Patents

Literature

41results about How to "Strong scale resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type composite corrosion and scale inhibitor

InactiveCN1919752ACreate pollutionStrong scale resistanceScale removal and water softeningMolybdateSuccinic acid

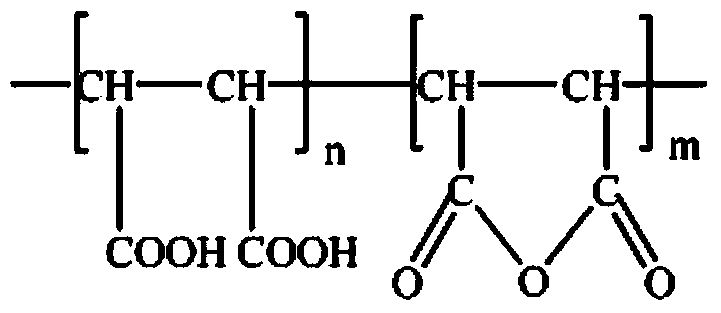

The invention discloses an environmental-protective composite inhibiting antisludging agent, which comprises the following parts: inhibiting component, antisludging component and deionized water, wherein the inhibiting component is composed of one or more materials in the molybdate, tungstate, borate, organic substituted carboxylic acid or organic heterocyclic compound; the inhibiting component contains one or more materials in the natural macromolecular compound, epoxy succinic acid or acroleic acid ternary copolymer.

Owner:BEIJING HANBOYING ELECTRIC POWER TECH

Low-phosphorous environment-friendly scale inhibitor adapting to 'three-high' water quality and preparation thereof

InactiveCN101913712AInhibition formationHigh charge densityScale removal and water softeningPhosphateWater quality

The invention provides a low-phosphorous environment-friendly scale inhibitor adapting to 'three-high' water quality and preparation thereof. The scale inhibitor is prepared from the following raw materials in part by weight: 1, 1.0 to 2.5 parts of polyamino polyether methylene phosphonic acid (PAPEMP); 2, 1.5 to 3.0 parts of polyepoxysuccinic acid (PESA); 3, 1.5 to 2.5 parts of acrylic acid-hydroxypropyl acrylate-AMPS terpolymer; 4, 1.5 to 2.5 parts of liquid caustic soda; 5, 0.5 to 1.0 part of hydrolyzed plymaleic anhydride; and 6, the balance of water. The scale inhibitor is prepared by the following steps of: pumping the raw materials 1, 2 and 3 into a reaction kettle during synthesis, and continuously stirring; and adding the material 4 into 5 and 6, pumping into the reaction kettle, continuously stirring for 35 to 45 minutes, and discharging to prepare the product. The scale inhibitor has good scale-inhibiting effect on carbonate and phosphate and the scale-inhibiting time of 100 hours, and is suitable for a high-hardness high-alkalinity high-mineralization circulating cooling water system and oil field water treatment. Therefore, the original concentration times is improved from 3 times to 5-6 times, the new water can be saved by 10 to 30 percent per year, and the phosphorus content of sewage treated by the scale inhibitor is 1.5 to 3ppm and accords with the national phosphorus discharge standard.

Owner:URUMQI KEFAZHAN FINE CHEM

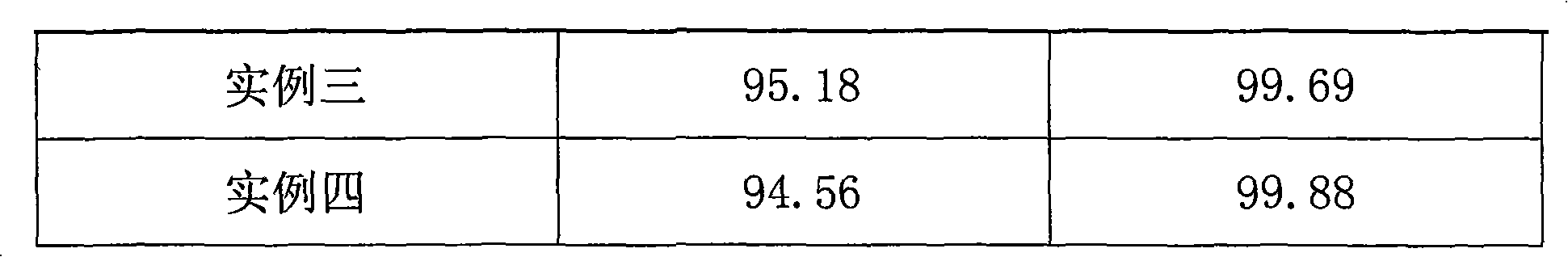

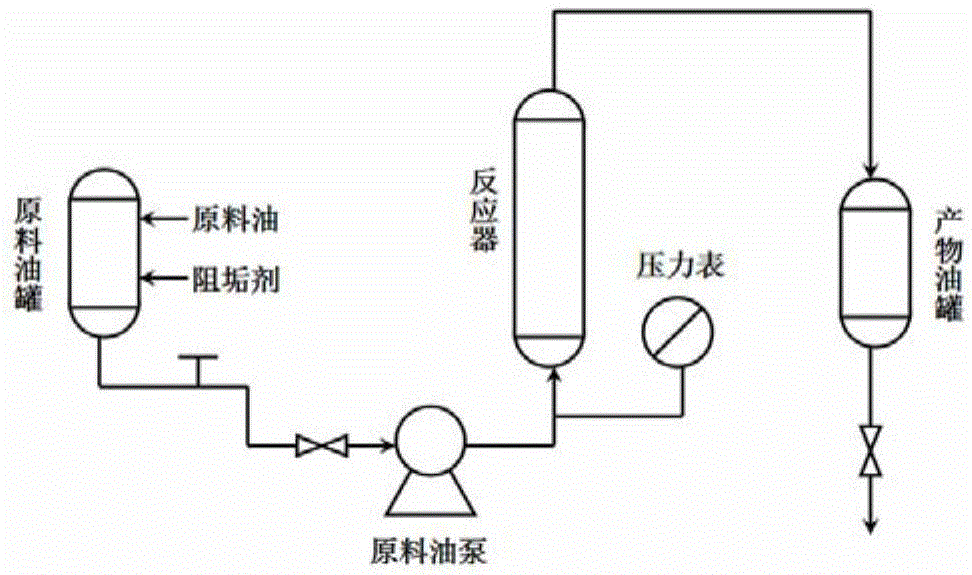

Scale inhibitor for oil refining technology process and preparation method thereof

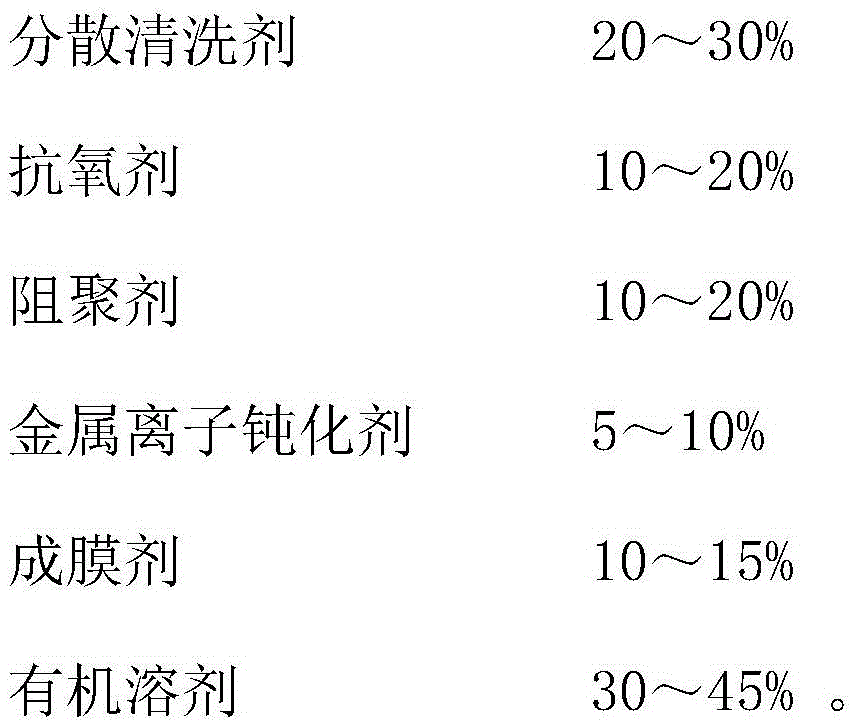

ActiveCN105482851AInhibition of polymeric foulingStrong scale resistanceTreatment apparatus corrosion/fouling inhibitionOrganic solventFuel oil

The invention relates to a scale inhibitor for the oil refining technology process. In order to provide an efficient environment-friendly scale inhibitor which is suitable for various oil refining technologies, the invention provides the scale inhibitor for the oil refining technology process. The scale inhibitor is characterized by being prepared from, by mass, 10%-40% of scattered detergent, 5%-30% of antioxygen, 5%-30% of polymerization inhibitor, 5%-15% of metal-ion passivator, 5%-20% of film-forming agent and 20%-70% of organic solvent, and the scale inhibitor is obtained by compounding all the substances. The scale inhibitor for the oil refining technology process has the advantages that the effect and the adaptability are strong, wherein the scattered detergent can scatter the scale inhibitor in the material, and the scale inhibitor is not prone to stick to and deposit on the surface of equipment; the stability is good, the scale inhibitor can still play a role under the high-temperature conditions such as heavy oil hydrogenation, therefore, polymerization and scaling of a hydrogenation system can be effectively inhibited, and long period operation of a device is guaranteed; elements of sulphur, phosphorus and the like are not contained, toxicity and undesirable odor do not exist, and pollution does not exist in the preparation and use process.

Owner:SHENZHEN GCD PETROLEUM ADDITIVE CO +1

Scale inhibition particle as well as preparation method and application thereof

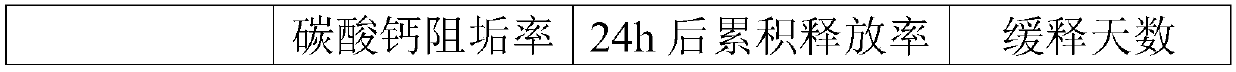

PendingCN111233176AGood sustained release effectAchieve long-term effectTreatment using complexing/solubilising chemicalsControl releasePhysical chemistry

The invention provides a scale inhibition particle as well as a preparation method and application thereof, the scale inhibition particle comprises scale inhibition powder, an adsorption material anda binder, and the binder is a combination of a water-soluble binder and a cured binder; the scale inhibition particle prepared by the invention has the advantages of strong descaling capability, longscale inhibition life, good water resistance, excellent water purification function, good slow release effect, controllable release rate, long action, simple preparation process and low cost, are usedfor water quality scale inhibition treatment, and are especially suitable for scale inhibition treatment of household water.

Owner:BEYCLEAN ENVIRONMENTAL PROTECTION TECH

Cleaning method of boiler

InactiveCN107747728AReduce sewagePrevents the production of calcium saltsBoiler cleaning apparatusChemistryPolyaspartic acid

The invention provides a cleaning method of a boiler. The cleaning method comprises the steps of impurity removing, flushing, soda boiling, flushing, acid pickling, acid liquor jacking and draining and water flushing, rinsing and passivating. According to the cleaning method of the boiler, a soda boiling solution is utilized to react with oil stain on the inner wall of the boiler, the oil stain isthoroughly removed, the soda boiling solution does not contain inorganic phosphate, and the dirt discharge amount is reduced; acid is utilized to react with incrustation, copper scale and iron rust on the inner wall of the boiler in the acid pickling process, the incrustation and the iron rust on the inner walls of the boiler and a pipeline are dissolved, polyaspartic acid in an acid pickling solution has a good scale inhibition capability, and calcium salt can be effectively prevented from being generated; and etidronic acid has a dispersion effect, calcium and magnesium ions in water can bestabilized, on one hand, a corrosion inhibitor can effectively disperse and inhibit the scale, on the other hand, impurities are not introduced into a boiler system, and the dirt discharge amount ofboiler cleaning is reduced. According to the cleaning method of the boiler, a passivation solution is an organic passivation solution, chemical reaction can be generated on the passivation solution and the inner wall of the boiler to generate a passivating film, no ammonium ion is generated, and ammonia corrosion is prevented from being generated to the boiler.

