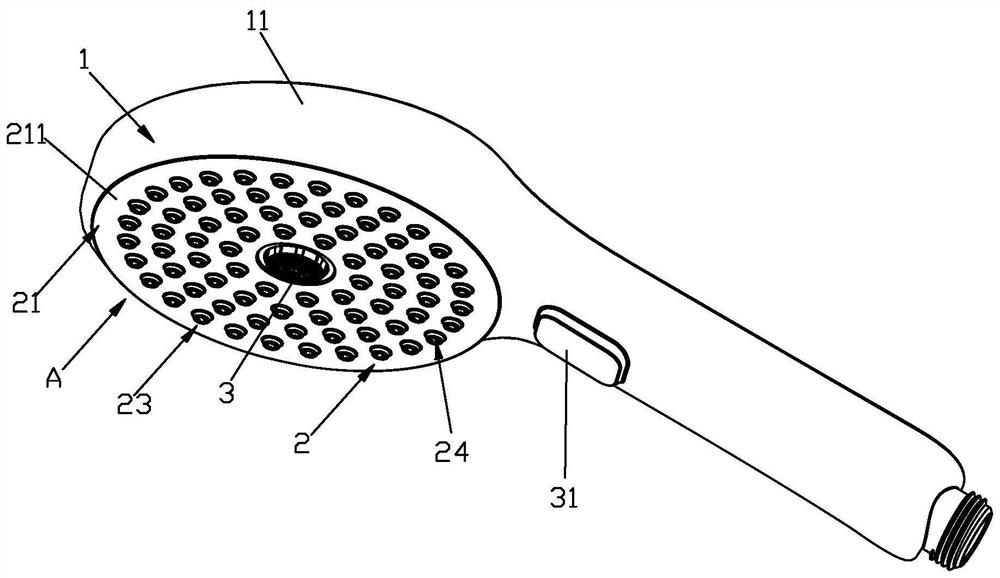

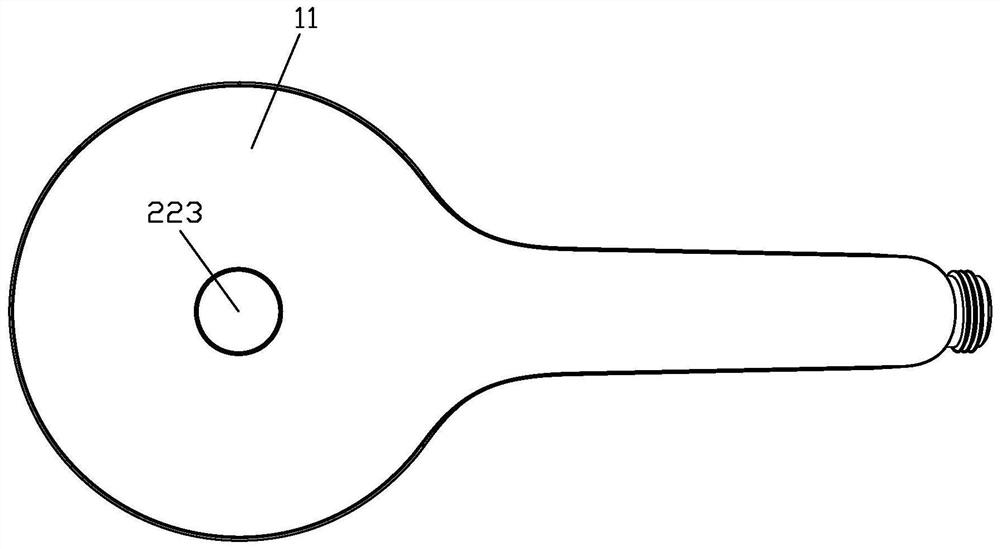

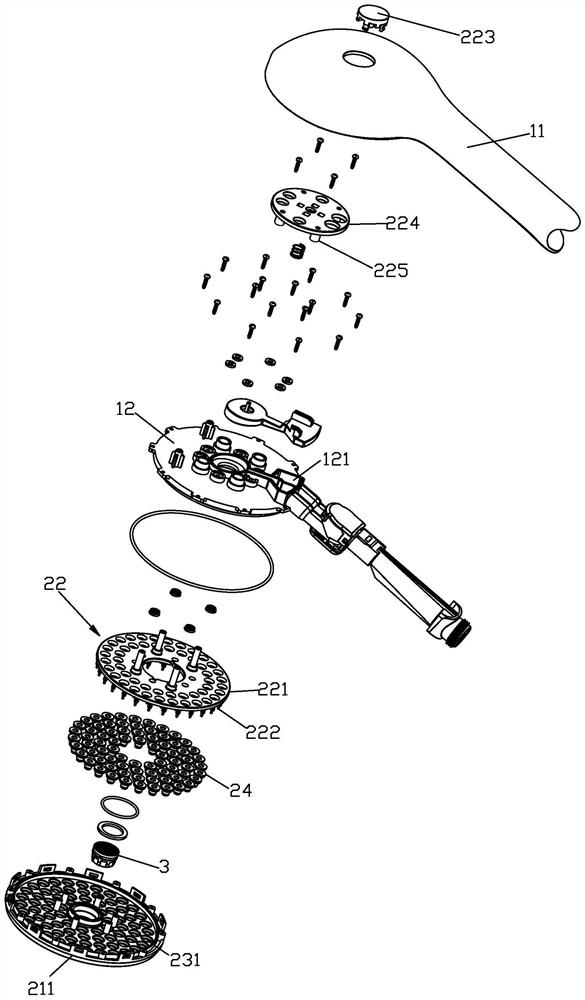

[0052] Please check Figure 1 to Figure 9 , the shower, including a liquid outlet device A, the liquid outlet device A includes a body part 1 and a descaling mechanism 2 . The body part 1 includes a body 11 and a fixing seat 12 , and the descaling mechanism 2 includes a liquid outlet unit 21 and a driving mechanism 22 movable relative to the liquid outlet unit 21 . The liquid outlet unit 21, the fixing seat 12 and the body 11 are fixedly connected together and the fixing seat 12 is at least partly arranged between the liquid outlet unit 21 and the body 11. The fixing seat and the body can also be fixed as required, but the liquid outlet unit 21 Can rotate relative to the fixed seat.

[0053] The liquid outlet unit 21 includes a water outlet surface cover 211, and the water outlet surface cover 211 is provided with a plurality of first liquid outlet nozzles 23, and the first liquid outlet nozzles 23 include installation holes 231 provided through the water outlet surface cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com