High-temperature corrosion-resistant fuel cell engine antifreeze and preparation method thereof

A fuel cell and antifreeze technology, which is applied in the field of antifreeze, can solve the problems of difficulty in meeting the requirements of fuel cell vehicles, shorten the service life of fuel cells, damage fuel cell stacks, etc., and achieve low electrical conductivity, low freezing point, and slow down oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

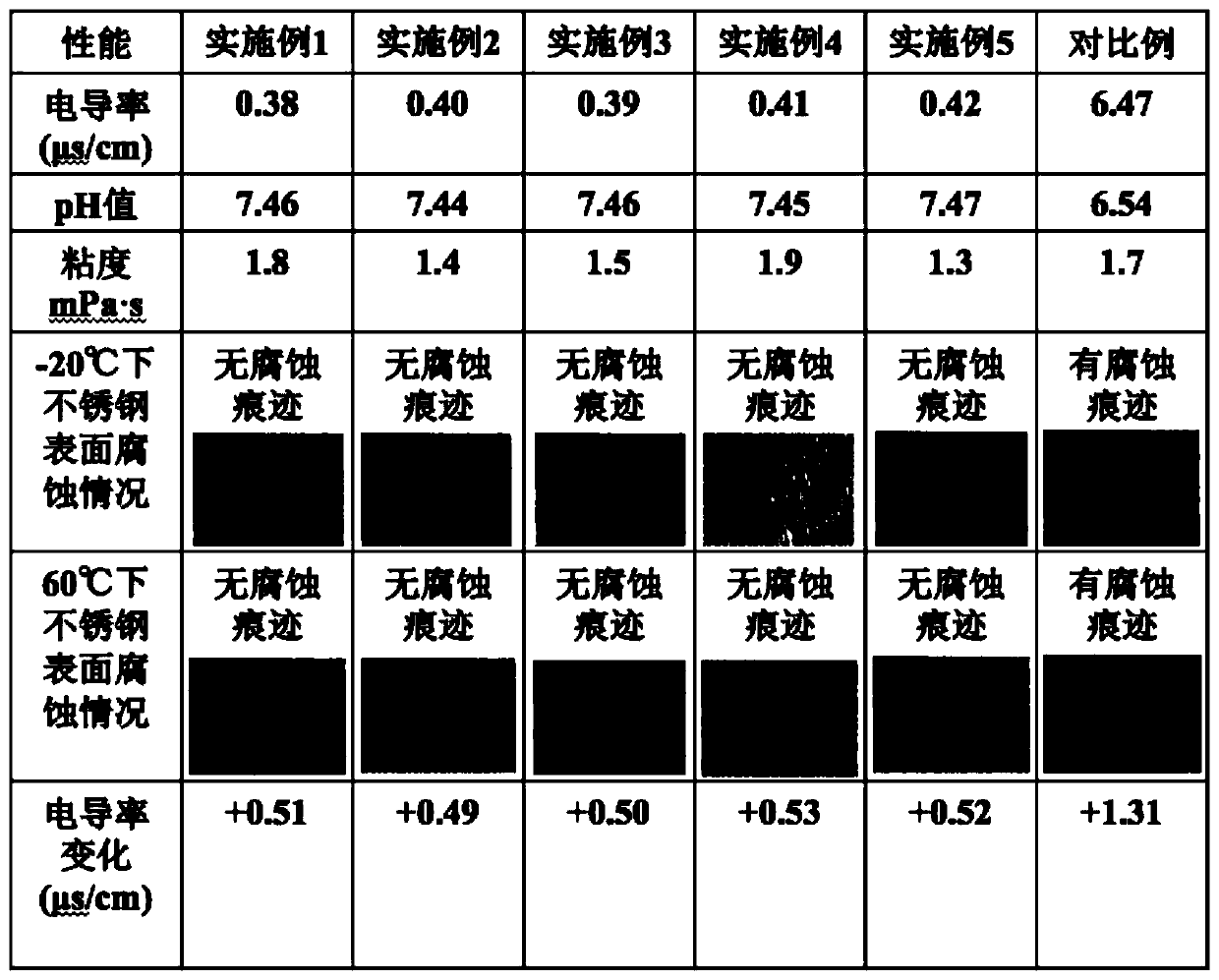

Examples

Embodiment 1

[0032] A high-temperature corrosion-resistant fuel cell engine antifreeze of this embodiment, said antifreeze is composed of the following components in mass percentage:

[0033] Ethylene glycol 98.5wt%; Additive 1.5wt%; Wherein the additive is 1,8-diazacyclo[5,4,0]undecene-70.2wt%, N-methyl-N-(trimethylsilane base) 0.2wt% of trifluoroacetamide, 0.2wt% of 3-methylindole, 0.2wt% of dipyridamole, 0.3wt% of coco-based monoethanolamide polyoxyethylene ether, and 0.4wt% of polyacrylamide.

[0034] The above-mentioned antifreeze of the present embodiment adopts following method to make, comprises the steps:

[0035] Put ethylene glycol into the reaction kettle according to the above ratio, and then successively add 1,8-diazacyclo[5,4,0]undecene-7,N-methyl-N-(trimethylsilyl ) trifluoroacetamide, 3-methylindole, dipyridamole is added in the reaction kettle, adopts ultrasonic vibration 30min to make above raw material directly dissolve in the ethylene glycol at room temperature, after...

Embodiment 2

[0038] A high-temperature corrosion-resistant fuel cell engine antifreeze of this embodiment, said antifreeze is composed of the following components in mass percentage:

[0039] Ethylene glycol 98.8wt%, additive 1.2wt%; wherein the additive is 1,8-diazacyclo[5,4,0]undecene-70.2wt%, N-methyl-N-(trimethylsilane Base) 0.2wt% of trifluoroacetamide, 0.16wt% of 3-methylindole, 0.04wt% of dipyridamole, 0.3wt% of coco-based monoethanolamide polyoxyethylene ether, and 0.3wt% of polyacrylamide.

[0040] The above-mentioned antifreeze of the present embodiment adopts following method to make, comprises the steps:

[0041]Put ethylene glycol into the reaction kettle according to the above ratio, and then successively add 1,8-diazacyclo[5,4,0]undecene-7,N-methyl-N-(trimethylsilyl ) trifluoroacetamide, 3-methylindole, dipyridamole is added in the reaction kettle, adopts ultrasonic vibration 30min to make above raw material directly dissolve in the ethylene glycol at room temperature, afte...

Embodiment 3

[0043] A high-temperature corrosion-resistant fuel cell engine antifreeze of this embodiment, said antifreeze is composed of the following components in mass percentage:

[0044] Ethylene glycol 99wt%, additive 1wt%; the additive is 1,8-diazacyclo[5,4,0]undecene-70.09wt%, N-methyl-N-(trimethylsilyl) 0.08wt% of trifluoroacetamide, 0.05wt% of 3-methylindole, 0.01wt% of dipyridamole, 0.3wt% of cocoyl monoethanolamide polyoxyethylene ether, and 0.47wt% of polyacrylamide.

[0045] The above-mentioned antifreeze of the present embodiment adopts following method to make, comprises the steps:

[0046] Put ethylene glycol into the reaction kettle according to the above ratio, and then successively add 1,8-diazacyclo[5,4,0]undecene-7,N-methyl-N-(trimethylsilyl ) trifluoroacetamide, 3-methylindole, dipyridamole is added in the reaction kettle, adopts ultrasonic vibration 30min to make above raw material directly dissolve in the ethylene glycol at room temperature, afterwards coco oil ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com