Owner:GUANGZHOU JINRUN ENVIRONMENTAL PROTECTION TECH

Preparation method of phosphorus-free green environment-friendly scale inhibitor

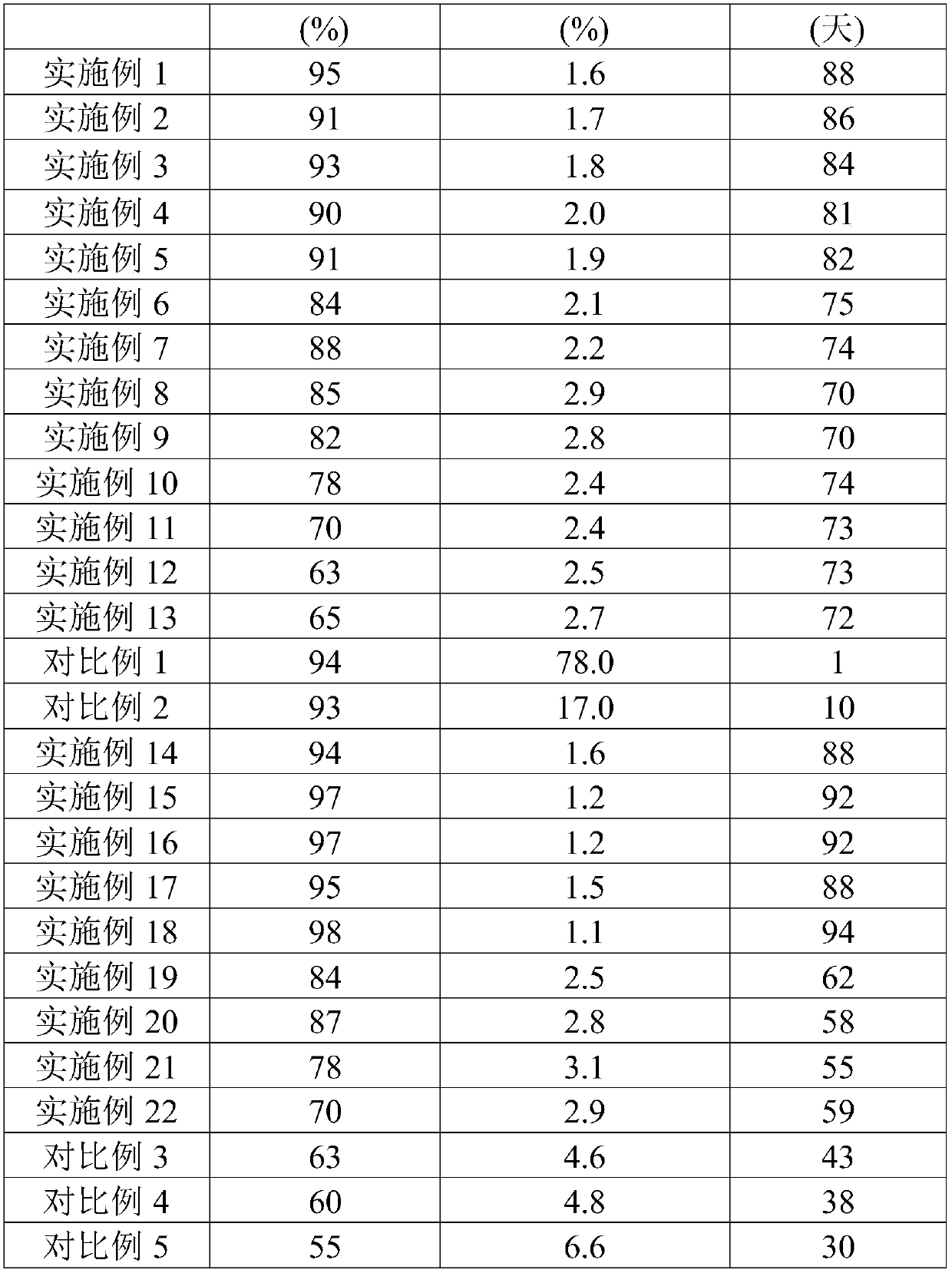

InactiveCN102358772APrevent scalingReduce dosageScale removal and water softeningPersulfateAmmonium sulfate

The invention discloses a preparation method of a phosphorus-free green environment-friendly scale inhibitor. The scale inhibitor is characterized by being a quarternary polymerization one and comprising components by weight of 25-40 parts of acomitic acid, 8-20 parts of acrylic acid, 12-18 parts of maleic anhydride, 6-12 parts of sodium alkyl sulfonate, 3-7 parts o fammonium persulfate and 130-220 parts of water. The invention also discloses a preparation method of the phosphorus-free green environment-friendly scale inhibitor. The scale inhibitor prepared by the invention has excellent scale inhibiting effects on scales of calcium carbonate, calcium phosphate and barium sulfate, and characteristics of rust inhibition, high temperature resistance, stable molecular weight and on phosphorus. The whole production process has no ''three wastes (waste gas, waste water and industrial residue)'' discharge. The product of the invention can be used for treating industrial circulating water and oil field water with a simple technology, and has small usage amount, low costs, good effect and good economic benefits and wide social benefits.

