Efficient and environment-friendly corrosion inhibitor and preparation method thereof

A corrosion inhibitor and environmental protection technology, applied in the field of slow release agents, can solve the problems of pollution, adverse effects of regional ecological balance, restrictions on the use of organic phosphonic acid water quality stabilizers, etc., and achieve the effect of preventing corrosion

Inactive Publication Date: 2014-04-23

URUMQI KEFAZHAN FINE CHEM

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, circulating water has been widely used in industrial cooling water instead of once-through water, but there are problems such as corrosion, scaling, deposition and microbial reproduction in the circulating cooling water system. Only according to the characteristics of different water quality, different water quality stabilization technologies are used to strengthen The improvement and control of circulating water quality can achieve the goals of saving water, prolonging the service life of equipment, reducing energy consumption, protecting the environment and improving economic benefits. According to the requirements of sustainable development strategy, the utilization rate of water resources can be improved

[0003] In most of the circulating cooling water systems in my country, the phosphorus content of the chemicals used is relatively high, and the water quality stabilizers used in oil fields, petrochemical, thermal power and other fields are still mainly organic phosphonic acids, and a large amount of phosphorus is discharged. It has a negative impact on the regional ecological balance, so the use of organic phosphonic acid water quality stabilizers is increasingly restricted

Although the widely used phosphorus corrosion and scale inhibitors, polyacrylic acid and other polymers and copolymers have made breakthroughs in water treatment technology, they will cause eutrophication of water bodies or are highly non-biodegradable, so they are all Environmentally unacceptable pollutants

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0016] Take 2.0 parts of PESA (polyepoxysuccinic acid), 2.5 parts of sodium gluconate, 2.0 parts of zinc sulfate, and 93.5 parts of water;

example 2

[0018] Take 2.0 parts of PESA (polyepoxysuccinic acid), 2.0 parts of sodium gluconate, 2.5 parts of zinc sulfate, and 93.5 parts of water;

example 3

[0020] Take 2.5 parts of PESA (polyepoxysuccinic acid), 2.0 parts of sodium gluconate, 2.0 parts of zinc sulfate, and 93.5 parts of water;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

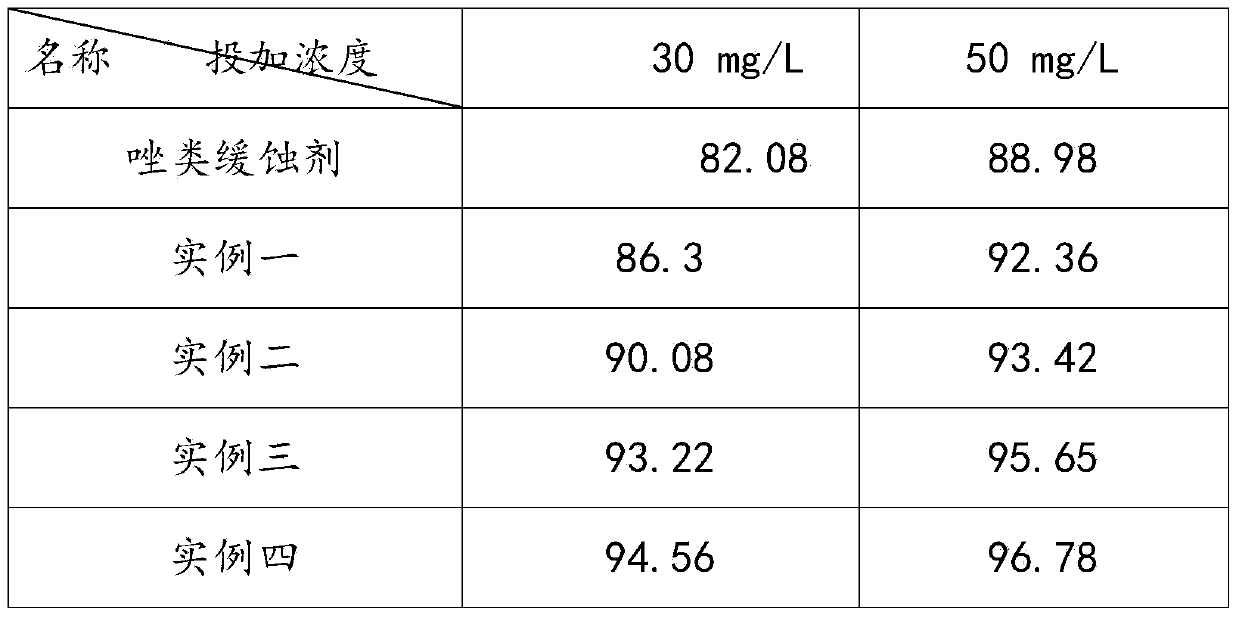

The invention relates to an efficient and environment-friendly corrosion inhibitor and a preparation method thereof. The corrosion inhibitor is composed of: 1.7-2.3 parts of polyepoxysuccinic acid, 2.2-2.8 parts of sodium gluconate, 1.8-2.2 parts of zinc sulfate, and 92.7-94.3 parts of water. The preparation method includes: placing polyepoxysuccinic acid and sodium gluconate in a reaction kettle, performing stirring for 20-30min under room temperature under atmospheric pressure, adding zinc sulfate after stirring zinc sulfate in water uniformly, then further conducting stirring for 45-50min, thus obtaining a finished product. Corrosion inhibition rate test is performed by: selecting a standard A3 carbon steel test piece, rotating it at a linear speed of 0.35m / s under 50DEG C, evaporating and concentrating water by 1.3-1.8 times, and conducting timing for 68-74h, thus determining that the test piece has a weightless corrosion inhibition rate up to 94%.

Description

technical field [0001] The invention relates to a slow-release agent in the chemical industry. The slow-release agent can effectively prevent problems such as corrosion, scaling, deposition and microbial reproduction of cooling water circulation equipment. Background technique [0002] At present, circulating water has been widely used in industrial cooling water instead of once-through water, but there are problems such as corrosion, scaling, deposition and microbial reproduction in the circulating cooling water system. Only according to the characteristics of different water quality, different water quality stabilization technologies are used to strengthen The improvement and control of circulating water quality can achieve the goals of saving water, prolonging the service life of equipment, reducing energy consumption, protecting the environment and improving economic benefits. According to the requirements of sustainable development strategy, the utilization rate of water...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F5/12

Inventor 申建军杨桂萍

Owner URUMQI KEFAZHAN FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com