Coal chemical industry grey water scale inhibitor

A technology of scale inhibitor and coal chemical industry. It is applied in the field of gray water scale inhibitor. It can solve the problems of scale inhibition rate and corrosion inhibition, many solid deposits, and rapid corrosion of equipment, so as to improve corrosion inhibition, reduce decomposition, Delays the effect of being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

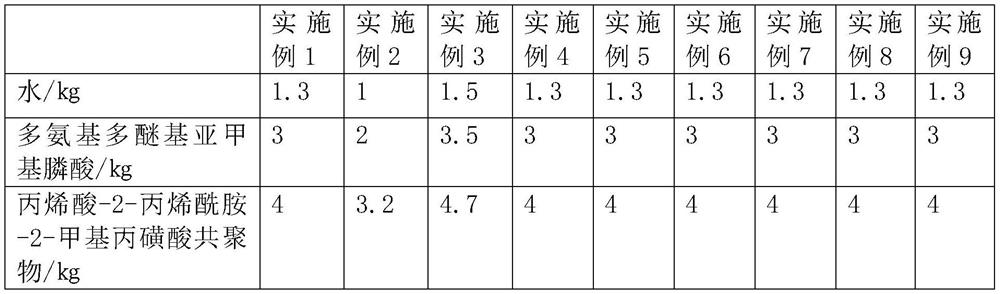

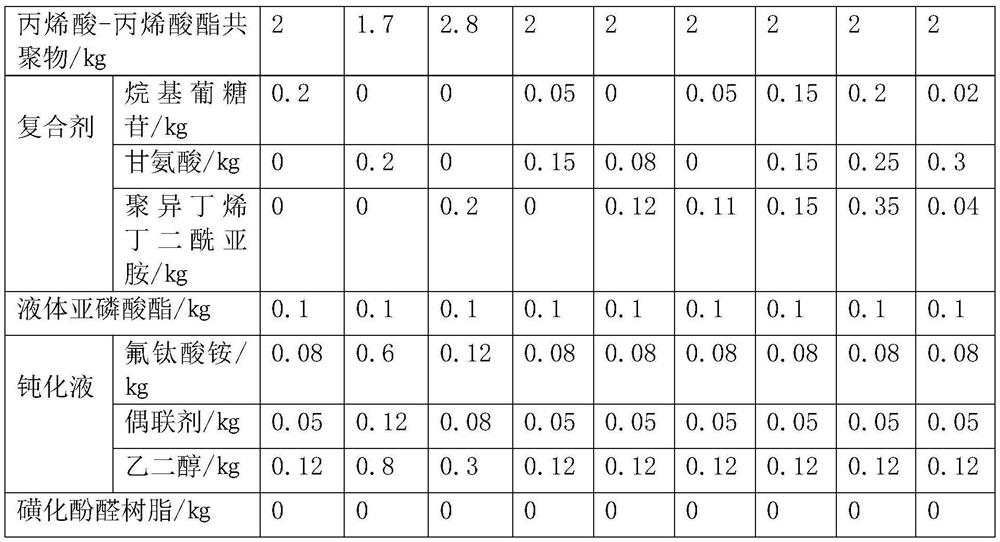

Embodiment 1

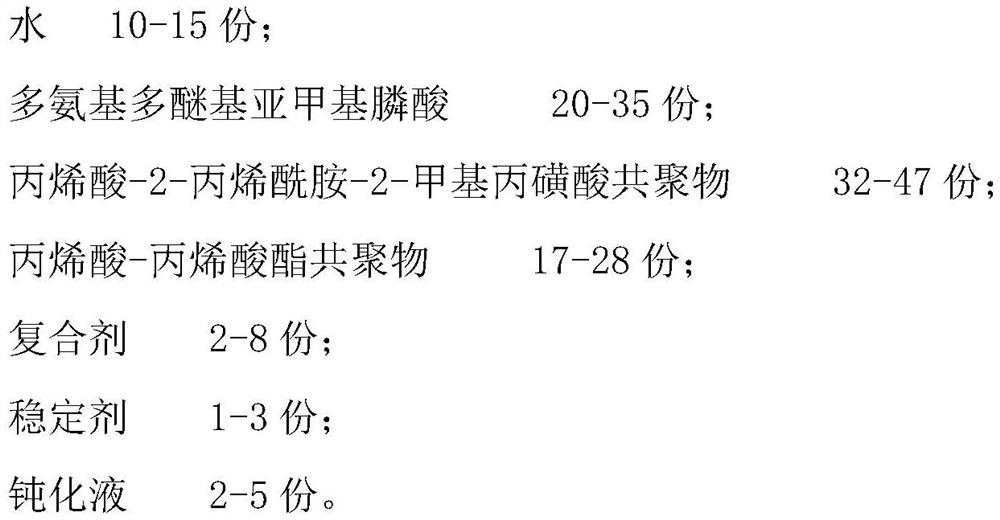

[0029] A coal chemical gray water scale inhibitor, comprising the following components by weight:

[0030] Water 1.3kg;

[0031] Polyamino polyether group methylene phosphonic acid 3kg;

[0032] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 4kg;

[0033] Acrylic acid-acrylate copolymer 2kg;

[0034] The complex agent is composed of 0.2 kg of alkyl glucoside;

[0035] Stabilizer consists of liquid phosphite 0.1kg;

[0036] The passivation solution is 0.3kg, and the passivation solution is composed of 0.08kg of ammonium fluotitanate, 0.05kg of coupling agent and 0.17kg of ethylene glycol.

Embodiment 2

[0038] A coal chemical gray water scale inhibitor, comprising the following components by weight:

[0039] 1kg of water;

[0040] Polyaminopolyether group methylene phosphonic acid 2kg;

[0041] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 3.2kg;

[0042] Acrylic acid-acrylate copolymer 1.7kg;

[0043] The complex agent is composed of glycine 0.2kg;

[0044] The stabilizer is composed of liquid phosphite 0.1kg;

[0045] The passivation solution is 0.2kg, and the passivation solution is composed of ammonium fluotitanate 0.06kg, coupling agent 0.02kg and ethylene glycol 0.12kg.

Embodiment 3

[0047] A coal chemical gray water scale inhibitor, comprising the following components by weight:

[0048] 1.5kg of water;

[0049] Polyamino polyether group methylene phosphonic acid 3.5kg;

[0050] Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 4.7kg;

[0051] Acrylic acid-acrylate copolymer 2.8kg;

[0052] The composite agent is composed of 0.2 kg of polyisobutylene succinimide;

[0053] The stabilizer is composed of liquid phosphite 0.1kg;

[0054] The passivation solution is 0.5kg, and the passivation solution is composed of 0.12kg of ammonium fluotitanate, 0.08kg of coupling agent and 0.3kg of ethylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com