Owner:UNIV OF JINAN

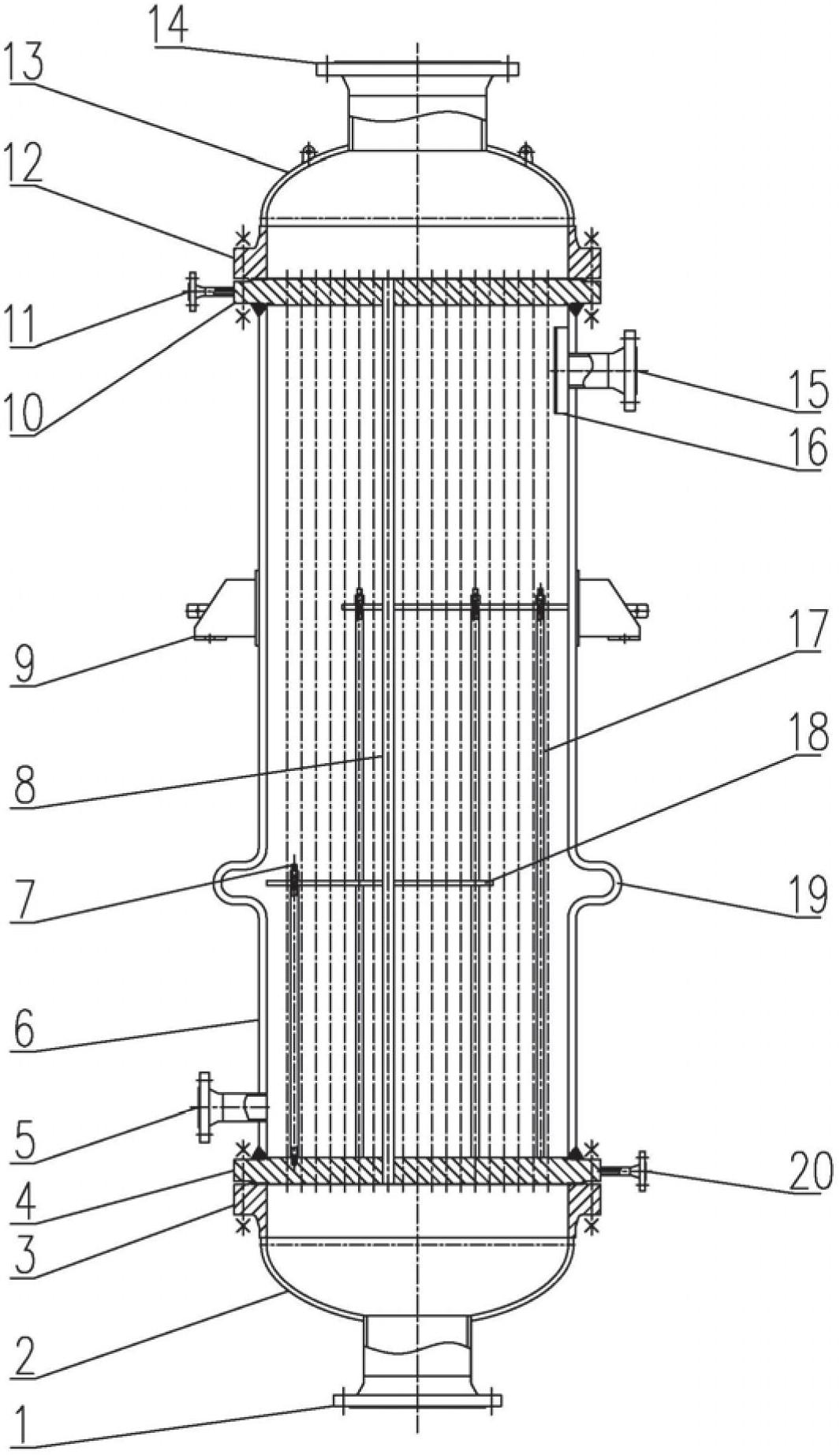

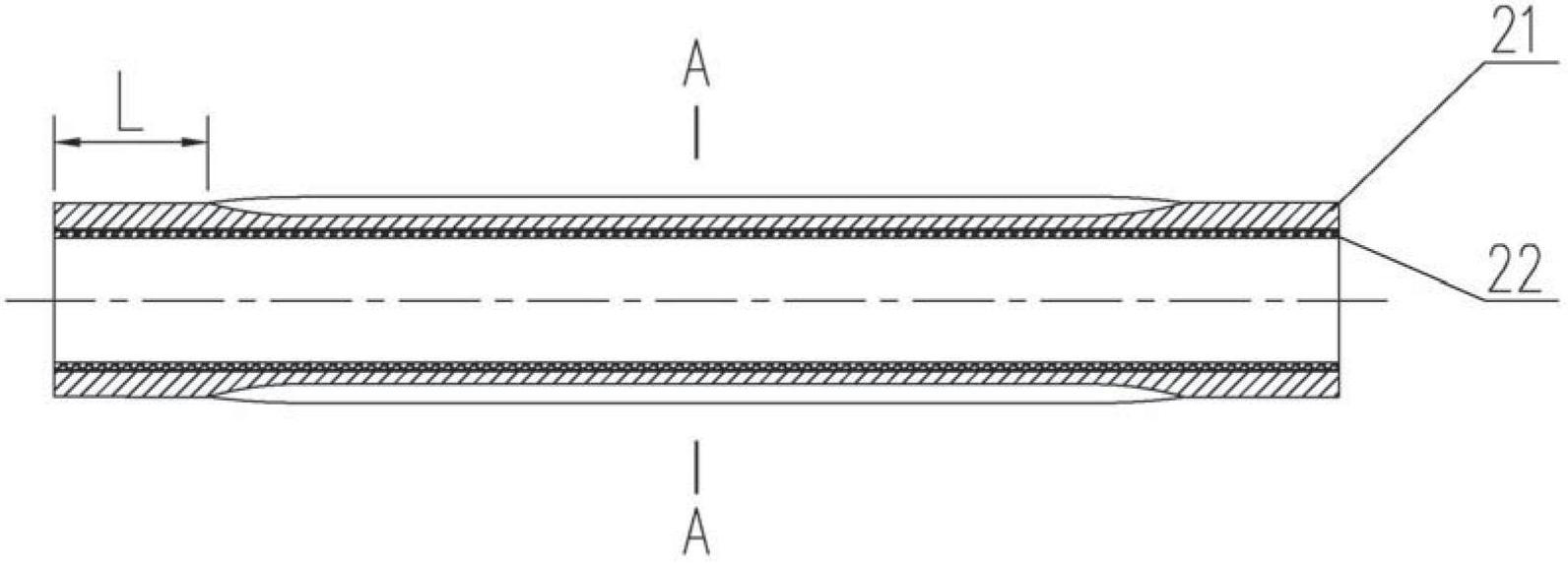

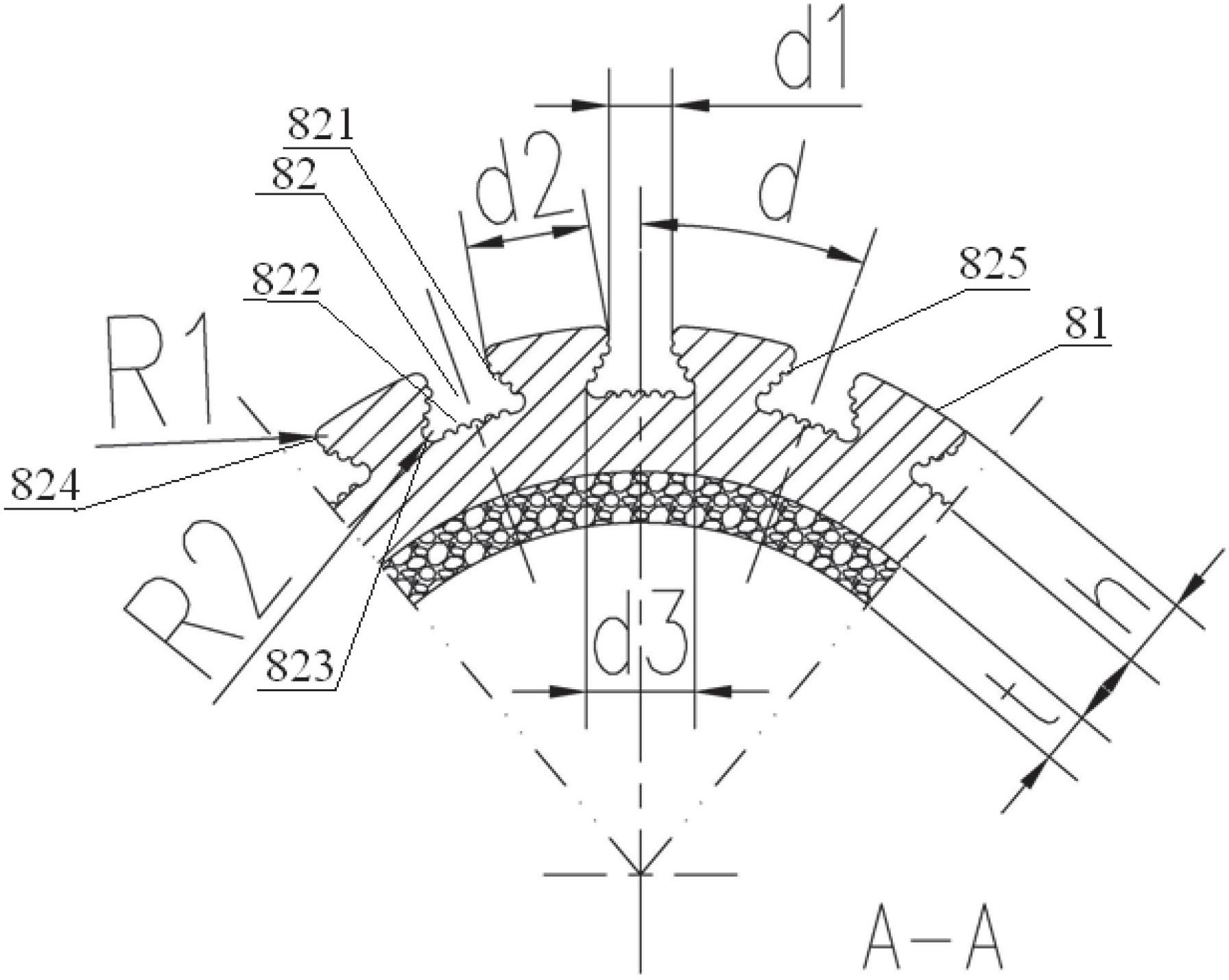

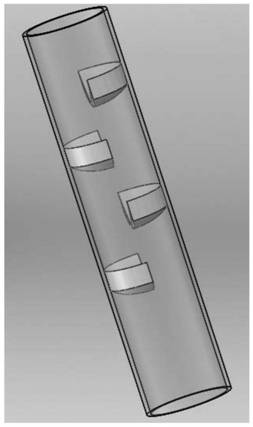

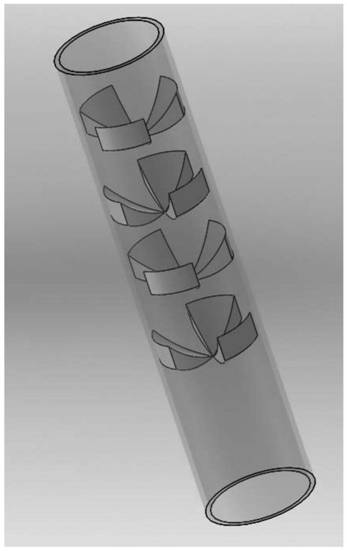

Reboiler

ActiveCN102671399AExtended cleaning cycleImprove heat transfer efficiencyBoiling apparatusReboilerPorous layer

The invention discloses a reboiler which comprises a cylinder and a plurality of heat exchange tubes, wherein a material inlet and a material outlet are arranged at two ends of the cylinder respectively; a steam inlet is arranged on the cylinder on the side of the material outlet; and a condensate outlet is arranged on the cylinder on the side of the material inlet. According to the reboiler, a porous layer is processed on inner surfaces of heat exchange tube substrates and the porous layer has a heating surface with increased roughness so as to form an artificial evaporating core, so that the heat transfer efficiency of the heat exchange tubes is increased. Meanwhile, longitudinal grooves are processed on the outer surfaces of the heat exchange tube substrates, circular bulges are arranged in the longitudinal grooves, longitudinal nicks are arranged on a teeth part, the thickness of a liquid film is reduced by utilizing a surface tension and then the condensation effect on the exteriors of the heat exchange tubes is improved. According to the invention, the total coefficient of heat transfer of the reboiler is above 3 times of that of a light tube reboiler; anti-scaling capacity of boiling sides of the heat exchange tubes is increased; the dirt deposition rate is less than that of a smooth tube, so that the cleaning period of the reboiler is prolonged.

Owner:CHINA ELEVENTH CHEM CONSTR +1

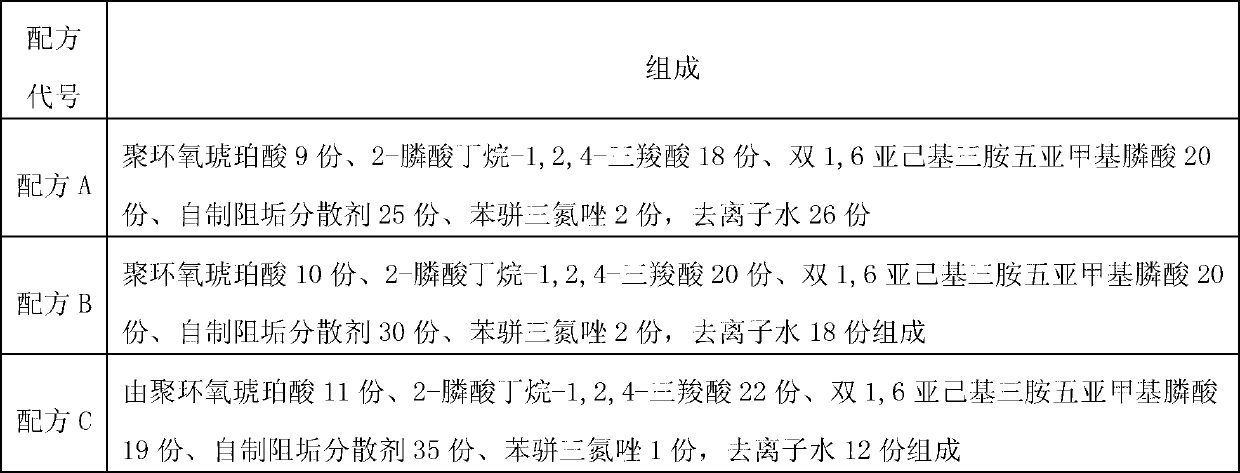

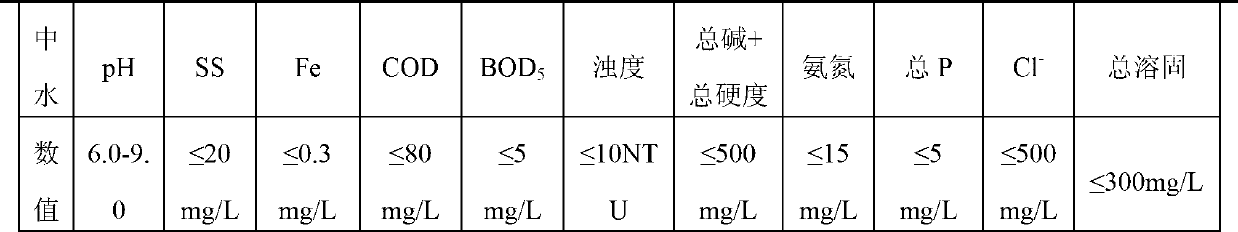

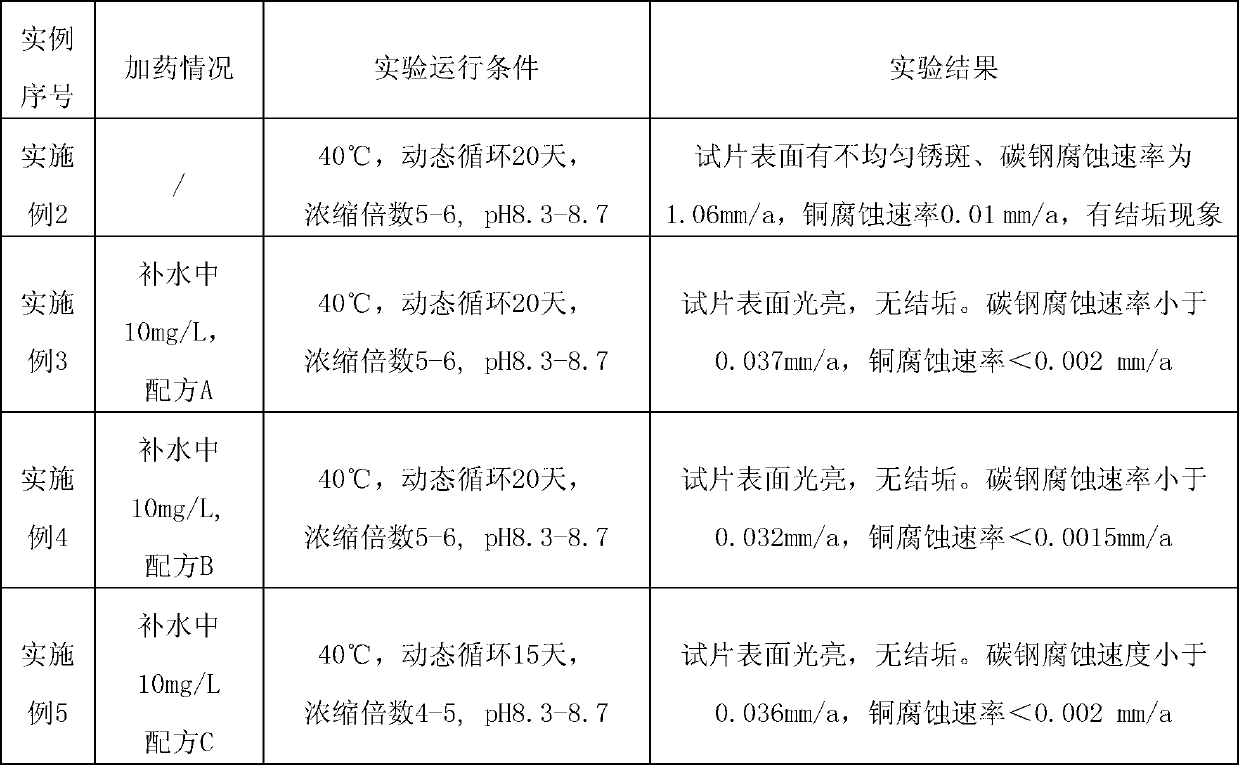

Chemical processing method of coal chemical industry recycled circulating cooling water

ActiveCN102976512AGood anti-scaling effectReduce phosphorus contentScale removal and water softeningMultistage water/sewage treatmentIonTotal phosphorus

