Scale inhibitor for air conditioning circulating water system in textile mill and preparation method of scale inhibitor

A technology of air conditioning cycle and scale inhibitor, which is applied in chemical instruments and methods, natural water treatment, non-polluted water treatment, etc., can solve the problems of complex preparation process and low scale inhibition efficiency, and achieves reduction of crystal growth rate and extended use. Life, the effect of solving the scaling problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

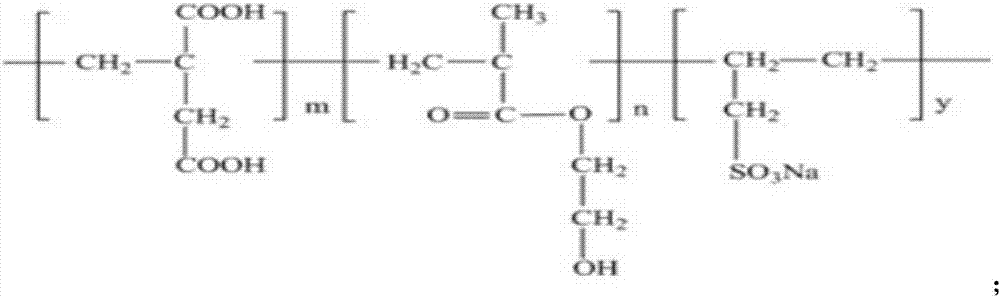

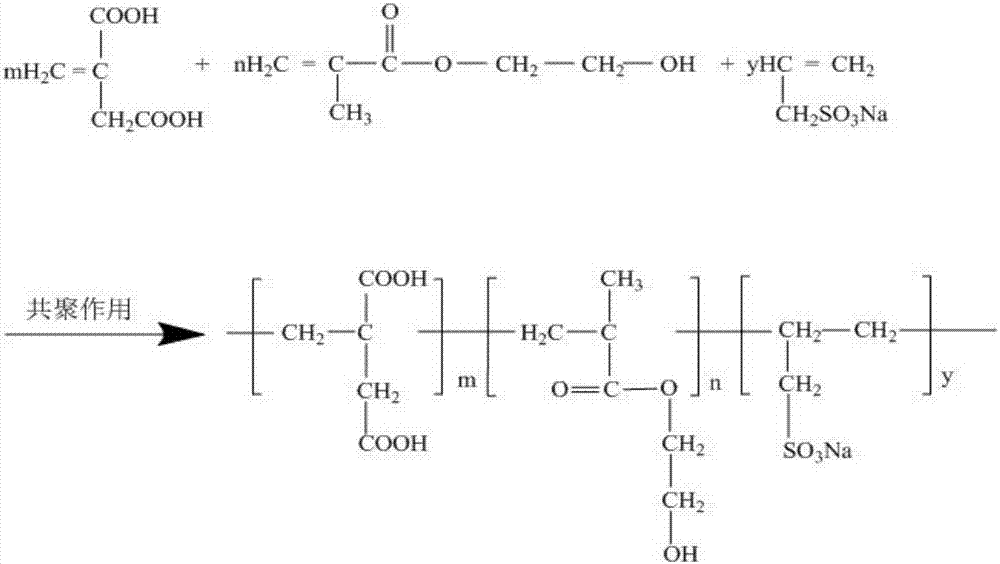

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Weigh respectively: itaconic acid (IA) 9.2929g, sodium allyl sulfonate (SAS) 4.12g, hydroxyethyl methacrylate (HEMA) 2.97463g, ammonium persulfate 1.4077g, tert-butanol 1.6385g g, distilled water 300g;

[0036] Step 2, the itaconic acid (IA) that is taken in step 1, sodium allyl sulfonate (SAS), hydroxyethyl methacrylate (HEMA), tert-butyl alcohol and distilled water are added in the three-necked flask, and the three-necked flask is fixed On a constant temperature heating magnetic stirrer, stir and heat to 90°C until all the solids are dissolved to obtain the mixed liquid a;

[0037] Step 3, add ammonium persulfate dropwise to the mixed solution a in step 2 through a constant pressure dropping funnel, keep warm for 1.5h after the dropwise addition is completed, then cool to room temperature, adjust the pH value to 5 with potassium hydroxide solution, and obtain light yellow Transparent liquid, i.e. mixed liquid b;

[0038] Step 4. Add 95% absolute ethanol whos...

Embodiment 2

[0040] Step 1. Weigh respectively: itaconic acid (IA) 13.01g, sodium allyl sulfonate (SAS) 4.12g, hydroxyethyl methacrylate (HEMA) 1.48731g, ammonium persulfate 1.7422g, tert-butanol 1.8614 g, distilled water 300g;

[0041] Step 2, the itaconic acid (IA) that is taken in step 1, sodium allyl sulfonate (SAS), hydroxyethyl methacrylate (HEMA), tert-butyl alcohol and distilled water are added in the three-necked flask, and the three-necked flask is fixed On a constant temperature heating magnetic stirrer, stir until all the solids are dissolved and heat to 85°C to obtain the mixed solution a;

[0042] Step 3, add ammonium persulfate dropwise to the mixed solution a in step 2 through a constant pressure dropping funnel, keep warm for 3 hours after the dropwise addition is completed, then cool to room temperature, adjust the pH value to 5 with potassium hydroxide solution, and obtain a light yellow transparent Liquid, i.e. mixed liquid b;

[0043] Step 4. Add 95% absolute ethanol...

Embodiment 3

[0045]Step 1. Weigh respectively: itaconic acid (IA) 13.01g, sodium allyl sulfonate (SAS) 4.12g, hydroxyethyl methacrylate (HEMA) 2.97463g, ammonium persulfate 2.7099g, tert-butanol 2.0102 g, distilled water 300g;

[0046] Step 2, the itaconic acid (IA) taken in step 1, sodium allyl sulfonate (SAS), hydroxyethyl methacrylate (HEMA), tert-butyl alcohol and distilled water are added in the three-necked flask, and the three-necked flask is fixed on Heating on a magnetic stirrer at a constant temperature, stirring until all the solids are dissolved and heating to 75°C to obtain a mixed liquid a;

[0047] Step 3, add ammonium persulfate dropwise to the mixed solution a in step 2 through a constant pressure dropping funnel, keep warm for 2 hours after the dropwise addition is completed, then cool to room temperature, adjust the pH value to 5 with potassium hydroxide solution, and obtain light yellow transparent Liquid, i.e. mixed liquid b;

[0048] Step 4. Add 95% absolute ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com