Diamond material and diamond composite material ball valve

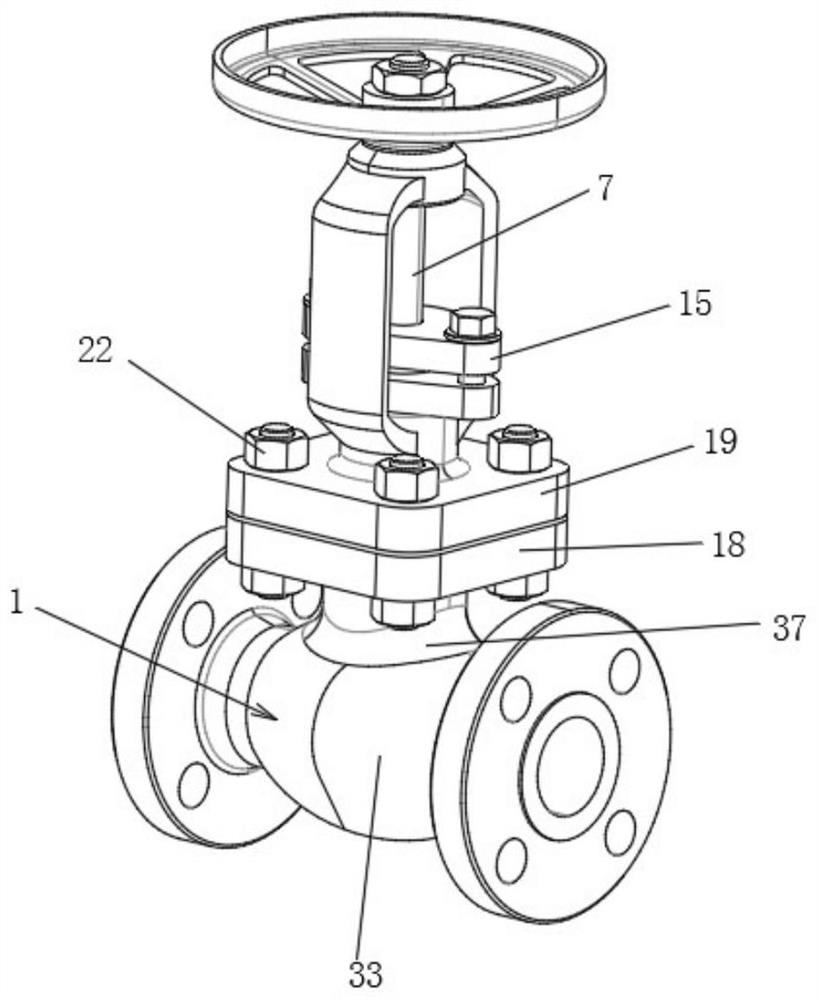

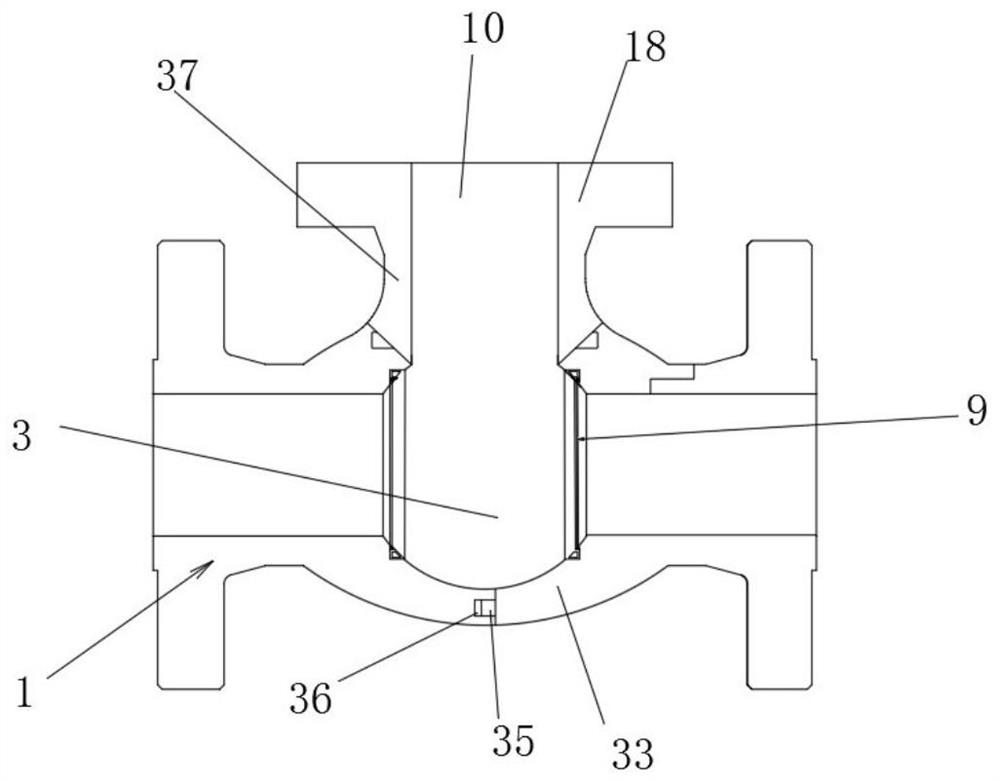

A composite material and diamond technology, applied in the field of diamond material and diamond composite ball valve, can solve the problems of wear, sealing failure, ball valve leakage, etc., and achieve the effect of avoiding leakage, prolonging service life and reducing production accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

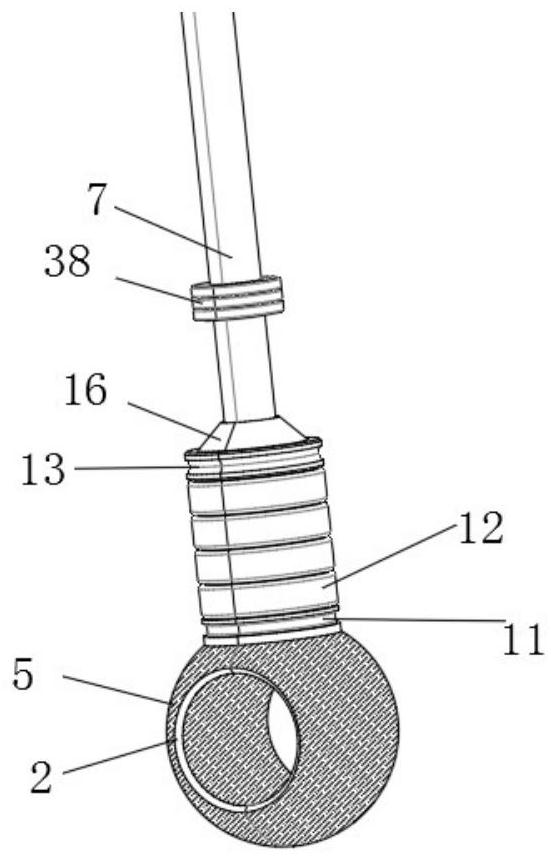

[0030] Embodiment: A diamond material of the present invention, the diamond composite material is prepared by the following weight components, 90-110 parts of diamond particles, 12-20 parts of nickel-chromium alloy powder, and 4-6 parts of binder;

[0031] The diamond composite material is prepared by the following steps:

[0032] Step 1: Ultrasonic treatment of diamond particles, and cleaning;

[0033] Step 2: add the binder to the cleaned diamond particles and mix well, then add nickel-chromium alloy powder for stirring, and then place them at a temperature of 200-250°C for 1-2 hours to obtain pretreated diamond particles ;

[0034] Step 3: Grinding the pretreated diamond particles with ultra-micro processing equipment to obtain a powdered diamond composite material. The diamond particles and the nickel-chromium alloy powder are bonded and mixed through a binder, and then pulverized to obtain a powdery diamond composite material, so that the obtained powder diamond composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com