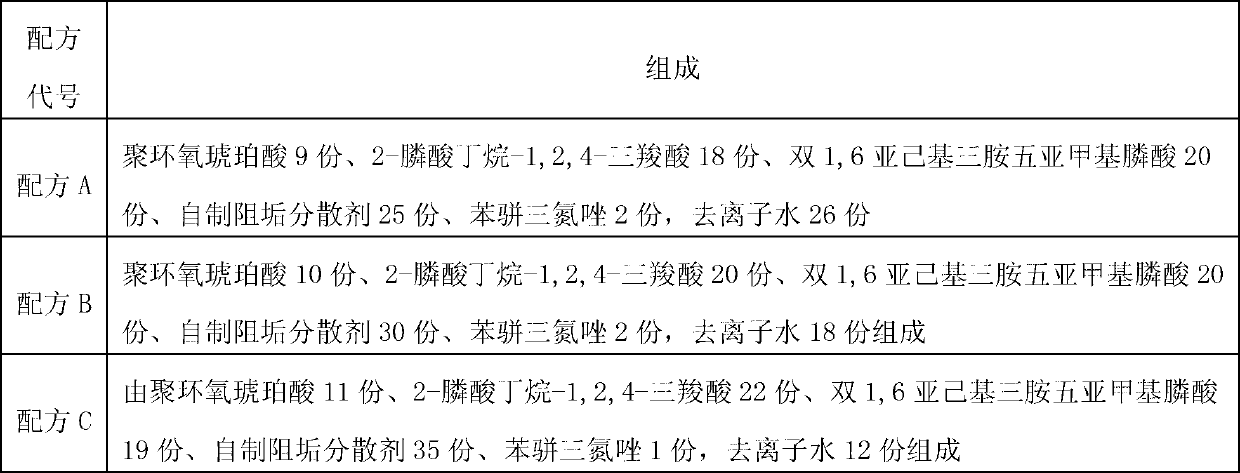

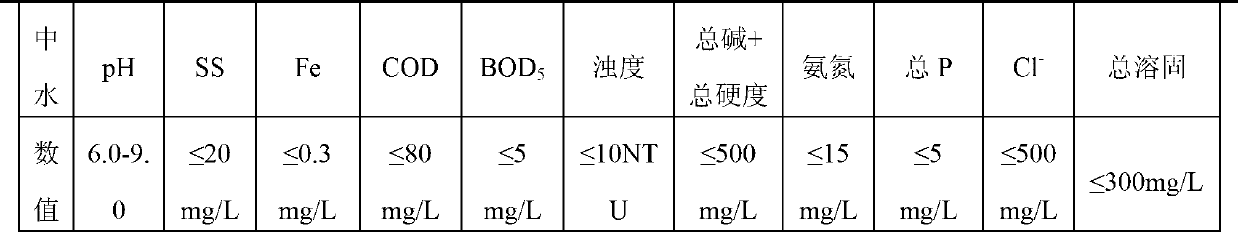

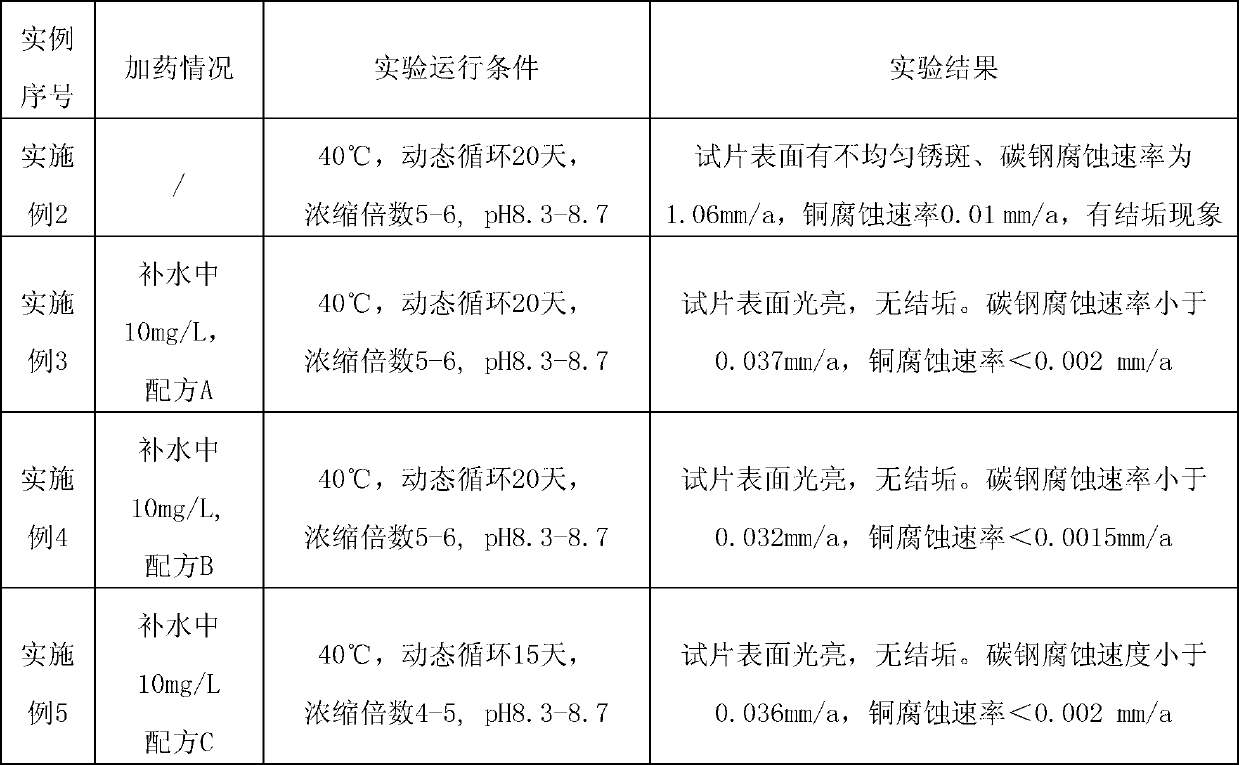

The invention provides a chemical processing method of coal chemical industry recycled circulating cooling water. An agentia is composed of composite scale and corrosion inhibitor which is composed of 9-11 parts of polyepoxysuccinic acid, 18-22 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 19-21 parts of methylene phosphonic acid, 25-35 parts of dirt dispersion agent, 1-3 parts of benzotriazole, and 9-18 parts of deionized water. First, adding polyepoxysuccinic acid into the 2-phosphonobutane-1,2,4-tricarboxylic acid, placing the polyepoxysuccinic acid and the 2-phosphonobutane-1,2,4-tricarboxylic acid in a container and evenly mixing, sequentially adding the methylene phosphonic acid, the dirt dispersion agent and the deionized water into the container, then stirring for 25-35 minutes, keeping the temperature at 20-35 DEG C, then adding the benzotriazole, continuously stirring for 30-60 minutes and keeping the temperature at 20-35 DEG C, and then, the composite scale and corrosion inhibitor is obtained. Dosage of the composite scale and corrosion inhibitor is 10mg / L, based on middle warmer strengthening water, total phosphorus of the circulating water is controlled to be 4-7mg / L, and a concentration ratio is controlled to be 5.0-6.0 times. The method further comprises sterilization and algae removing process and optimization of the circulating water.

Owner:XINJIANG DEAN ENVIRONMENTAL PROTECTION ENG

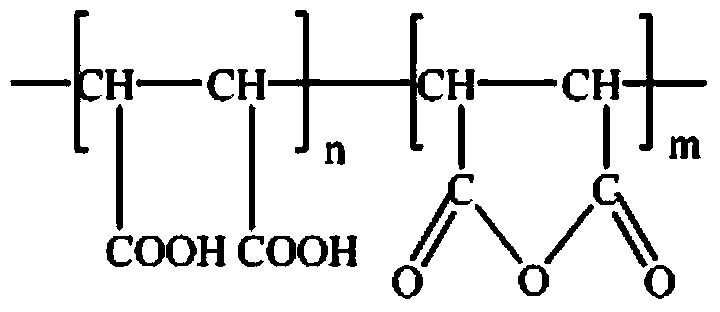

Scale inhibitor

InactiveCN104176837AStrong scale resistanceAvoid it happening againScale removal and water softeningItaconic acidWastewater

The invention relates to a scale inhibitor which has a relatively good corrosion and scale inhibition effect and can effectively treat industrial high-mineral-ion wastewater. The scale inhibitor comprises a component A and a component B which are mixed with each other, wherein the component A is hydrolytic polymaleic anhydride (HPMA); the component B is copolymer synthesized by using itaconic acid (IA), 2-acrylamido-2-methyl propyl sulfonic acid (AMPS) and 2-2-acrylamido-2-methyl propyl phosphonic acid (AMPP); in a molecular formula of the copolymer, x, y and z represent mole numbers of IA, AMPS and AMPP respectively, and the ratio of x to y to z is (50.3-70.6) to (11-16) to (33-41); the mass part ratio of the component A to the component B is (4-6) to 1.

Owner:WUHAN UNIV OF TECH

Non-phosphorus antisludging agent containing tracer polymer and preparation method of non-phosphorus antisludging agent

InactiveCN109761380ALow costStrong scale resistanceScale removal and water softeningSocial benefitsPolyaspartic acid

The invention belongs to the technical field of water treatment, and particularly discloses a non-phosphorus antisludging agent containing tracer polymer and a preparation method of the non-phosphorusantisludging agent. The antisludging agent is prepared from the following raw materials: (1) AA / AHPSE; (2) zinc chloride; (3) polyaspartic acid; (4) organic amine; (5) triethanolamine; (6) polyepoxysuccinic acid; (7) sodium gluconate; (8) hydrogen peroxide; (9) a tracer agent PTSA; and (10) the balance of pure water. The prepared non-phosphorus antisludging agent containing tracer polymer is a water treatment antisludging agent having the good effect, low cost, high antisludging capability, and capable of being monitoring adding and usage conveniently, and has oustanding social benefits andeconomic popularization value.

Owner:URUMQI KEFAZHAN FINE CHEM

Preparation method of reverse osmosis membrane antisludging agent with high iron content

InactiveCN104707485ACause secondary pollutionEffective complexationSemi-permeable membranesScale removal and water softeningWater bathsDiethylenetriamine

The invention relates to a preparation method of a reverse osmosis membrane antisludging agent with the high iron content. The preparation method comprises the following steps: firstly placing 50g of diethylenetriamine pentaacetic acid ammonium salt in a 250mL beaker, and stirring until the diethylenetriamine pentaacetic acid ammonium salt dissolves to obtain a solution; secondly adding 50g of polyaspartic acid into the solution, and carrying out water-bath stirring for 60 minutes at the temperature of 45 DEG C to obtain a mixture; and finally, cooling the mixture to the room temperature to obtain a finished product. The preparation method has beneficial effects that the diethylenetriamine pentaacetic acid ammonium salt and the polyaspartic acid are compounded to form a novel reverse osmosis membrane antisludging agent, the antisludging agent can be effectively complexed with iron ions in water and is high in antisludging capability for calcium carbonate and calcium sulfate, the cost is low, and the secondary pollution on a membrane can be avoided.

Owner:WEIHAI XIANGYU TECH

Metal water-based rust removal antirust solution and preparing method thereof

InactiveCN108018567AWide temperature rangeEmulsifyingMetallic material coating processesWater basedMesoporous silica

The invention provides a metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution comprises raw materials including, by weight part, 2 to 6 parts of citric acid, 2 to 8 parts of lauryl sodium sulfate, 2 to 4 parts of tartaric acid, 1 to 5 parts of sodium citrate, 2 to 6 parts of polyaspartic acid, 0.4 to 1.2 parts of oxidized starch, 5 to 10 parts of cetyl-trimethyl ammonium bromide, 10 to 15 parts of polyoxyethylene fatty alcohol sodium sulfate, 1 to 2 parts of OP-10, 1 to 3 parts of chitosan, 2 to 8 parts of mesoporous silica, 10 to 20 parts of PEG200, 15 to 20 parts of propanediol butyl ether and 60 to 90 parts of water. The invention further provides a preparing method of the metal water-based rust removal antirust solution. The metal water-based rust removal antirust solution has multiple functions of rust removal, dirt removal, phosphatization, passivation and the like, a reaction is carried out at the normal temperature, the rust removal time is short, the antirust time is long, and corrosion to the metal is avoided.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

