Ternary polymerization type corrosion and scale inhibitor for central air-conditioning circulating cooling water and preparation method thereof

A technology of circulating cooling water and corrosion and scale inhibitors, applied in chemical instruments and methods, compositions for inhibiting chemical changes, water pollutants, etc. Corrosion, scale inhibition and comprehensive requirements for sterilization and antibacterial, etc., to solve the problem of water quality deterioration, conducive to safe and stable operation, and the effect of low dosing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

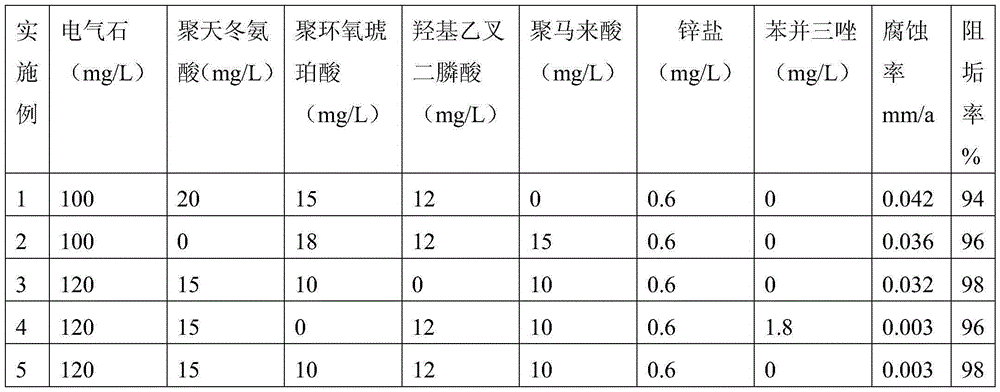

Examples

Embodiment 1

[0026] A ternary polymerization type corrosion and scale inhibitor for central air-conditioning circulating cooling water, polyaspartic acid 20g, polyepoxysuccinic acid 15g, hydroxyethylidene diphosphonic acid 12g, ZnSO 4 0.6 g of the solid was successively dissolved in 1000 ml of deionized water. The temperature was raised to 65°C, and under the condition of stirring, the above polymer solution was kept warm for 5 hours and then cooled to obtain the ternary polymerization mother liquor.

[0027] In 1L of central air-conditioning circulating cooling water, first add 100mg of tourmaline directly or through a recyclable tourmaline dosing device, and then directly add 1mg of ternary polymerization mother liquor. Tourmaline can be recycled and recycled.

Embodiment 2

[0029] A ternary polymerization type corrosion and scale inhibitor for central air-conditioning circulating cooling water, polyaspartic acid 20g, polyepoxysuccinic acid 18g, hydroxyethylidene diphosphonic acid 12g, polymaleic acid 15g, ZnSO 4 0.6 g of the solid was successively dissolved in 1000 ml of deionized water. The temperature was raised to 65°C, and under the condition of stirring, the above polymer solution was kept warm for 5 hours and then cooled to obtain the ternary polymerization mother liquor.

[0030] In 1L of central air-conditioning circulating cooling water, first add 100mg of tourmaline directly or through a recyclable tourmaline dosing device, and then directly add 1mg of ternary polymerization mother liquor. Tourmaline can be recycled and recycled.

Embodiment 3

[0032] A ternary polymerization type corrosion and scale inhibitor for central air-conditioning circulating cooling water, polyaspartic acid 15g, polyepoxysuccinic acid 10g, polymaleic acid 10g, ZnSO 4 0.6 g of the solid was successively dissolved in 1000 ml of deionized water. The temperature was raised to 55°C, and under the condition of stirring, the above polymer solution was incubated and reacted for 4 hours, and then cooled to obtain the terpolymerization type mother liquor.

[0033] In 1L of central air-conditioning circulating cooling water, first add 120mg of tourmaline directly or through a recyclable tourmaline dosing device, and then directly add 1mg of ternary polymerization mother liquor. Tourmaline can be recycled and recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com