Method for the vibration- and noise-reduced operation of an electric-motor device and electric-motor device

A technology of electric equipment and noise reduction, applied in the direction of motor control, AC motor control, application, etc., can solve the problems of high motor consumption, can not optimize the reduction of running noise, etc., to improve the service life, high running stability and noise. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

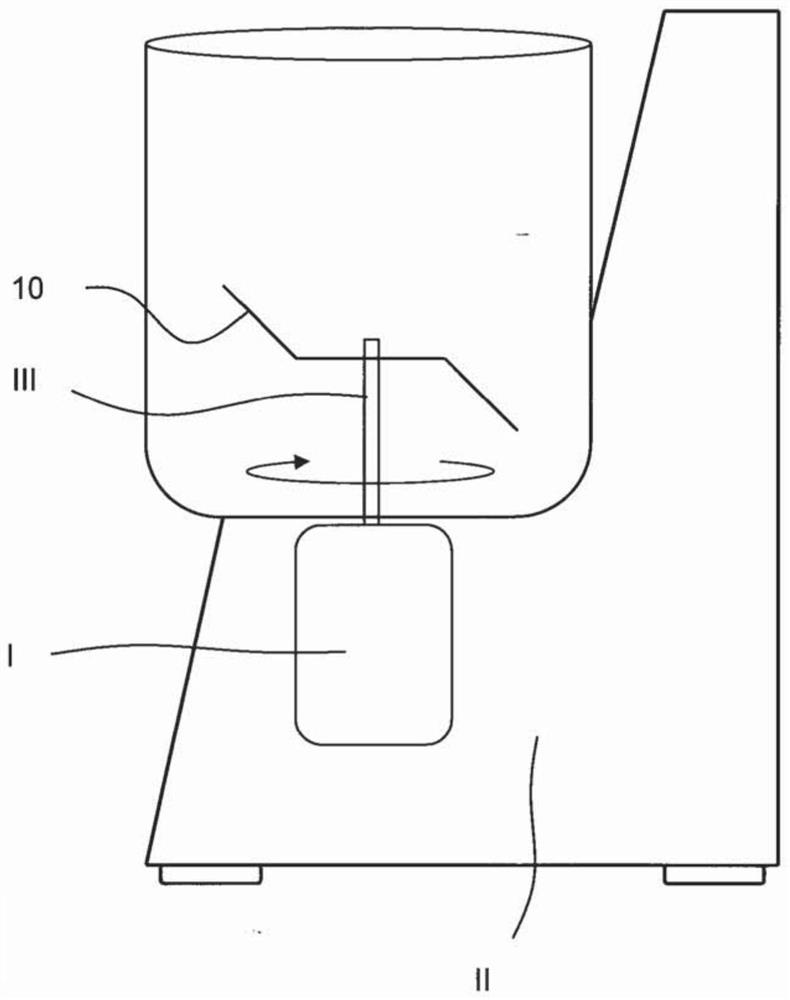

[0118] figure 1 A schematic view of an electric device is shown, which is designed in the exemplary embodiment as an electrically driven domestic appliance. The exemplary embodiment is a multifunctional tool with a replaceable driven working group. figure 1 The base body II is shown, on which the electric motor arrangement I and the driven working group III are arranged. The driven working group III has a transmission shaft, which carries the food mincer 10 . The food mincing mechanism 10 is a rotating cutter in this embodiment.

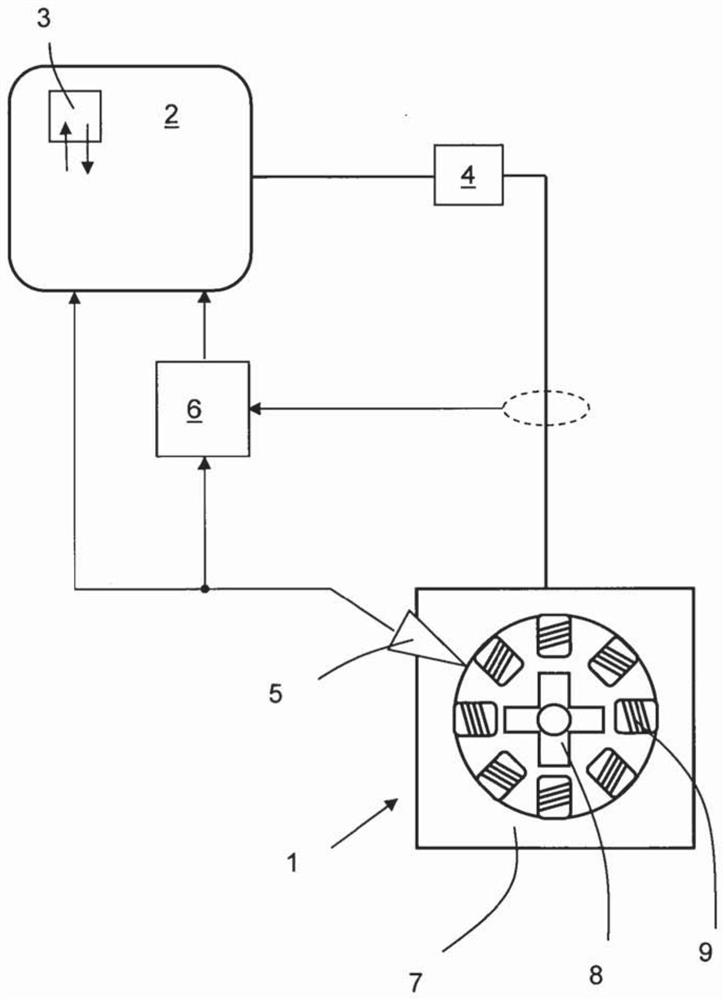

[0119] figure 2 A schematic configuration of an electric motor device is shown. The electric motor arrangement has a control and evaluation unit 2 , a data store 3 , a current regulator 4 , a rotor angle sensor 5 , a torque evaluator 6 and an electric motor 1 .

[0120] The current regulator 4 , the rotor angle sensor 5 and the torque evaluator 6 are each connected to the electric motor 1 and the control and evaluation unit 2 .

[0121] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com