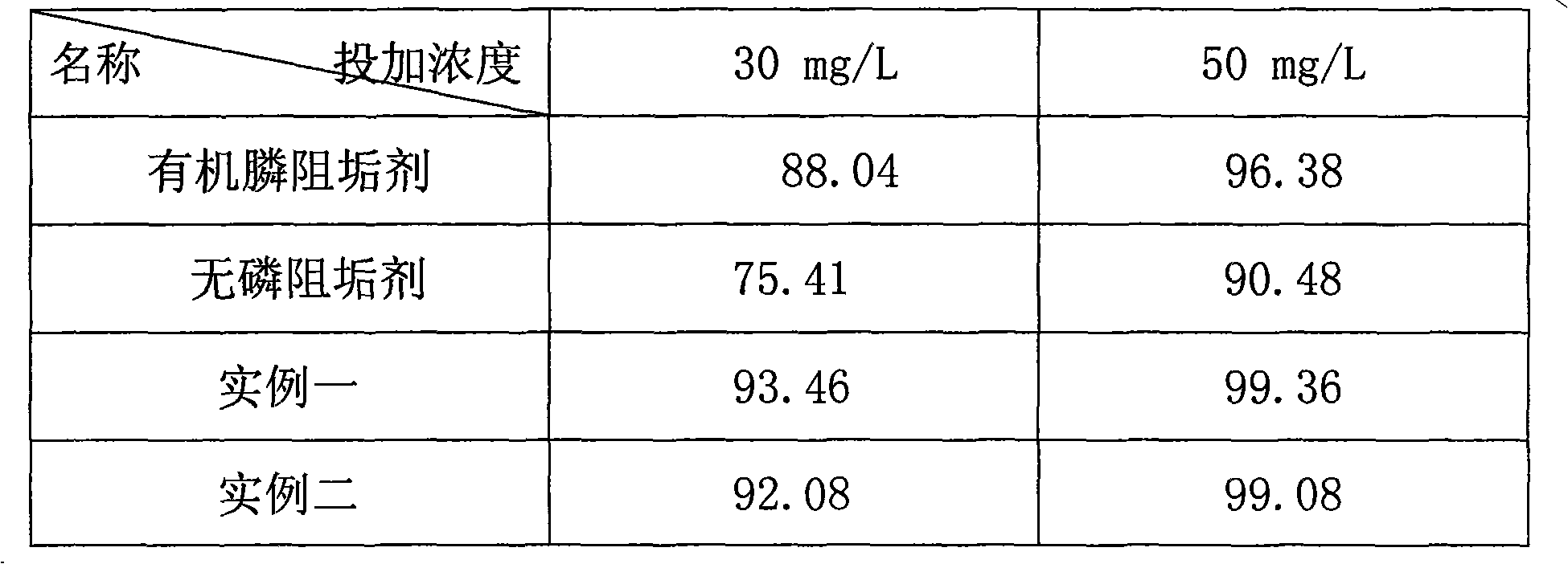

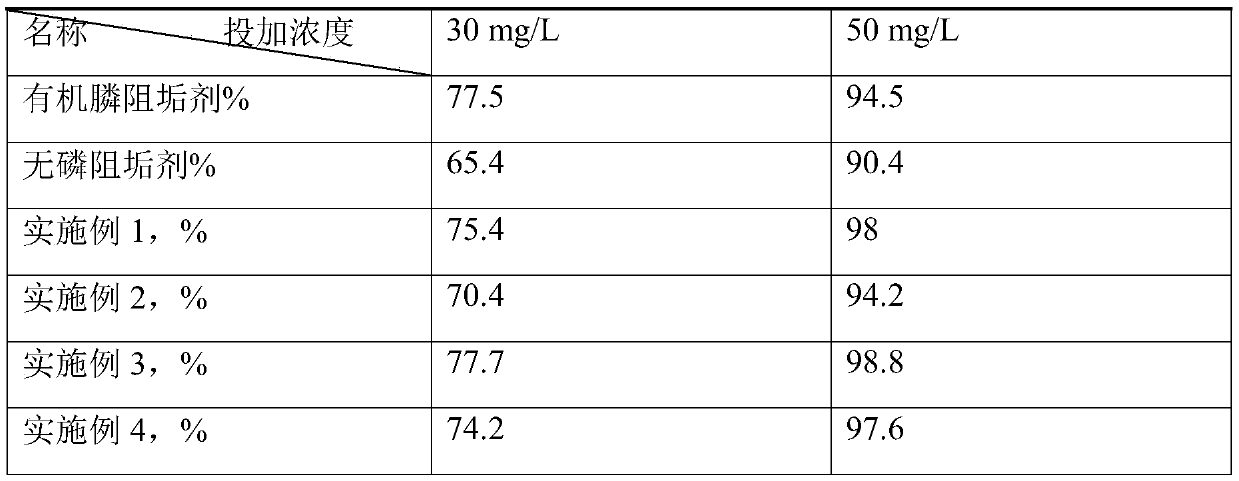

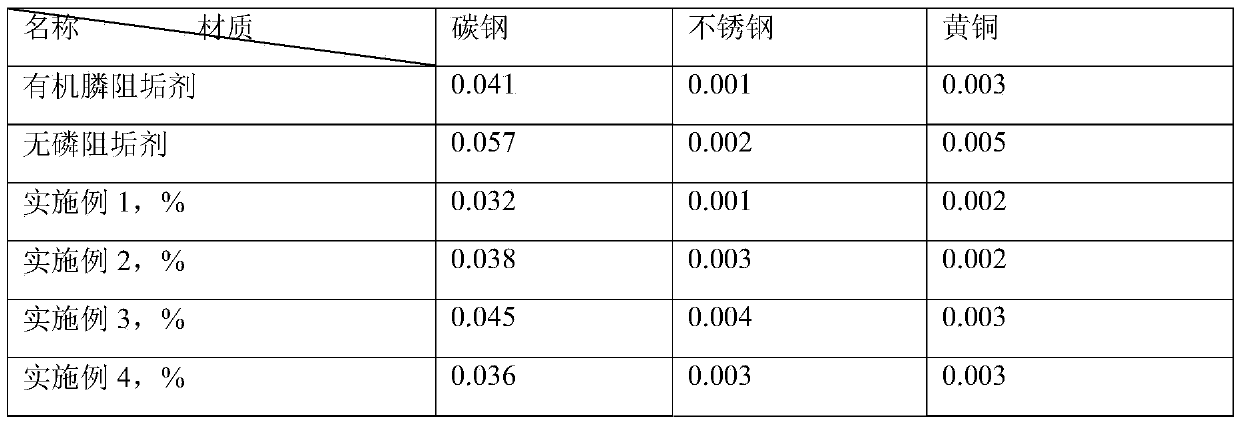

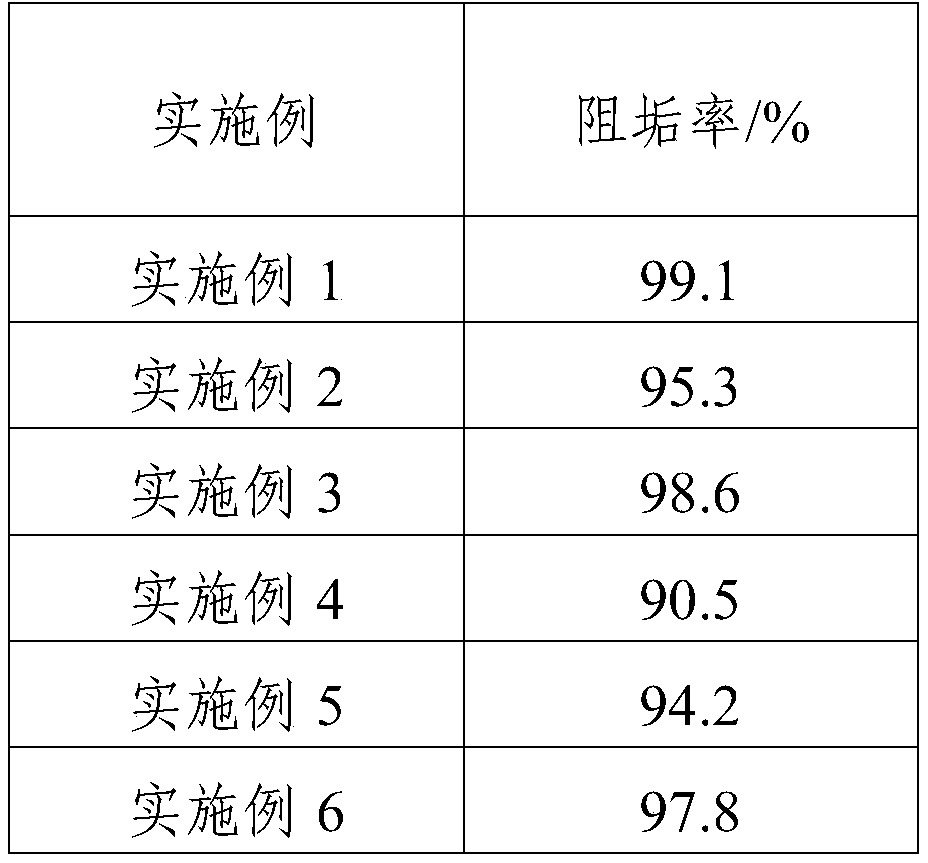

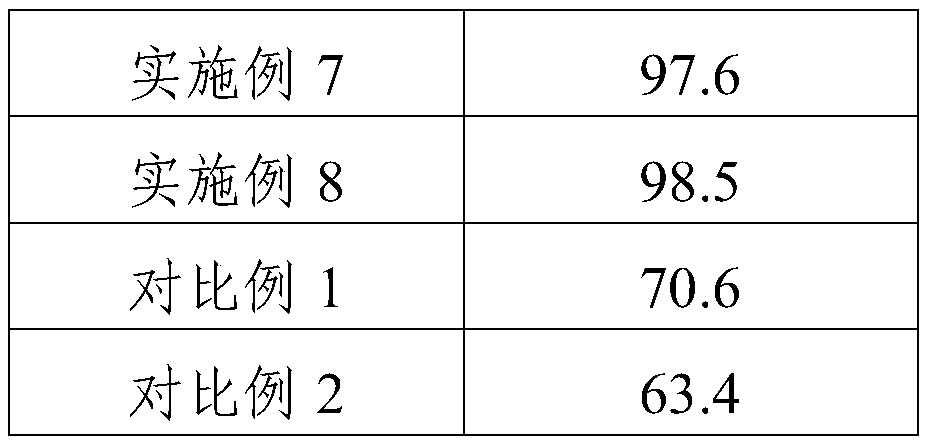

Preparation method of efficient scale inhibitor for circulating cooling water system

InactiveCN111056648AImprove bindingImprove adsorption capacitySpecific water treatment objectivesWater contaminantsInorganic saltsPhysical chemistry

The invention provides a preparation method of an efficient scale inhibitor for a circulating cooling water system, and relates to the field of scale inhibitors, and the preparation method specifically comprises the following steps: preparing an intermediate A; preparing an intermediate B; uniformly mixing and stirring the intermediate A, the intermediate B, a maleic acid-acrylic acid copolymer, inorganic salt and water to obtain a mixed solution; adding methylated-beta-cyclodextrin, and uniformly stirring so as to obtain the scale inhibitor. According to the efficient scale inhibitor preparedthrough the method, the scale inhibition rate of a static scale inhibition experiment reaches 90% or above, the optimal scale inhibition rate of the performance can reach 99.1%, the scale inhibitionrequirement of a circulating cooling water system can be met, and the efficient scale inhibitor has very wide application prospects.

Owner:安徽遨信网络科技有限公司

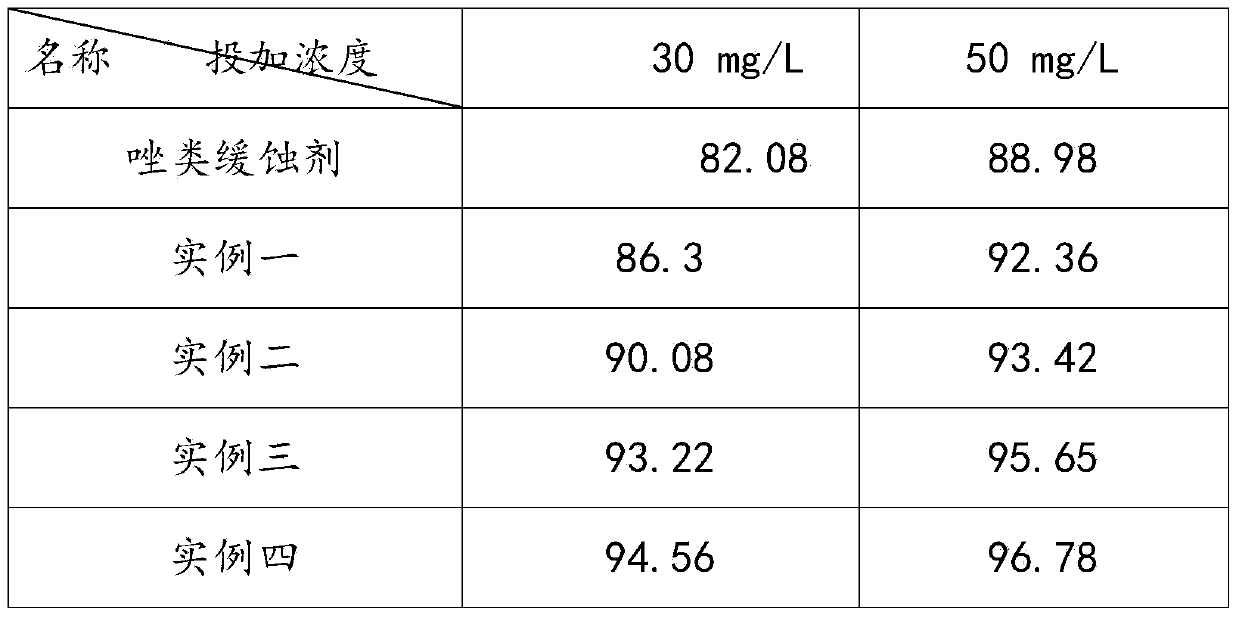

Efficient and environment-friendly corrosion inhibitor and preparation method thereof

InactiveCN103739095AStrong complexing abilityPromote generationScale removal and water softeningSulfateRoom temperature

The invention relates to an efficient and environment-friendly corrosion inhibitor and a preparation method thereof. The corrosion inhibitor is composed of: 1.7-2.3 parts of polyepoxysuccinic acid, 2.2-2.8 parts of sodium gluconate, 1.8-2.2 parts of zinc sulfate, and 92.7-94.3 parts of water. The preparation method includes: placing polyepoxysuccinic acid and sodium gluconate in a reaction kettle, performing stirring for 20-30min under room temperature under atmospheric pressure, adding zinc sulfate after stirring zinc sulfate in water uniformly, then further conducting stirring for 45-50min, thus obtaining a finished product. Corrosion inhibition rate test is performed by: selecting a standard A3 carbon steel test piece, rotating it at a linear speed of 0.35m / s under 50DEG C, evaporating and concentrating water by 1.3-1.8 times, and conducting timing for 68-74h, thus determining that the test piece has a weightless corrosion inhibition rate up to 94%.

Owner:URUMQI KEFAZHAN FINE CHEM

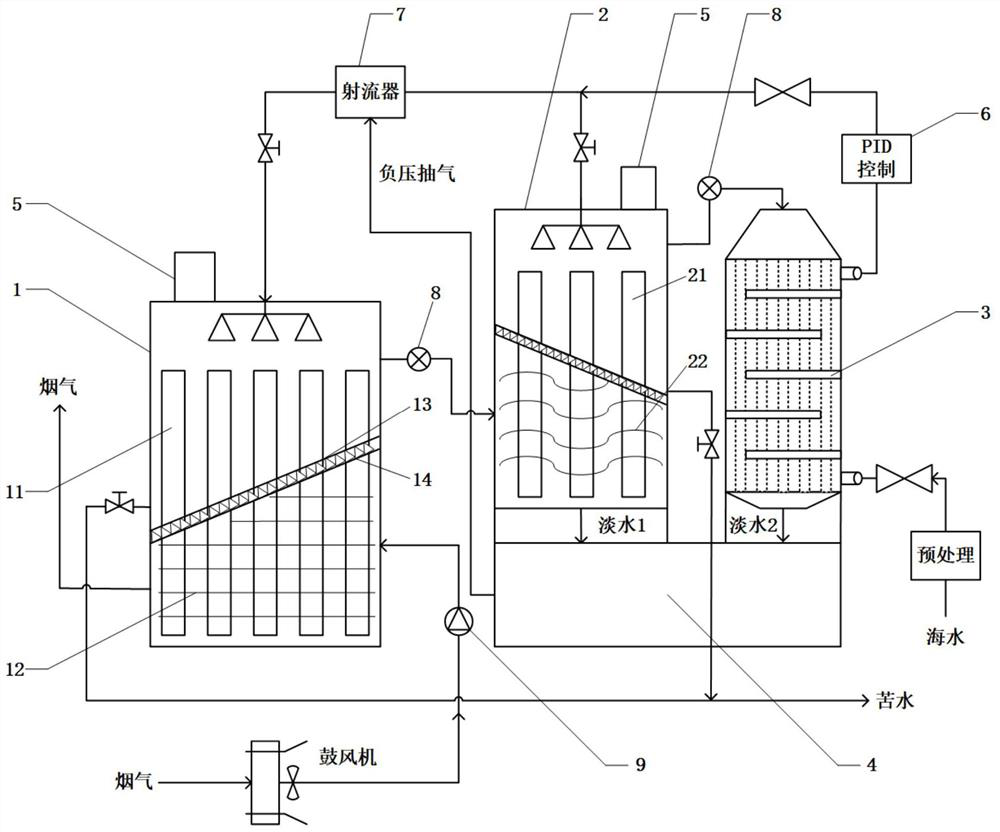

Flue gas temperature control music early warning heat pipe heat exchange device

ActiveCN114526621AAvoid Low Temperature CorrosionImprove utilization efficiencyGeneral water supply conservationSeawater treatmentData connectionTemperature control

The invention relates to a smoke temperature control music early warning heat pipe heat exchange device. A smoke exhaust pipe is provided with a temperature sensor, the temperature sensor is in data connection with a controller, the controller controls the input flow of smoke according to the smoke exhaust temperature, the smoke is conveyed to a cold end through an air blower, and when the detected smoke exhaust temperature is lower than a preset value, the air blower is turned on. If yes, the controller controls the power of the air blower to be increased, the smoke input amount is increased, the controller is connected with a music playing circuit, and the controller plays different sounds according to the detected smoke exhaust temperature. According to the heat exchange device capable of early warning the exhaust gas temperature in advance, intelligent detection is carried out according to the exhaust gas temperature, and meanwhile, intelligent different sound early warning is carried out, so that it is guaranteed that the exhaust gas temperature exceeds the critical value, and low-temperature corrosion is avoided.

Owner:SHANDONG UNIV

Metal oil removal agent and use method thereof

The invention provides a metal oil removal agent. The agent comprises raw materials including, by weight part, 4 to 12 parts of potassium hydroxide, 10 to 20 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 5 to 10 parts of polyaspartic acid, 0.5 to 2 parts of oxidized starch, 10 to 20 parts of cetyl-trimethyl ammonium bromide, 15 to 25 parts of butyl cellosolve, and 4 to 10 parts of sodium pyrophosphate. The invention further provides a use method of the metal oil removal agent. Under the normal temperature state, the metal oil removal agent has the higher dissolving capacity on various kinds of grease, heavy oil and aging deteriorated grease can be dissolved, the cleaning speed is high, the higher dispersion and anti-staining capacity can be achieved, the stain removal capacity is high, oil dirt of workpiece cleaning can be prevented from reversely contaminating the metal surface, the raw material cost is reduced, the cleaning effect is improved, and the cleaning time isshortened.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Rust remover and preparing method thereof

InactiveCN108018566AWide temperature rangePromote chelationMetallic material coating processesSlagPolyethylene glycol

The invention provides a rust remover. The rust remover comprises raw materials including, by weight part, 5 to 10 parts of hydrochloric acid, 6 to 12 parts of citric acid, 1 to 3 parts of oxalic acid, 1 to 5 parts of glycolic acid, 3 to 8 parts of sodium gluconate, 4 to 8 parts of polyaspartic acid, 0.5 to 1.5 parts of oxidized starch, 10 to 20 parts of cetyl-trimethyl ammonium bromide, 1 to 5 parts of sodium tripolyphosphate, 2 to 6 parts of Turkey red oil, 4 to 10 parts of polyethylene glycol and 50 to 70 parts of deionized water. The invention further provides a preparing method of the rust remover. The rust remover can efficiently finish metal surface rust removal within short time, meanwhile, it is ensured that after rust removal, metal can be free of rusting for a long time, meanwhile, after rust removal, the metal surface is free of rust, and is smooth in surface, the metal surface treatment quality is improved, acid fog can be effectively restrained, waste liquid and waste slag discharge can be reduced, and environment is protected.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

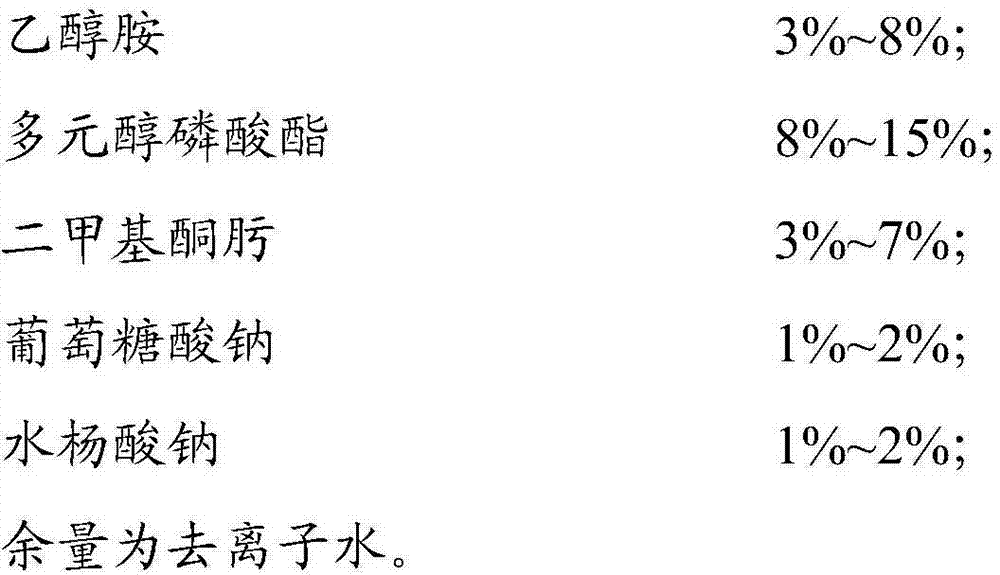

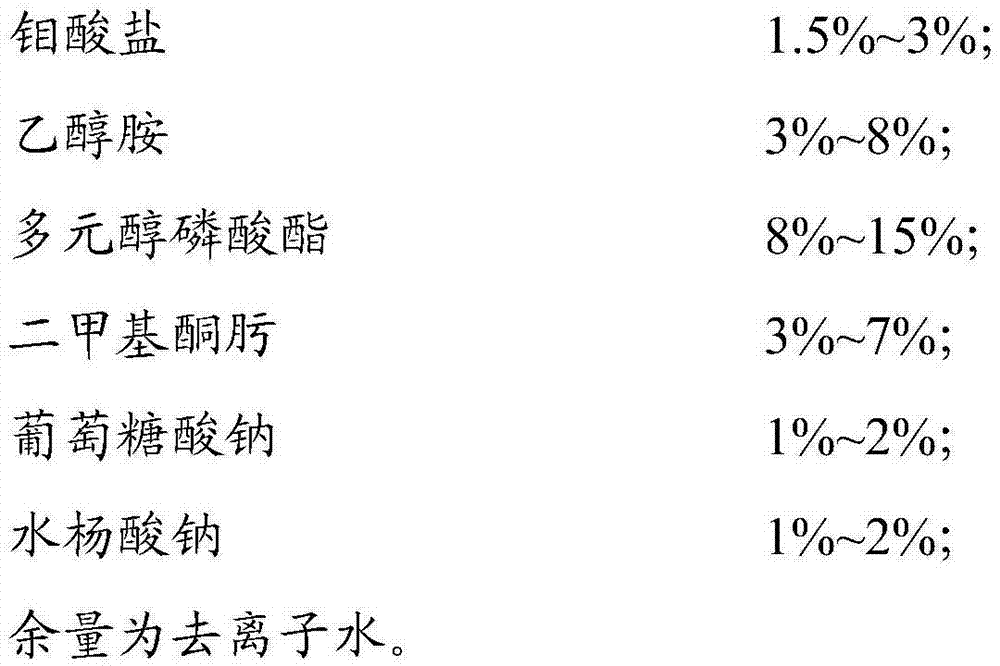

Corrosion inhibitor for recirculated cooling water

InactiveCN104773845AImprove high temperature resistanceHigh corrosion inhibition rateScale removal and water softeningAlcoholMolybdate

The invention discloses a corrosion inhibitor for recirculated cooling water. The corrosion inhibitor comprises, by weight, 1.5-3% of molybdate, 3-8% of ethanolamine, 8-15% of polyhydric alcohol phosphate ester, 3-7% of dimethyl ketoxime, 1-2% of sodium gluconate, 1-2% of sodium salicylate and the balance deionized water. The corrosion inhibitor has the advantages of good high temperature resistance, high corrosion inhibition efficiency and good scale inhibition capability.

Owner:SAE TECH DELEVOPMENT DONGGUAN

Phosphorus-free composite cylinder cleaning agent for low-pressure boiler and preparation method thereof

InactiveCN111233178AEasy to useEasy to operateSpecific water treatment objectivesScale removal and water softeningSoftened waterTap water

The invention discloses a phosphorus-free composite cylinder cleaning agent for a low-pressure boiler and a preparation method thereof, which belong to the field of boiler water treatment. The productprovided by the invention is composed of a deoxidant component, a corrosion inhibitor component, a scale inhibitor component, a pH stabilizer component and the like. The cleaning agent is prepared bycompounding the following components in percentage by weight: 5%-20% of the deoxidant component, 1%-10% of the corrosion inhibitor component, 0.1%-10% of the scale inhibitor component, 0.1%-10% of the pH stabilizer component and the balance of pure water according to specific steps. The production process is simple, and the product is widely suitable for low-pressure steam boilers and hot water boilers with pure water, softened water and common tap water as supplemented water. After the product is added into boiler make-up water, water supply dissolved oxygen corrosion can be eliminated, theslow-release scale inhibition effect can be achieved in the boiler water, meanwhile, the corrosion problem of the condensate water end can be effectively solved through the specific neutralizing aminecomponent, a barrel type water treatment solution is provided for a low-pressure boiler, and the cleaning agent is free of phosphorus, environmentally friendly, safe and efficient.

Owner:威海翔泽新材料科技有限公司

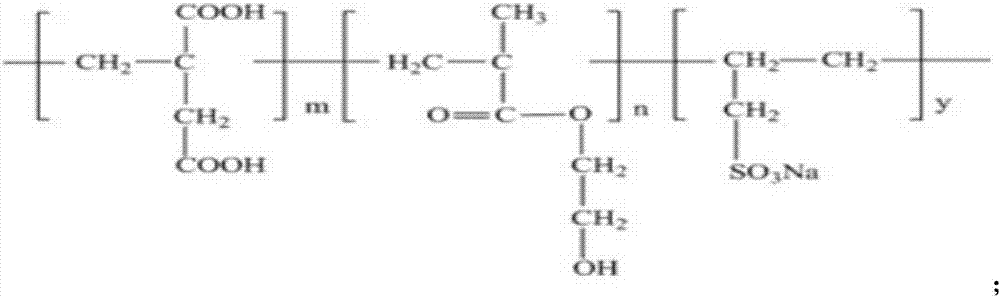

Scale inhibitor for air conditioning circulating water system in textile mill and preparation method of scale inhibitor

InactiveCN107986462AHarm reductionAvoid badScale removal and water softeningNon-contaminated water treatmentTextile mill(Hydroxyethyl)methacrylate

The invention discloses a scale inhibitor for an air conditioning circulating water system in a textile mill. The scale inhibitor is prepared by the following steps: taking three monomers, namely itaconic acid, sodium allysulfonate and hydroxyethyl methylacrylate, as raw materials, and synthesizing a terpolymer scale inhibitor containing sulfonic group, carboxylic group, hydroxyl and ester groupsby virtue of a free radical solution copolymerization reaction. The scale inhibitor disclosed by the invention solves the problems in the prior art that the scale inhibitor is low in scale inhibitionefficiency and complicated in preparation process. The invention further discloses a preparation method of the scale inhibitor for the air conditioning circulating water system in the textile mill.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Coal chemical industry grey water scale inhibitor

PendingCN112194261AImprove thermal stabilityReduce decompositionSpecific water treatment objectivesScale removal and water softeningMeth-Greywater

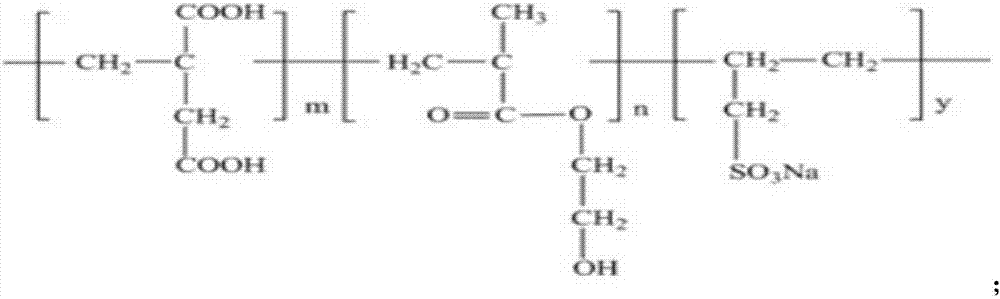

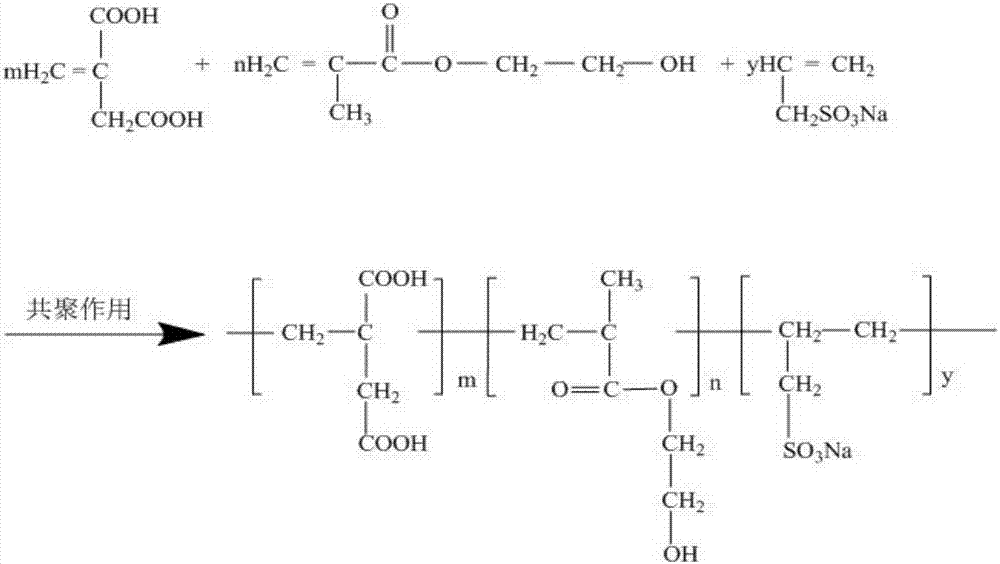

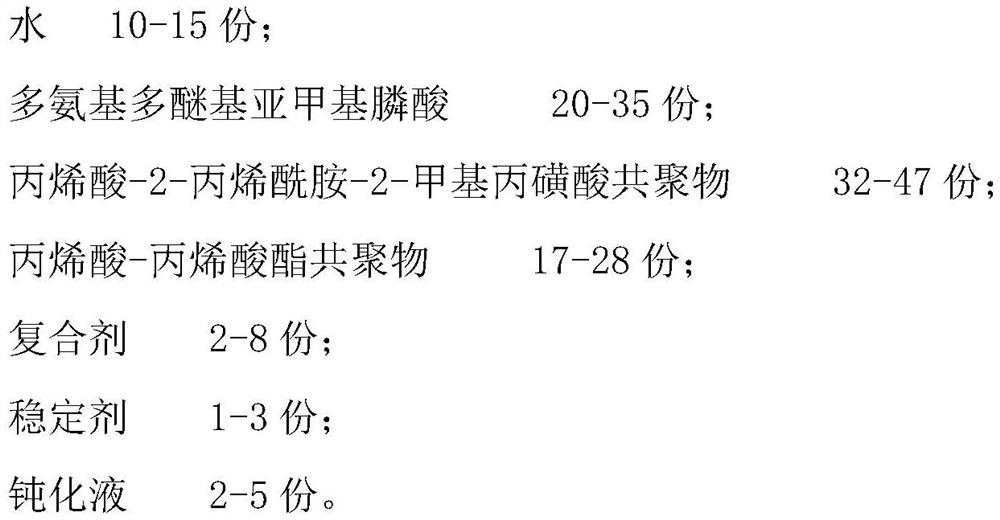

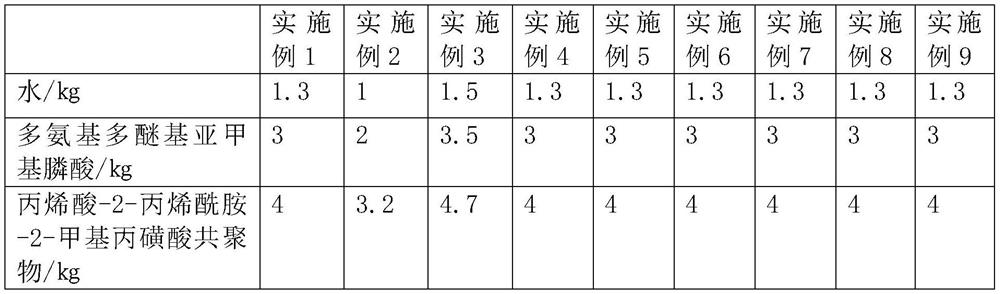

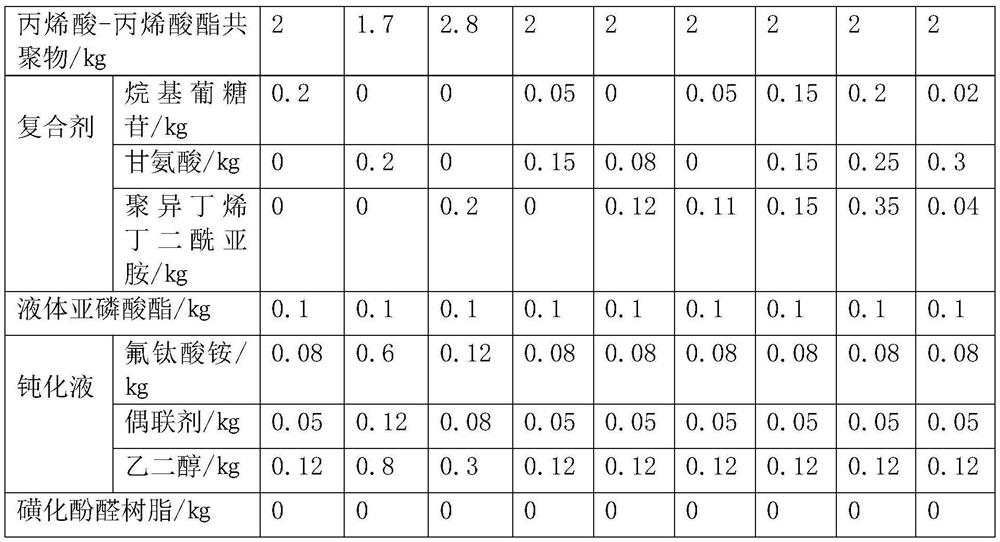

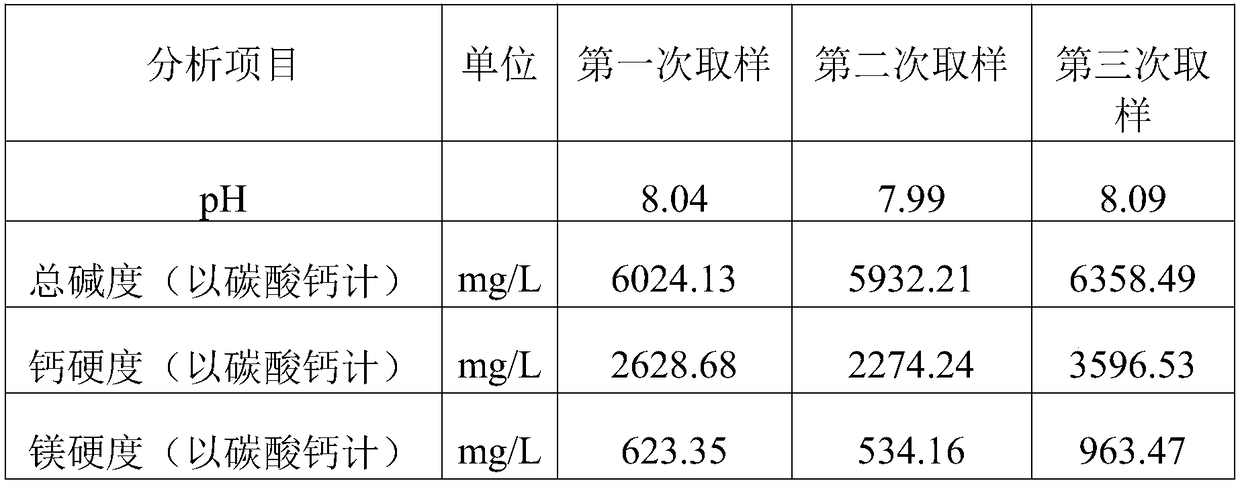

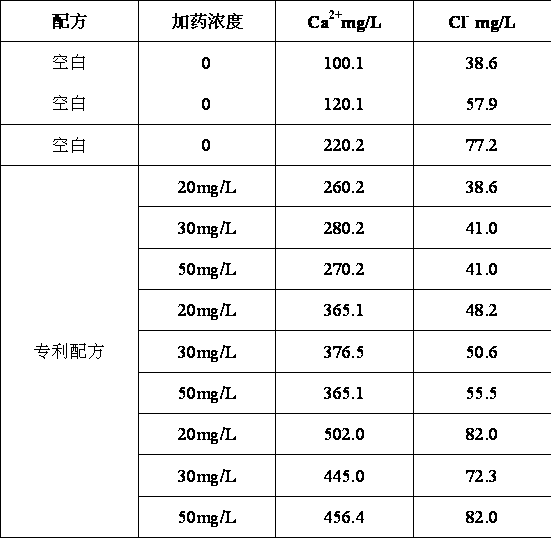

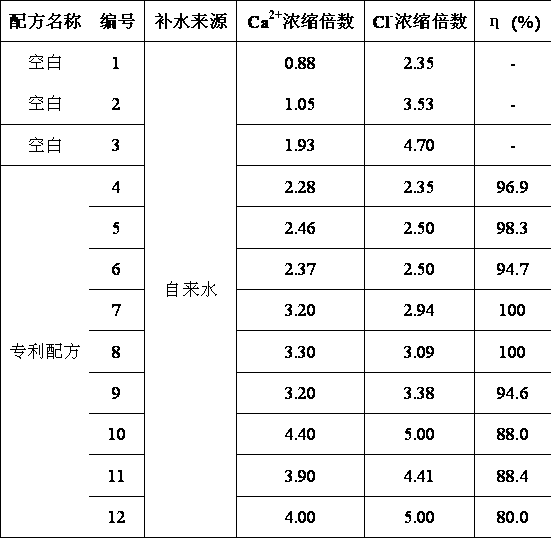

The invention discloses a coal chemical industry grey water scale inhibitor, and belongs to the technical field of grey water scale inhibitors. The coal chemical industry grey water scale inhibitor comprises the following components by weight: 10-15 parts of water; 20-35 parts of polyamino polyether methylene phosphonic acid; 32-47 parts of an acrylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer; 17-28 parts of an acrylic acid-acrylate copolymer; 2-8 parts of a compounding agent; 1-3 parts of a stabilizer; and 2-5 parts of a passivation solution. The scale inhibitor of the invention has the advantages of being stable at high temperature, high in scale inhibition rate and good in corrosion inhibition.

Owner:上海鲁昕化工科技有限公司

Scale inhibitor as well as preparation method and application thereof

InactiveCN108083456AStrong scale resistanceGuaranteed liquiditySpecific water treatment objectivesScale removal and water softeningPipe burstingEvery Two Months

The invention provides a scale inhibitor as well as a preparation method and an application thereof. A scale inhibition mechanism is based on chelation solubilization, dispersion, electrostatic repulsion and lattice distortion. Several medicament monomers are selected in a formula to be compounded and used, and the scale inhibition capability of the scale inhibitor is far higher than that of the medicament monomers by means of synergistic effect between the monomers; calcium carbonate scale and magnesium carbonate scale can be effectively prevented from being produced, wherein the inhibition rate of calcium carbonate scale is 89.3%-92.6%, the inhibition rate of magnesium carbonate scale is 92.1%-96.2%, organic scale can be effectively prevented from adhering to the pipe wall, so that the pipe wall is smooth, and circulation flux of a leachate is ensured; the pipe cleaning frequency of an existing anaerobic system can be reduced to once a year from once every two months; equipment suchas an anaerobic circulating pump, a denitrification water inlet pump and the like in contact with the leachate in a biochemical section in an anaerobic system can be protected, blockage of the equipment is prevented, and the service life of the equipment is prolonged; pipe bursting and other accidents caused by pipe fouling and blocking can be effectively prevented, and production can be performedcontinuously and stably.

Owner:武汉天源环保股份有限公司

Anti-corrosion oil remover for metal surface and using method of anti-corrosion oil remover

The invention provides an anti-corrosion oil remover for a metal surface. The anti-corrosion oil remover comprises the following raw materials in parts by weight: 4-12 parts of sodium stearate, 10-20parts of sodium carbonate, 5-10 parts of polyaspartic acid, 0.5-2 parts of oxidized starch, 10-15 parts of cetyl-trimethyl ammonium bromide, 15-25 parts of propanediol butyl ether, 4-10 parts of sodium citrate and 1-5 parts of sodium pyrophosphate. The invention provides a using method of the anti-corrosion oil remover for the metal surface. Under a normal-temperature state, the anti-corrosion oilremover for the metal surface has very strong dissolving capacity on various kinds of grease, can dissolve heavy oil, can age deteriorated grease, is high in cleaning speed, has very strong dispersing and pollution-preventing ability, is strong in detersive power, can prevent greasy dirt generated after cleaning a workpiece from polluting the metal surface, reduces the raw material cost, improvesthe cleaning effect and shortens cleaning time.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Rust removal and rust prevention liquid and preparation method thereof

InactiveCN108018563AWide temperature rangePromote chelationMetallic material coating processesMesoporous silicaFatty alcohol

The invention provides a rust removal and rust prevention liquid. The liquid comprises the raw materials of, by weight, 5-9 parts of long-oil alkyd resin, 2-6 parts of citric acid, 2-8 parts of laurylsodium sulfate, 2-4 parts of tartaric acid, 1-2 parts of ethylene diamine tetraacetic acid disodium, 2-6 parts of polyaspartic acid, 0.4 -1.2 part of oxidized starch, 5-10 parts of trimethyl cetyl ammonium bromide, 10-15 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 1-2 parts of turkey red oil, 1-3 parts of carboxymethyl cellulose, 2-8 parts of mesoporous silica, 10-20 parts of ethylene glycol, 15-20 parts of propylene glycol butyl ether and 60-90 parts of water. The invention further provides a preparation method of the rust removal and rust prevention liquid. The provided rust removal and rust prevention liquid has multiple functions such as rust removal, decontamination, phosphatization and passivation; and reaction can be carried out at normal temperature, the rust removal time is short, the rust prevention time is long, and the liquid does not corrode the metal.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Cleaning rust remover and preparation method thereof

InactiveCN108018568AWide temperature rangeAdjust pHMetallic material coating processesPhosphoric acidGluconic acid

The invention provides a cleaning rust remover. The cleaning rust remover comprises, by weight, 15-25 parts of 85wt% phosphoric acid, 8-12 parts of long-oil alkyd resin, 5-10 parts of sodium gluconate, 2-5 parts of triethanolamine, 2-8 parts of polyaspartic acid, 0.15-0.30 part of oxidized starch, 8-12 parts of trimethyl cetyl ammonium bromide, 60-80 parts of water, 8-15 parts of lauryl sodium sulfate and 5-12 parts of sodium tripolyphosphate. The invention further provides a preparation method of the cleaning rust remover. According to the cleaning rust remover, cleaning, phosphorous removal,rust removal, corrosion prevention and rust prevention of the surface of ferrous metal can be accomplished at the same time only by one procedure, and a plurality of procedures are reduced for ferrous metal surface treatment, so that the substrate of the ferrous metal surface is prevented from being excessively acidized.

Owner:HENAN ZHILIAN HUANYU INTPROP OPERATION CO LTD

Compound scale and corrosion inhibitor

InactiveCN110937699AGood dispersionGood lattice distortionSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsSulfonateCarboxylic acid

The invention relates to a compound scale and corrosion inhibitor which comprises the following components in percentage by mass: 20% of organic phosphonic carboxylic acid, 10% of a phosphonate, 20% of a sulfonate copolymer, 10% of polymaleic acid, 5% of zinc chloride, 1% of a copper corrosion inhibitor and 34% of purified water. A processing method comprises the following steps: S1, adding purified water accounting for 20% of the total water consumption of the purified water into a batching tank, and starting stirring; S2, adding organic phosphonic carboxylic acid and the phosphonate, and continuously stirring for 15 minutes; S3, adding the sulfonate copolymer and the polymaleic acid, and continuously stirring for 10 minutes; S4, adding zinc chloride, and continuously stirring for 15 minutes; after dissolving zinc chloride, adding the copper corrosion inhibitor; S5, adding all the rest purified water into the batching tank, and continuously stirring for 30 minutes until all the raw materials are completely dissolved and uniformly mixed; S6, stopping stirring, and standing for 2 hours to obtain a finished product. The compound scale and corrosion inhibitor has the characteristics of high slow release rate, high temperature resistance, strong scale inhibition capability, difficult decomposition and the like, has good chelating dispersion and lattice distortion effects, and can alleviate corrosion to copper materials.

Owner:武汉金鼎新环保科技有限公司

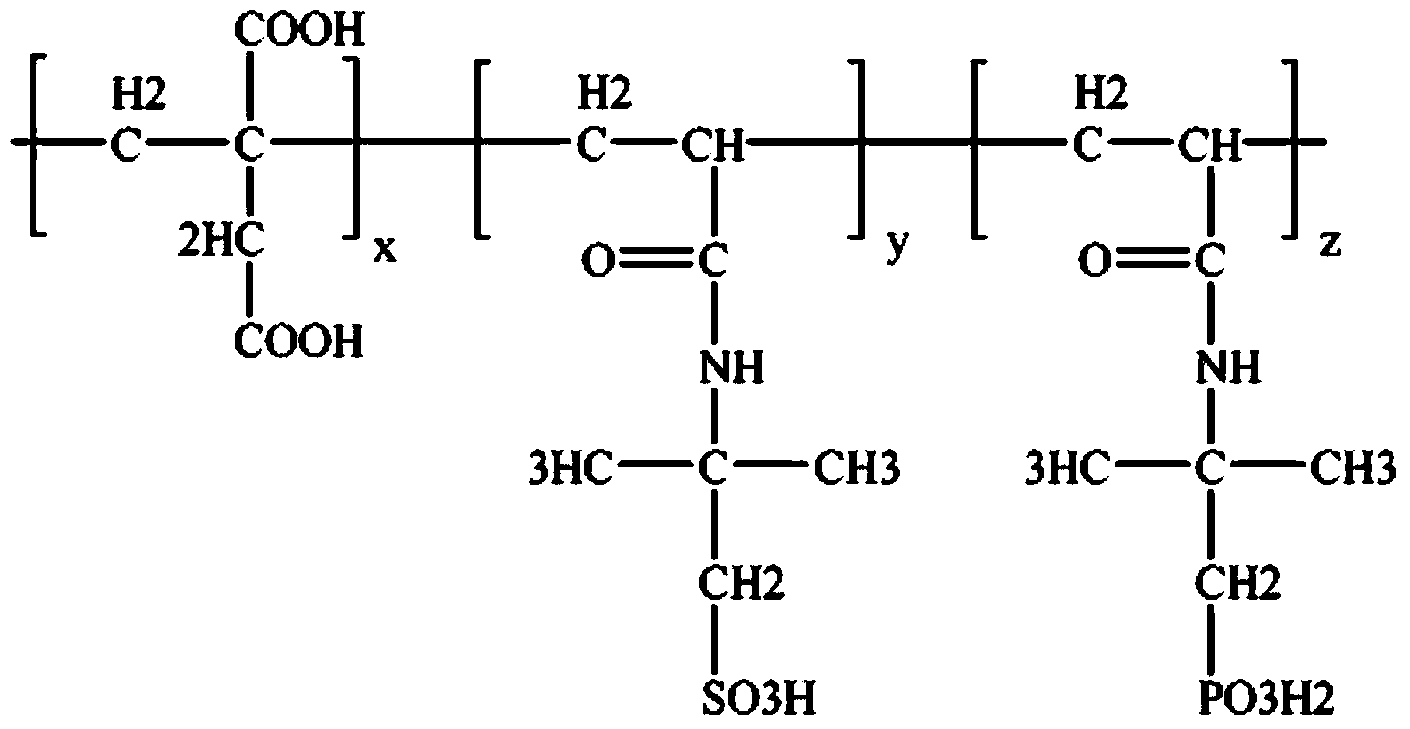

A kind of itaconic acid polymer containing phosphine group and sulfonic acid group and its preparation method

ActiveCN103319658BEasily biodegradableHigh hardnessScale removal and water softeningAlkalinityPolymer science

The invention discloses an itaconic acid polymer containing a phosphine group and a sulfo group, and a preparation method of the itaconic acid polymer, belonging to the technical field of chemical products. A multifunctional scale and corrosion inhibitor which has the properties of scale inhibition, corrosion inhibition and dispersion is synthesized by taking an itaconic acid as the main monomer, polymerizing through a solution and oxidizing and reducing a triggering system. The itaconic acid polymer is an agentia with low-phosphorous, high efficiency and good scale inhibition capability in high-alkalinity water, and the product has good corrosion inhibition. The polymer is easy to biologically degrade, and the biodegradability after 28 days can be 70%, so that the itaconic acid polymer belongs to environment-friendly products.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Chemical processing method of coal chemical industry recycled circulating cooling water

ActiveCN102976512BStrong alkali resistanceReduce contentScale removal and water softeningMultistage water/sewage treatmentChemical treatmentTricarboxylic acid

Owner:新疆德安环保科技股份有限公司

Method for improving saline and alkaline lands

InactiveCN108702887AIncreased side chain sizeImprove adsorption capacityOrganic fertilisersSoil-working methodsHumusHumic acid

The invention discloses a method for improving saline and alkaline lands. The method includes the steps: pretreating rice straws by a thin alkali method; grafting acrylic acid and amino trimethylene phosphonic acid to obtain modified rice straws; mixing ethylenediamine tetraacetic acid intercalated bentonite, the modified rice straws, wood charcoal powder and humus acid to obtain saline-alkali land improvers; improving the saline and alkaline lands by the saline-alkali land improvers, and planting plants on the improved saline and alkaline lands. According to the method, the saline and alkaline lands can be effectively improved for a long time, and the survival rate of the plants planted on the saline and alkaline lands is increased.

Owner:长沙小新新能源科技有限公司

Ternary polymerization type corrosion and scale inhibitor for central air-conditioning circulating cooling water and preparation method thereof

ActiveCN103739093BStrong scale resistanceGood corrosion inhibition effectSpecific water treatment objectivesWater contaminantsPolyaspartic acidEtidronic acid

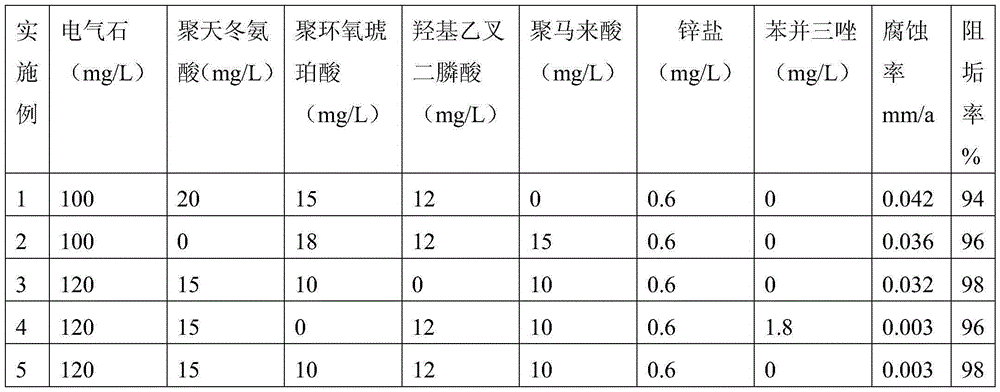

The invention discloses a ternary polymerization corrosion and scale inhibitor for central air-conditioning circulating cooling water, which consists of tourmaline, polyaspartic acid, polyepoxysuccinic acid, polymaleic acid and hydroxyethylidene diphosphine acid, zinc salt, etc. Among them, the amount of tourmaline is 5-500g / t (calculated as solid), and the amount of polyaspartic acid, polyepoxysuccinic acid, polymaleic acid and hydroxyethylidene diphosphonic acid is 2-60g / t (calculated as solid). liquid meter), the dosage of zinc salt is 0.2-0.8g / t. The corrosion and scale inhibitor formula provided by the invention has excellent performance, simple preparation method, convenient use, low dosing concentration, etc., and has broad application prospects and economic value.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com